Pile fabric transfer printing device

A transfer printing, plush fabric technology, applied in transfer printing, rotary printing machine, transfer local treatment and other directions, can solve the problem of non-vertical wool on the cloth, and achieve the effect of improving the effect of the cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings.

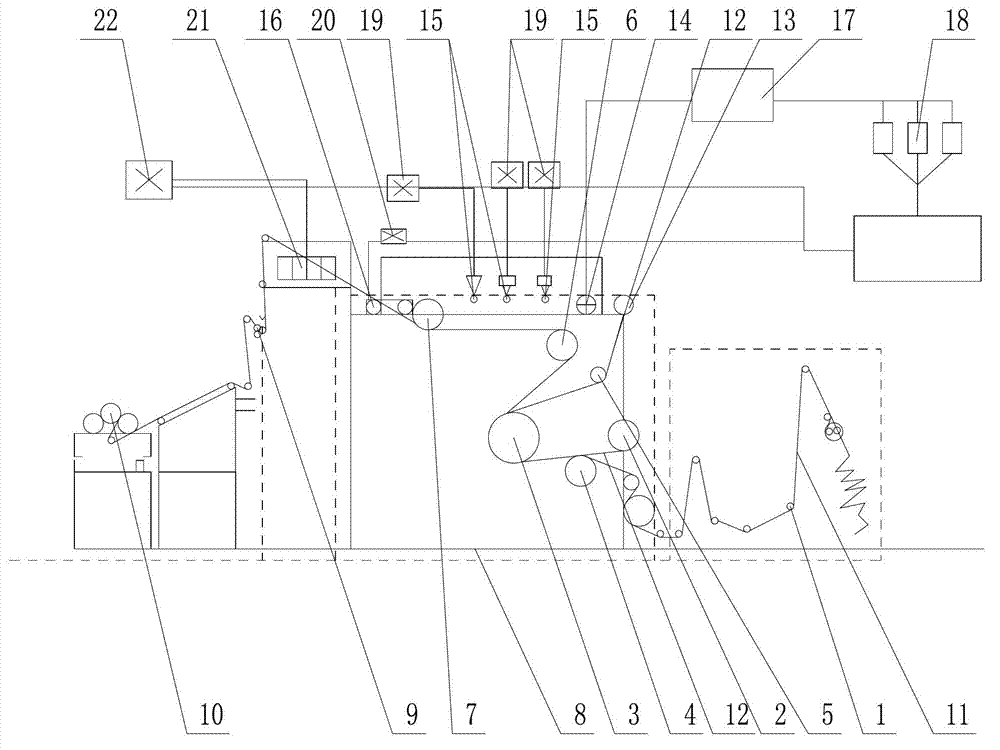

[0014] Such as figure 1 As shown: the plush fabric transfer printing device includes a cloth feed roller 1, a paper feed roller 2, a heating roller 3, an input roller 4, a paper discharge roller 5, a first cloth discharge roller 6, a second cloth discharge roller 7, a printing roller Chamber 8, Cloth Receiving Roller 9, Roller 10, Fabric 11, Printing Paper 12, Paper Receiving Roller 13, Vacuum Port 14, High Pressure Vent 15, Water Cooling Vent 16, Air Bag 17, Air Compressor 18, High Pressure Fan 19 , water-cooled motor 20, cooling tuyere 21, cooling fan 22, etc.

[0015] Such as figure 1 As shown, the present invention includes a cloth feeding mechanism, a printing mechanism and a winding mechanism, and the cloth feeding mechanism includes several cloth feeding rollers 1 for inputting fabric 11, and the rear side of the cloth feeding roller 1 is provided for inputting printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com