Crusher with pre-crushing function

A pre-crushing and crushing machine technology, applied in grain processing, etc., can solve the problems of high equipment damage rate and difficult crushing, and achieve the effect of reducing workload and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

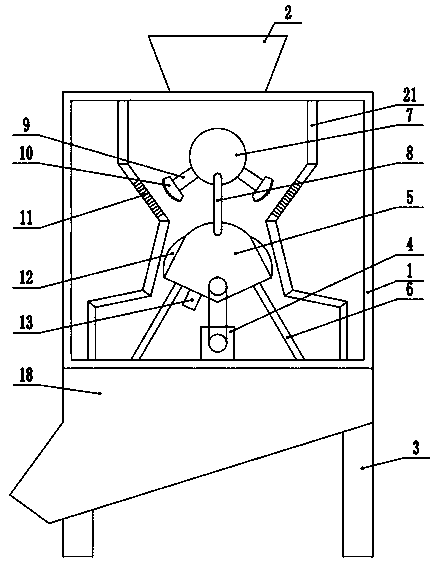

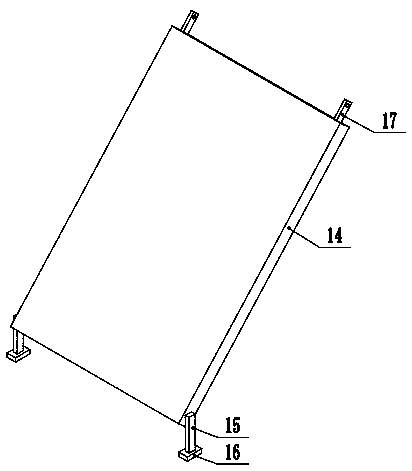

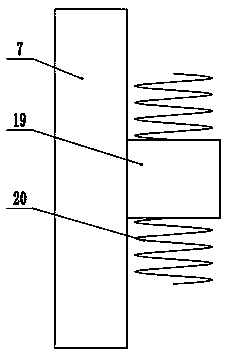

[0022] see Figure 1-3 , a crusher with pre-crushing function, comprising a crushing box 1, the top of the crushing box 1 is fixedly provided with a feed hopper 2, the bottom of the crushing box 1 is fixedly connected to a support leg 3, and the inside of the crushing box 1 is fixedly connected to the There is a crushing chamber inside the shield, the crushing chamber is connected to the pendulum 5 in rotation, the bottom of the crushing box 1 is fixedly connected to the drive motor 4, the drive motor 4 is connected to the pendulum 5 through transmission, and the pendulum 5 There is also a pretreatment device above the top, the pretreatment device includes a rotating disk 7, a connecting rod 8 is rotated between the rotating disk 7 and the pendulum 5, both sides of the rotating disk 7 are fixedly connected to the swing arm 9, and the swing arm 9 is away from the rotating One end of the disc 7 is fixedly connected to the hammer head 10 , the bottom end of the crushing box 1 is ...

Embodiment 2

[0025] see Figure 1-3 , The other content of this embodiment is the same as that of Embodiment 1, except that: both sides of the pendulum 5 are fixed with crushing protrusions 12, and the hammer head 10 is provided with crushing teeth.

[0026] In the present invention, the crushing function can be realized by setting the pendulum 5, and the pre-crushing work of the stones can be realized by setting the pretreatment mechanism to move when the pendulum moves, thereby reducing the working load of the pendulum and improving the service life of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com