Concrete distributing machine

A concrete and material distribution machine technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of long intervals between pipe changes, cumbersome operations, troublesome site layout, etc., and achieve uniform concrete distribution, simplified overall structure, Optimizing the effect of cloth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

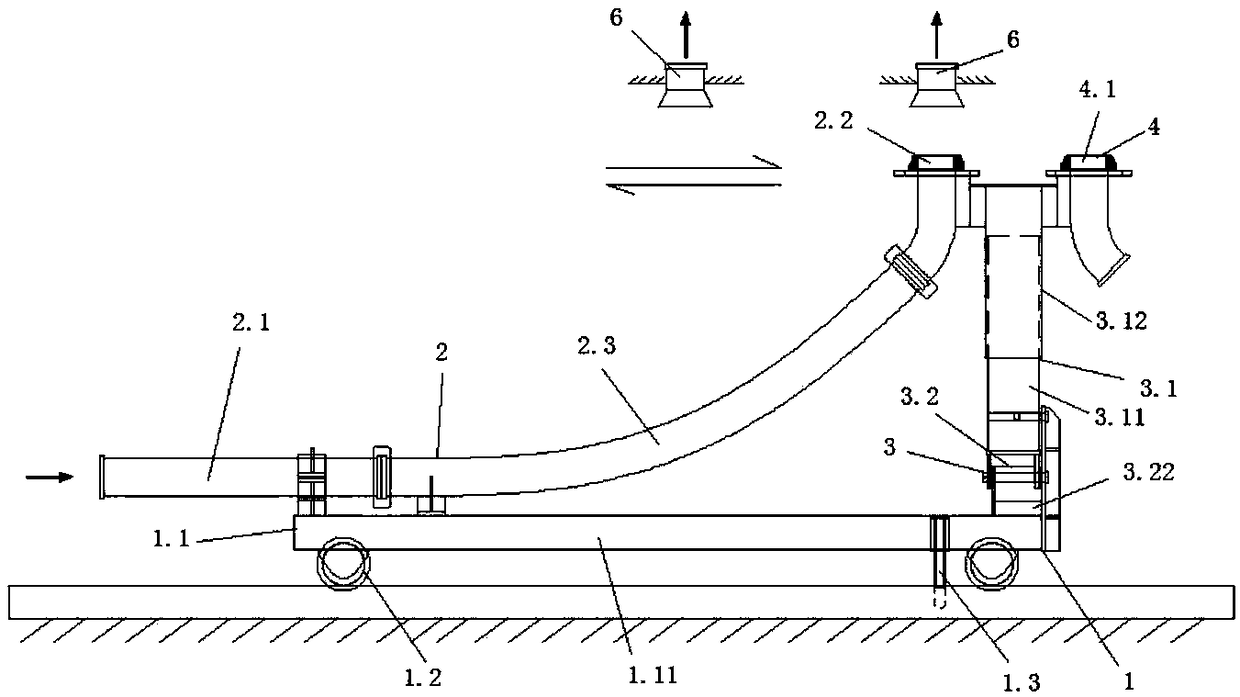

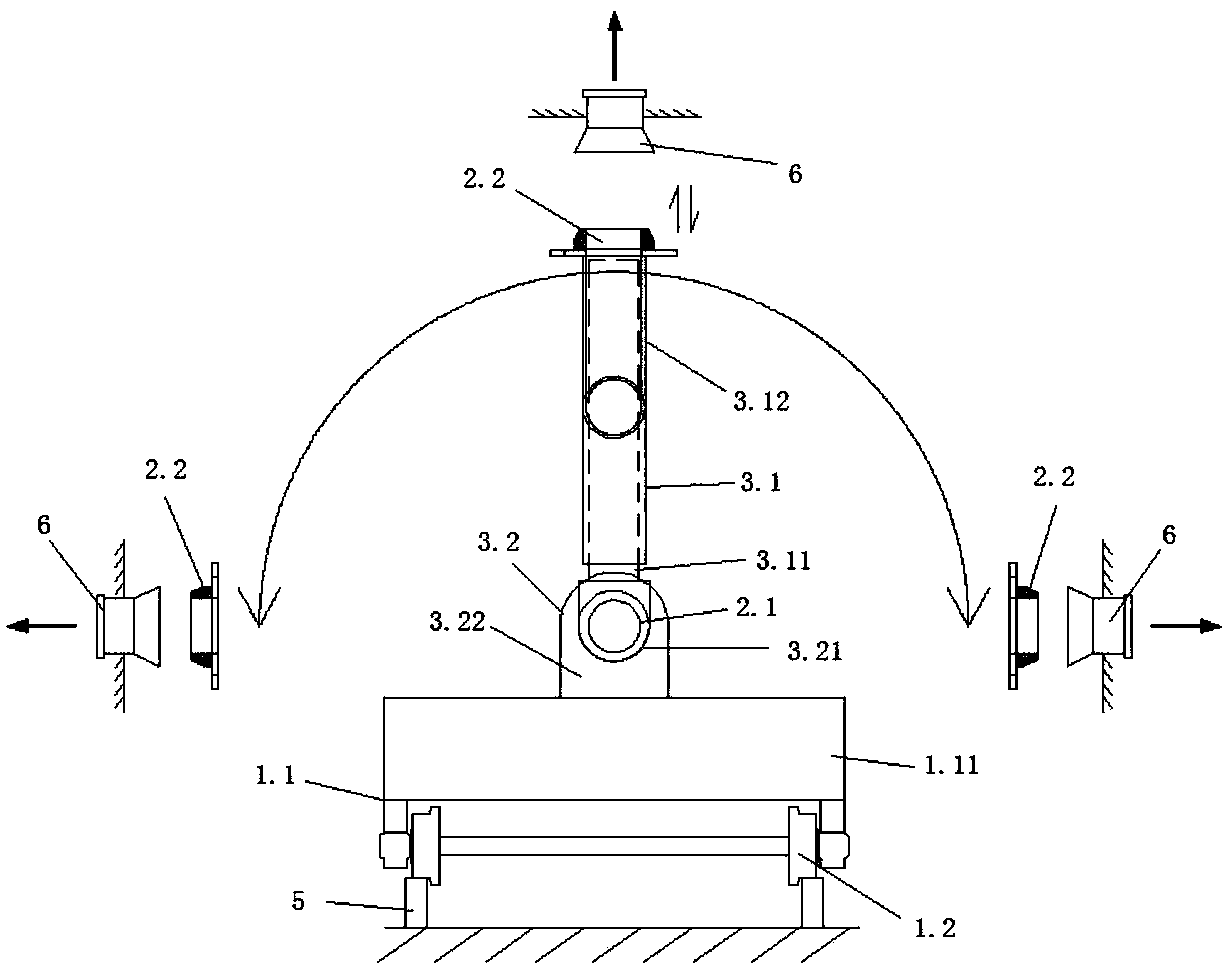

[0040] see figure 1 and figure 2 ( figure 1 and figure 2 The black arrows in represent the direction of the concrete, figure 1 The two-way arrow in the middle represents the direction of the car, figure 2 The double-headed arrow in represents the expansion and contraction direction of the telescopic cylinder, figure 2The arc-shaped arrow in the figure represents the rotation direction of the telescopic rotating arm), a concrete placing machine, including a trolley 1, a pipeline system 2, a telescopic rotating device 3 and a cleaning device 4, the trolley can travel longitudinally on the track, and the pipeline system consists of The hard pipe or flexible hose can be adjusted and changed with the movement of the trolley or telescopic rotating device to complete the docking and feeding.

[0041] The trolley 1 includes a car body 1.1, a running part 1.2 and a locking part 1.3, the car body 1.1 includes a bottom plate 1.11, the running part 1.2 is matched with the running...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com