Cloth expanding device of warp knitting machine

A technology of warp knitting machine and loop forming mechanism, which is applied in warp knitting, textiles, papermaking, knitting, etc. It can solve the problems of not meeting the process requirements, affecting the quality of cloth rolls and subsequent processes, and large deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

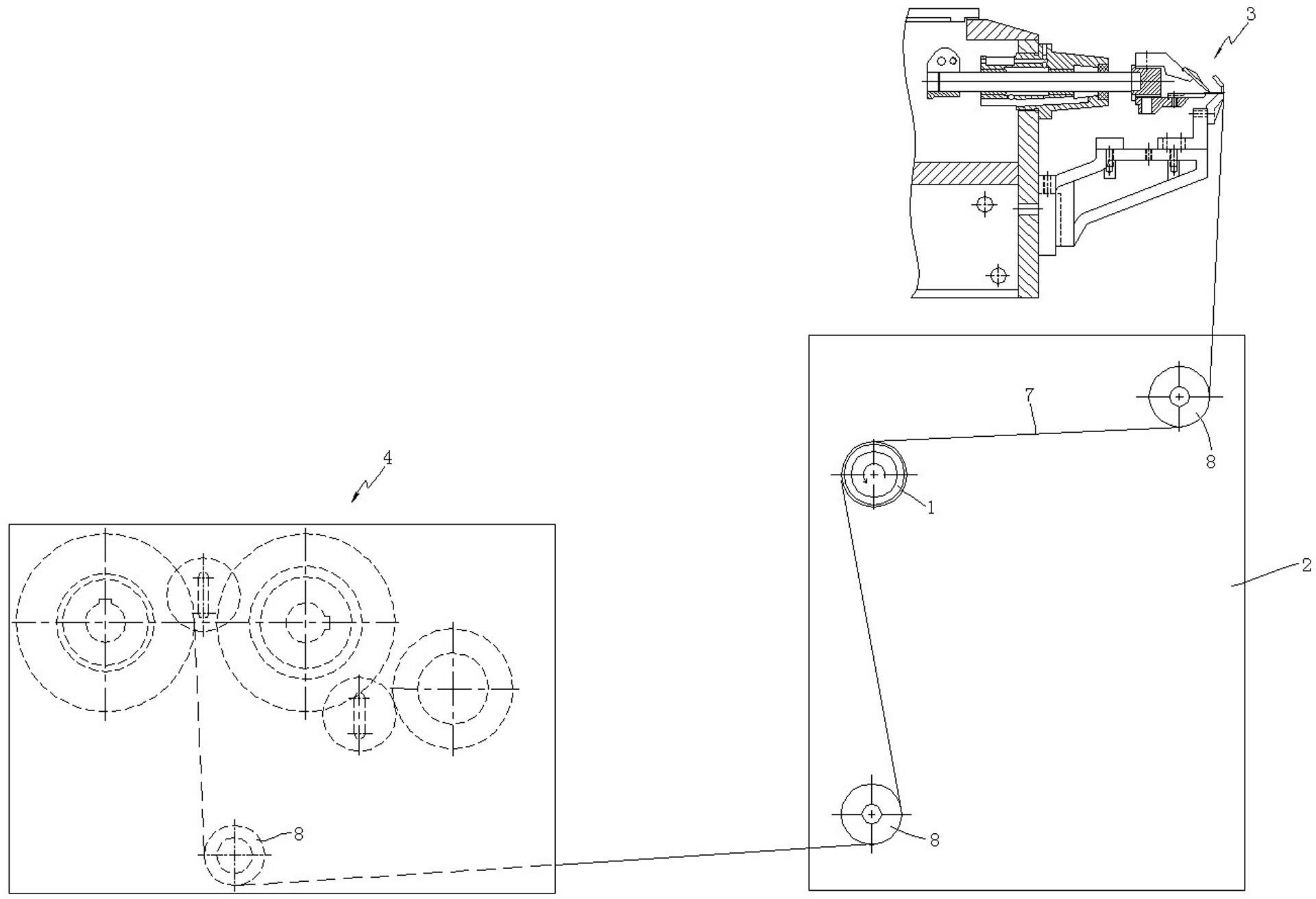

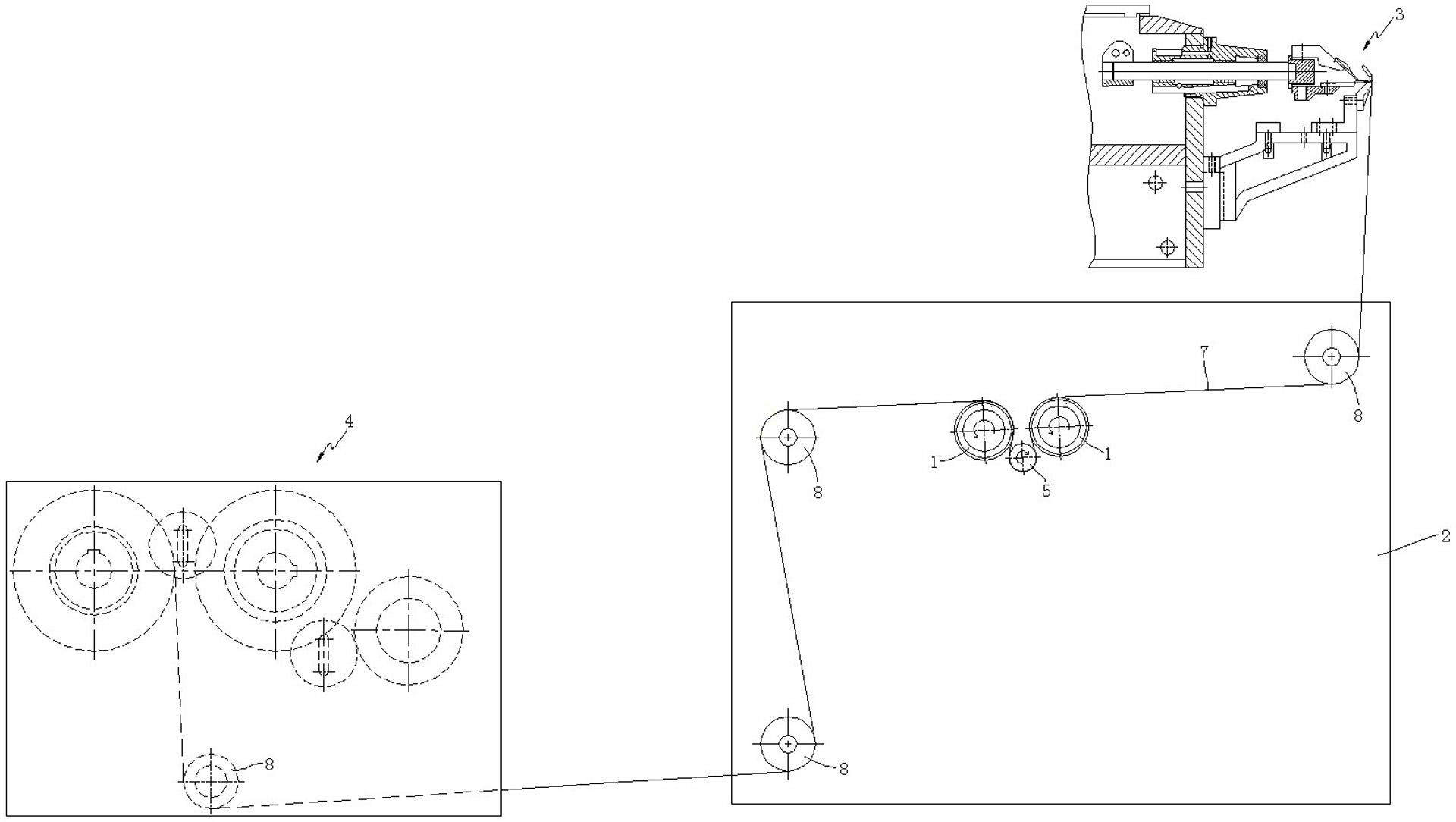

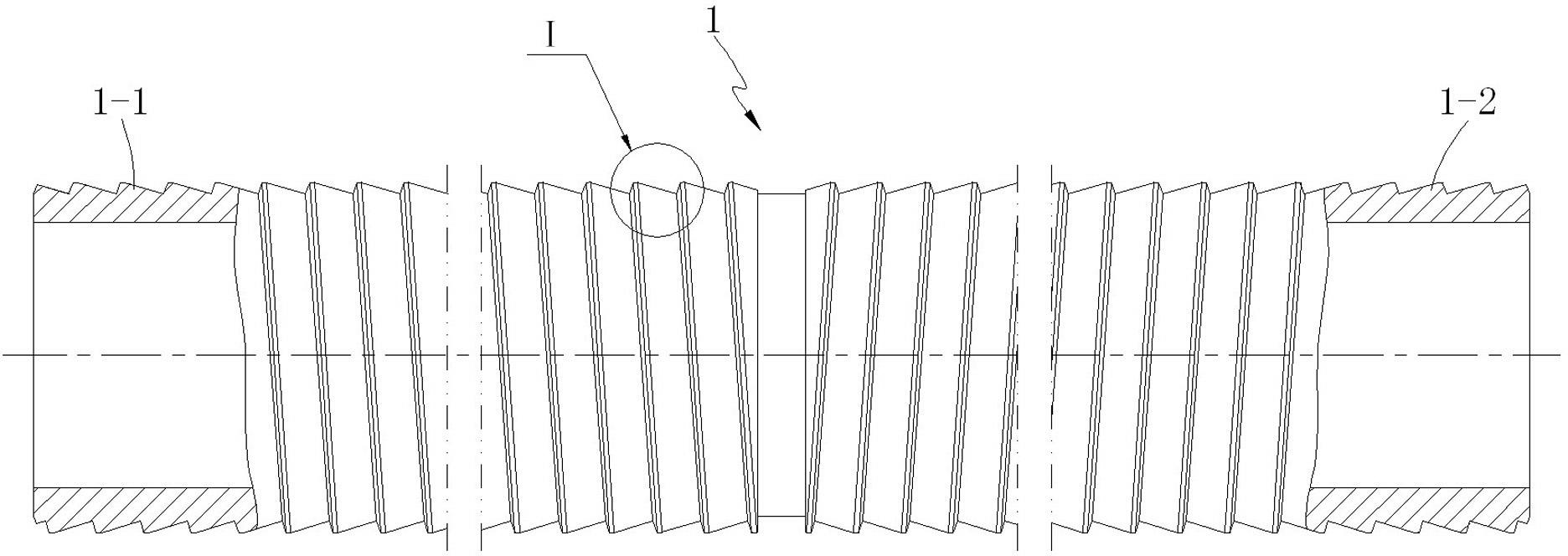

[0017] see Figure 1 to Figure 7 A warp knitting machine spreading device shown, the device includes at least one roller shaft 1 arranged between the warp knitting machine knitting mechanism 3 and the fabric pulling and winding mechanism 4, and the roller shaft 1 arranged on the On both sides, the wallboard 2 for supporting the roller shaft 1 in rotation; the outer peripheral surface of the roller shaft 1 is provided with a right-handed sawtooth thread 1-1 and a left-handed sawtooth thread 1-1 arranged opposite to each other along the axis direction left and right. Thread 1-2. In the present invention, as image 3 , 5 As shown, the roller shaft 1 is cylindrical, and the right-handed and left-handed zigzag threads 1-1, 1-2 can be formed by turning the outer peripheral surface of the roller shaft 1; Image 6 As shown, the two ends of the roller shaft 1 are rotatably supported on the wallboard 2 through bearings 6 respectively. like figure 1 As shown, when the warp knitting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Tooth depth | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com