Patents

Literature

30results about How to "Realize the breaking function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

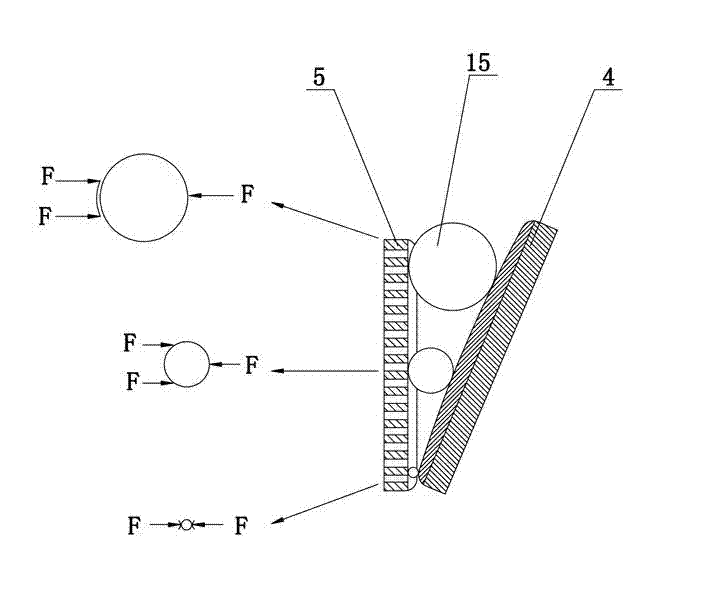

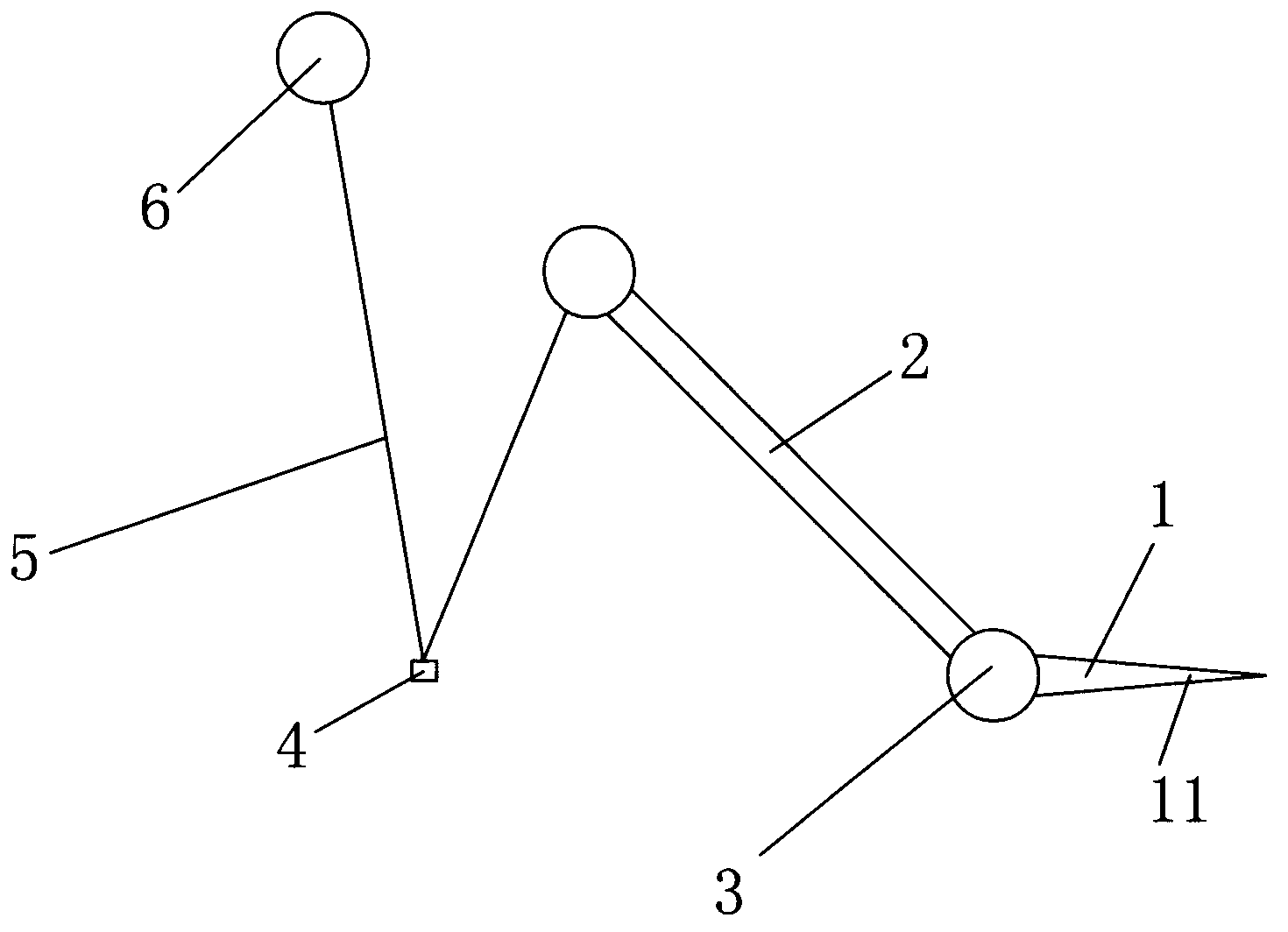

Jaw crusher with double shafts and double crank and rocker mechanisms

The invention discloses a jaw crusher with double shafts and double crank and rocker mechanisms. The jaw crusher comprises a rack, a fixed jaw plate, a movable jaw plate, a front crank and rocker mechanism, a rear crank and rocker mechanism and transmission wheels, wherein the front crank and rocker mechanism comprises a front movable jaw, a front knee plate and a front eccentric driving shaft; the rear crank and rocker mechanism comprises a rear movable jaw, a rear knee plate and a rear eccentric driving shaft; the front and rear jaw plates are respectively pivoted on the front and rear eccentric driving shafts; the front and rear eccentric driving shafts are respectively connected with the transmission wheels; one end of the front knee plate is pivoted below the rear side of the front movable jaw, and the other end of the front knee plate is pivoted below the front side of the rear movable jaw; one end of the rear knee plate is pivoted below the rear side of the rear movable jaw, and the other end of the front knee plate is pivoted on the rack; and the movable jaw plate is fixedly connected to the front movable jaw and faces the fixed jaw plate to form a crushing cavity. The jaw crusher has the advantages that: the function of the lower horizontal motion travel of the movable jaw is improved from material discharge to crushing, so crusher equipment has a secondary-crushing effect.

Owner:义乌市凌丰知识产权服务有限公司

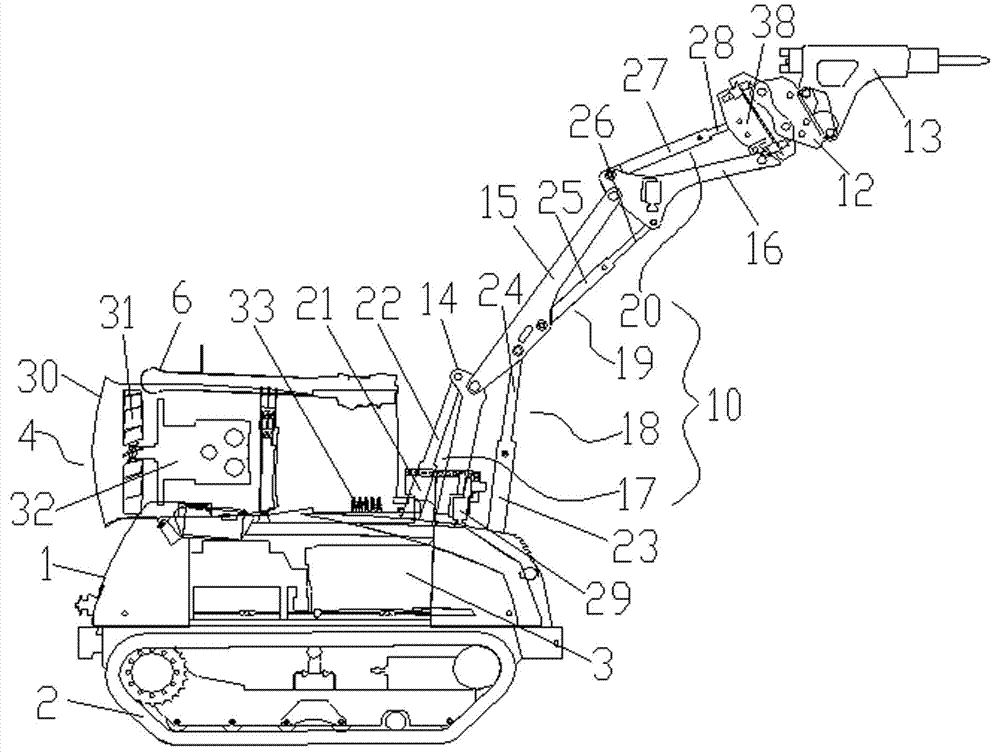

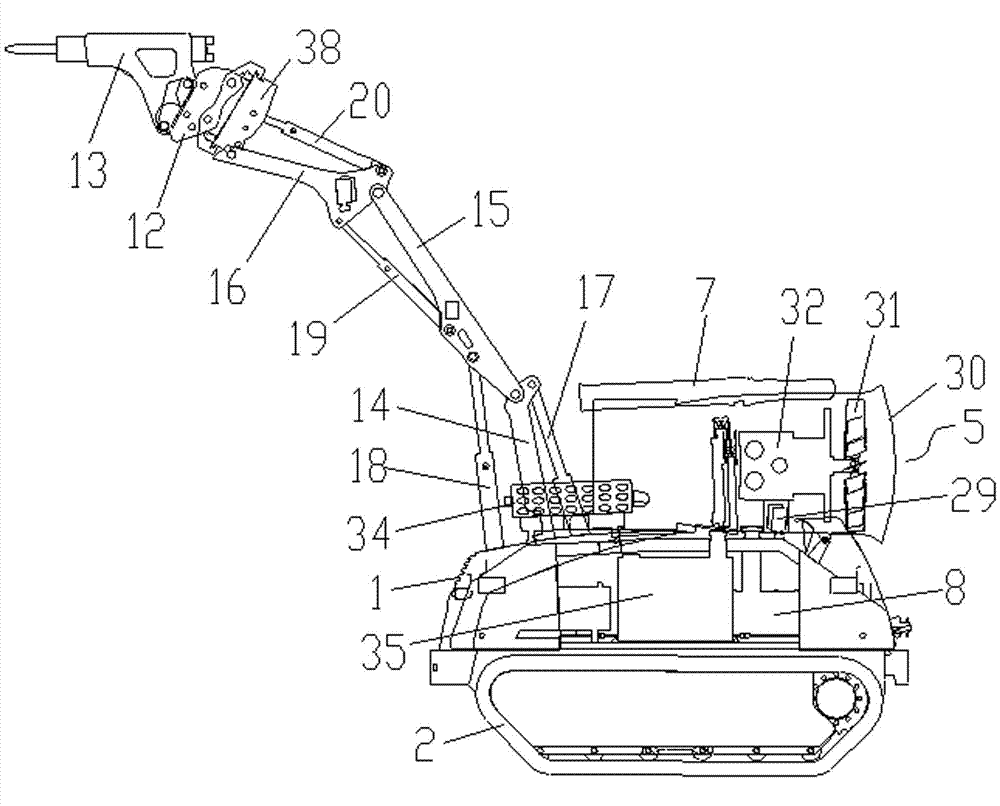

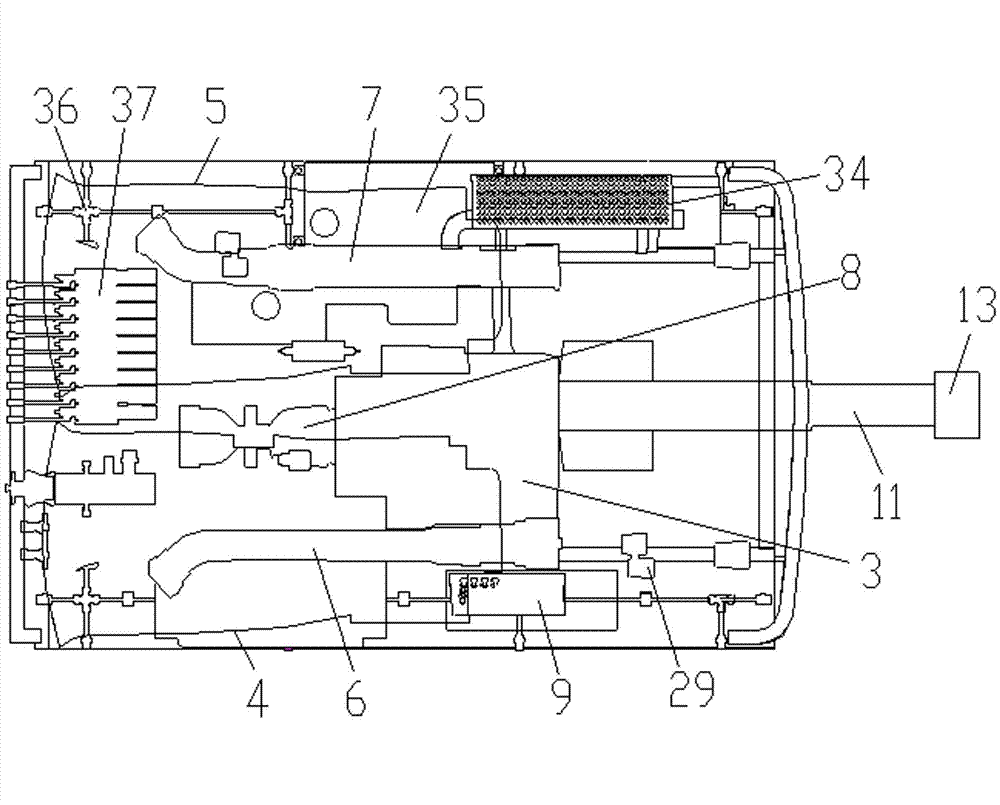

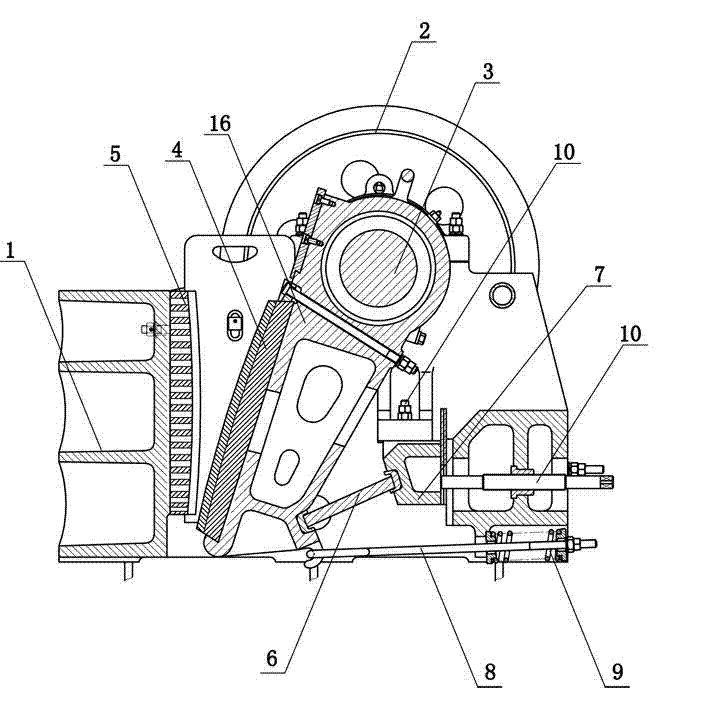

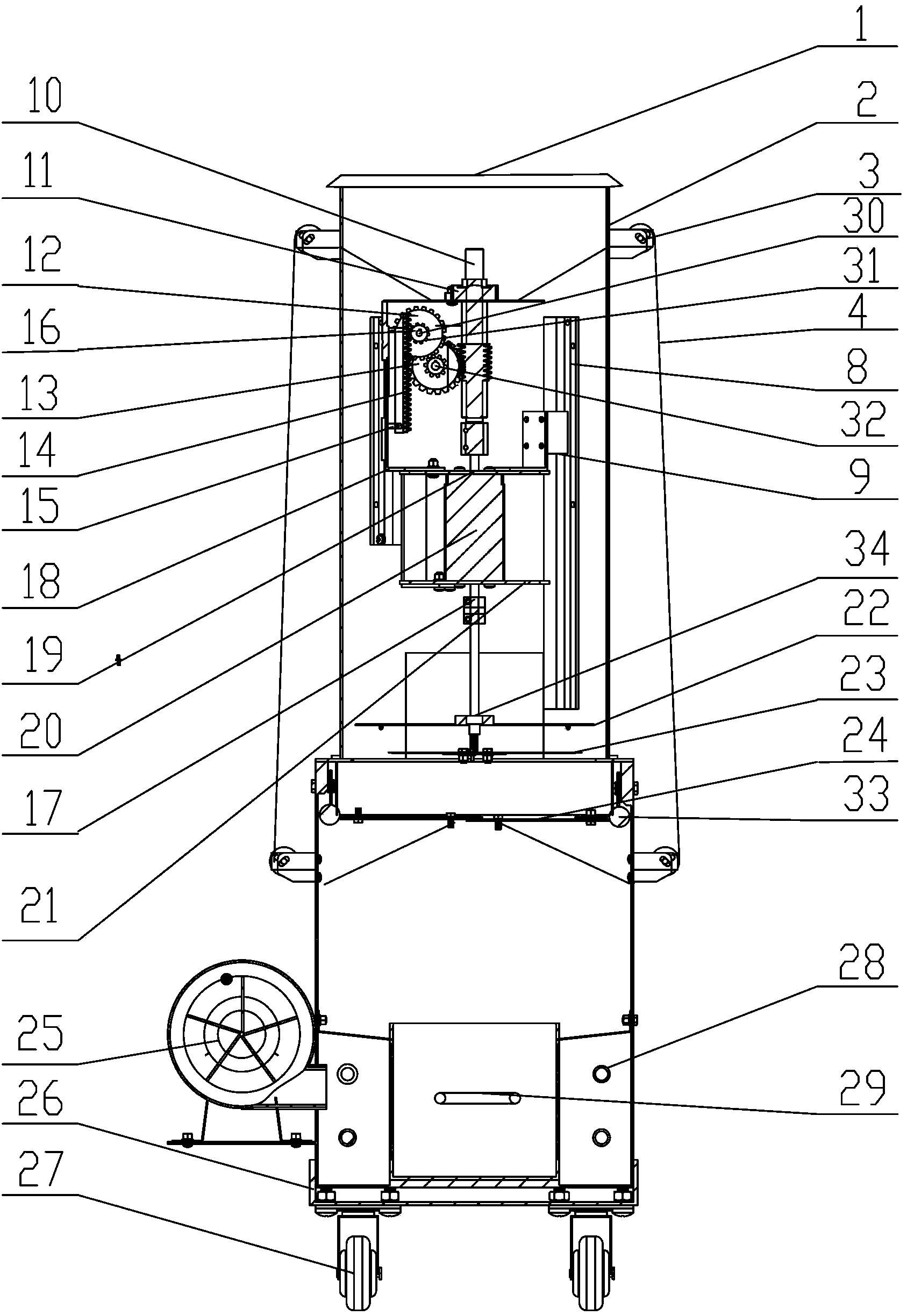

Smoke exhaust, fire extinguishment and dismantling robot

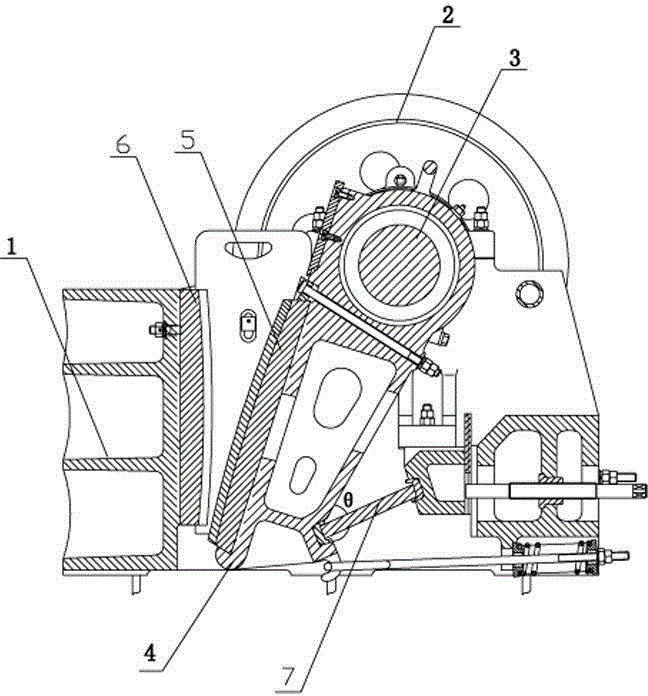

InactiveCN102755705AGood for reconnaissanceRealize the breaking functionFire rescueManipulatorVideo transmissionRemote control

The invention relates to a smoke exhaust, fire extinguishment and dismantling robot which comprises a vehicle body, a chassis walking device installed on the lower part of the vehicle body, a power device, a working device, a waterway system, a hydraulic system and an electric system, wherein two exhaust blowers are arranged on the upper part of the vehicle body; the side surfaces of the two exhaust blowers are respectively provided with a water cannon and a foam cannon; and a dismantling device is installed at the front end of the vehicle body and comprises an arm frame and a dismantling tool which is connected with the arm frame through a quick change coupler. The smoke exhaust, fire extinguishment and dismantling robot is concise in structure and strong in practicability, can be used for replacing a fire fighter to enter into a fire scene with important safety hidden dangers to carry out short distance fire fighting operation, can carry out water and foam remote control spraying and video transmission on the fire scene, has a self-protection sprinkling device and has the functions of large power smoke exhaust, water mist spraying and strong walking and climbing as well as the functions of dismantling, object grabbing and bucket to an obstacle, so that the working efficiency is greatly improved, the safety is high, and the smoke exhaust, fire extinguishment and dismantling robot is convenient to popularize and apply.

Owner:苏州海伦哲专用车辆有限公司

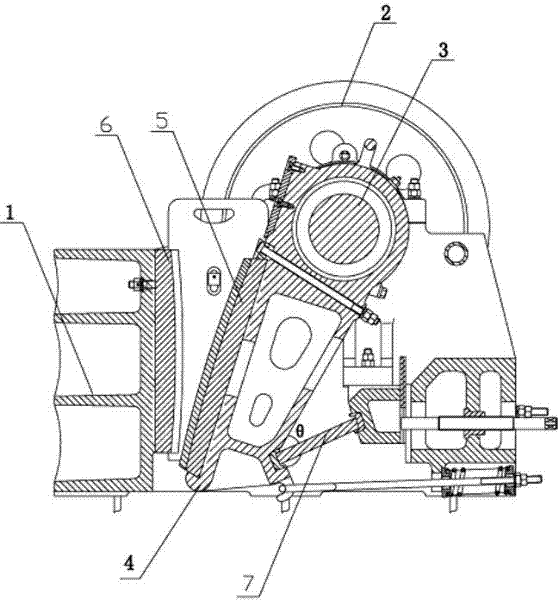

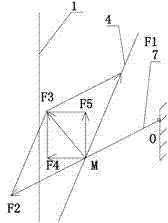

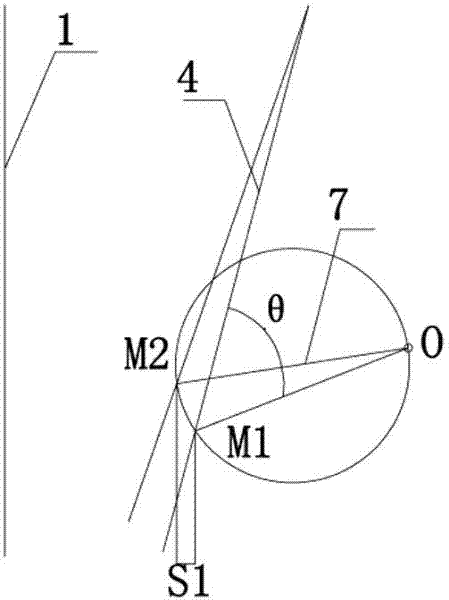

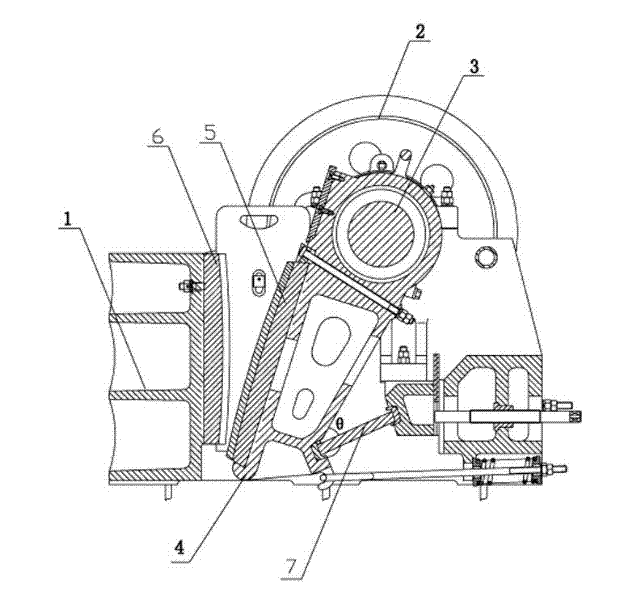

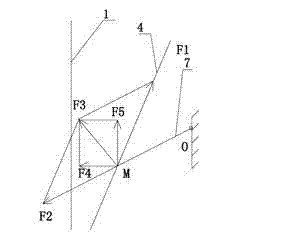

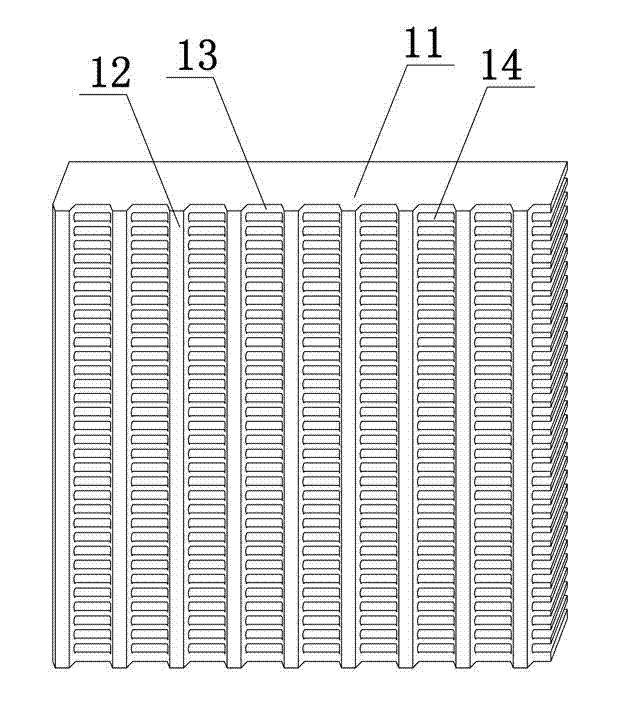

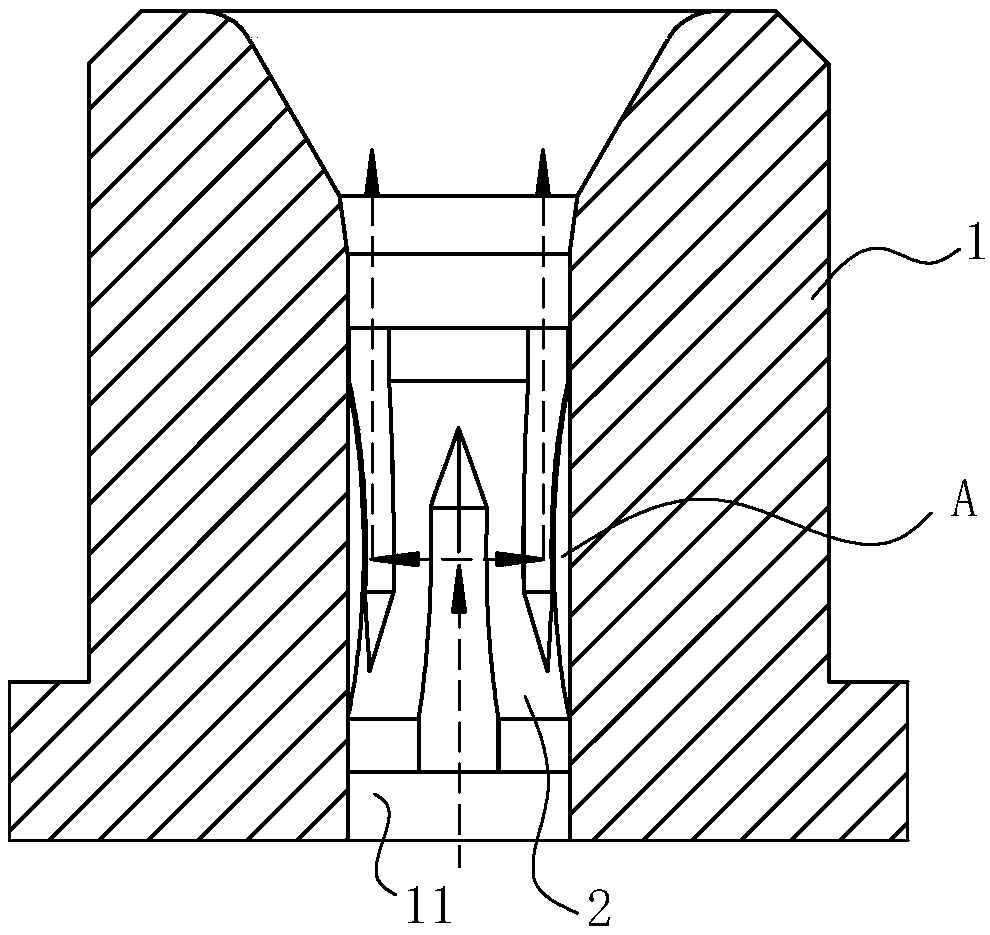

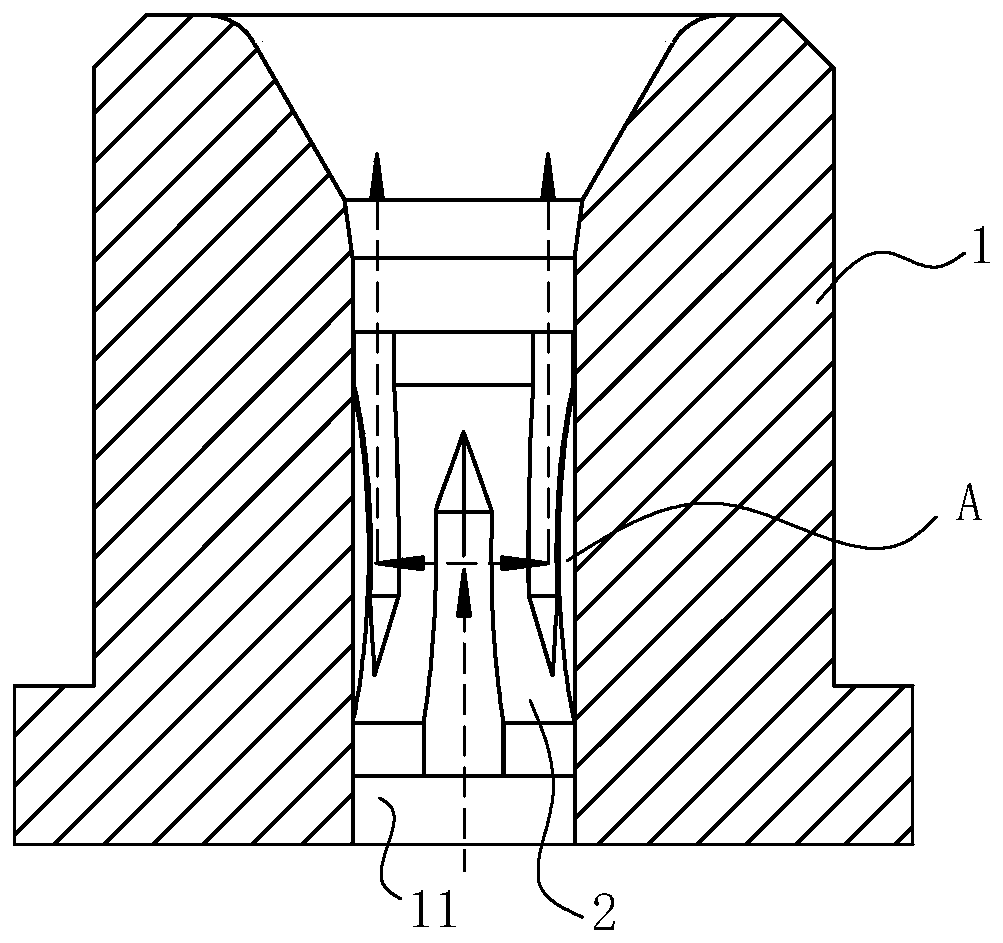

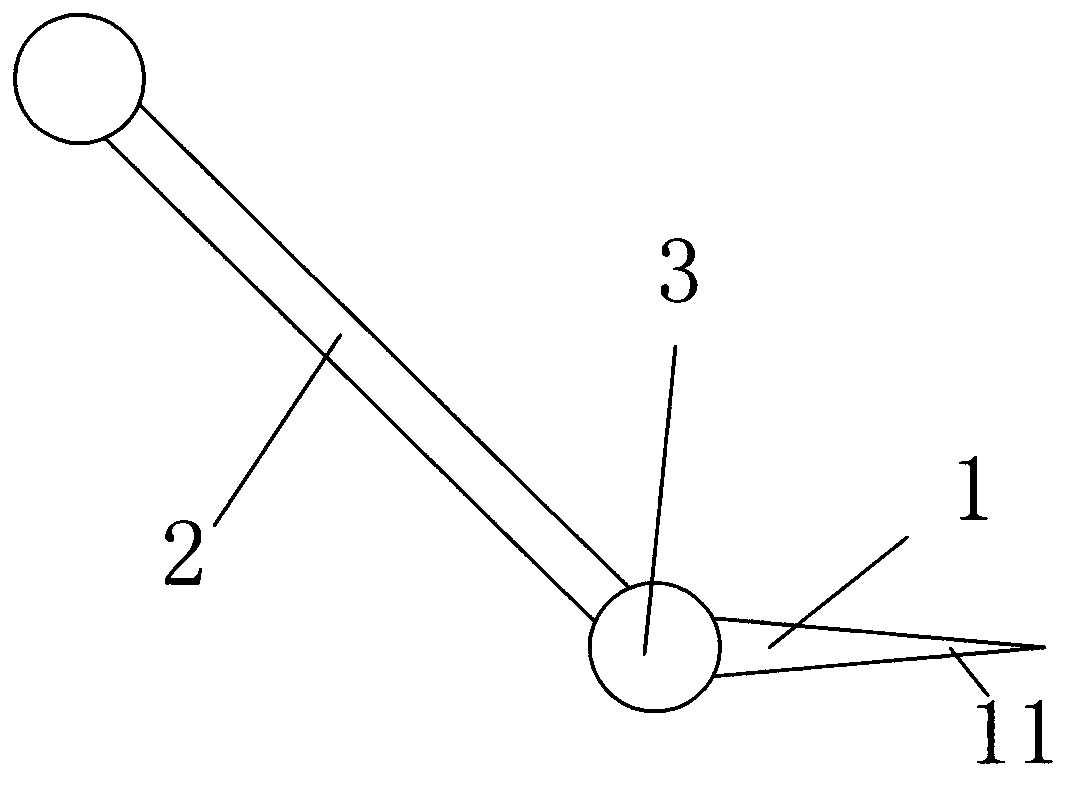

Jaw crusher with single-shaft double-crank-rocker mechanism

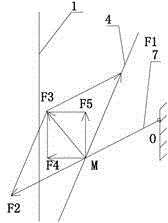

ActiveCN102198409AChange the mechanical structureEasily brokenGrain treatmentsDrive wheelDrive shaft

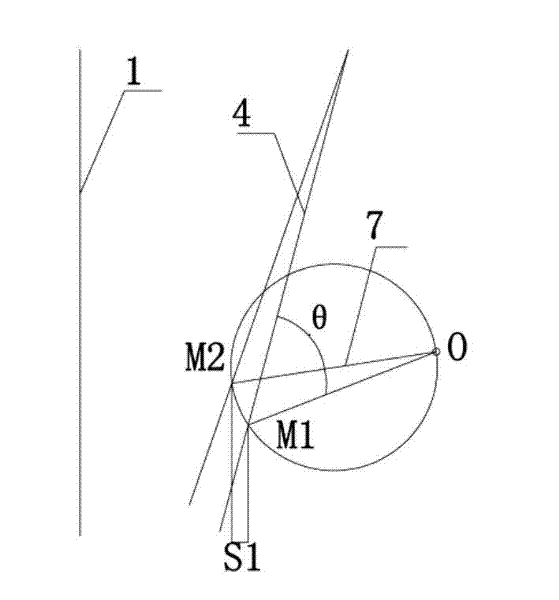

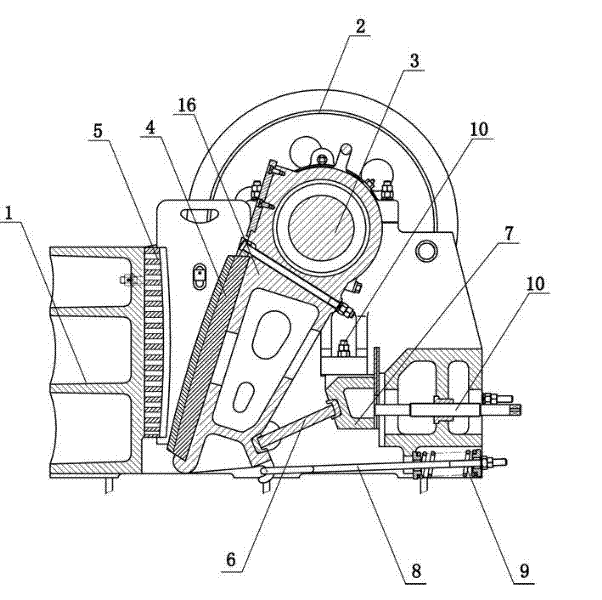

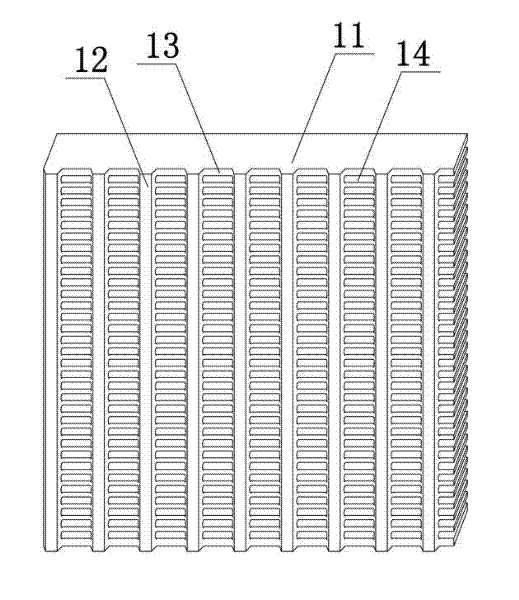

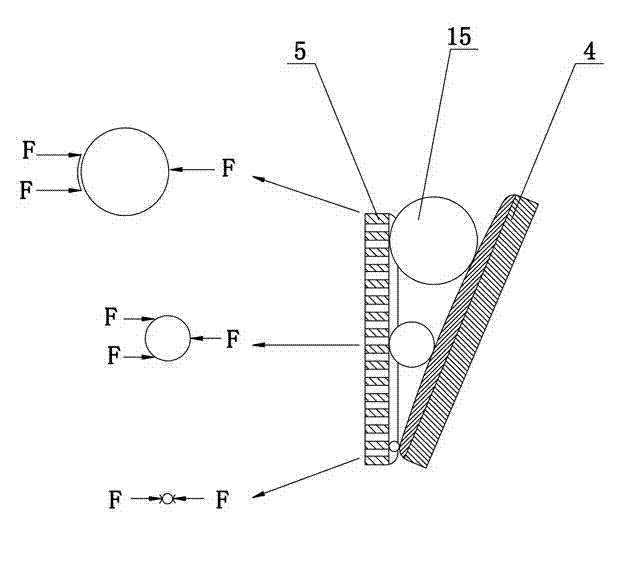

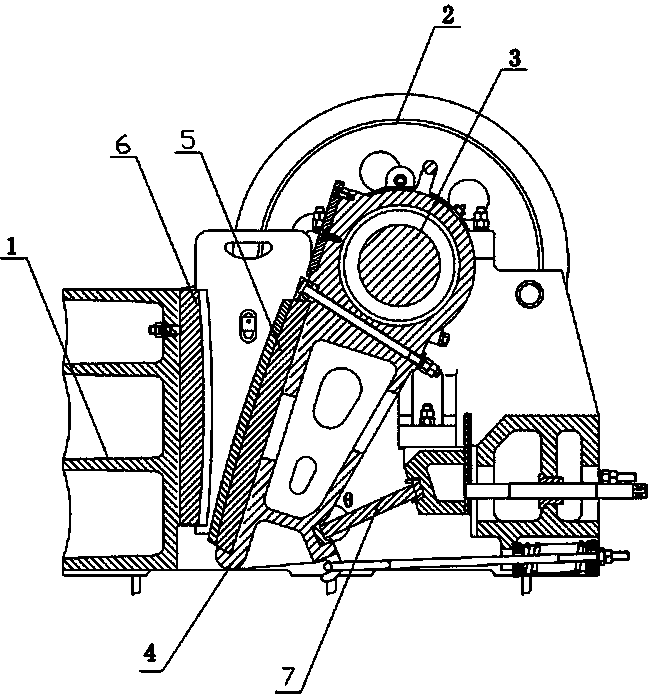

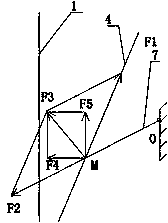

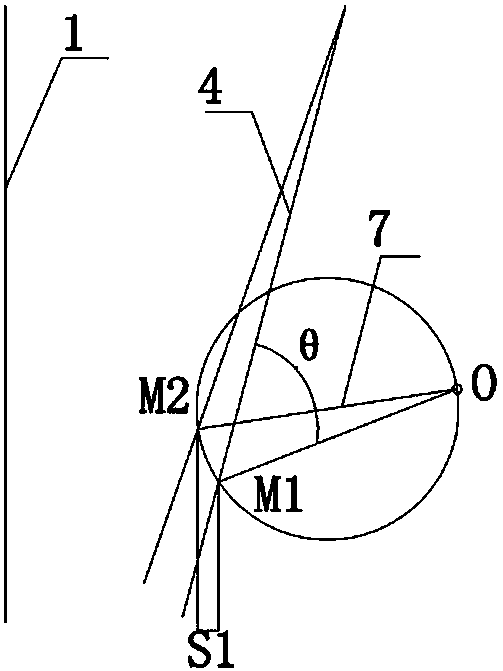

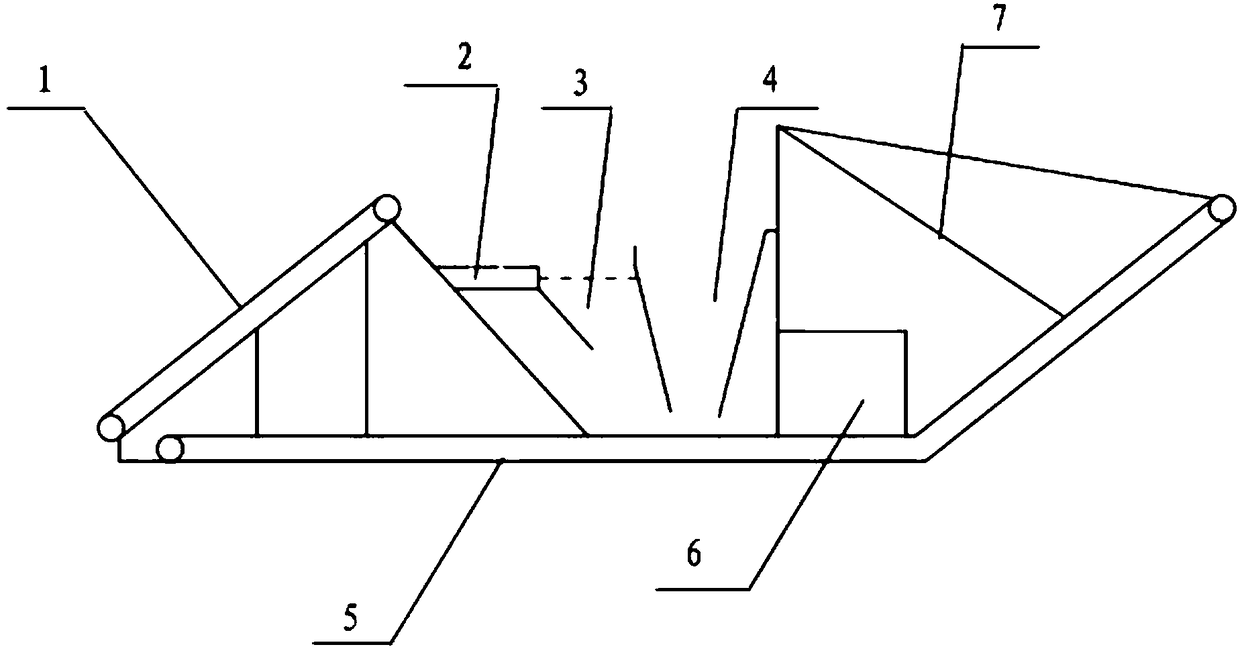

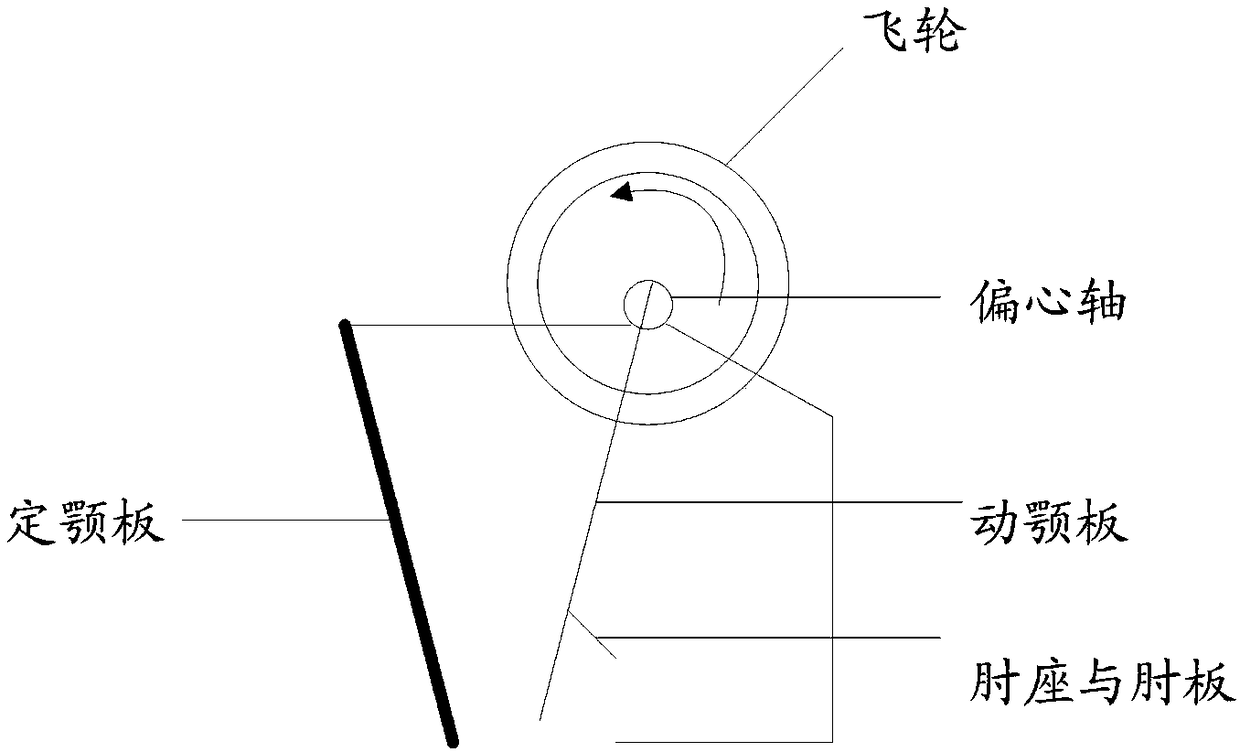

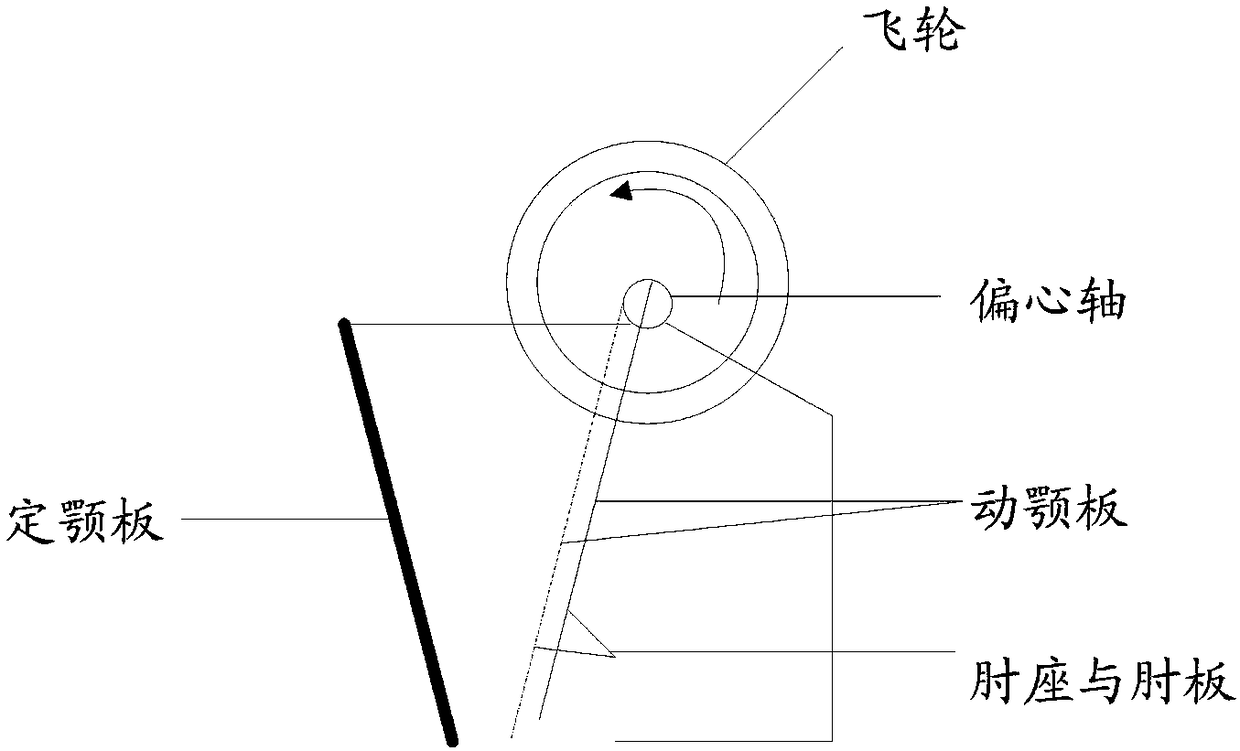

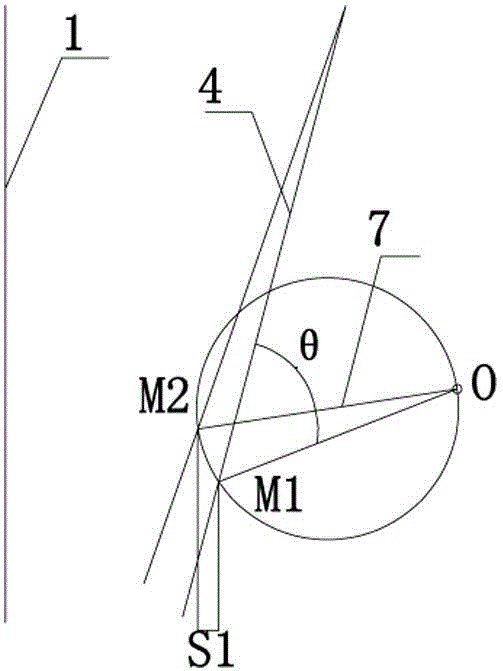

The invention discloses a jaw crusher with a single-shaft double-crank-rocker mechanism. The jaw crusher comprises a frame, a fixed jaw plate, a movable jaw plate, a front crank-rocker mechanism, a rear crank-rocker mechanism and a driving wheel, wherein, the front crank-rocker mechanism comprises a front movable jaw, a front toggle plate and an eccentric drive shaft; the rear crank-rocker mechanism comprises a rear movable jaw, a rear toggle plate and an eccentric drive shaft; the front movable jaw and the rear movable jaw are jointly pivoted with the eccentric drive shaft; one end of the front toggle plate is pivoted below the rear side of the front movable jaw, the other end of the front toggle plate is pivoted below the front side of the rear movable jaw, one end of the rear toggle plate is pivoted below the rear side of the rear movable jaw, and the other end of the rear toggle plate is pivoted with the frame; and the movable jaw plate is fixedly connected with the front movable jaw and is opposite to the fixed jaw plate to form a crushing cavity together with the fixed jaw plate. The jaw crusher has the obvious effect that horizontal movement stroke of the lower parts of the movable jaws with the main function of discharging materials is improved to a stroke with a main function of crushing so that one crusher has two-stage crushing efficacy.

Owner:ZHEJIANG SHENGDA MACHINERY

Jaw breaker with tooth profile self modification breaking pair

Owner:ZHEJIANG SHENGDA MACHINERY

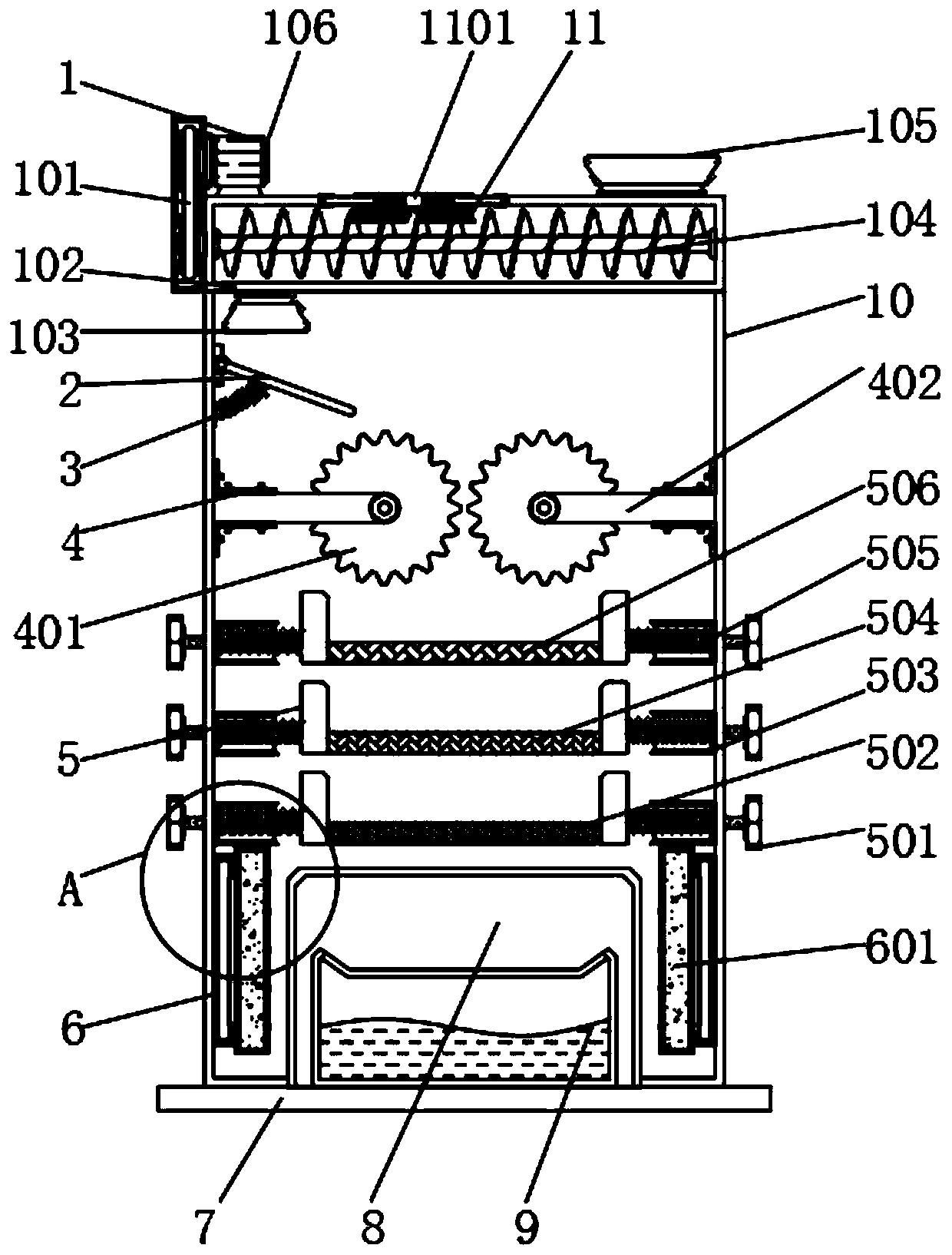

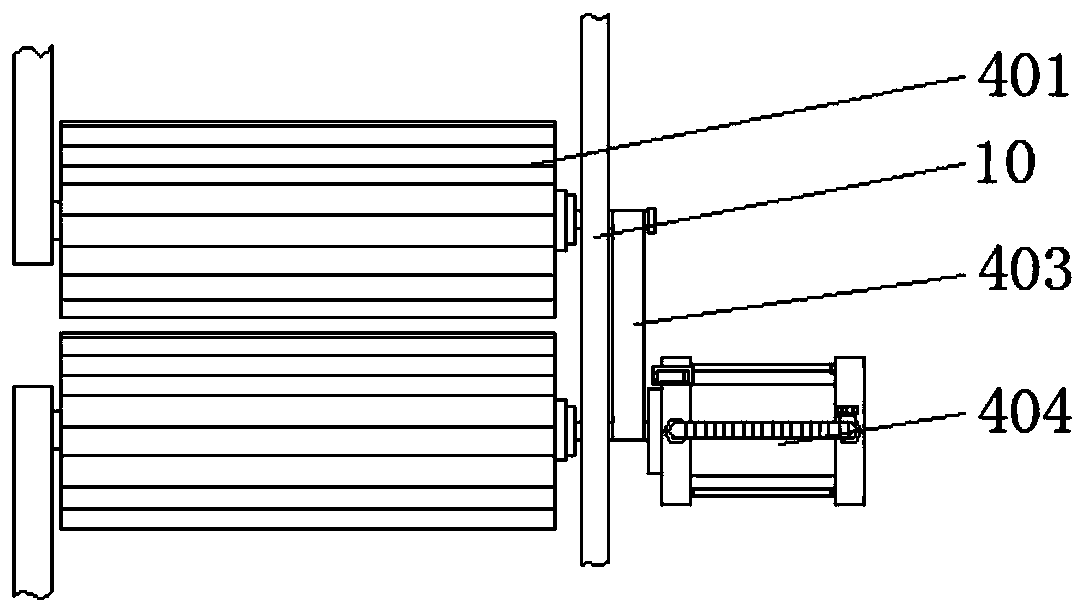

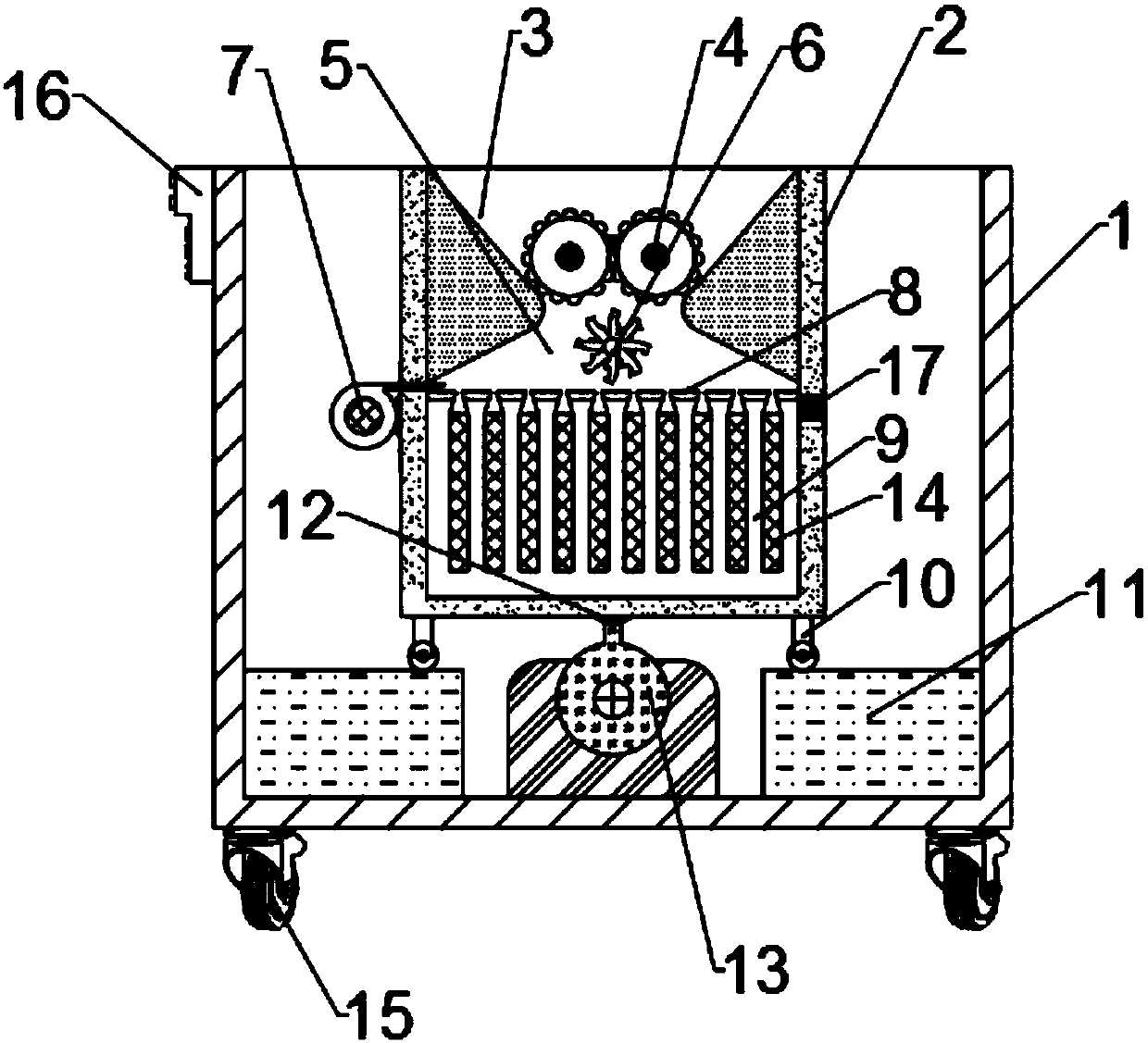

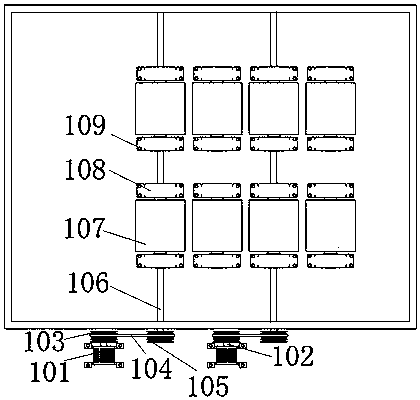

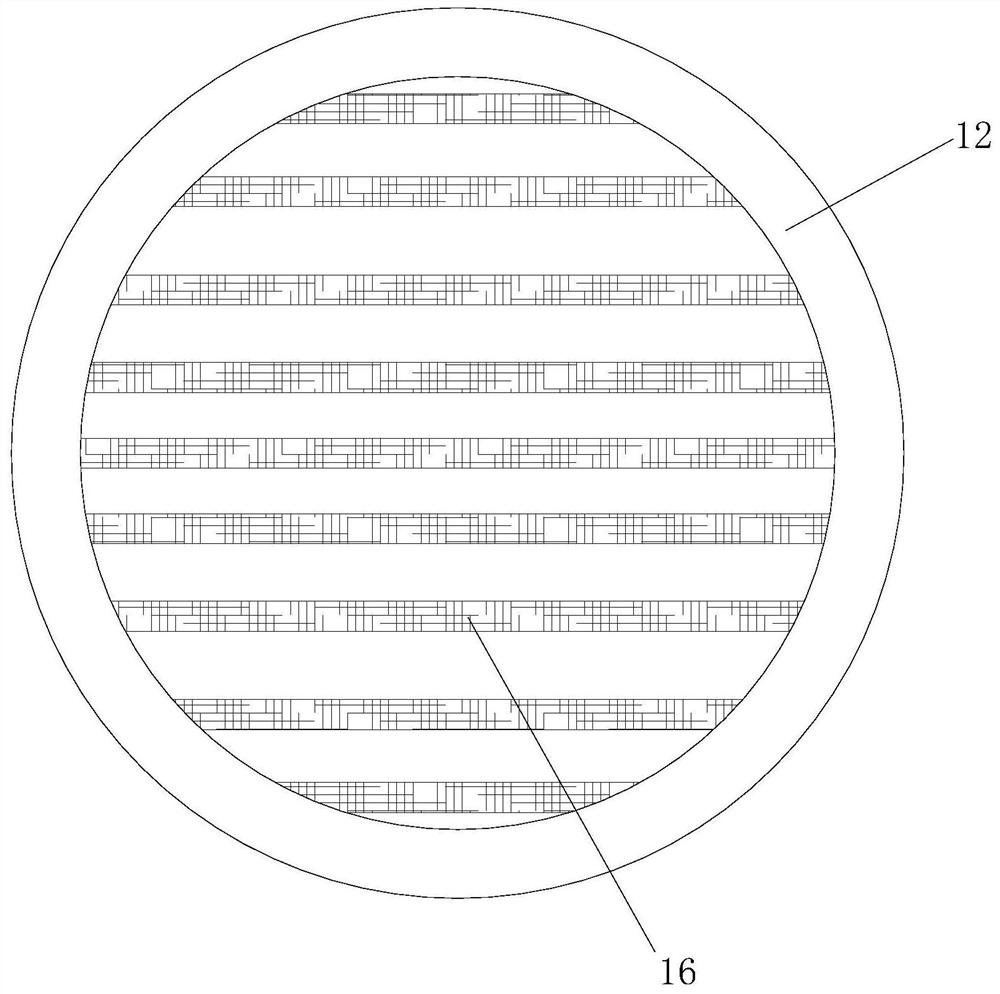

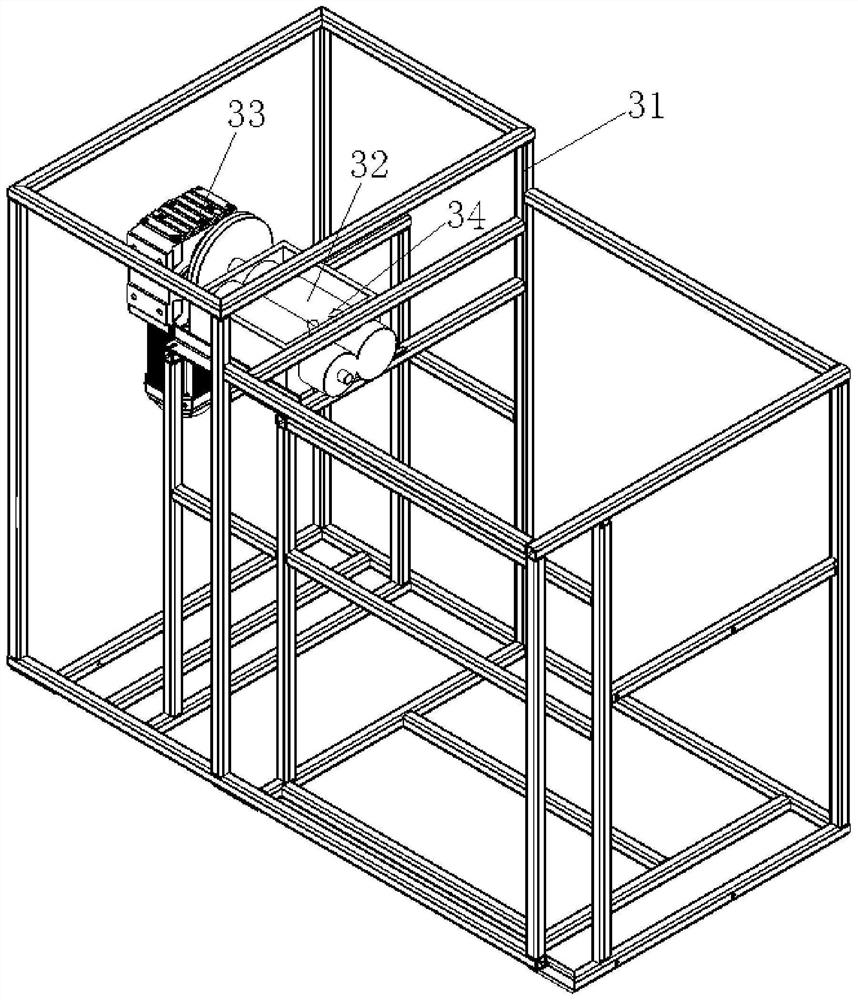

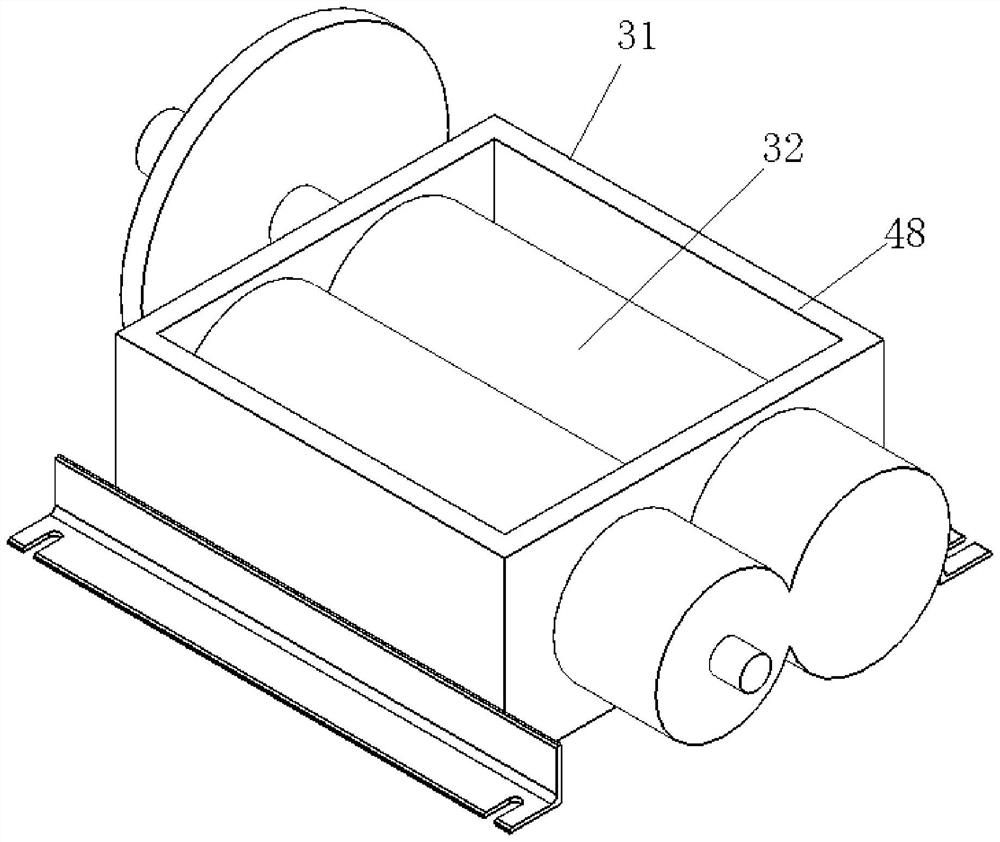

Crushing system for harmless swill separation and crushing method thereof

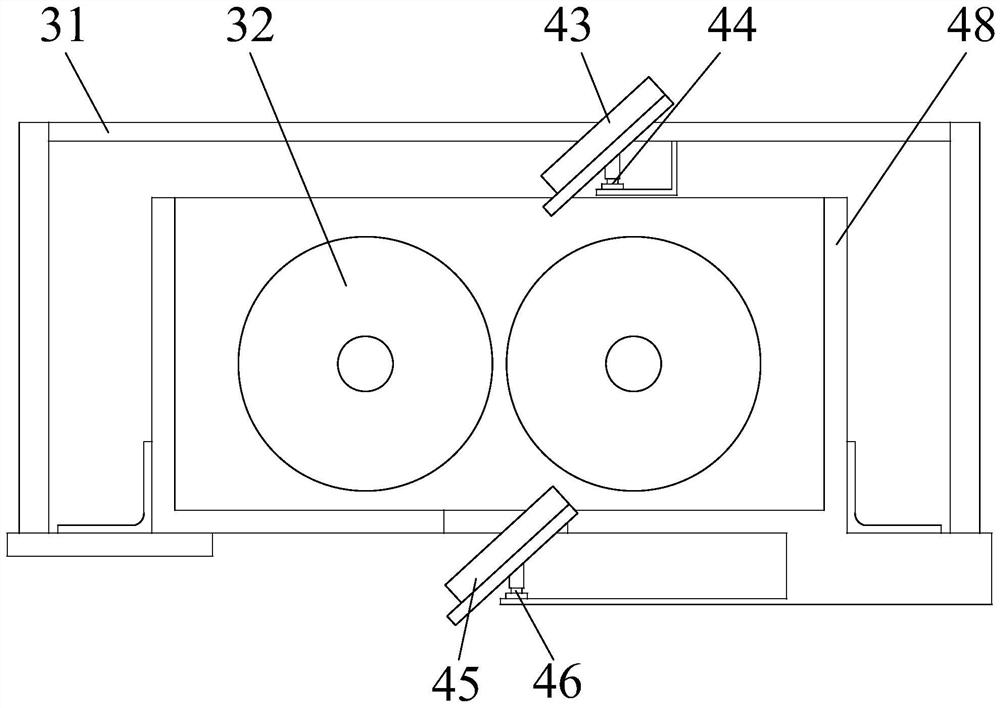

ActiveCN111036336AGuaranteed cleanlinessImprove crushing efficiencySievingScreeningElectric machineryProcess engineering

The invention discloses a crushing system for harmless swill separation and a crushing method thereof. The system comprises a frame body, at least two crushing rollers, a crushing motor, a flushing mechanism, a statistical mechanism and a crushing controller. Wet garbage enters from the same sides of the two crushing rollers, and leaves from the same sides after being rolled. The flushing mechanism comprises a plurality of spraying heads, and the spraying heads are used for spraying cleaning water to the roller surfaces of the crushing rollers. The statistical mechanism comprises a first detection assembly, a second detection assembly and a calculation module. The first detection assembly is used for detecting the first accumulation amount of the wet garbage entering a preset rolling spacewithin a preset time period. The second detection assembly is used for detecting the second accumulation amount of the wet garbage leaving the preset rolling space within the preset time period. Thecalculation module is used for calculating the accumulation difference between the first accumulation amount and the second accumulation amount. According to the crushing system for harmless swill separation and the crushing method thereof, the treatment efficiency and the crushing speed of the wet garbage are improved, the utilization rate of cleaning resources and energy can be improved, meanwhile, the crushing motor can be protected, and the service life of the crushing motor is prolonged.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

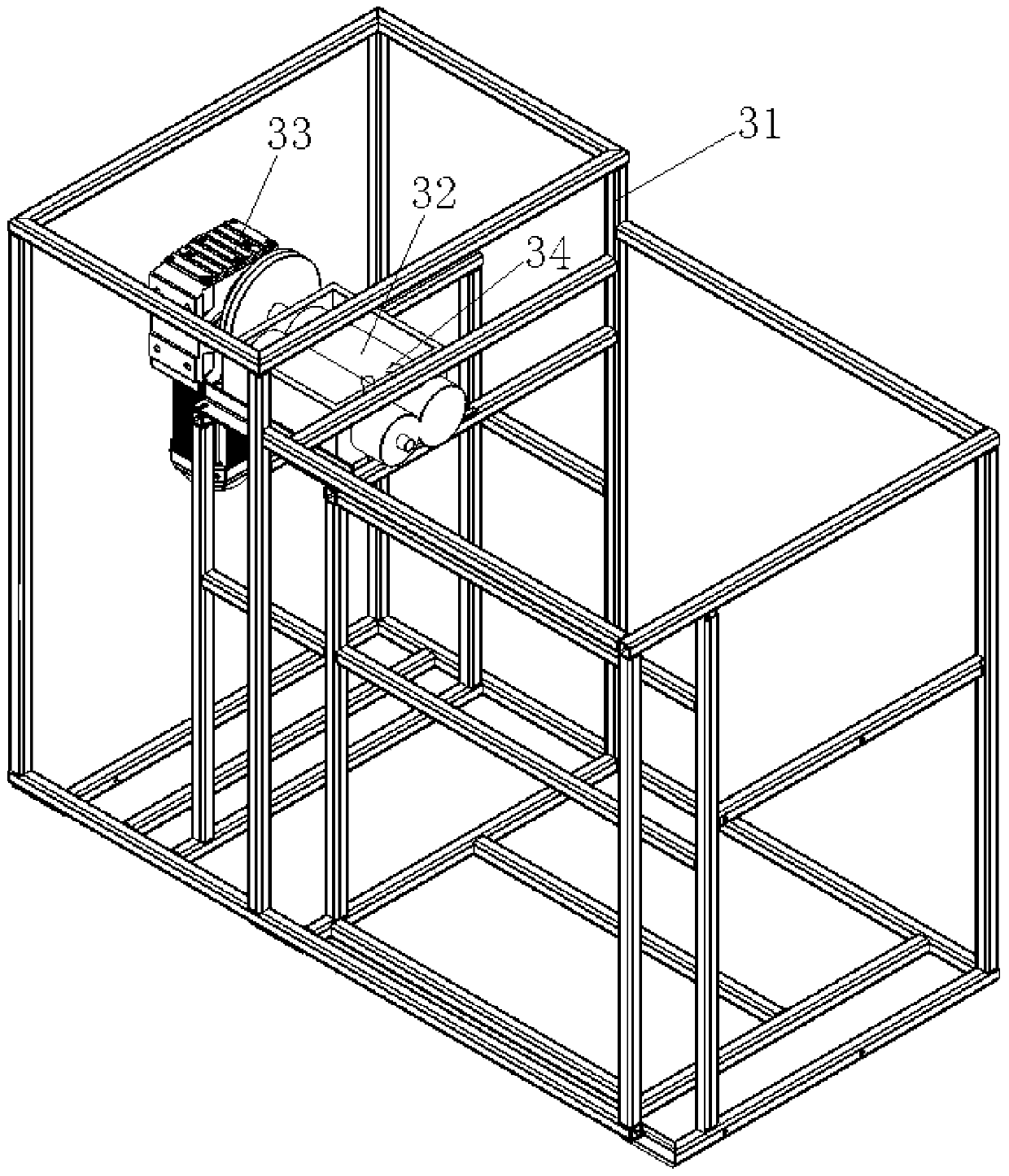

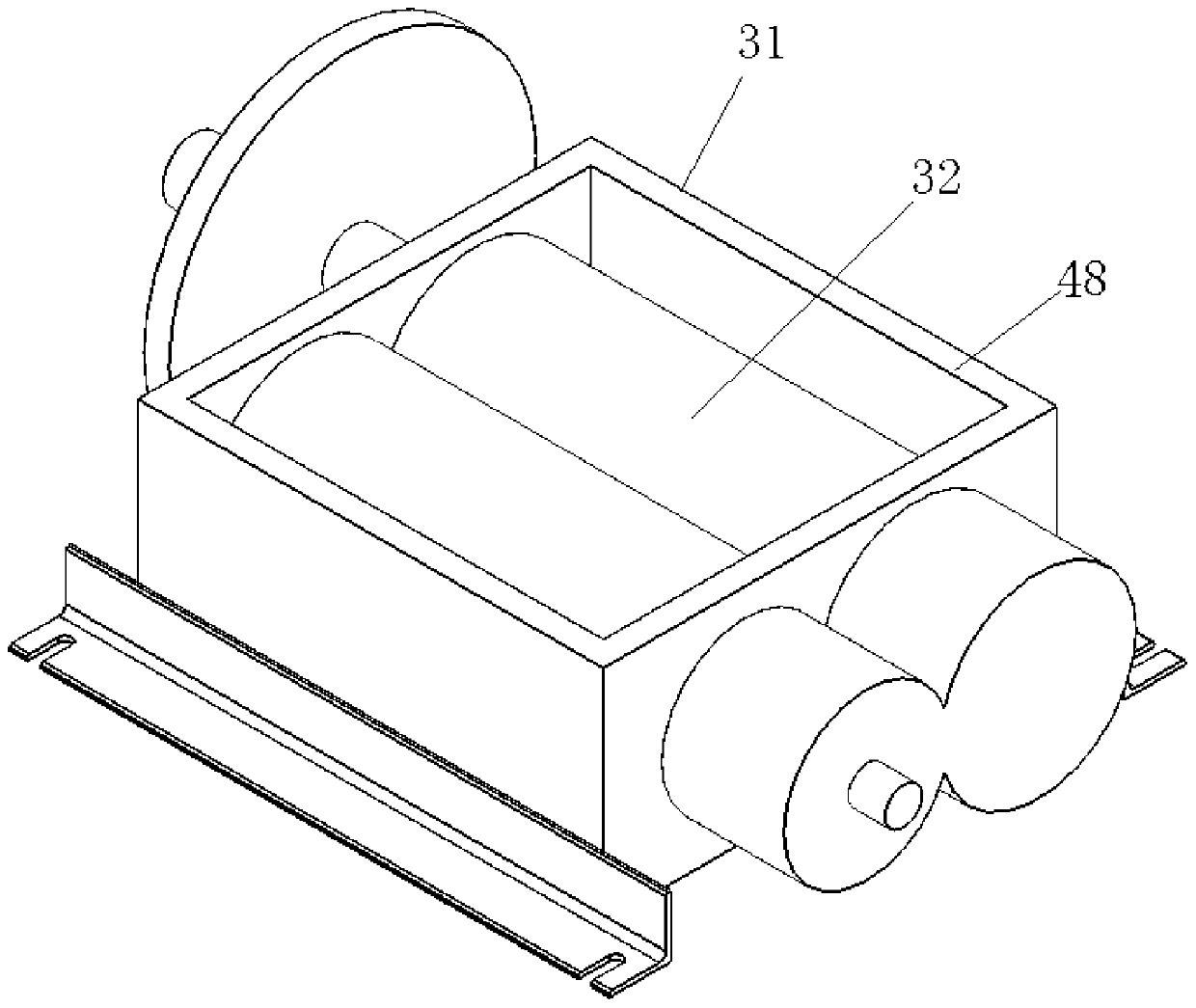

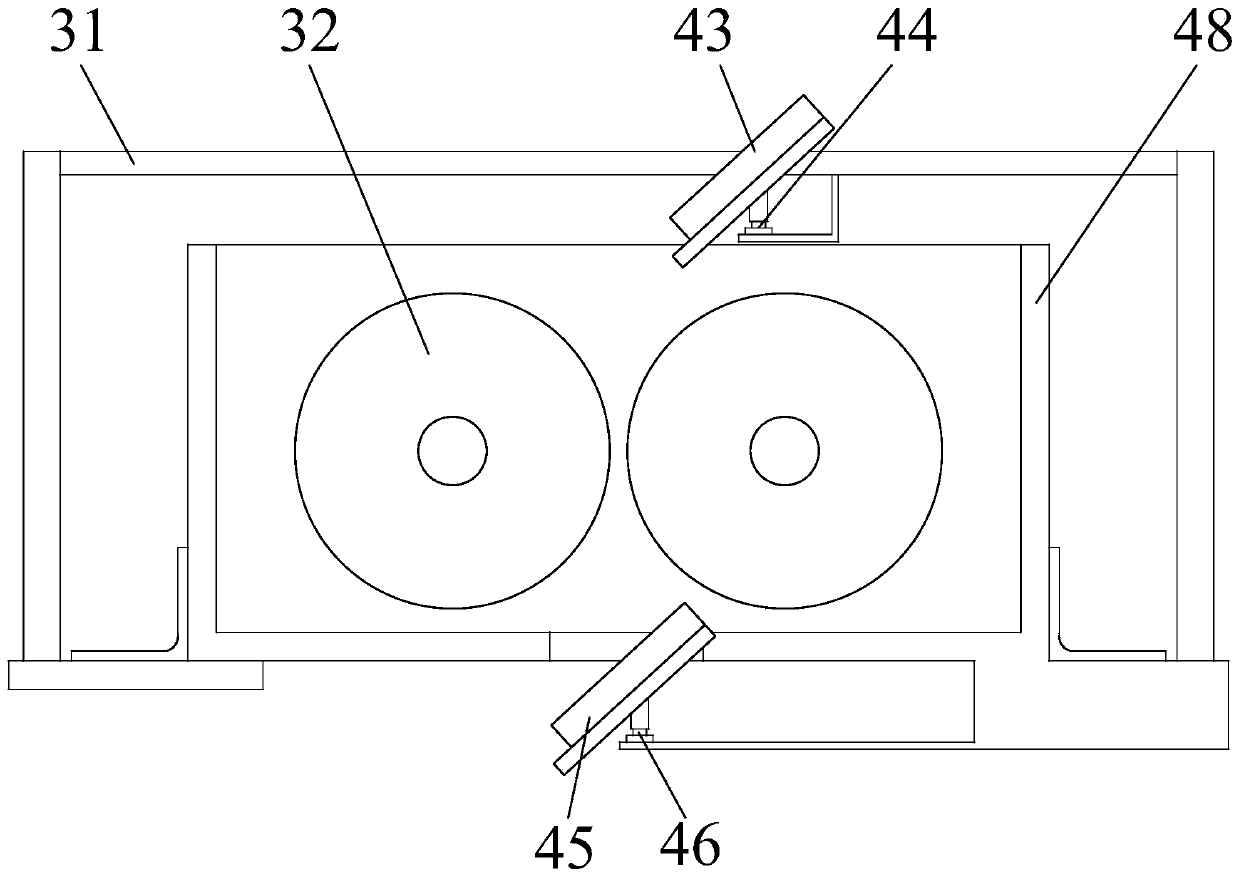

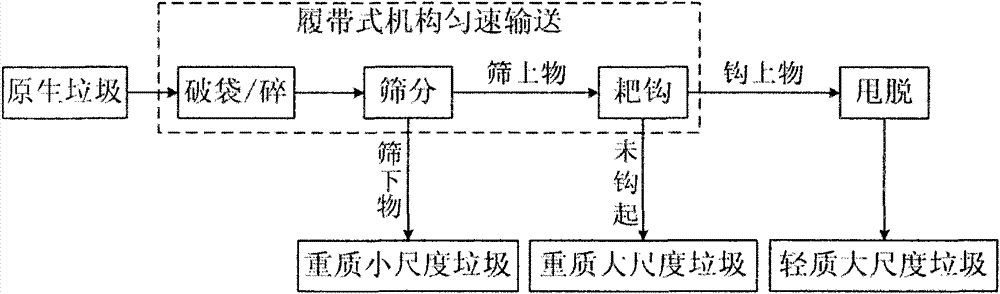

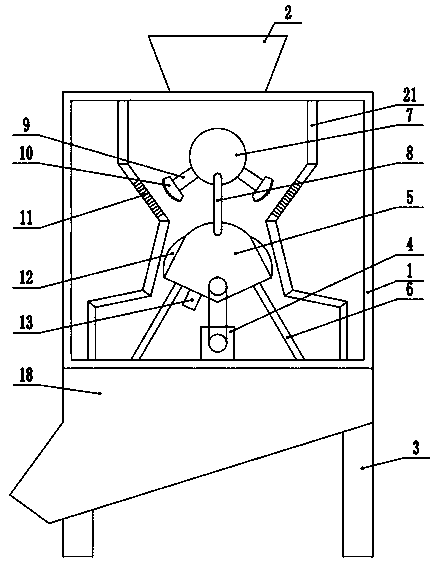

Automatic separating device and method for domestic garbage

ActiveCN101862748BImprove processing efficiencyImprove sorting effectSolid waste disposalSolid separationMotor driveEnvironmental engineering

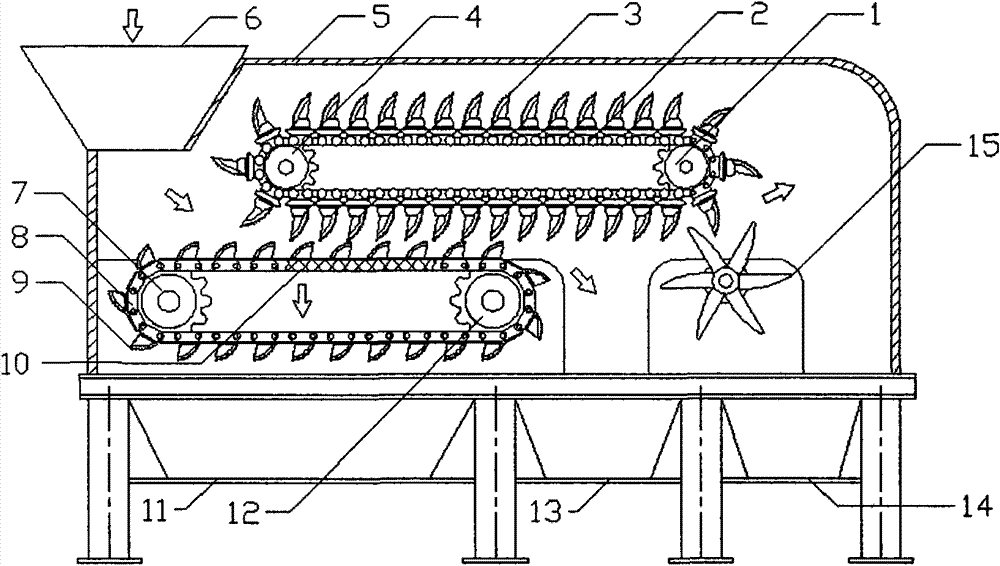

The invention discloses an automatic separating device and an automatic separating method for domestic garbage, and belongs to the technical field of garbage separation. The separating device has a differential crawler reciprocating structure, and comprises an upper crawler system consisting of an upper chain wheel, an upper chain wheel, an upper chain group and an upper harrow mechanism, a lowercrawler system consisting of a lower chain wheel, a lower chain group, a lower chain wheel and a lower harrow mechanism, a discharging system consisting of a strainer, a shaking-off mechanism, a first-level discharge hole, a second-level discharge hole and a third-level discharge hole, a feeding hole, a frame and a motor driving system. In the method, the continuous conveying of the materials is realized through the crawler harrow mechanism, the bag-breaking and crushing treatment on the materials is realized through the relative tearing force generated by the upper and lower harrow mechanisms, and the separation of the materials is realized through the sieving and shaking-off mechanisms, so three functions of conveying, bag-breaking / crushing and separating the materials are integrated and the domestic garbage is separated into three classes, namely heavy small-sized garbage, heavy large-sized garbage and light large-sized garbage. The device and the method have the advantages of highseparation efficiency, large treatment capacity, low energy consumption and environmental friendliness.

Owner:SHOUGANG ENVIRONMENTAL IND

Jaw crusher with double shafts and double crank and rocker mechanisms

The invention discloses a jaw crusher with double shafts and double crank and rocker mechanisms. The jaw crusher comprises a rack, a fixed jaw plate, a movable jaw plate, a front crank and rocker mechanism, a rear crank and rocker mechanism and transmission wheels, wherein the front crank and rocker mechanism comprises a front movable jaw, a front knee plate and a front eccentric driving shaft; the rear crank and rocker mechanism comprises a rear movable jaw, a rear knee plate and a rear eccentric driving shaft; the front and rear jaw plates are respectively pivoted on the front and rear eccentric driving shafts; the front and rear eccentric driving shafts are respectively connected with the transmission wheels; one end of the front knee plate is pivoted below the rear side of the front movable jaw, and the other end of the front knee plate is pivoted below the front side of the rear movable jaw; one end of the rear knee plate is pivoted below the rear side of the rear movable jaw, and the other end of the front knee plate is pivoted on the rack; and the movable jaw plate is fixedly connected to the front movable jaw and faces the fixed jaw plate to form a crushing cavity. The jaw crusher has the advantages that: the function of the lower horizontal motion travel of the movable jaw is improved from material discharge to crushing, so crusher equipment has a secondary-crushing effect.

Owner:义乌市凌丰知识产权服务有限公司

Hydraulic jaw crusher unit

The invention discloses a hydraulic jaw crusher unit. The hydraulic jaw crusher unit comprises a feeding device, a screening device, a jaw crusher, a conveying device, a hydraulic station and an integrated frame, wherein the feeding device, the screening device, the jaw crusher, the conveying device and the hydraulic station are arranged in the integrated frame; the jaw crusher adopts a crusher jaw plate structure adopting deep cavity as a double-curved cavity form; the hydraulic station is used for supplying working oil pressure to the feeding device, the screening device, the jaw crusher andthe conveying device; materials enter the screening device through the feeding device and enter the jaw crusher for being crushed after passing through the screening device; the crushed materials enter the conveying device. In-factory pre-installing debugging can be realized by all parts of equipment of the whole unit, integrated transportation is realized, assembling is not required during a production site, and civil construction is not required.

Owner:北京博岳恒科技发展有限公司 +1

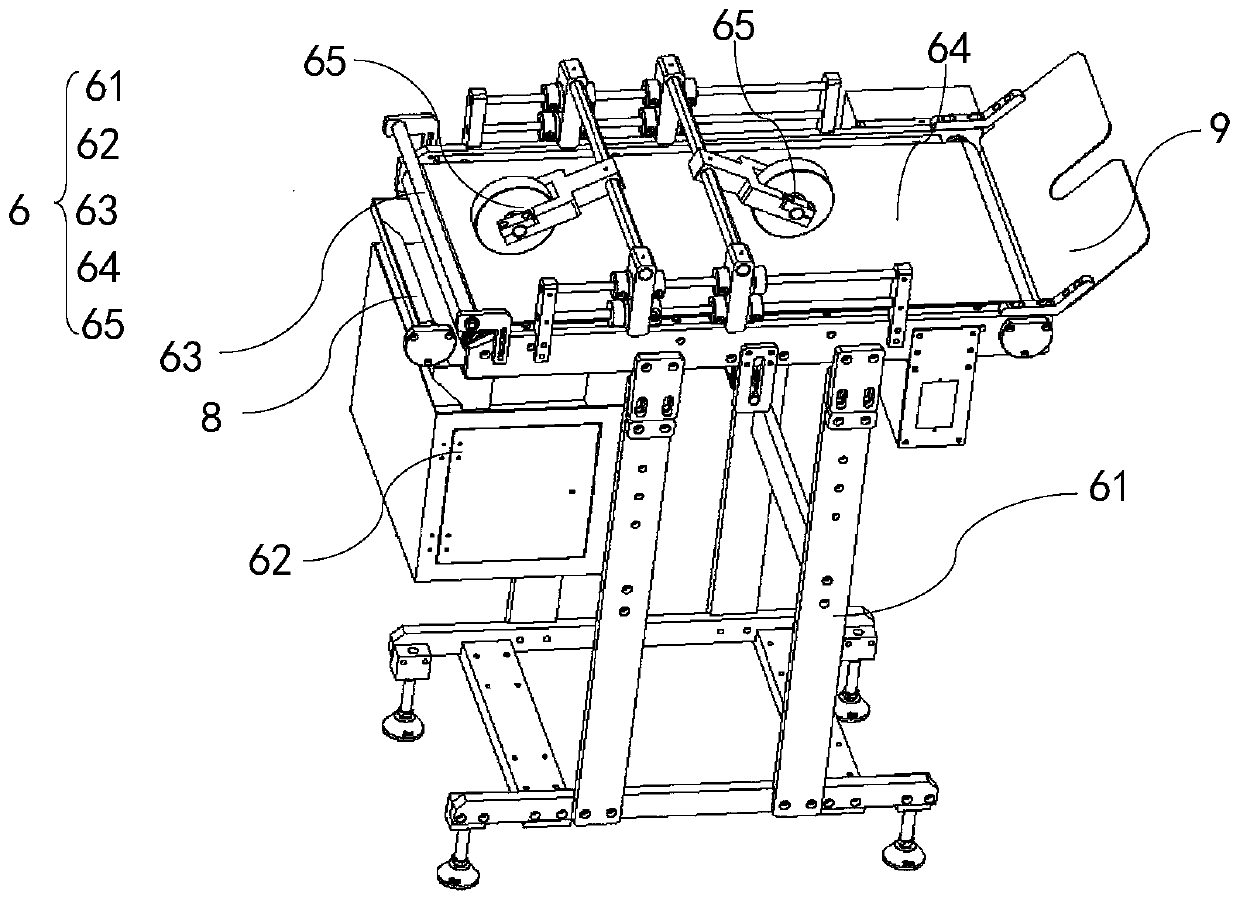

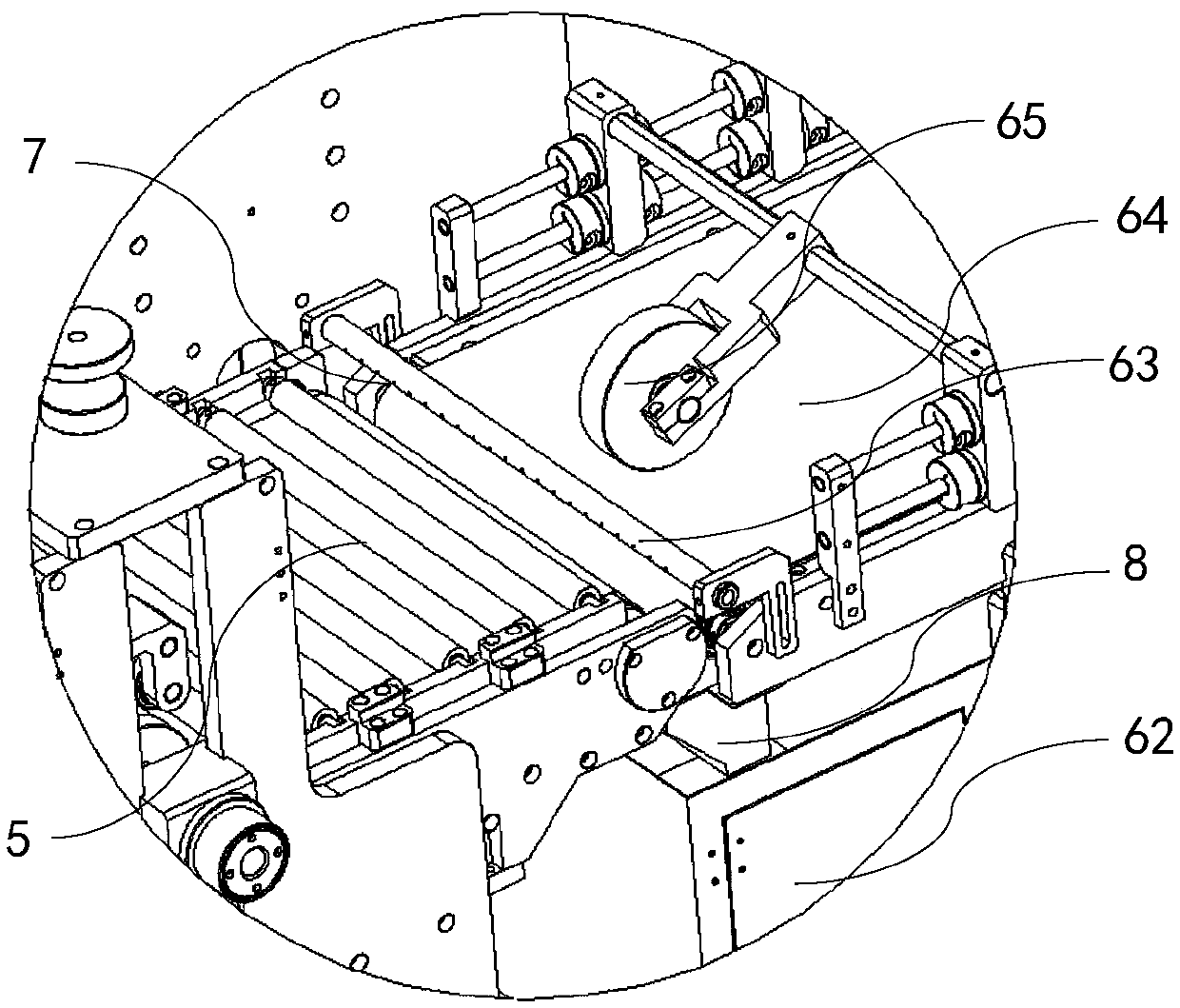

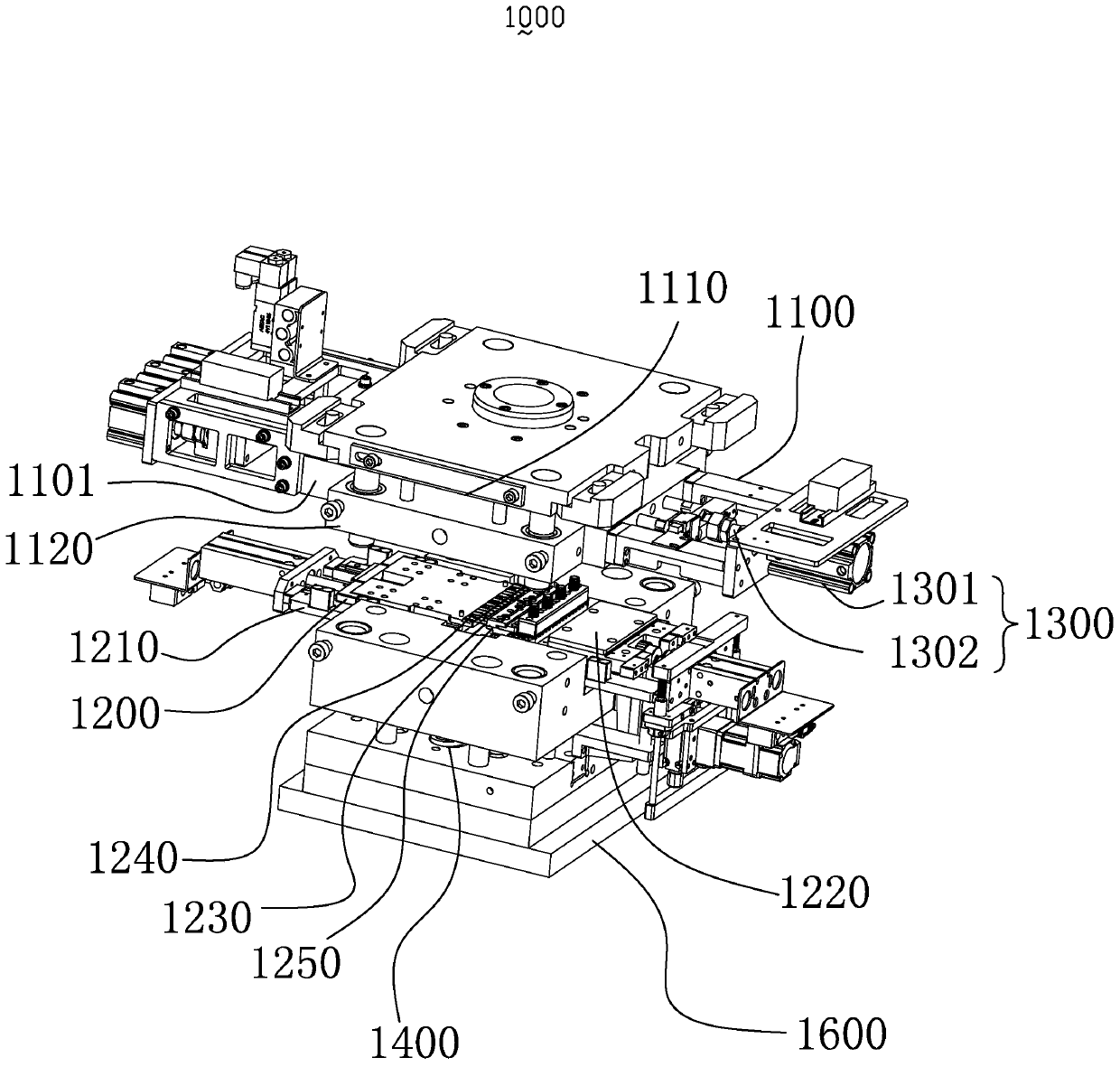

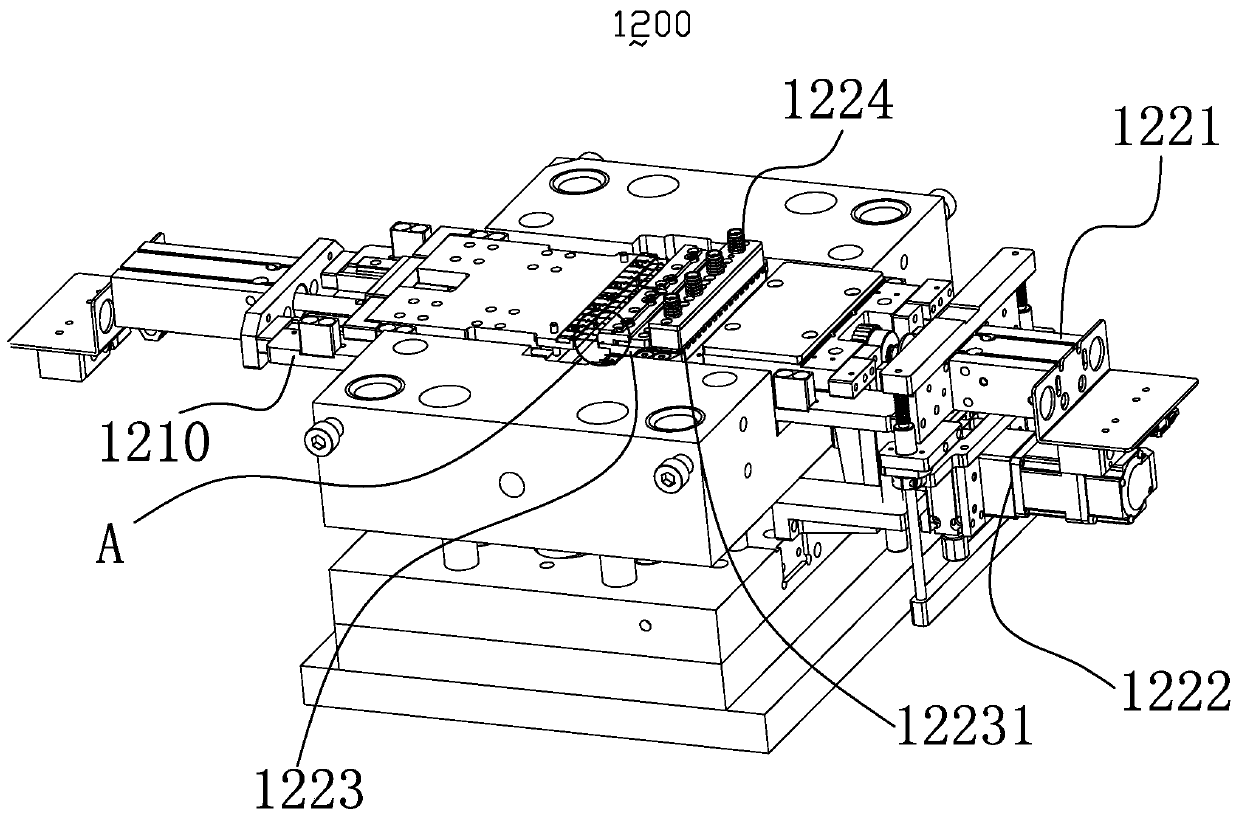

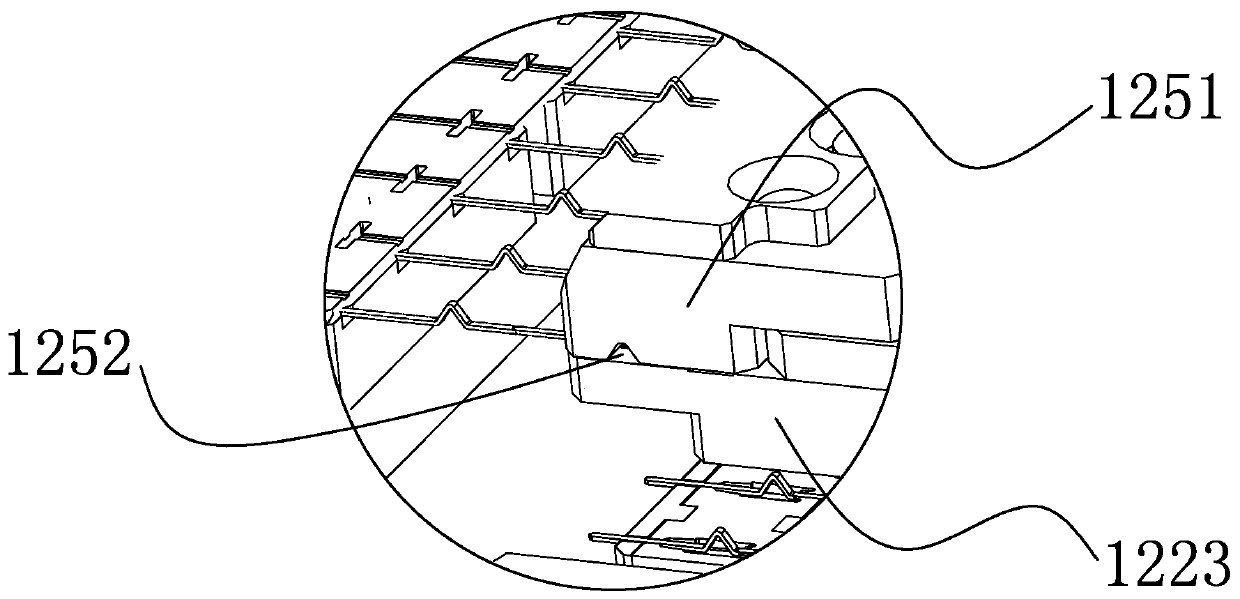

Fully servo automatic quality inspection machine

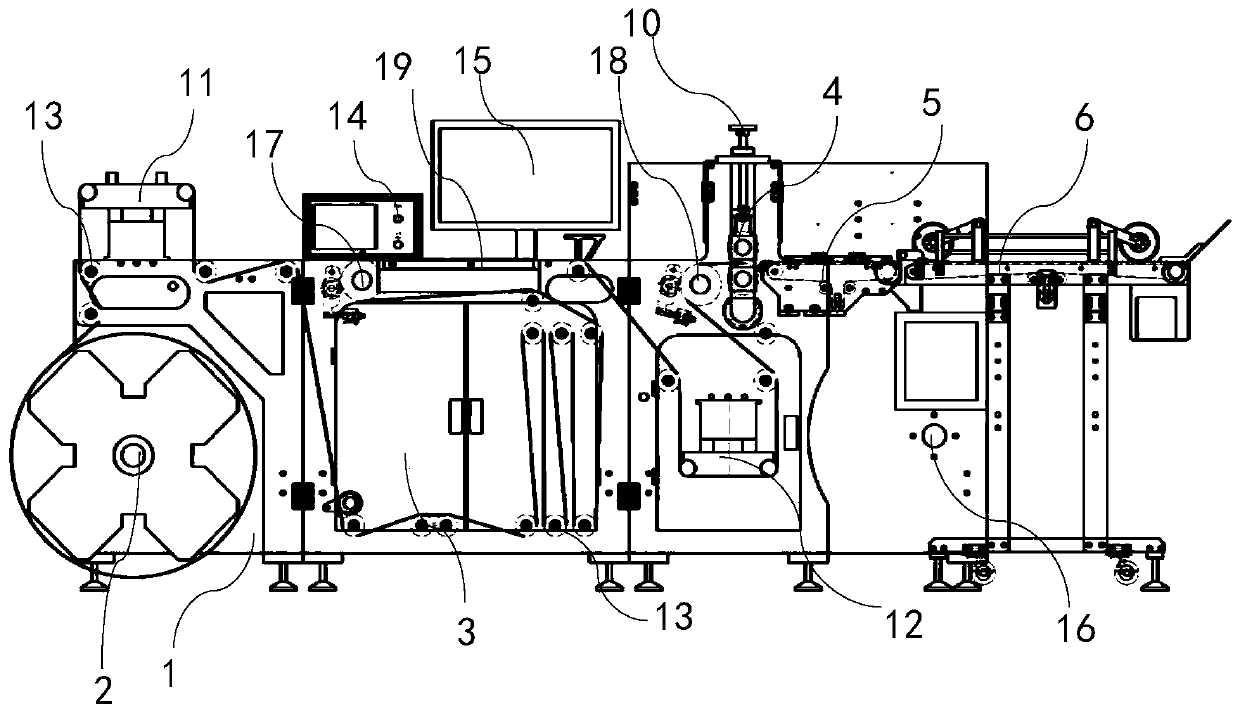

PendingCN110745595AIncrease profitHigh economic valueMetal working apparatusWebs handlingVisual inspectionProcess engineering

The invention relates to the technical field of printing equipment, and discloses a fully servo automatic quality inspection machine. The fully servo automatic quality inspection machine comprises a machine frame, wherein an unwinding mechanism, a visual inspection mechanism, a die-cutting mechanism, a paper receiving mechanism, a material receiving mechanism and a control mechanism are arranged on the machine frame. The unwinding mechanism, the visual inspection mechanism, the die cutting mechanism, the paper receiving mechanism and the material receiving mechanism are electrically connectedwith the control mechanism, and the material receiving mechanism is detachably mounted in the machine frame. When the material receiving mechanism and the machine frame are in a connected state, one end of a label to be cut is wound on the unwinding mechanism and passes through the visual inspection mechanism and the die-cutting mechanism in sequence, the die-cutting mechanismsplits the label to be cut and a plurality of label bodies are formed, the paper receiving mechanism transfers the label bodies to the material receiving mechanism, and the material receiving mechanism recycles the labelbodies. The problems of low utilization rate and low economic value due to the fact that a quality inspection machine in the prior art cannot meet the requirement of slitting the labels are solved.

Owner:GUANGZHOU PULISI TECH CO LTD

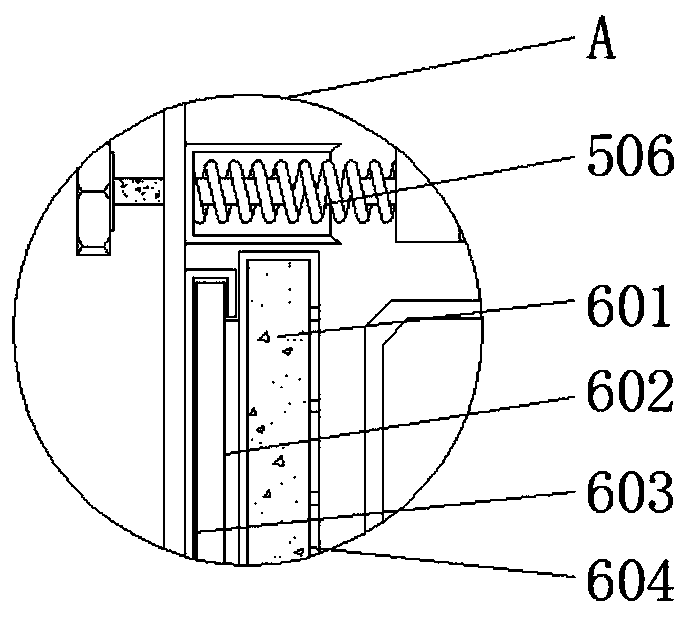

River sludge treatment device for ecological environmental protection

InactiveCN110746060AReasonable structureAchieve deodorization functionSievingSludge treatmentEcological environmentSludge

The invention discloses a river sludge treatment device for ecological environment protection. The river sludge treatment device comprises a crushing component, a filtering component, a base and a cleaning component, wherein a shell is arranged at the top end of the base; a feeding component is arranged at the top end of the shell; the cleaning component is arranged at the top end inside the feeding component; a buffer plate is mounted at the top end of one side inside the shell; a buffer spring is arranged on one side of the buffer plate; the crushing component is mounted at the top end inside the shell; the filter element is arranged below the crushing component; and deodorization components are arranged at bottom ends on both sides inside the shell. Due to adoption of the crushing component, a function of crushing impurities in sludge is achieved; when the device is used, a second belt wheel can be driven by rotation of a servo motor to drive crushing rollers on both sides inside the device to rotate oppositely, so that sludge impurities passing through the crushing rollers can be crushed, and the device can be effectively prevented from influence of the sludge impurities.

Owner:JIANGXI LYVJUREN MUNICIPAL GARDEN CO LTD

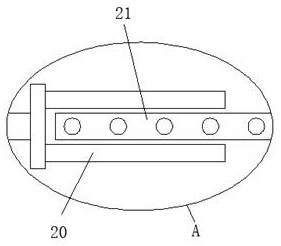

In-mold bending and punching-off device

PendingCN111391225AAchieve clampingPrevent back slipShaping toolsCoatingsPunchingStructural engineering

The invention provides an in-mold bending and punching-off device. The in-mold bending and punching-off device comprises a first assembly and a second assembly, wherein the first assembly is sequentially provided with a first cutter and a first forming mold, the second assembly comprises a fixing frame, a linear material feeding device, a second cutter and a second forming mold, the linear material feeding device is arranged on the fixing frame, the linear material feeding device plays a role in conveying linear machining raw materials, the linear material feeding device is further provided with a bending module, and the bending module is arranged on the linear material feeding device, so that the in-mold bending and punching-off device can bend the linear machining raw materials while achieving linear material feeding; and the second forming mold is arranged on the fixing frame and matched with the first forming mold, and the injection molding function can be achieved. According to the device, a linear material feeding module, the bending module and a punching-off module are all arranged in the molds, the functions of linear material feeding, bending and punching-off can be conveniently and rapidly achieved, and a structure is compact.

Owner:深圳市三多乐智能传动有限公司

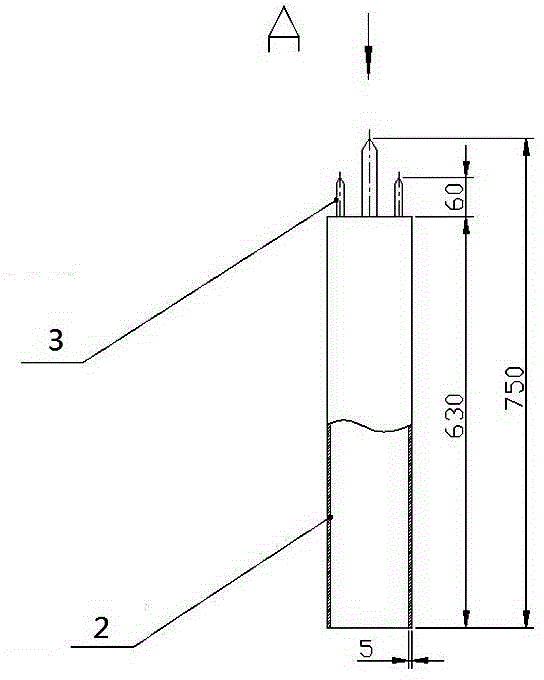

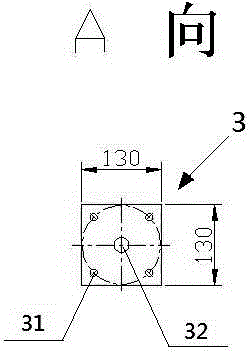

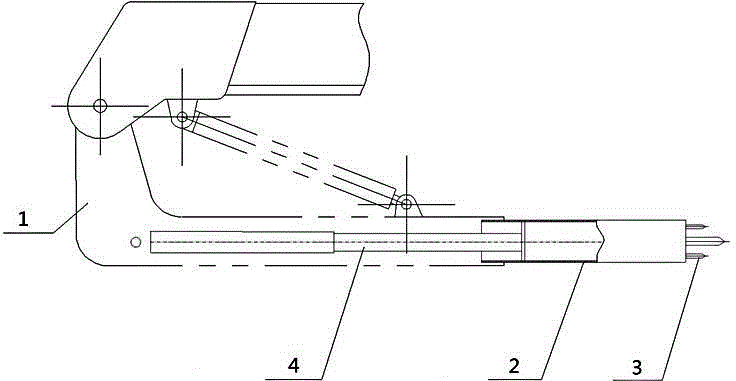

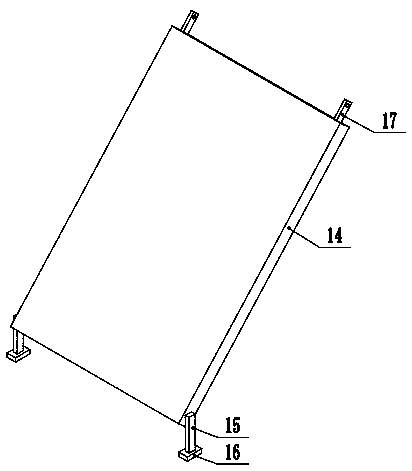

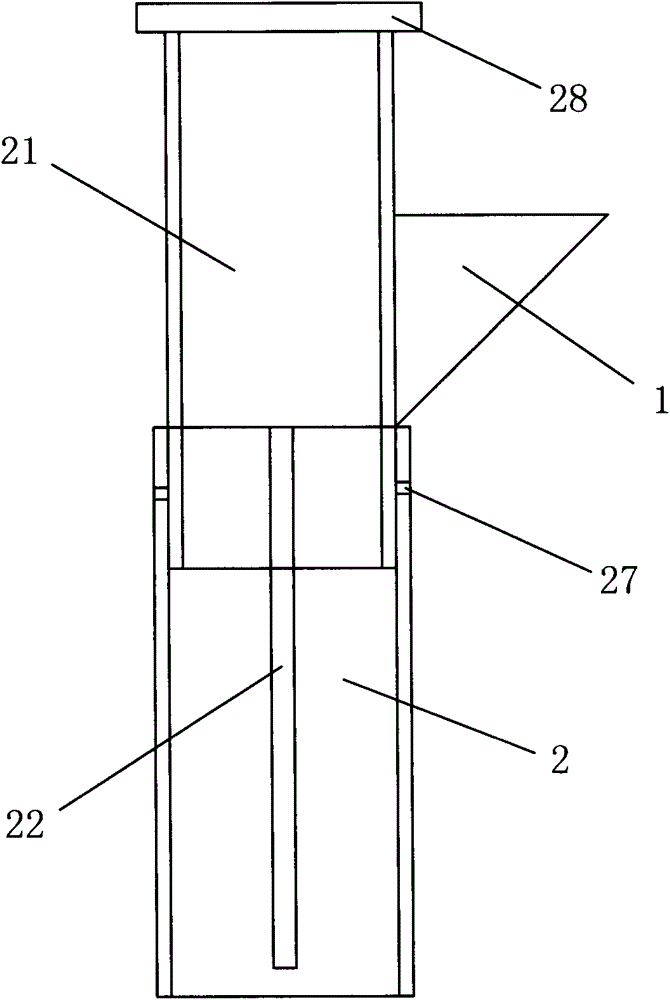

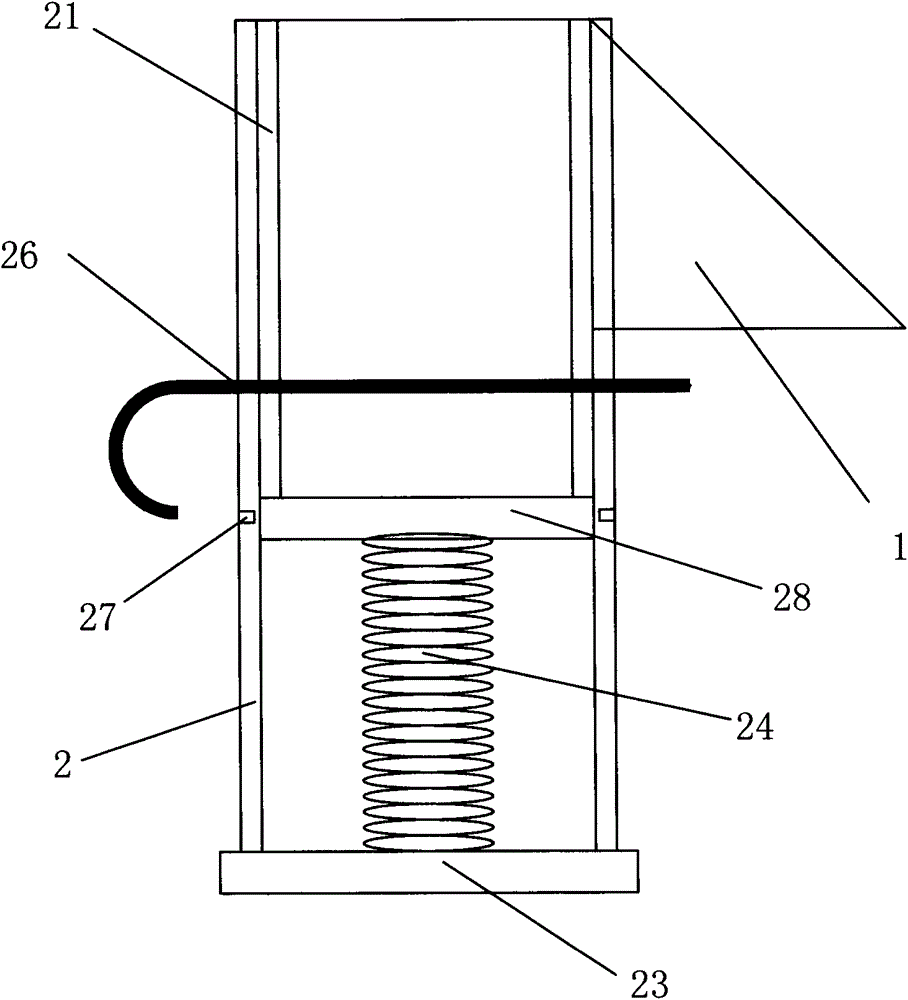

Retractable glass curtain wall breaker

The invention discloses a retractable glass curtain wall breaker which comprises a suspension arm. A breaker body is connected to the front end of the suspension arm and is composed of a hollow upright and a plurality of sharp breaking needles, the sharp breaking needles are fixedly connected on one end face of the upright, a hydraulic rod on a hydraulic cylinder is fixedly connected at the position of the other end face of the upright through a hollow cavity in the upright, the hydraulic cylinder is fixed in the suspension arm, and the upright and the inner wall of the suspension arm is in clearance sliding fit therebetween. The glass curtain wall breaker can be mounted at the top end of the suspension arm of various cranes and is driven to be ejected or retracted through the hydraulic cylinder, the sharp breaking needles are adopted, and stress is more concentrated, so that breaking functions is realized since glass can be easily pierced by the breaking needles during breaking, breaking efficiency is high, and time is saved.

Owner:JIANGSU ZHENXIANG VEHICLE EQUIP

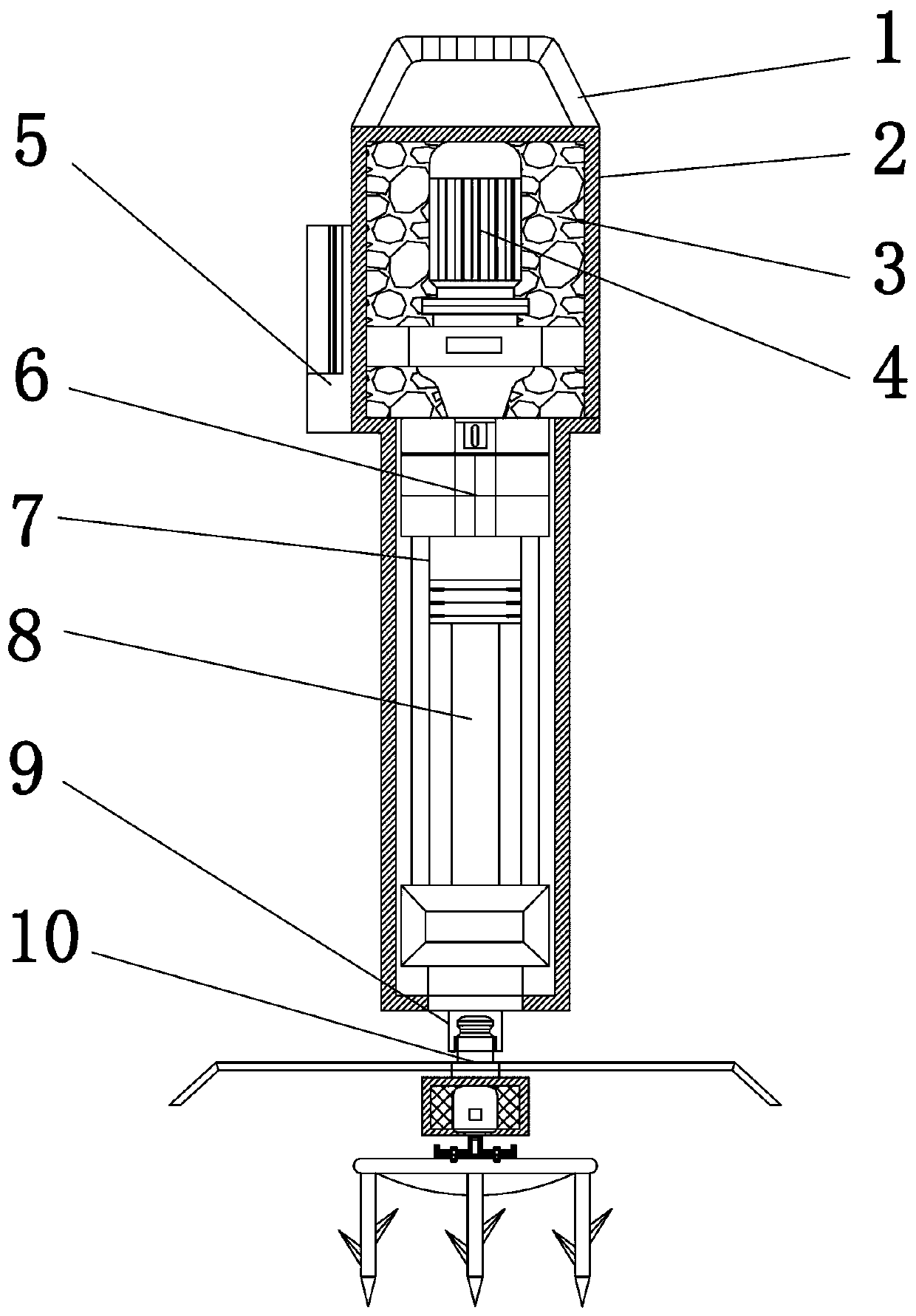

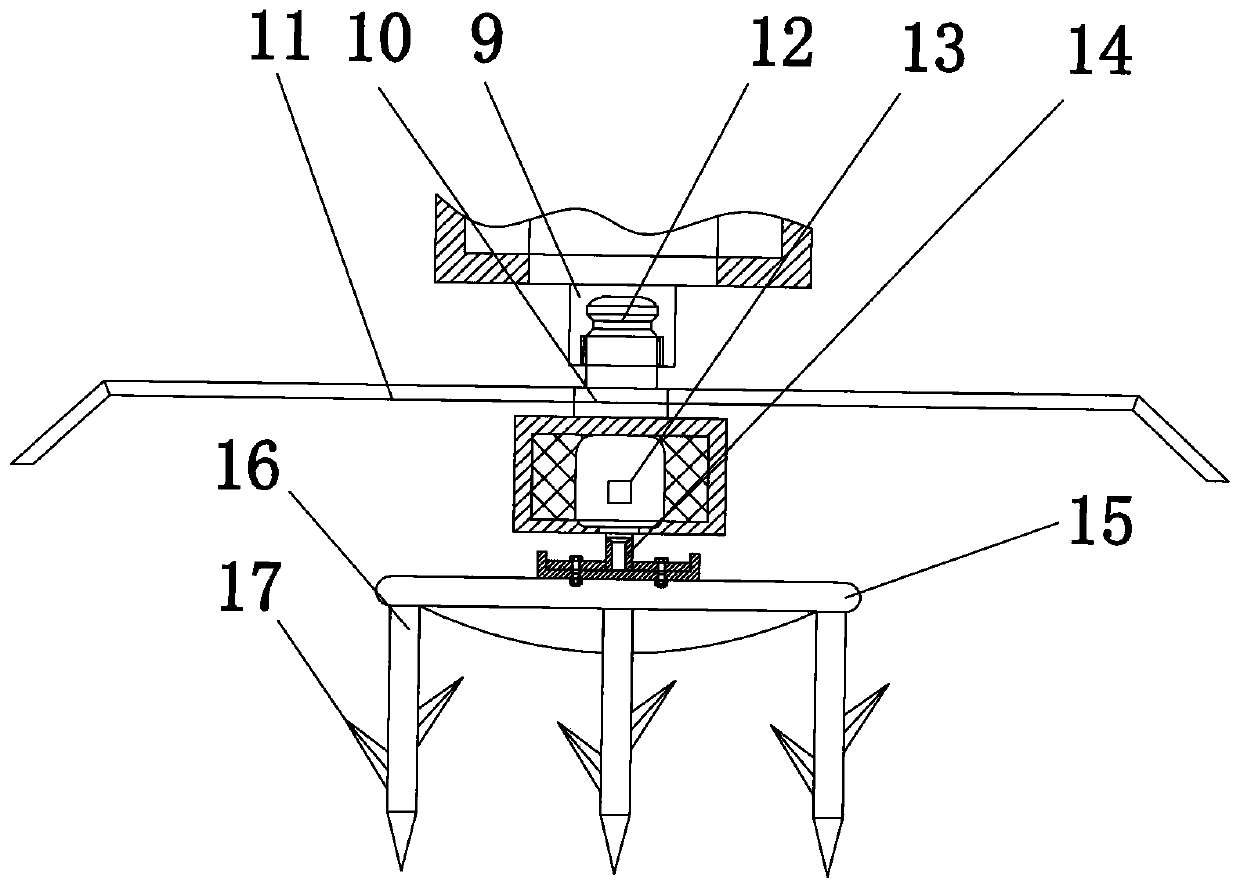

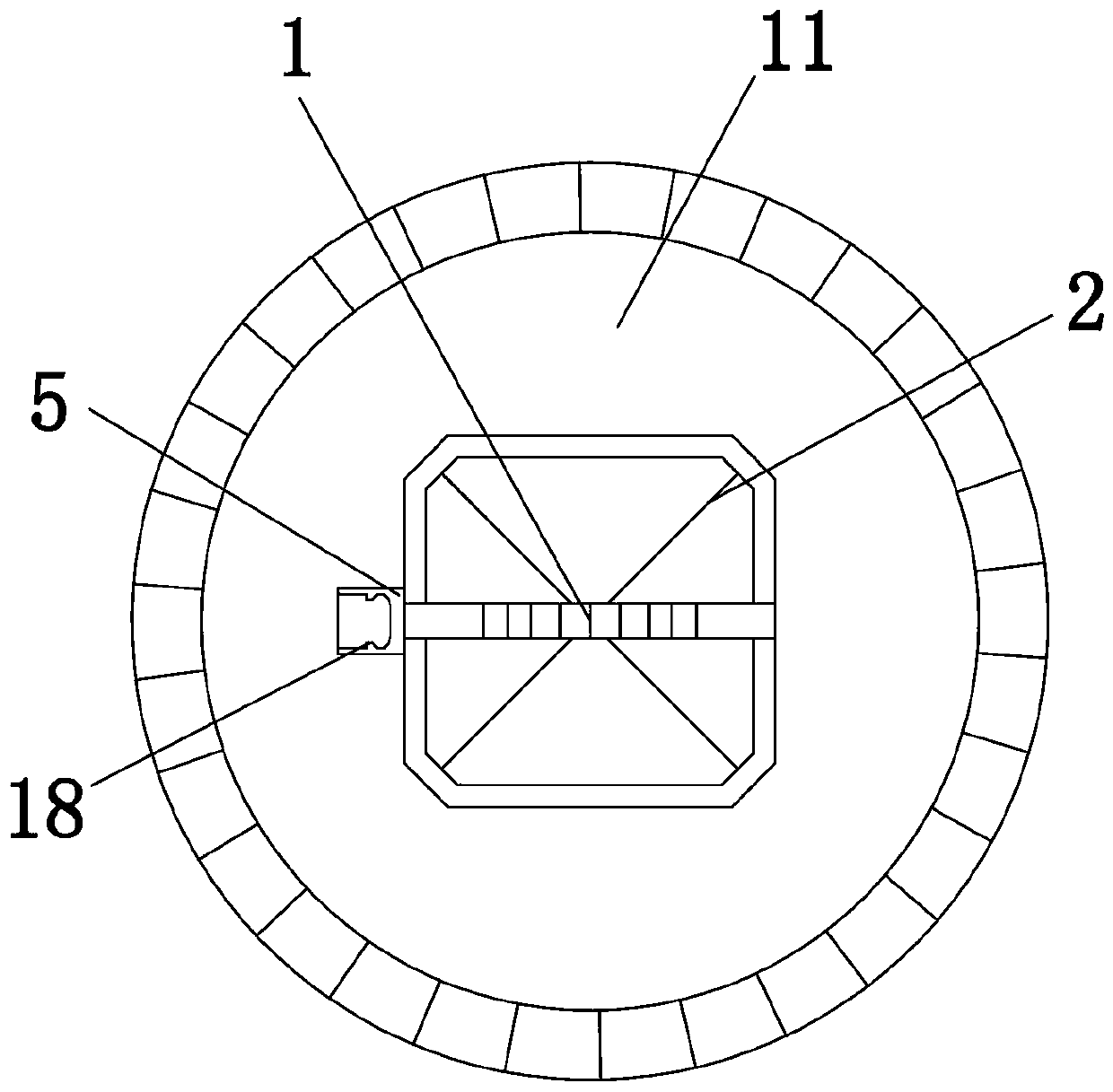

Portable agricultural soil loosening device

PendingCN110149812ADeepen the loosening depthIncrease motivationHand equipmentsMicro motorEngineering

The invention discloses a portable agricultural soil loosening device. The portable agricultural soil loosening device comprises a handle, an air pump and a micro motor. A shell is fixed to the lowerend of the handle, a sponge filling layer is arranged in the shell, the air pump is mounted in the middle of the sponge filling layer, the micro motor is fixed to the lower end of a fender, and a rotating shaft is mounted at the lower end of the micro motor. The portable agricultural soil loosening device has the advantages that the micro motor can drive a rotating platform and a drill pipe to rotate through the rotating shaft to break soil blocks; when the drill pipe enters the soil and is pulled up, conical barbs fixed to the drill pipe can move the soil surrounding the drill pipe, so that the loosening area of the drill pipe at a time is increased, and the soil loosening efficiency is improved; a slider on a soil loosening pawl is matched with a sliding groove in a fixing block in size,so that the slider can be guided into the sliding groove to fix the soil loosening pawl to the fixing block, and the whole soil loosening device is further downsized to facilitate carrying and storing.

Owner:ANHUI UNIV OF SCI & TECH

Plastic crushing machine

InactiveCN107553786ASimple structureReduce manufacturing costPlastic recyclingGrain treatmentsCamEngineering

The invention provides a plastic crushing machine. The plastic crushing machine comprises a machine body; a crusher is arranged in the machine body, and is provided with a conical opening; a rolling wheel is arranged at the bottom of the opening; a crushing bin is arranged below the opening; a crushing wheel is arranged in the crushing bin; a fan is arranged on one side of the crushing bin; a filter screen is arranged at the bottom of the crushing bin; the bottom is connected with a detachable unloading bin; the unloading bin is fixed on a support platform, arranged at the bottom of the machine body, through support legs capable of extending; and a cam mechanism is arranged at the bottom of the unloading bin, and is driven by a motor arranged at the bottom of the machine body. The plasticcrushing machine is simple in structure, realizes the crushing function of defective beverage bottles, also can be used for small-batch crushing of other plastic, and reduces the production cost.

Owner:宜昌山尔饮料有限公司

Crushing device for building stone

InactiveCN107790217ARealize the breaking functionImprove crushing effectGrain treatmentsDrive shaftAgricultural engineering

The invention relates to a building stone crushing device, which includes a motor, the output shaft of the motor is connected with a pulley A, the pulley A is connected with a pulley B through a belt, and a transmission shaft is installed on the pulley B, so A crushing wheel is installed on the transmission shaft, and the transmission shaft is also located on the bearing seat. The bearing seat is connected and fixed in the silo through anchor bolts. The crushing wheels are used in pairs, and only one crushing wheel is installed on the transmission shaft. , the bearing seat is located on both sides of the crushing wheel, the motor is connected and fixed on the ground through anchor bolts, there are two motors, and two crushing wheels are installed on the transmission shaft. The present invention helps realize the function of crushing building stones by setting crushing wheels, has high working efficiency, good stone crushing effect, simple structure, convenient operation, and is economical and practical.

Owner:青岛明耀石业有限公司

Jaw breaker with tooth profile self modification breaking pair

Owner:ZHEJIANG SHENGDA MACHINERY

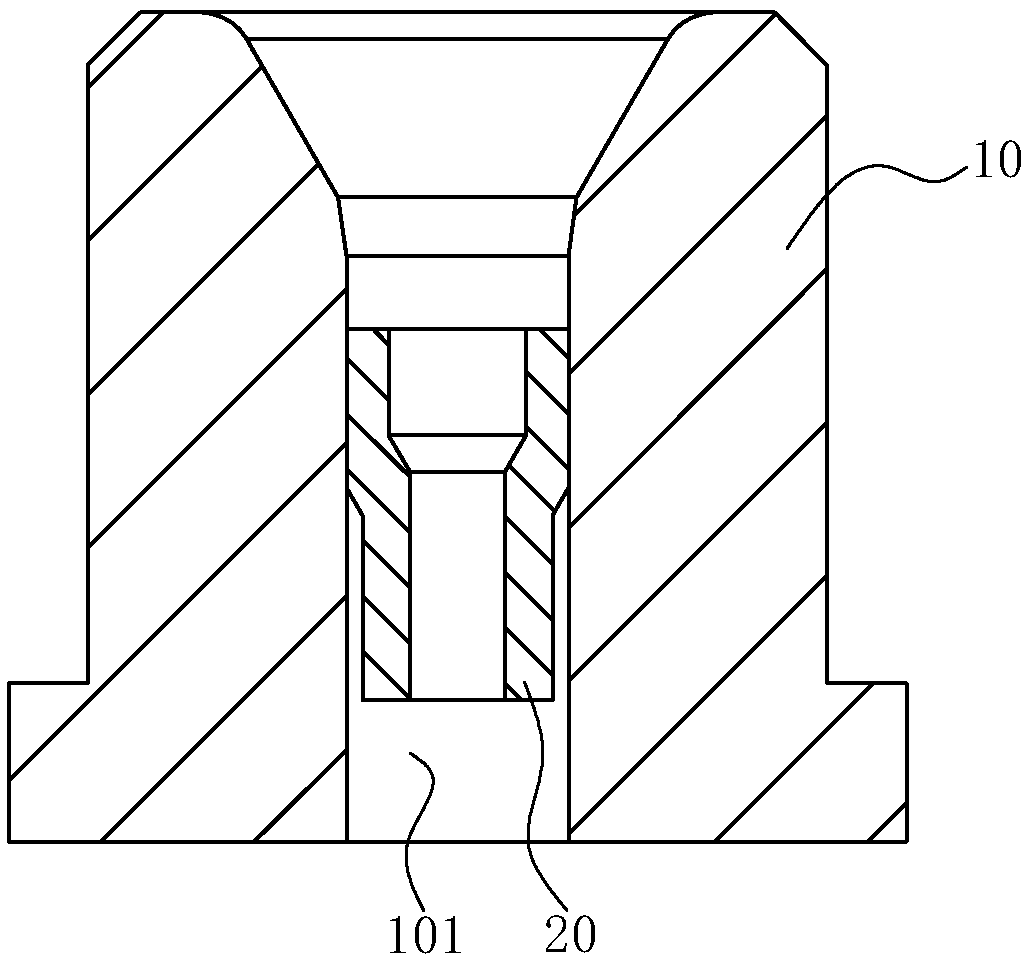

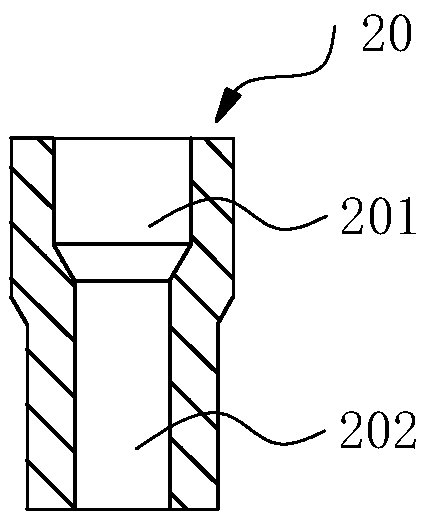

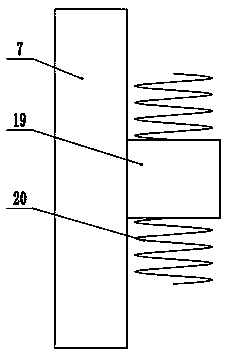

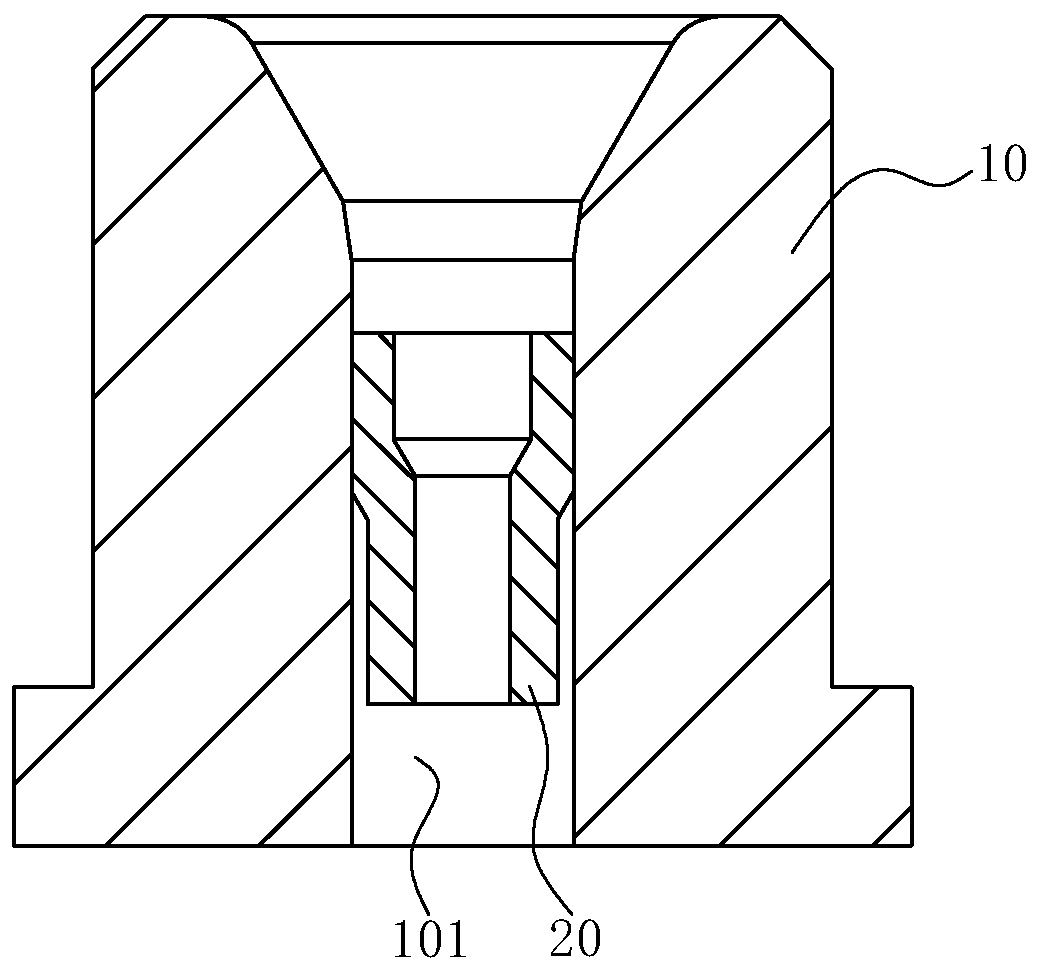

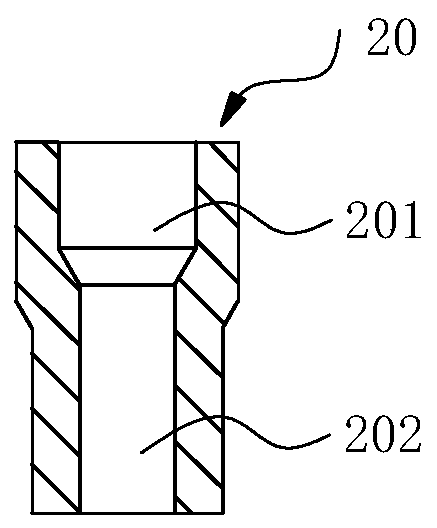

Common rail pipe

ActiveCN109441684AThe central cross-sectional area is smallRealize the breaking functionMachines/enginesSpecial fuel injection apparatusFailure rateCommon rail

The invention discloses a common rail pipe. The common rail pipe is characterized in that a throttling filter is arranged in an inner hole of an oil port of an oil inlet or / and an oil outlet of the common rail pipe, the throttling filter comprises an oil inlet end cylindrical section, an oil inlet end circular truncated cone section, an oil outlet end circular truncated cone section and an oil outlet end cylindrical section which are sequentially arranged in the axial direction, the oil inlet end cylindrical section and the oil outlet end cylindrical section are in tight fit with the inner hole of the oil port, gaps are reserved between the oil inlet end circular truncated cone section as well as the oil outlet end circular truncated cone section and the inner hole of the oil port, an oilinlet groove and an oil outlet groove which extend in the axial direction and are arranged at intervals are arranged on the surface of the throttling filter, the oil inlet groove starts from the oil inlet end cylindrical section and stops at the oil outlet end circular truncated cone section, and the oil outlet groove starts from the oil outlet end cylindrical section and stops at the oil inlet end circular truncated cone section. According to the common rail pipe, the throttling function and the filtering function on high-pressure fuel oil are achieved, so that the blockage failure rate, caused by particle impurities, of an oil atomizer is effectively reduced, and a prominent contribution is made to normal operation of an engine.

Owner:WEICHAI POWER CO LTD

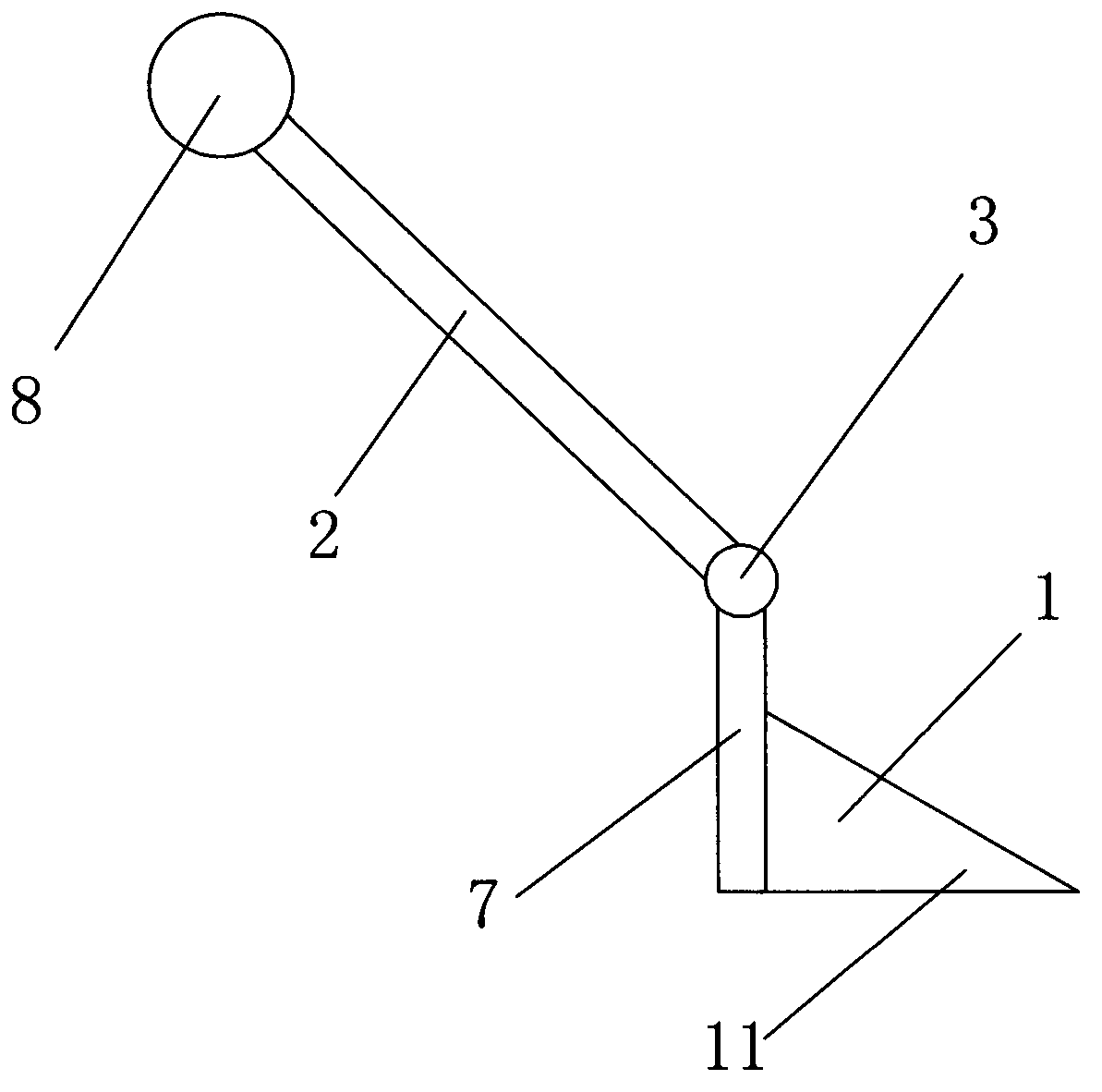

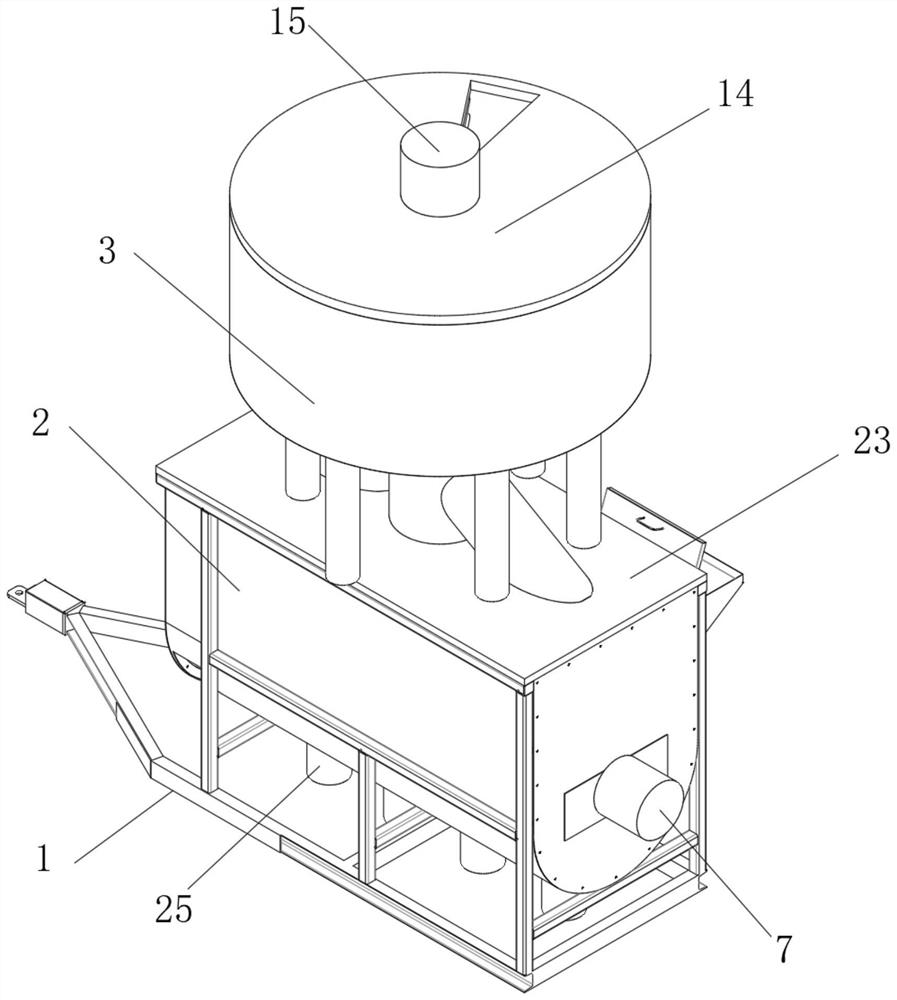

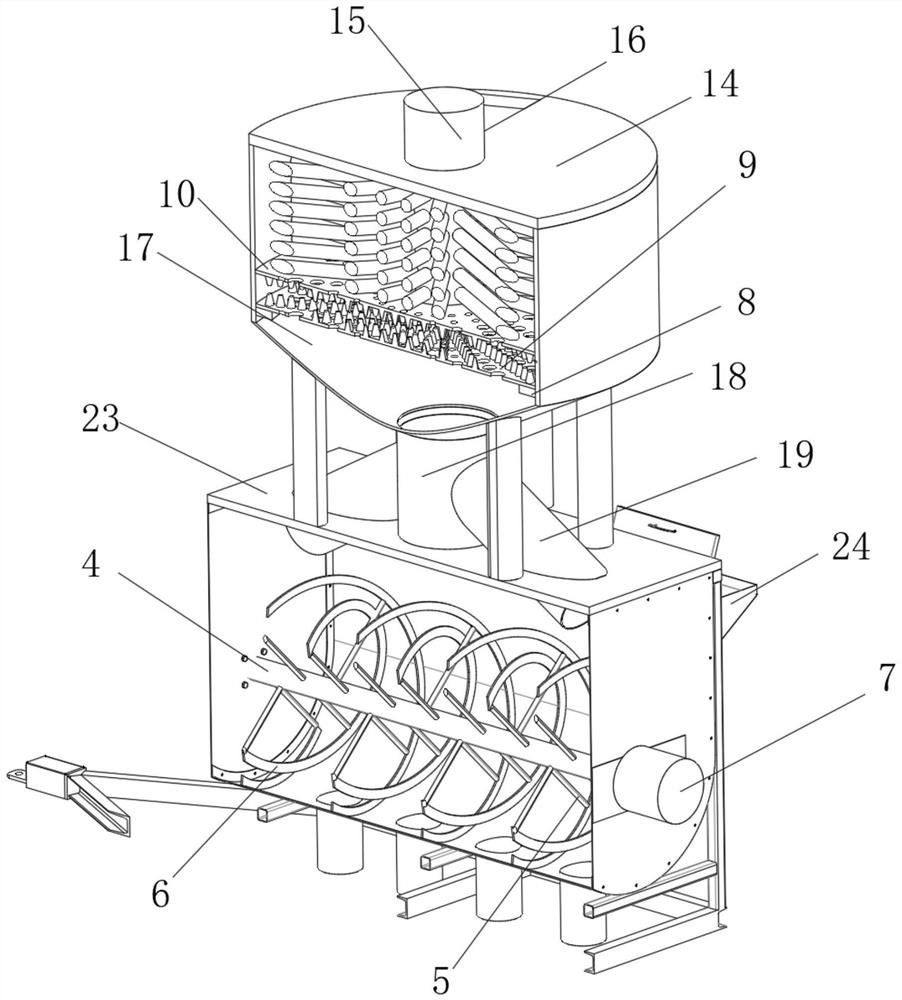

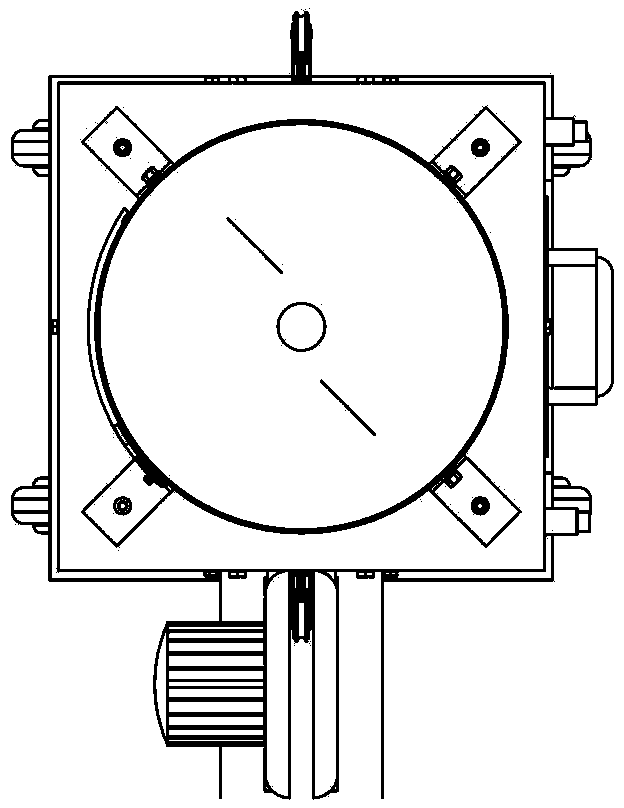

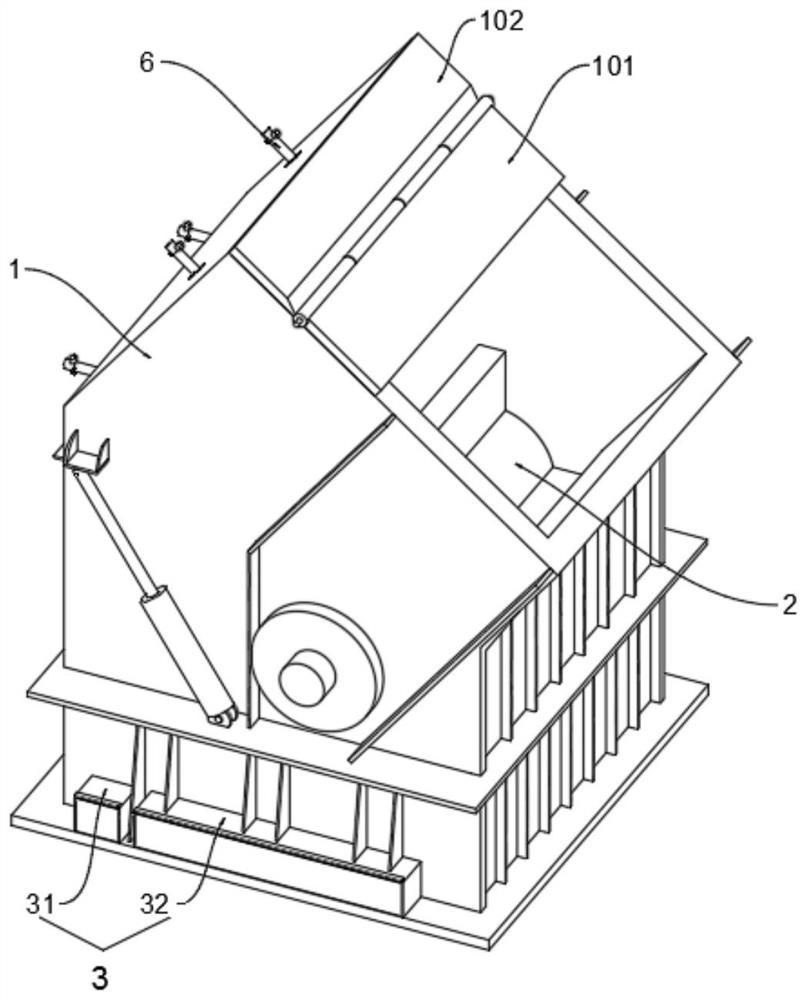

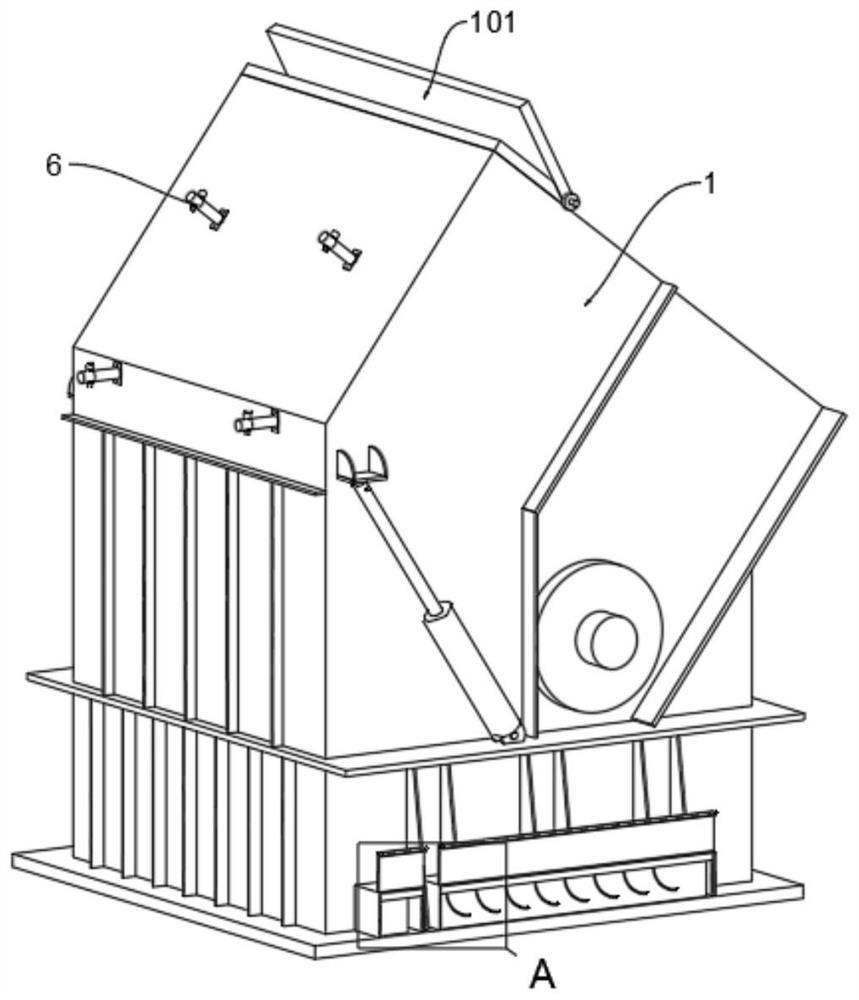

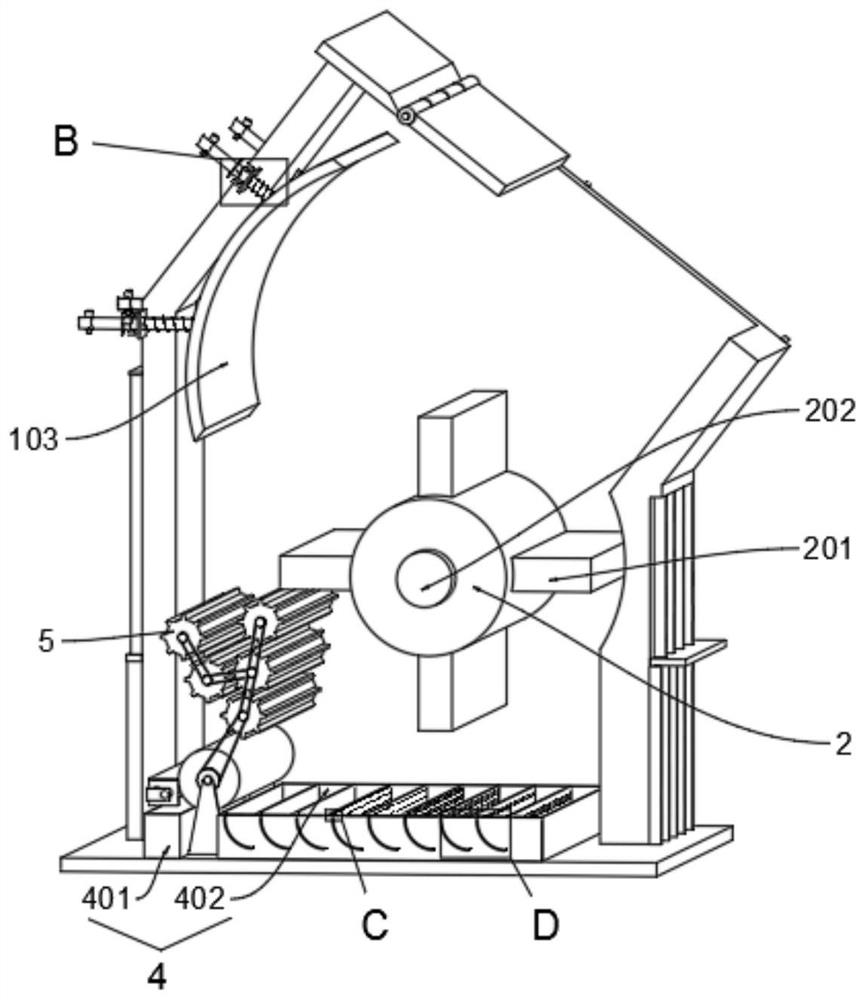

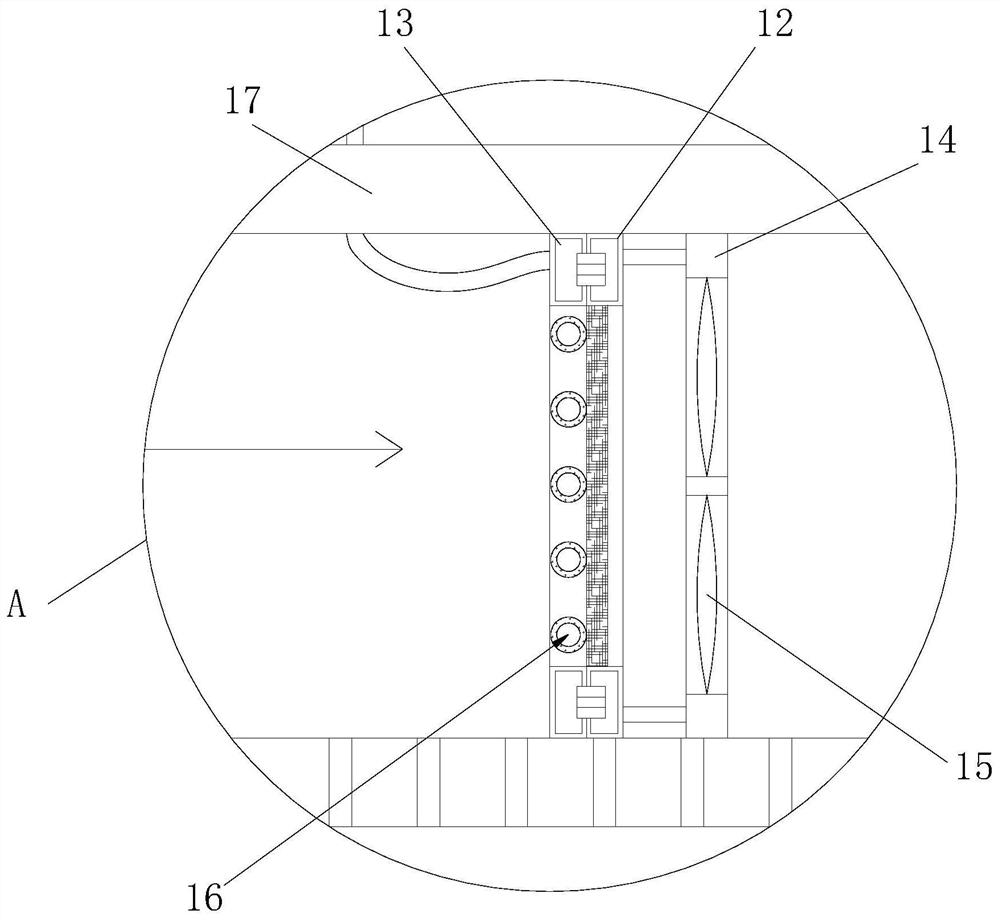

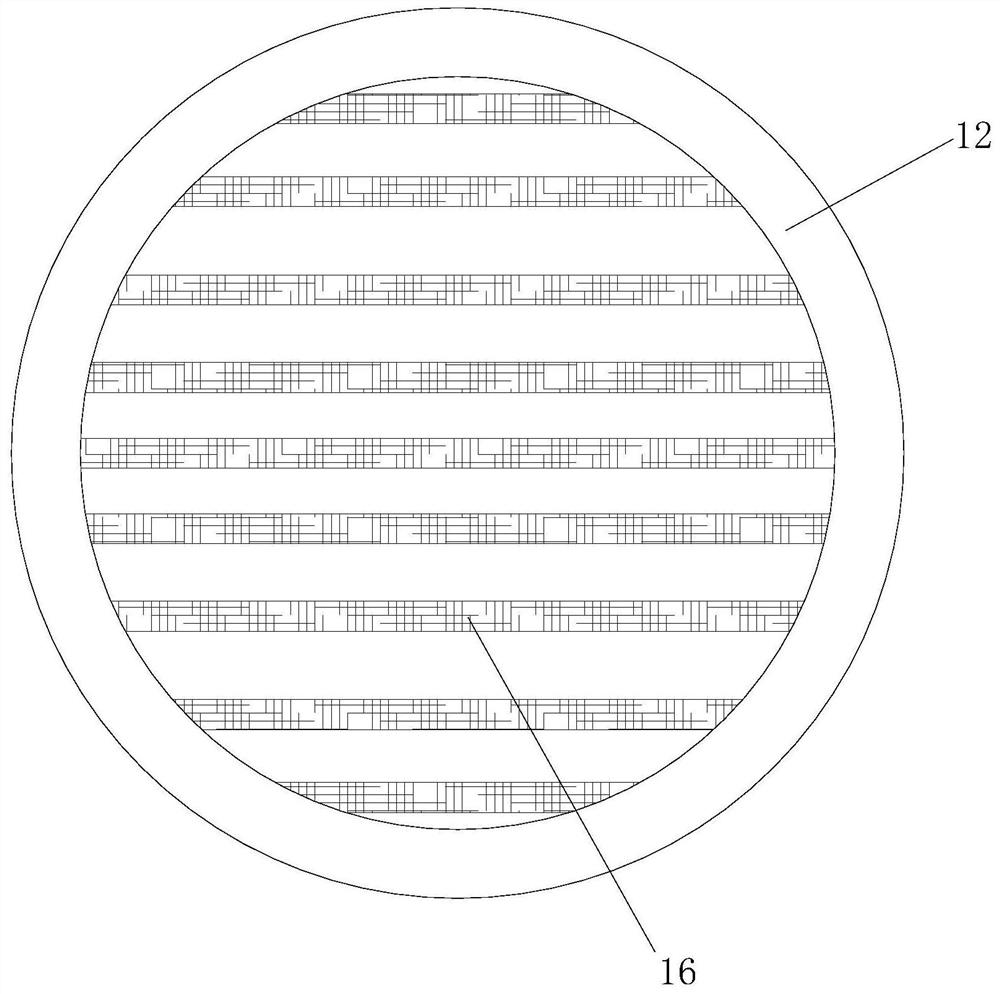

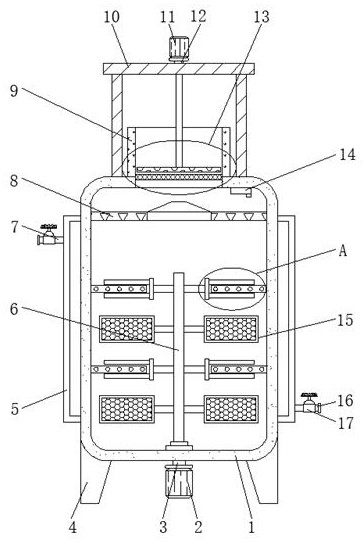

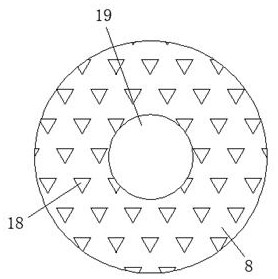

Crusher with pre-crushing function

InactiveCN110947466AReduce workloadRealize the breaking functionGrain treatmentsClassical mechanicsElectric machinery

The invention discloses a crusher with a pre-crushing function, and relates to the field of crushers. The crusher comprises a crushing box, wherein a feeding hopper is fixedly arranged at the top endof the crushing box; supporting legs are fixedly connected to the bottom end of the crushing box; an inner blocking cover is fixedly connected in the crushing box; a crushing cavity is formed in the inner blocking cover; a pendulum bob is rotationally connected in the crushing cavity; a driving motor is fixedly connected to the bottom end in the crushing box; the driving motor is in transmission connection with the pendulum bob; a pretreatment device is further arranged above the pendulum bob; the pretreatment device comprises a rotating disc; a connecting rod is rotationally connected betweenthe rotating disc and the pendulum bob; swing arms are fixedly connected to the two sides of the rotating disc; and the ends, far away from the rotating disc, of the swing arms are fixedly connectedwith a hammer head. According to the crusher, the crushing function can be realized by arranging the pendulum bob, and the pretreatment mechanism can move along with the pendulum bob when the pendulumbob moves so as to realize the pre-crushing work of stones, so that the working load of the pendulum bob is reduced, and the service life of the device is prolonged.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

Common rail tube

ActiveCN109441684BThe central cross-sectional area is smallRealize the breaking functionMachines/enginesSpecial fuel injection apparatusCommon railEngineering

The invention discloses a common rail pipe. The common rail pipe is characterized in that a throttling filter is arranged in an inner hole of an oil port of an oil inlet or / and an oil outlet of the common rail pipe, the throttling filter comprises an oil inlet end cylindrical section, an oil inlet end circular truncated cone section, an oil outlet end circular truncated cone section and an oil outlet end cylindrical section which are sequentially arranged in the axial direction, the oil inlet end cylindrical section and the oil outlet end cylindrical section are in tight fit with the inner hole of the oil port, gaps are reserved between the oil inlet end circular truncated cone section as well as the oil outlet end circular truncated cone section and the inner hole of the oil port, an oilinlet groove and an oil outlet groove which extend in the axial direction and are arranged at intervals are arranged on the surface of the throttling filter, the oil inlet groove starts from the oil inlet end cylindrical section and stops at the oil outlet end circular truncated cone section, and the oil outlet groove starts from the oil outlet end cylindrical section and stops at the oil inlet end circular truncated cone section. According to the common rail pipe, the throttling function and the filtering function on high-pressure fuel oil are achieved, so that the blockage failure rate, caused by particle impurities, of an oil atomizer is effectively reduced, and a prominent contribution is made to normal operation of an engine.

Owner:WEICHAI POWER CO LTD

Crusher structure for tempered glass

InactiveCN103405859AQuick breakIncrease chance of escapePedestrian/occupant safety arrangementBuilding rescueDrive shaftEngineering

The invention discloses a crusher structure for tempered glass. The crusher structure comprises an impacting component and a cutter matched with the impacting component. The impacting component comprises a drive rod, the front end of the drive rod is matched with a drive shaft, and the cutter is matched with the drive shaft. The crusher structure is simple in structure, safe, simple and convenient to operate, capable of performing crushing rapidly during danger and improving the escape probability of persons and widely applicable to the field of crushing of different kinds of tempered glass.

Owner:SHENZHEN KEYUAN CONSTR GRP

A tempered glass breaker

ActiveCN103405860BSimple structureOperational securityPedestrian/occupant safety arrangementBuilding rescueEngineeringCrusher

The invention discloses a crusher for tempered glass. The crusher comprises an impacting component and a cutter mounted on the impacting component. The impacting component further comprises a base and a cutter handle which is matched with the base and capable of moving vertically in the base, the cutter is mounted on the cutter handle, and a cutter groove for vertical moving of the cutter and corresponding to the edge or corner position of tempered glass is opened in the base. The crusher is simple in structure, safe, simple and convenient to operate, capable of performing crushing rapidly during danger and improving the escape probability of persons and widely applicable to the field of crushing of different kinds of tempered glass.

Owner:SHENZHEN KEYUAN CONSTR GRP

Concrete circulating crushing device

ActiveCN113441239ARealize the breaking functionAchieve adsorptionHollow article cleaningCleaning using gasesPolyesterStructural engineering

The invention discloses a concrete circulating crushing device, and belongs to the technical field of concrete crushing. According to the concrete circulating crushing device, a crushing function on concrete can be realized through a first crushing cutter and a second crushing cutter, the crushed concrete can be screened by using a filter screen, qualified concrete can penetrate through a filter screen to enter a recycling box, a connecting column barrel can spray out a large amount of gas under the action of a first air blower, dust in a crushing box is discharged through an exhaust pipe, a first circular frame in the exhaust pipe rotates under the action of a windmill, so that a polyester coating and a plastic coating on the surface of a rubber pipe rub with each other to generate static electricity to adsorb dust in air; and in addition, the rubber pipe can be expanded through a second air blower, the adhesive force of the dust can be reduced through expansion of the rubber pipe, round holes in the surface of the rubber pipe are opened while the rubber pipe is expanded, and airflow in the rubber pipe is sprayed out through the round holes to achieve the function of cleaning dust on the surface of the rubber pipe.

Owner:日照华领砼业有限公司

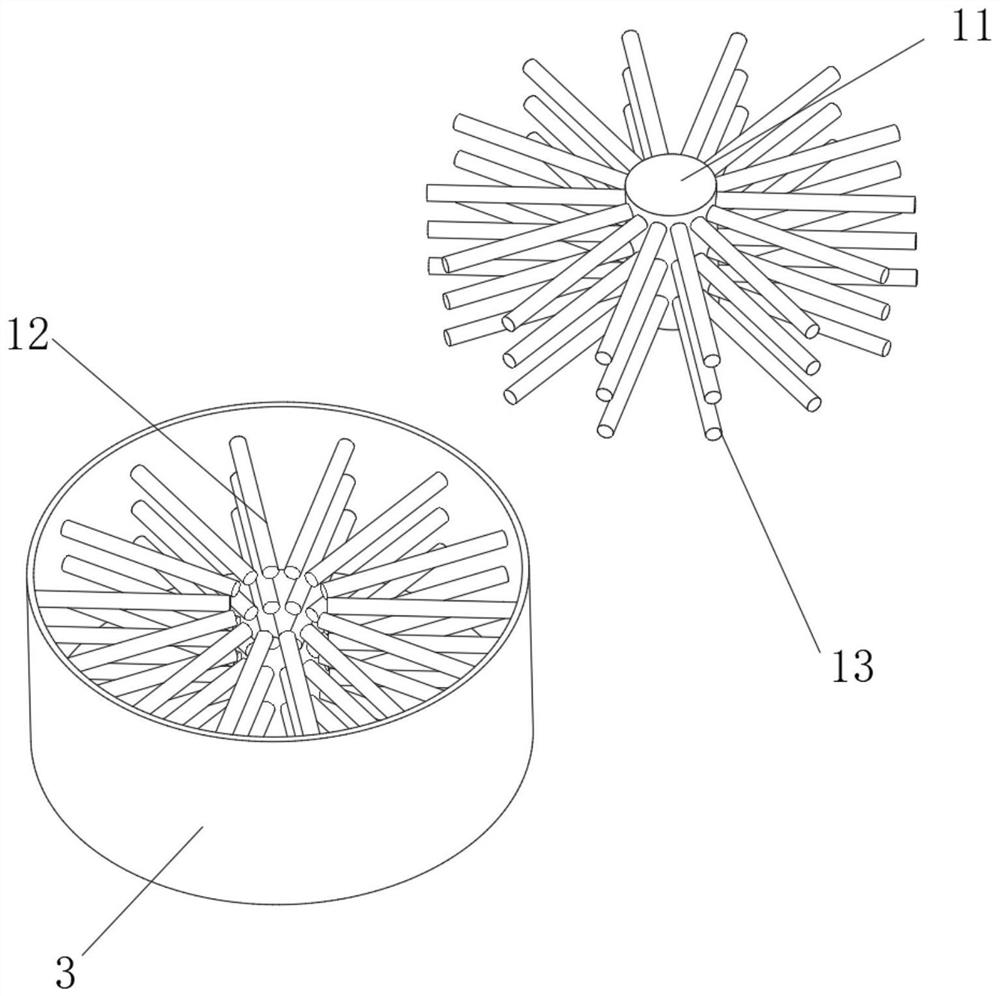

Fertilizer stirring device for planting

InactiveCN114870732AReduce loadRealize the breaking functionBio-organic fraction processingRotary stirring mixersAgricultural scienceAgricultural engineering

The invention discloses a fertilizer stirring device for planting, and particularly relates to the technical field of fertilizer production, the fertilizer stirring device comprises a mounting rack, a stirring mechanism is arranged at the top of the mounting rack, a crushing and grinding mechanism is arranged at the top of the stirring mechanism, and a flow guide assembly is arranged between the crushing and grinding mechanism and the stirring mechanism. Through corresponding cooperative use of all the structures, the whole device is arranged in an integrated mode, integrated synchronous operation of crushing, grinding and stirring of raw materials is achieved, additional equipment is not needed for processing the raw materials, it can be effectively ensured that the raw materials can be crushed into material blocks with the uniform size, and the raw materials are effectively prevented from being crushed into blocks with the uniform size. The stirring device has the advantages that the stirring efficiency and effect of the stirring device are improved, the load borne by a subsequent device during stirring is relieved, meanwhile, the crushed raw materials are crushed and ground again, material caking is avoided, the stirring device can oscillate back and forth through the rotating torsion of the flow guide stirring belt, the stirring efficiency and effect of the stirring device are improved, and the stirring device is simple in design and has good practicability.

Owner:重庆亿栎农业发展有限公司

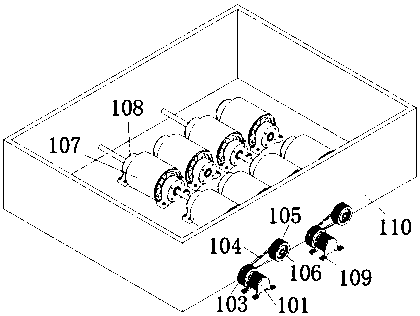

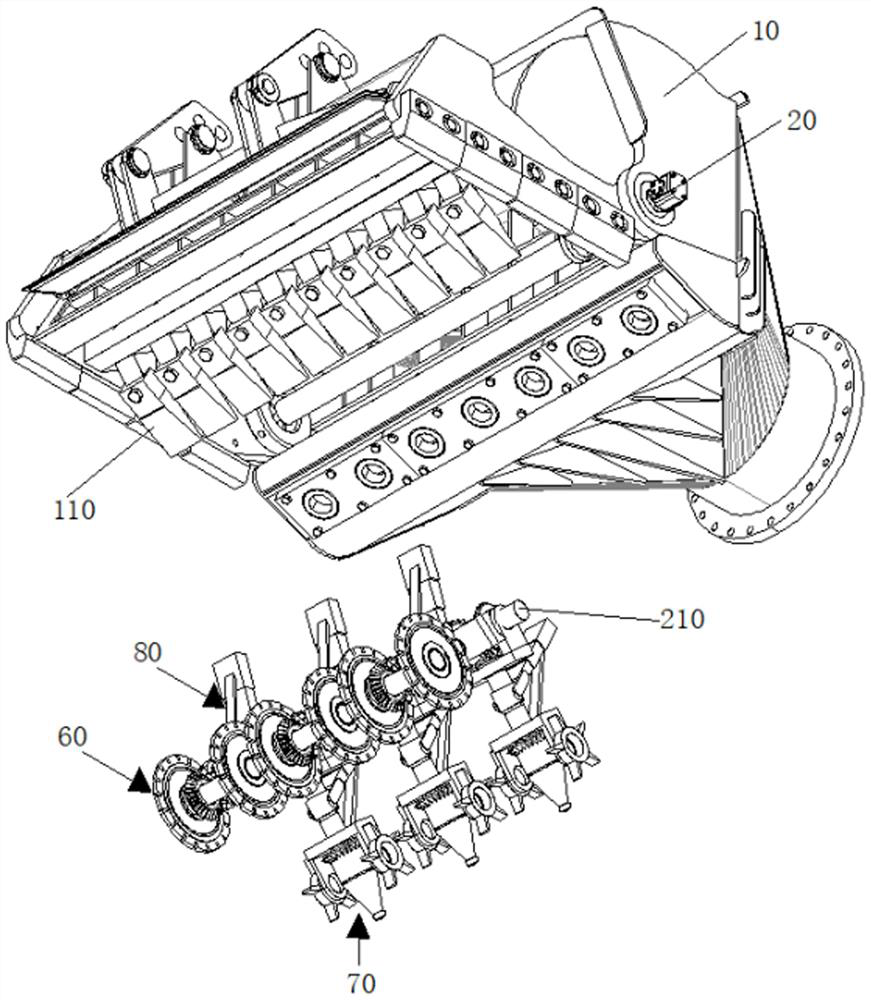

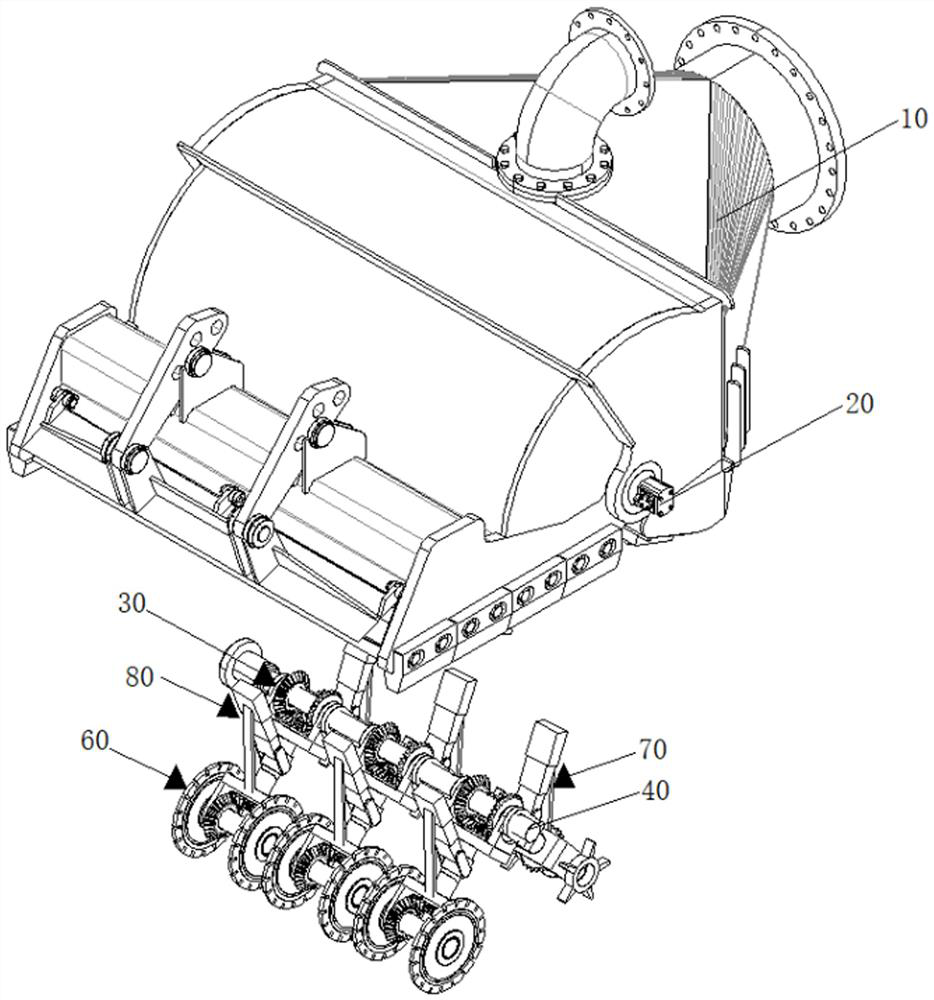

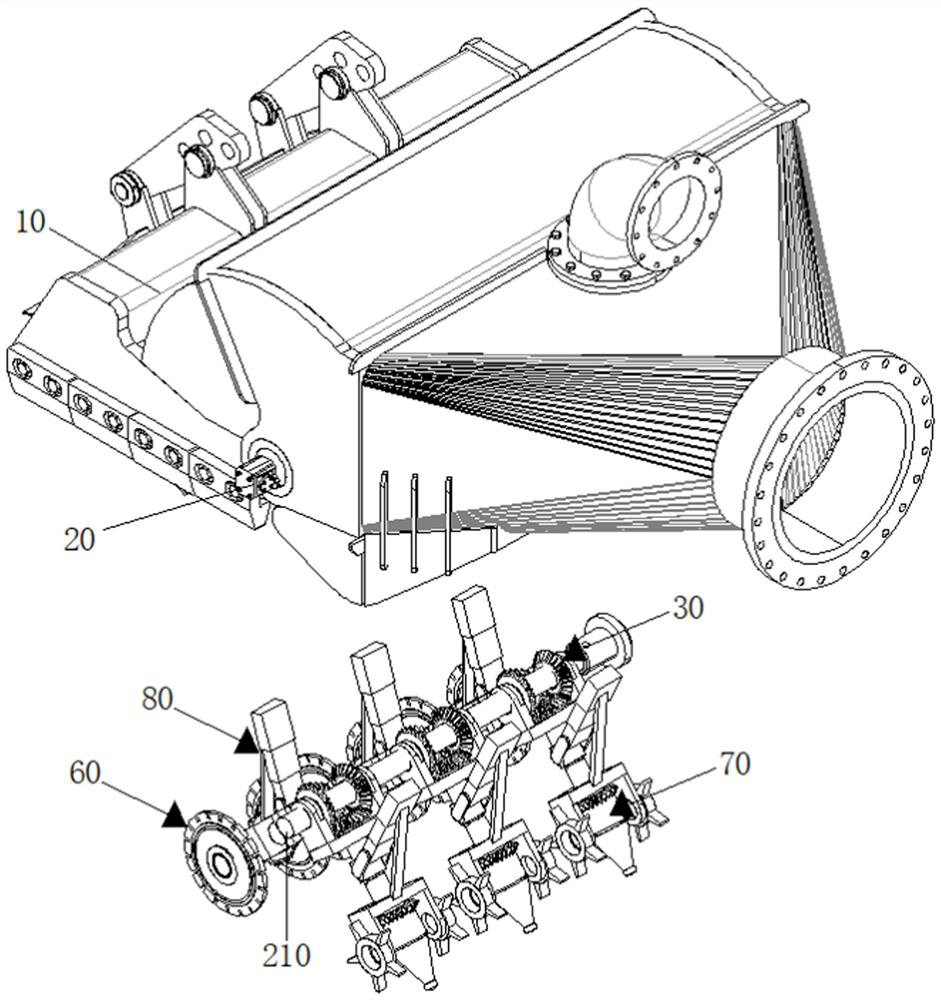

Rake head for rapidly and automatically excavating seabed mud

ActiveCN114508137ARealize pre-crushing functionReduce the difficulty of breakingMechanical machines/dredgersDrive shaftElectric machinery

The invention discloses a rapid and automatic excavating drag head for seabed mud, and belongs to the technical field of equipment for dredging engineering. A rapid and automatic digging rake head for seabed mud comprises a rake head cover, rake teeth installed at the front end of the rake head cover, an underwater gear motor installed on the side wall of the rake head cover and a transmission shaft installed at the output end of the underwater gear motor and located in an inner cavity of the rake head cover, and further comprises first transmission bevel gear sets arranged on the outer wall of the transmission shaft in a sleeving mode at equal intervals, and second transmission bevel gear sets arranged on the outer wall of the transmission shaft, the rotating shaft is used for converting axial rotation of the transmission shaft into radial rotation adjustable in direction; the transmission rod is mounted at the transmission end of the first transmission bevel gear set; the buffer adjusting mechanism is mounted at the middle section of the transmission rod and used for adjusting the included angle between the transmission rod and the transmission shaft; according to the pre-crushing function of the channel rock substrate, the crushing function of the rock substrate in different concave-convex states is achieved, and the problems that hob damage is aggravated due to the too large hob crushing depth and the drag suction efficiency is low due to the poor crushing effect caused by the too small crushing depth are solved.

Owner:CHEC DREDGING

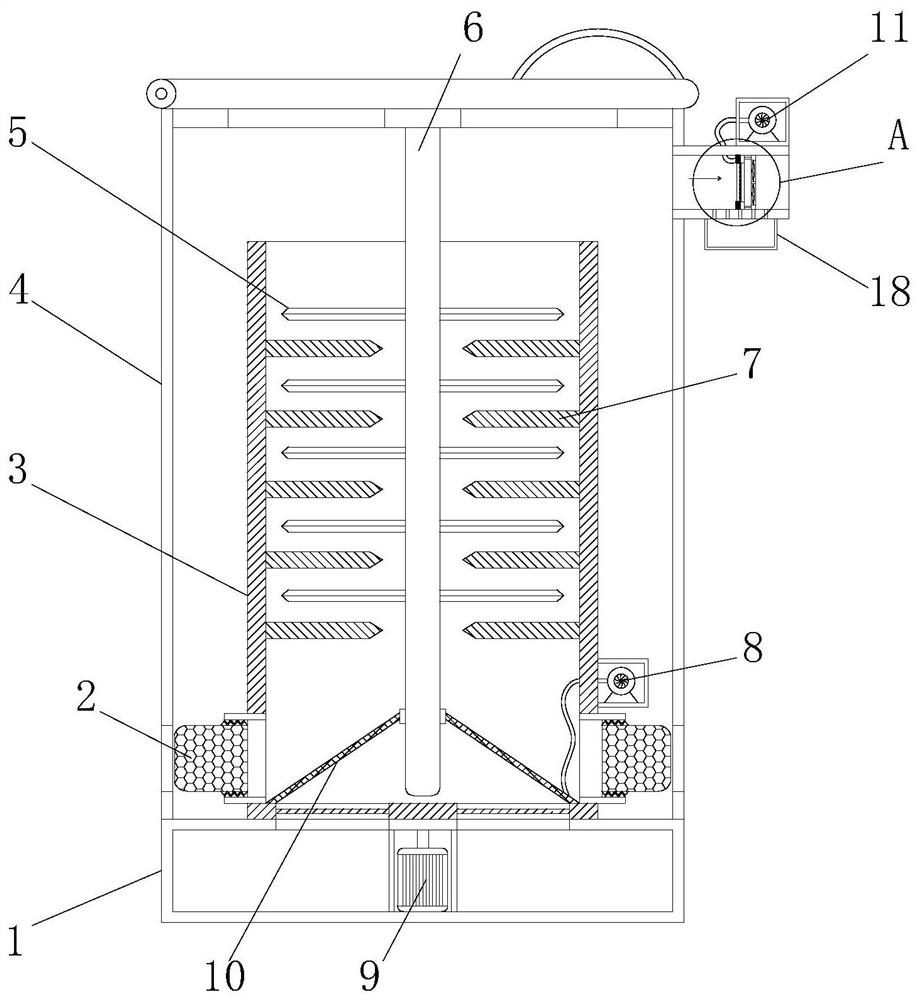

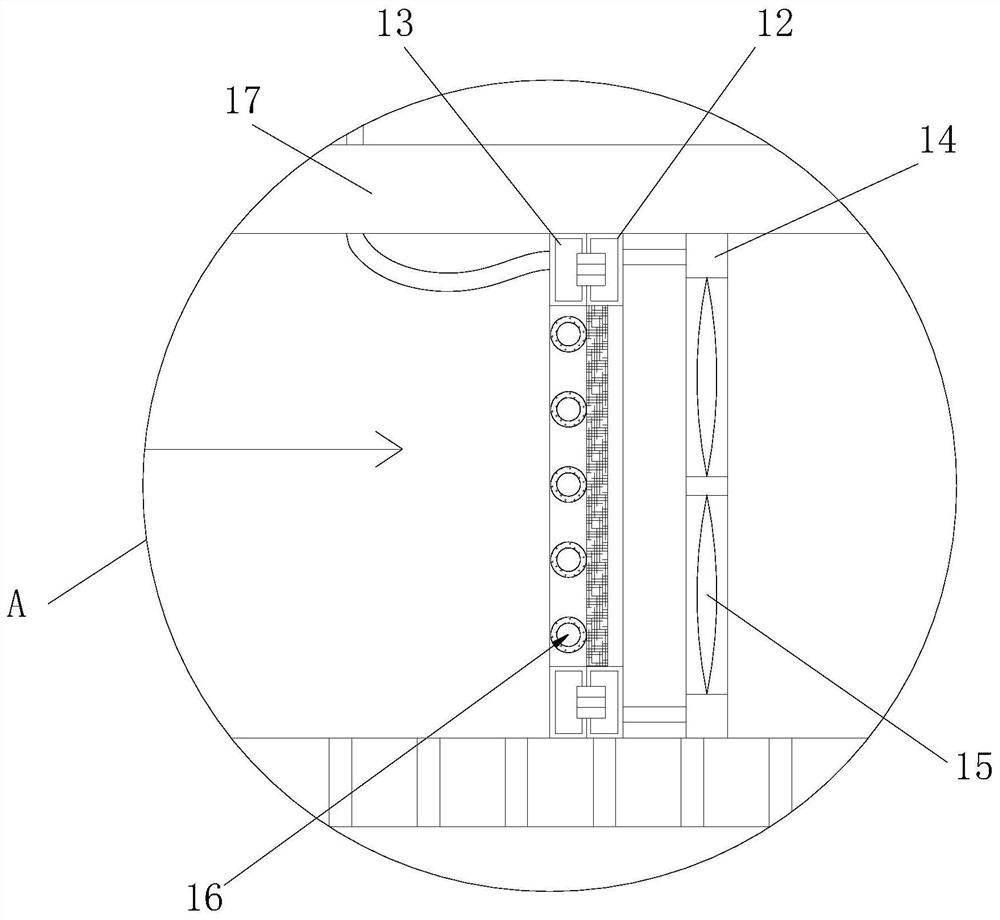

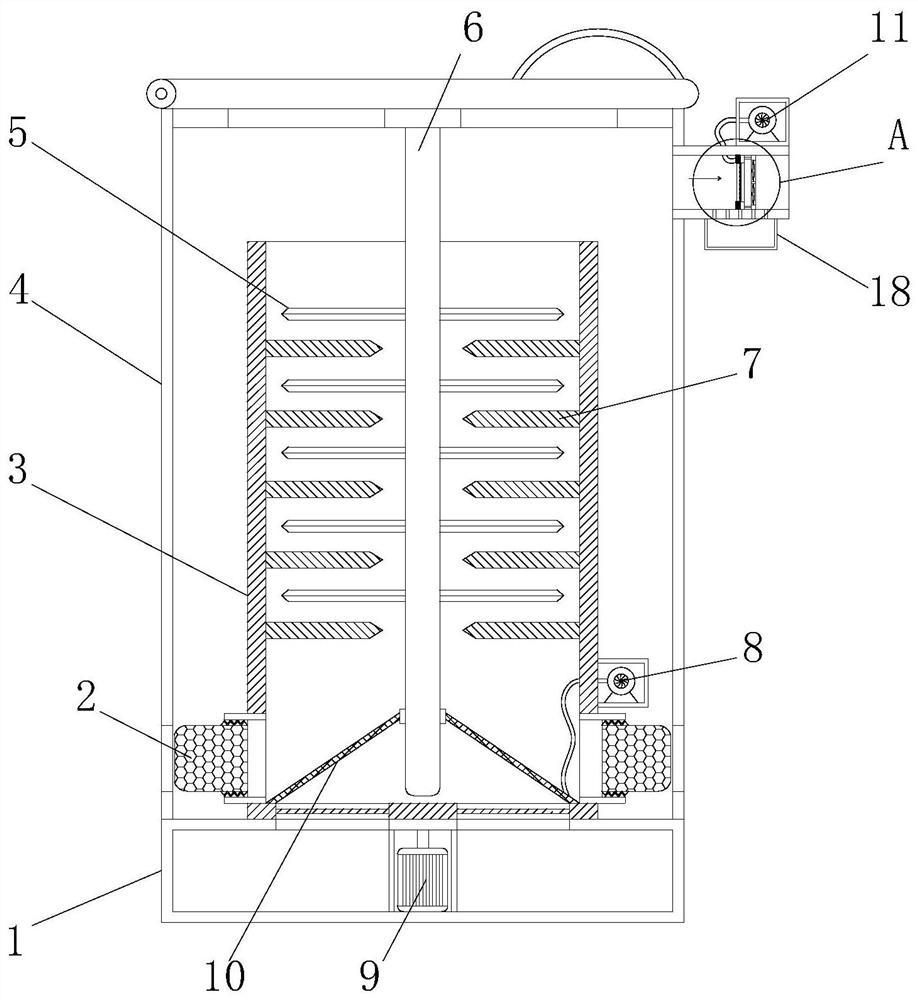

Household food garbage processor

The invention provides a household food garbage processor comprising a milling device, a milling chamber and a storage chamber, wherein the milling device is mounted above the milling chamber; the milling chamber is mounted on the storage chamber in a sealed manner; the milling chamber is communicated with the storage chamber through a connector; the storage chamber is externally provided with a moving device for driving the milling device to move in a vertical direction; and the moving device drives the milling device to move upwards in the vertical direction. According to the household food garbage processor, food garbage can be crushed into slurry liquid or very small grains; in-time, convenient and fast kitchen cleaning can be easily realized; and pathogenic bacteria, mosquitoes and peculiar smells, which are caused by depositing untreated food garbage, are avoided; and therefore, a domestic environment is effectively optimized and the problem that a sewer is easy to block is completely solved.

Owner:HUNAN AGRICULTURAL UNIV

A crushing system and crushing method for harmless separation of swill

ActiveCN111036336BImprove crushing efficiencyRealize the breaking functionSievingScreeningElectric machineryProcess engineering

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

Jaw crusher with single-shaft double-crank-rocker mechanism

ActiveCN102198409BChange the mechanical structureEasily brokenGrain treatmentsDrive wheelDrive shaft

The invention discloses a jaw crusher with a single-shaft double-crank-rocker mechanism. The jaw crusher comprises a frame, a fixed jaw plate, a movable jaw plate, a front crank-rocker mechanism, a rear crank-rocker mechanism and a driving wheel, wherein, the front crank-rocker mechanism comprises a front movable jaw, a front toggle plate and an eccentric drive shaft; the rear crank-rocker mechanism comprises a rear movable jaw, a rear toggle plate and an eccentric drive shaft; the front movable jaw and the rear movable jaw are jointly pivoted with the eccentric drive shaft; one end of the front toggle plate is pivoted below the rear side of the front movable jaw, the other end of the front toggle plate is pivoted below the front side of the rear movable jaw, one end of the rear toggle plate is pivoted below the rear side of the rear movable jaw, and the other end of the rear toggle plate is pivoted with the frame; and the movable jaw plate is fixedly connected with the front movable jaw and is opposite to the fixed jaw plate to form a crushing cavity together with the fixed jaw plate. The jaw crusher has the obvious effect that horizontal movement stroke of the lower parts of the movable jaws with the main function of discharging materials is improved to a stroke with a main function of crushing so that one crusher has two-stage crushing efficacy.

Owner:ZHEJIANG SHENGDA MACHINERY

Building waste recovery equipment based on construction cost control

PendingCN114850186AEasy to recycleEasy to separateSolid waste managementSolid waste disposalArchitectural engineeringStructural engineering

The invention provides building waste recovery equipment based on construction cost control, and relates to the technical field of building waste recovery equipment. The bottom surface of the left side outside the main body is fixedly connected with the sealing box group; the storage box group is placed on the bottom surface inside the main body; the sealing box group comprises a small outer box and a large outer box; the storage box set comprises a metal box and a powder box, the outer end of the left side of the metal box is arranged in the small outer box, the outer end of the left side of the powder box is arranged in the large outer box, after the sliding rod drives the screening plate to slide in the sliding way with the shaft as the circle center, the screening plate pokes powder smashed in the powder box to the front side, screening holes of the screening plate are gradually enlarged from back to front, and the powder is smashed. The powder is separated in the shifting process from back to front, the larger the particles are, the larger the particles are, the larger the particles are, the powder is shifted forwards, the powder in the powder box is separated, follow-up recycling according to the particle sizes is facilitated, the sand screening time cost is saved, and the problem that recycling cannot be conducted according to the particle sizes, and the time cost is saved is solved.

Owner:林环周

A concrete circulating crushing device

ActiveCN113441239BRealize the breaking functionAchieve adsorptionHollow article cleaningCleaning using gasesPolyesterStructural engineering

The invention discloses a concrete circulatory crushing device, belonging to the technical field of concrete crushing. A concrete circulatory crushing device can realize the crushing function of concrete through a first crushing blade and a second crushing blade, and can use a filter screen to crush the concrete after crushing. Under the action of the first blower, the connecting cylinder can spray a large amount of gas, so that the dust in the crushing box is discharged through the exhaust pipe, and the inside of the exhaust pipe The first circular frame is rotated under the action of the windmill, so that the polyester coating and the plastic coating on the surface of the hose rub against each other to generate static electricity to adsorb dust in the air. In addition, the use of the second blower can make the hose Expansion, the expansion of the hose can reduce the adhesion of dust. When the hose expands, the circular holes on its surface are opened, and the airflow inside the hose is ejected through the circular holes to clean the dust on the surface of the hose.

Owner:日照华领砼业有限公司

Uniform mixing equipment of fluorescent whitening agent composition for papermaking

InactiveCN112237880AGood dispersionRealize the breaking functionTransportation and packagingMixer accessoriesWhitening AgentsElectric machine

The invention discloses uniform mixing equipment of a fluorescent whitening agent composition for papermaking; the uniform mixing equipment comprises an equipment shell, a stirring rod, a dispersing disc, a crushing mechanism and a stirring paddle; the stirring rod is rotatably mounted in the equipment shell, and a first motor is mounted at the bottom end of the equipment shell at the position ofthe stirring rod; a first rotating shaft is installed at the output end of the first motor through a coupler, supporting legs are fixed to the two sides of the bottom end of the equipment shell, a feeding port is formed in the center of the top end of the equipment shell, a fixing frame is fixed to the top end of the equipment shell on the outer side of the feeding port, and a second motor is installed at the top end of the fixing frame; and a second rotating shaft is mounted at the output end of the second motor through a coupler, and a crushing mechanism is arranged in the feeding port. According to the invention, the mixing uniformity is improved, the crushing function of the raw materials is realized, the dispersity of the raw materials during addition is improved, and the device is convenient to cool.

Owner:江门市新会区银湖纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com