Swing-type belt distributing device and method for determining sizes of gears of elliptical gear case of swing-type belt distributing device

A technology of oval gear box and oval gear, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problem of uneven distribution of the swing belt distributor, and achieve the effect of simple structure, stable and reliable performance, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, with reference to the drawings, through the description of the embodiments, the specific implementation of the present invention such as the shape and structure of the various components involved, the mutual position and connection relationship between the various parts, the function and working principle of each part, and the manufacturing process And operation and use methods, etc., for further details.

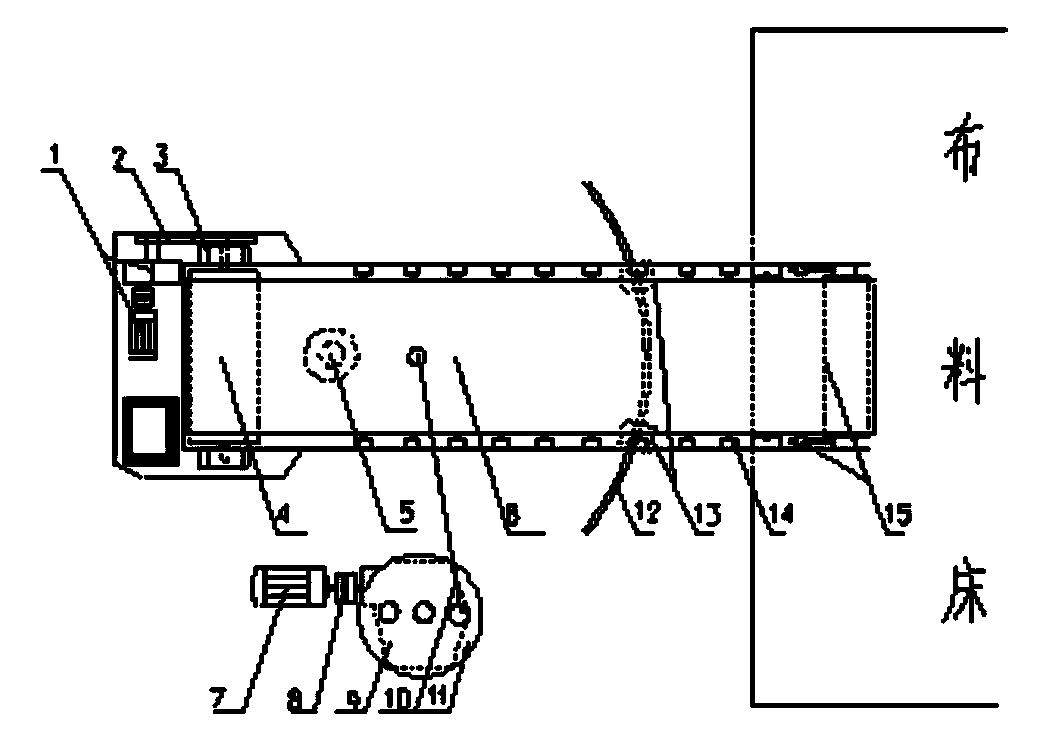

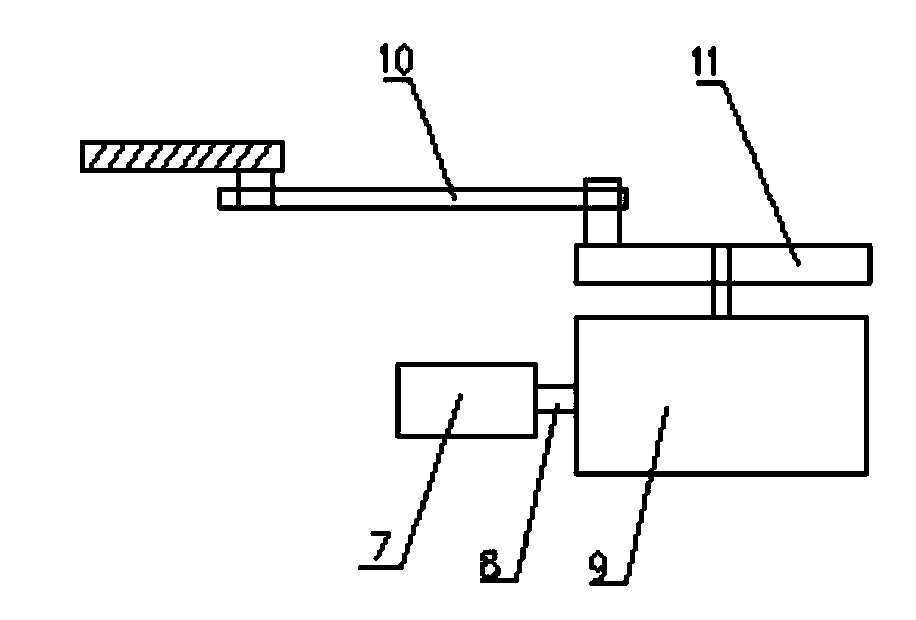

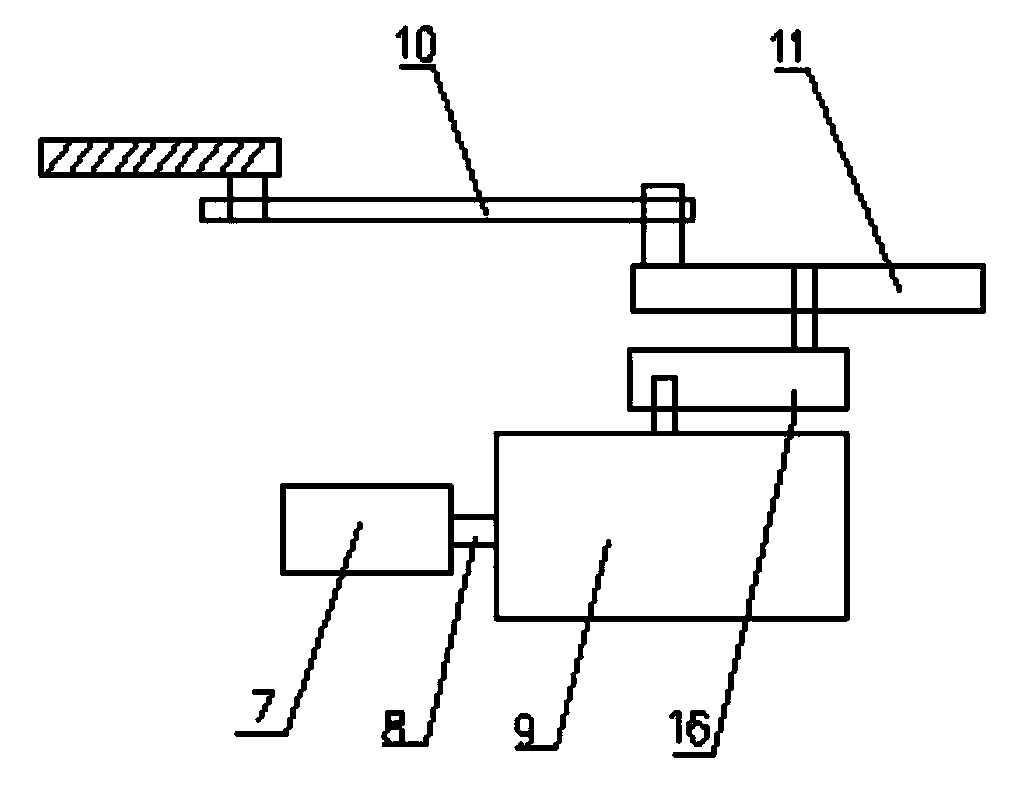

[0020] Pendulum belt distributor is a cloth device widely used in various industries. Such as figure 1 with figure 2 As shown, the device includes a transmission motor reducer 1, a transmission device, a crank connecting rod mechanism, an arc track 12, a traveling wheel 13, an idler 14 and a redirecting wheel and adjuster 15, wherein the transmission device includes a sprocket chain 2 , Bearing seat 3, head wheel 4, main shaft 5, tape 6, crank connecting rod mechanism includes swing motor 7, take over 8, swing reducer 9, connecting rod 10, crank 11, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com