Efficient smashing device for raw materials of medicine

A technology for processing devices and raw materials, applied in the field of high-efficiency crushing and processing devices for pharmaceutical raw materials, can solve the problems of inability to meet the diversified production requirements of biomass particle raw materials, the inability of materials to be quickly discharged from a pulverizing chamber in time, and the unreasonable arrangement of matching structures, etc. To achieve the effect of good crushing effect, large crushing ratio and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the technical solutions of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings.

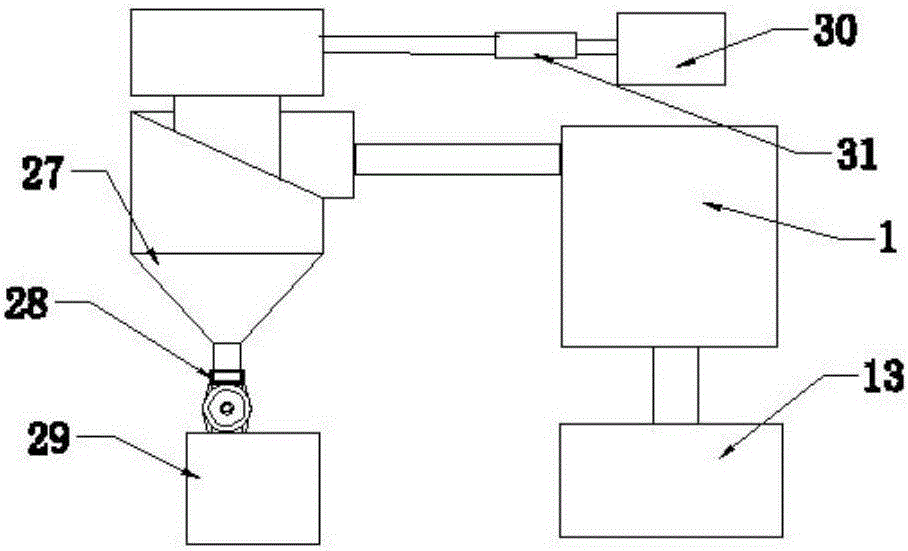

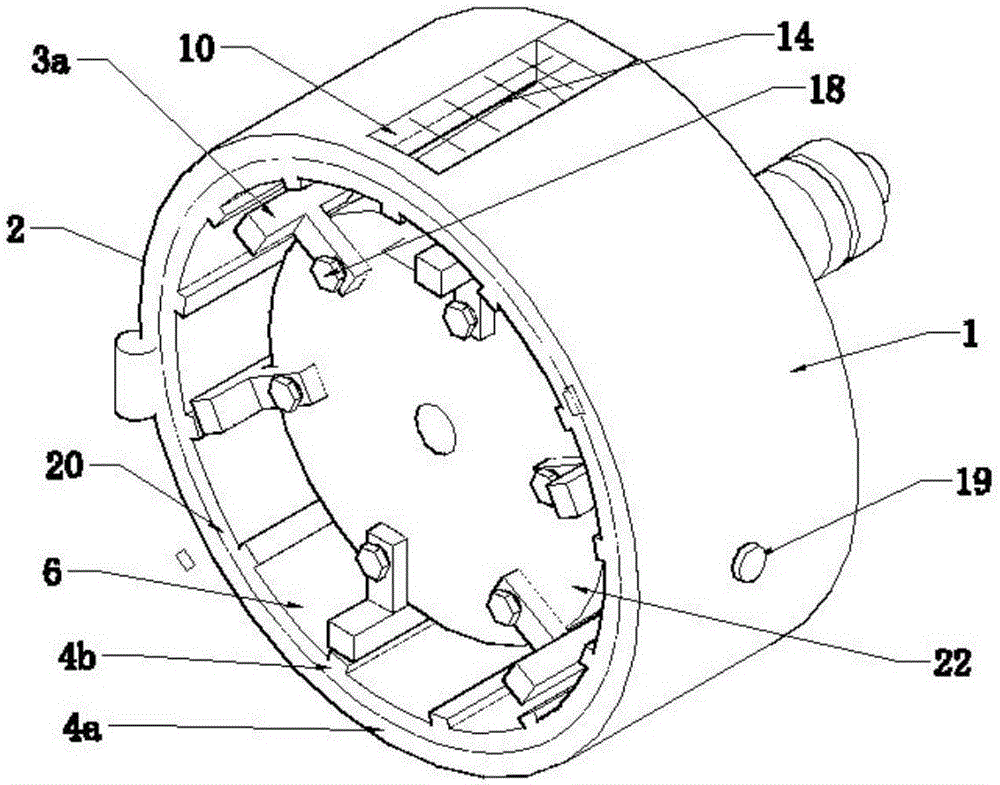

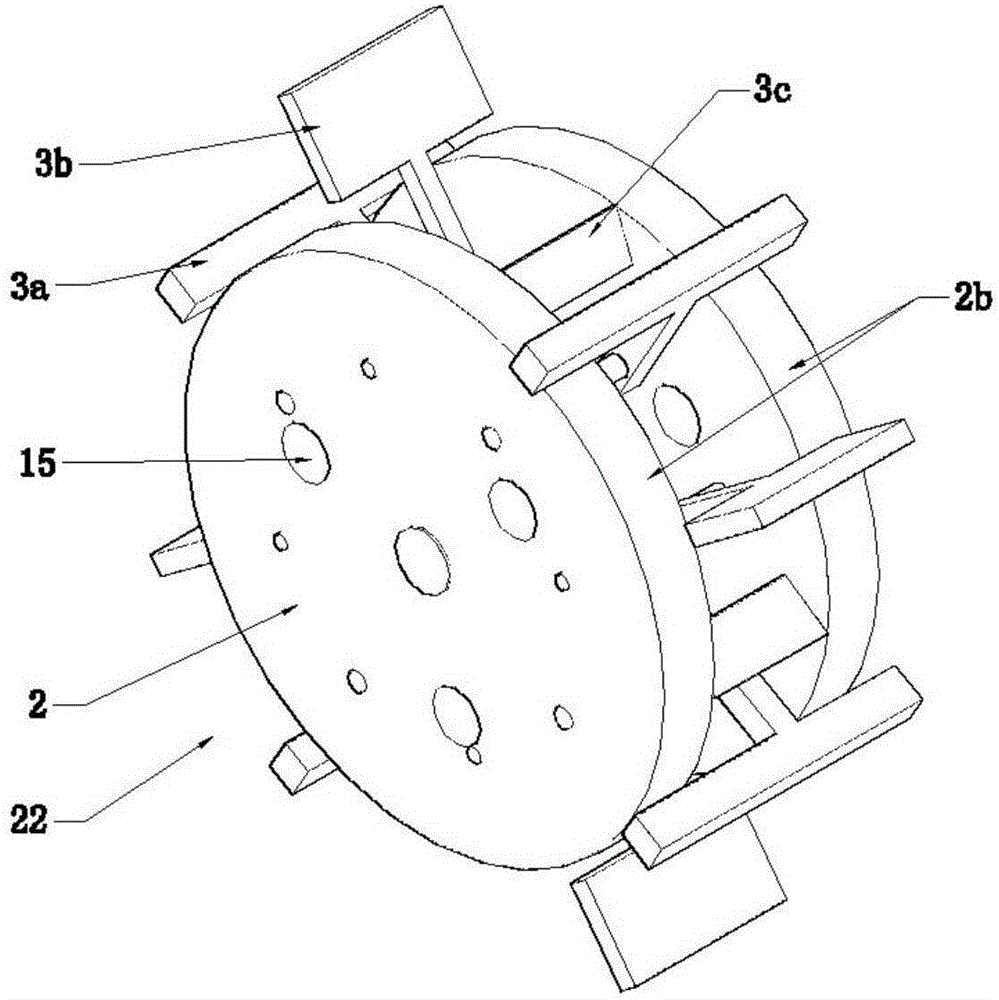

[0012] Such as figure 1 and 2 As shown, the high-efficiency crushing and processing device for pharmaceutical raw materials in this embodiment includes a DC drive motor 17, a crushing bin 1, a crushing mechanism 22, a body, and the like. The invention also includes an intelligent controller, which is connected to the driving motor of the crushing mechanism through corresponding signal lines, and the intelligent controller implements speed control and corresponding running time control on the driving motor of the crushing mechanism. A screener 13 is connected to the output end of the crushing bin.

[0013] In this example, the body is a box body 13, the crushing bin 1 and the DC drive motor 17 are respectively arranged on the box body 13, and the material output bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com