Color fixing substitution alkali for low-salt dyeing by using reactive dye pad steaming process

A technology of reactive dyes and alkali substitutes, which can be used in dyeing, textiles and papermaking, etc. It can solve the problem that the buffer stability and color fixation stability are not as good as soda ash, the pH value of the dye solution and the color fixation depth fluctuate greatly, and the dyeing process is prolonged. Time and other issues, to achieve the effect of ensuring reproducibility and stability, low water quality requirements, and good cloth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment the present invention is described in further detail.

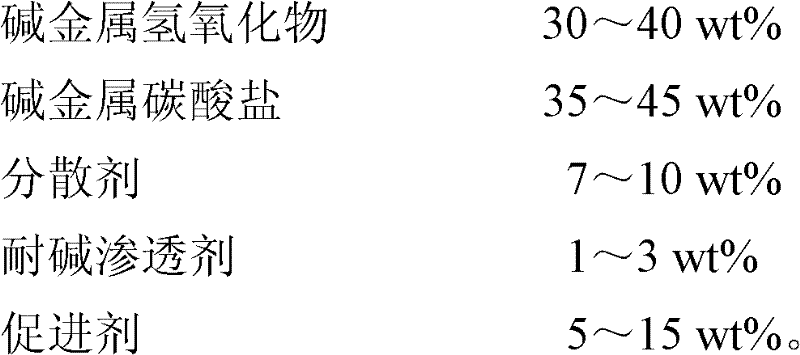

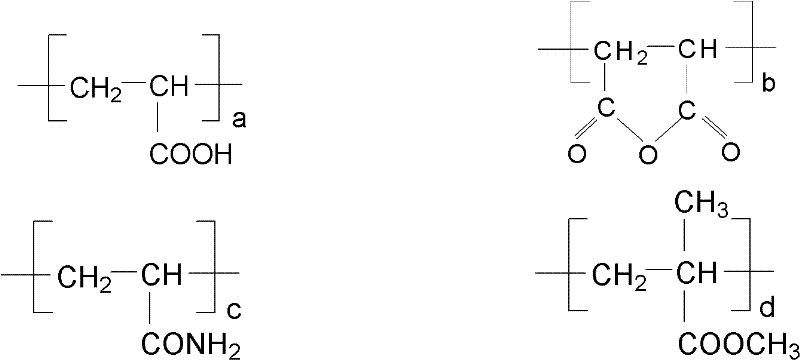

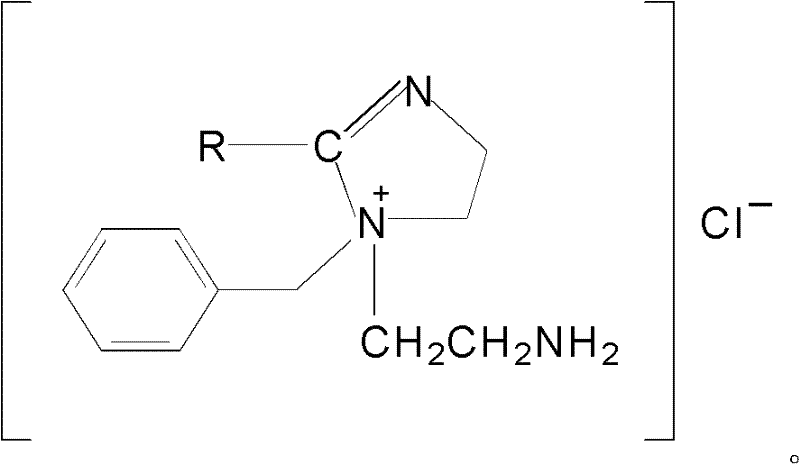

[0031] The color-fixing substitute alkali for low-salt dyeing of reactive dyes by pad-steaming method of the present invention is mainly prepared from the following components:

[0032]

[0033] The present invention provides six embodiments, and the consumption of each component among the embodiment 1-6 is expressed as follows by table 1:

[0034] Table 1

[0035]

[0036] The color-fixing substitute alkali of the present invention is compared with the consumption of soda ash in the application example of pad-steam dyeing:

[0037] Pad steam dyeing process:

[0038] Cloth feeding → pad dyeing solution (one soaking and one padding, the padding rate is 80%) → drying (infrared drying 100°C ~ 120°C) → padding color fixing liquid → steaming (105°C) → water washing (flat washing tank hot 1 compartment of water, 2 compartments of cold water)→neutralization (glacial acetic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com