Raising method of velvet cloth and velvet cloth prepared by raising method

A velvet cloth and fleece technology, which is applied in the direction of improved hand feeling fiber, fabric kneading/softening, roughening, etc., can solve the problem of limited improvement in the anti-pilling performance of gray fabrics, and achieve good appearance, moisture permeability and Excellent warmth retention effect and high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A method for raising velvet cloth, comprising soft setting, napping, intermediate setting, combing, shearing, polarizing, and final setting. The specific operations of each step are as follows:

[0057] Softening and shaping: the gray cloth is soaked in the softening liquid and enters the setting machine. The temperature of the setting machine is set at 130°C and the cloth speed is 20m / min. The softening liquid is an aqueous solution of softener composed of PEP softener and water. The mass percentage is calculated as 0.8%.

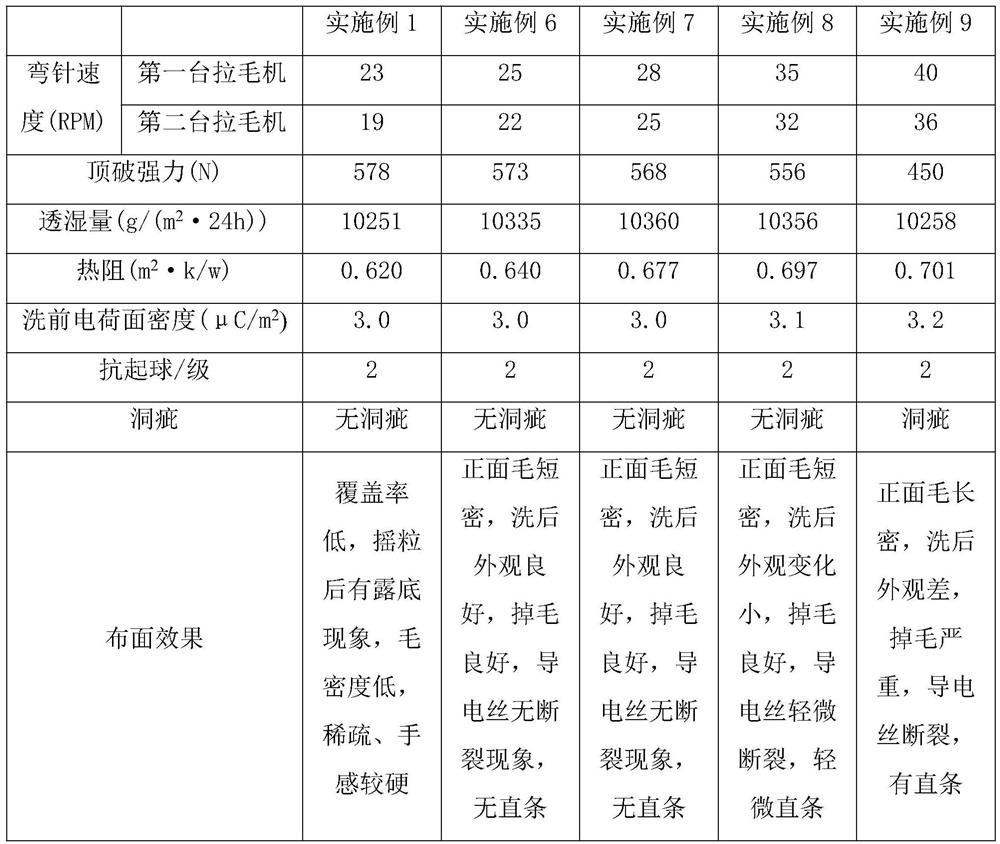

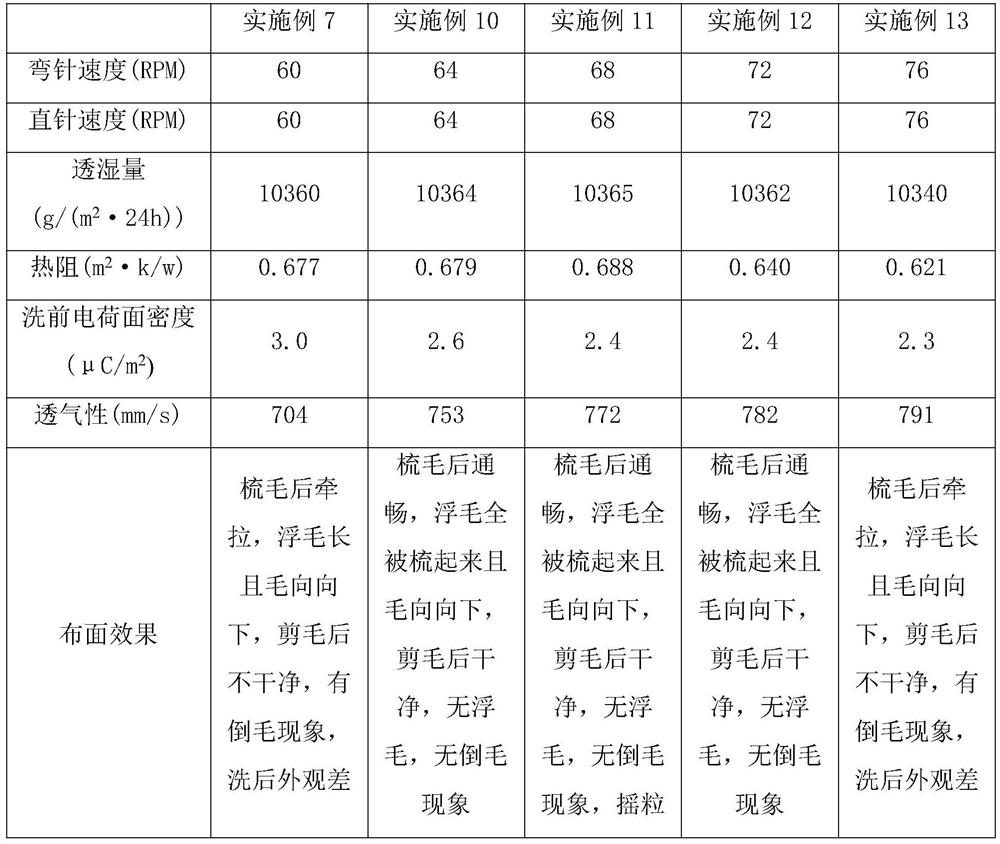

[0058] Napping: The soft and shaped gray cloth is continuously napped by two napping machines. The specific process parameters are as follows:

[0059] The first napping machine: the total speed is 10YPM, the cloth feeding speed is 7.5YPM, the cloth output speed is 9.2YPM, the tension roller tension is 2kgf, the looper speed is 23RPM, the straight needle speed is 15RPM, and the roller speed is 155RPM;

[0060] The second napping machine: the total ...

Embodiment 2

[0067] A method for raising velvet cloth, the difference from Example 1 is that in the process of softening and setting the gray cloth, the softening solution is an aqueous solution of softening agent composed of PEP softening agent and water, wherein the concentration of PEP softening agent is calculated by mass percentage It is 1%, and all the other steps and processing parameters are identical with embodiment 1.

Embodiment 3

[0069] A method for raising velvet cloth, the difference from Example 1 is that in the process of softening and setting the gray cloth, the softening solution is an aqueous solution of softening agent composed of PEP softening agent and water, wherein the concentration of PEP softening agent is calculated by mass percentage It is 1.5%, and all the other steps and processing parameters are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com