Polyester-silk crepe-de-chine woven fabric

A polyester crepe de chine and woven fabric technology, applied in the field of clothing fabrics, can solve the problems of inability to create a crepe and noble feeling, strong heat shrinkage stress difference of chemical fiber products, etc., and achieve rich colors, low prices, and increased charm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

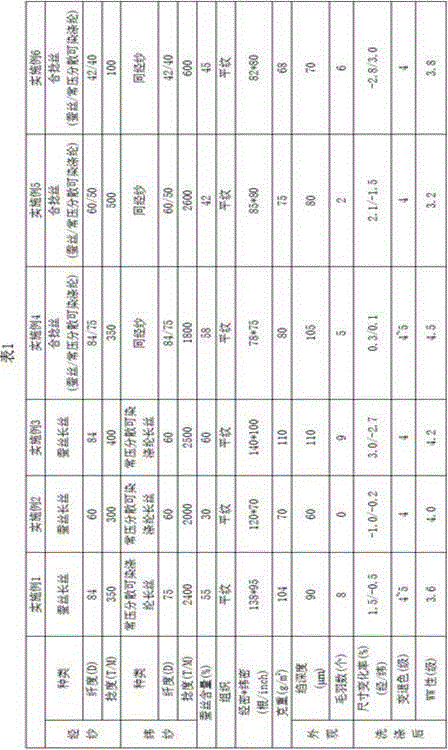

Embodiment 1

[0048] The warp yarn is 84D silk filament, and the weft yarn is disperse dyeable polyester filament under normal pressure. The specific specification is 75D-72F-FDY. ), water-absorbent and soft resin processing, finishing and shaping to obtain the woven fabric of the present invention.

[0049] Among them, the warp twist is 350T / M, the weft twist is 2400T / M, S:Z=2:2, the silk content of the finished fabric is 55%, the warp density is 138 threads / inch, and the weft density is 95 threads / inch. Gram weight is 104g / m 2 .

[0050] The finished crepe has a depth of 90 μm, and the number of hairs with a length ≽50 μm is 8. After washing 3 times according to JIS1096 2010 standard, the dimensional change rate in the warp direction is 1.5%, the dimensional change rate in the weft direction is -0.5%, and the color change rate is 4~5. Grade, WW grade is 3.6. Details are shown in Table 1.

Embodiment 2

[0052] The warp yarn is 60D silk filament, and the weft yarn is atmospheric pressure disperse dyeable polyester filament, the specific specification is 60D-36F-FDY. After the gray fabric is obtained by plain weave weaving, 95 degree scouring, 170 degree intermediate setting and dyeing are carried out (one-bath method) ), water-absorbent and soft resin processing, finishing and shaping to obtain the woven fabric of the present invention.

[0053] Among them, the warp twist is 300T / M, the weft twist is 2000T / M, S:Z=2:2, the silk content of the finished fabric is 30%, the warp density is 120 threads / inch, and the weft density is 70 threads / inch. Gram weight is 70g / m 2 .

[0054] The depth of the finished crepe is 60μm, and the number of hairs with a length ≽50μm is 0. After washing 3 times according to JIS1096 2010 standard, the dimensional change rate in the warp direction is -1.0%, and the dimensional change rate in the weft direction is -0.2%. The color change and fading is g...

Embodiment 3

[0056] The warp yarn is 84D silk filament, and the weft yarn is disperse dyeable polyester filament under normal pressure. The specific specification is 60D-36F-FDY. ), water-absorbent and soft resin processing, finishing and shaping to obtain the woven fabric of the present invention.

[0057] The warp twist is 400T / M, the weft twist is 2500T / M, S:Z=2:2, the silk content of the finished fabric is 60%, the warp density is 140 threads / inch, and the weft density is 100 threads / inch. Gram weight is 110g / m 2 .

[0058] The depth of the finished crepe is 110μm, and the number of hairs with a length ≽50μm is 9. After washing 3 times according to the JIS1096 2010 standard, the dimensional change rate in the warp direction is 3.0%, and the dimensional change rate in the weft direction is -2.7%, and the color change is grade 4. The WW property is 4.2. The details are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Twist | aaaaa | aaaaa |

| Twist | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com