Gravimetric-method material distribution device for medium and small sized ironmaking blast furnaces and material distribution method of device

A technology of gravimetric material distribution and iron-making blast furnace, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as the failure of normal material distribution, the failure of material tanks to be unloaded, and the impact on blast furnace production, so as to achieve good material distribution effects and improve production efficiency , to avoid the effect of material jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

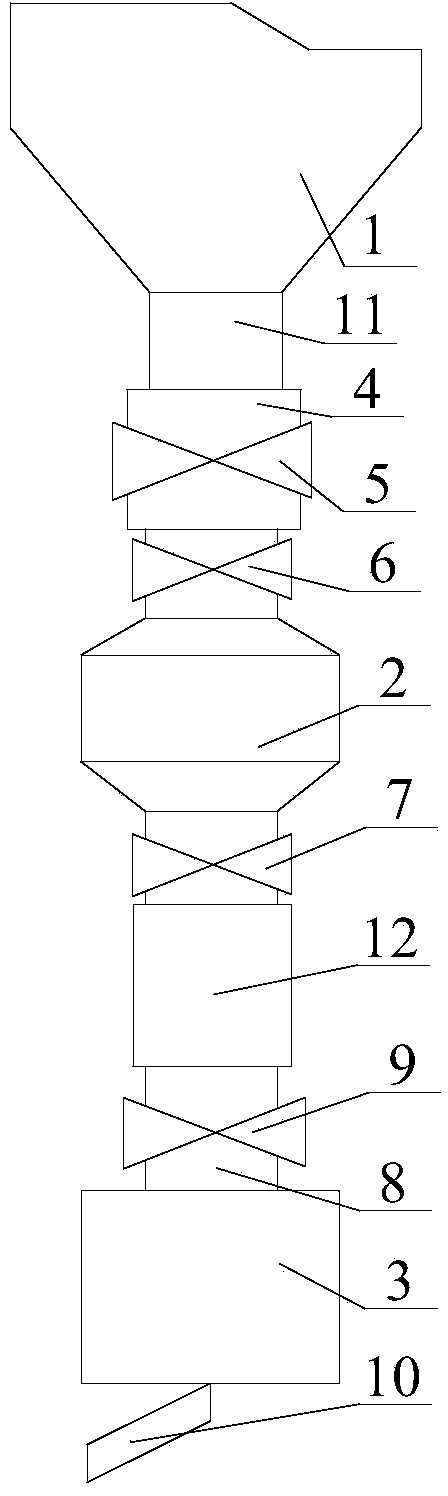

[0023] A gravimetric distribution device for small and medium-sized ironmaking blast furnaces, including a receiving hopper 1, a material tank 2, and a distribution device 3 arranged sequentially from top to bottom, and also includes an automatic control system. The outlet of the receiving hopper 1 is provided with a first pipeline 4, The first pipeline 4 communicates with the inlet of the material tank 2, the first pipeline 4 is provided with a stop valve 5, the material inlet of the material tank 2 is provided with an upper sealing valve 6, and the material outlet of the material tank 2 is provided with a material flow Regulating valve 7, the discharge port of material tank 2 is provided with a second pipeline 8, the second pipeline 8 communicates with the inlet of the distributor 3, the second pipeline 8 is provided with a lower sealing valve 9, and the bottom of the distributor 3 is provided with The chute 10, the upper sealing valve 6, the retaining valve 5, and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com