One-bath dyeing process of brocade cotton fabric

The technology of nylon-cotton fabric and bath method is applied in the field of dyeing and finishing, which can solve the problems of difficult adjustment of process conditions, unsatisfactory homochromatic effect, etc., and achieve the effects of convenient process operation, shortening of dyeing time and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

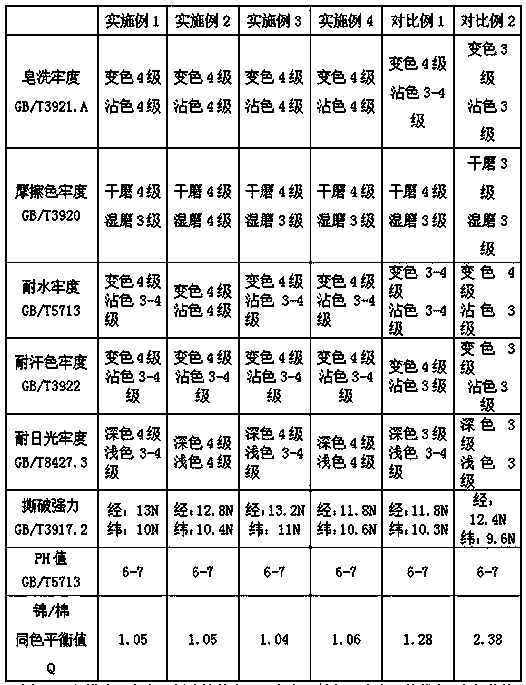

Examples

Embodiment 2

[0026] The present embodiment provides a kind of one-bath dyeing process of polyamide cotton fabric, taking dyeing black as an example, specifically comprising the following steps:

[0027] 1) Cold pile desizing: the gray cloth is rolled into the medicine tank of the cold pile machine to run at a speed of 50m / min, and the temperature of the medicine tank is kept at 85℃~95℃. After the predetermined time is reached, the rolls are unrolled immediately, and the slurry and residual chemicals carried by the cloth surface are thoroughly cleaned by a washing machine for dyeing. Wherein: the chemical consumption of cold pile desizing is: 32% sodium hydroxide 8g / l, tea saponin 8g / l, degreasing agent 2g / l.

[0028] 2) Dyeing: put the Nylon-cotton fabric after the cold batch desizing treatment into the dyeing vat of the air-flow dyeing machine, the bath ratio is 1:5, then add Anoky NC type reactive dyes to the dyeing vat, and wait for the reactive dyes to dissolve evenly. Add sodium sulf...

Embodiment 3

[0038] The present embodiment provides a kind of one-bath dyeing process of polyamide cotton fabric, taking dyeing maroon as an example, specifically comprising the following steps:

[0039] 1) Cold pile desizing: the gray cloth is rolled into the medicine tank of the cold pile machine to run at a speed of 45m / min, and the temperature of the medicine tank is kept at 85℃~95℃. After the predetermined time is reached, the rolls are unrolled immediately, and the slurry and residual chemicals carried by the cloth surface are thoroughly cleaned by a washing machine for dyeing. Wherein: the chemical consumption of cold pile desizing is: 32% sodium hydroxide 8.5g / l, tea saponin 9g / l, degreasing agent 5g / l.

[0040] 2) Dyeing: Put the Nylon / cotton fabric that has undergone cold-batch desizing treatment into the dye vat of the overflow dyeing machine with a liquor ratio of 1:10, then add Anoky NC reactive dyes to the dye vat, and wait for the reactive dyes to dissolve evenly Add sodium...

Embodiment 4

[0050] The present embodiment provides a kind of one-bath dyeing process of polyamide cotton fabric, taking dyeing dark blue as an example, specifically comprising the following steps:

[0051] 1) Cold pile desizing: the gray cloth is rolled into the medicine tank of the cold pile machine to run at a speed of 48m / min, and the temperature of the medicine tank is kept at 85℃~95℃. After the predetermined time is reached, the rolls are unrolled immediately, and the slurry and residual chemicals carried by the cloth surface are thoroughly cleaned by a washing machine for dyeing. Wherein: the chemical consumption of cold pile desizing is: 32% sodium hydroxide 5g / l, tea saponin 8g / l, degreasing agent 4g / l.

[0052]2) Dyeing: Put the Nylon / cotton fabric after the cold batch desizing treatment into the dye vat of the overflow dyeing machine, the bath ratio is 1:10, then add Anoky NC reactive dye to the dye vat, and wait for the reactive dye to dissolve evenly Add sodium bicarbonate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com