Smoke exhaust, fire extinguishment and dismantling robot

A robot and demolition technology, applied in manipulators, fire rescue, manufacturing tools, etc., can solve the problems of small manual demolition, time-consuming, life-threatening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

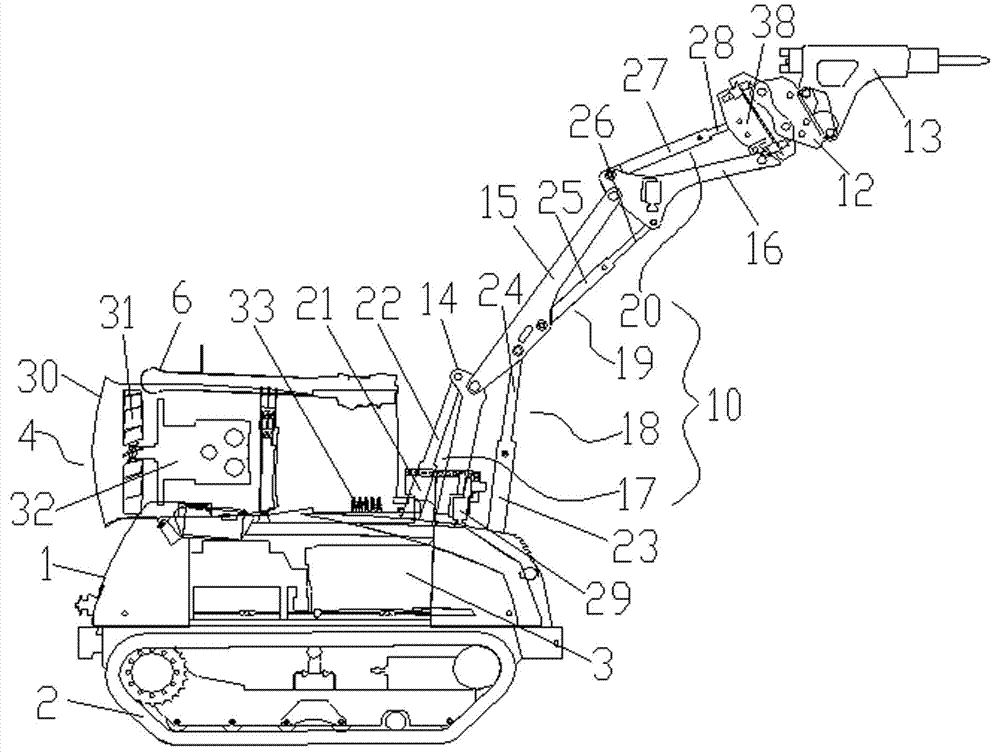

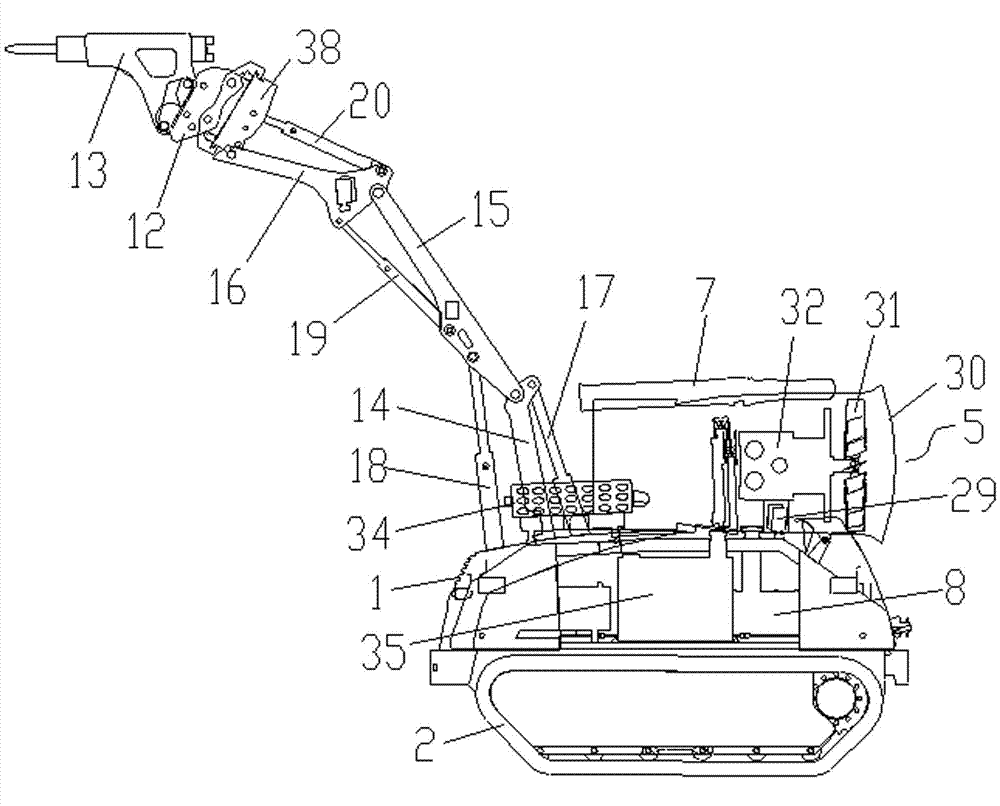

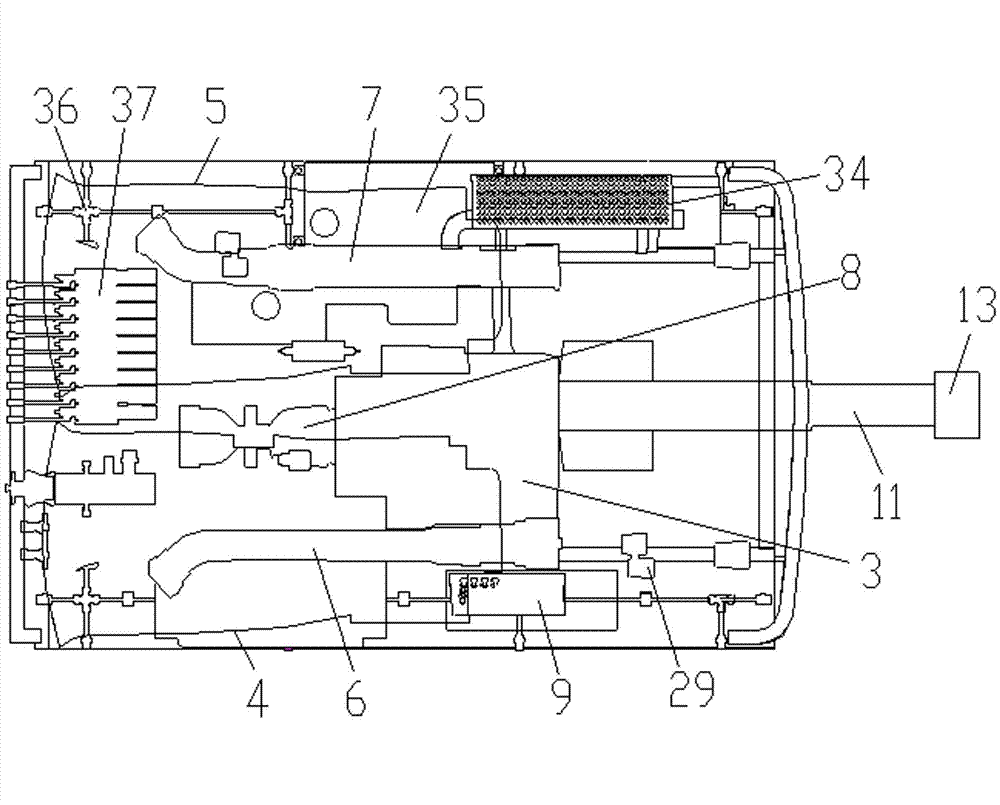

[0024] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0025] Such as figure 1 , figure 2 , image 3 Shown, a kind of smoke exhaust, fire extinguishing, rescue robot, comprise car body 1, be installed in the chassis traveling device 2 of car body 1 bottom, power unit 3, working device, waterway system, hydraulic system and electric system, described power The device 3 and the chassis running device 2 are connected by transmission. The upper part of the vehicle body 1 is provided with two smoke exhausters 4, 5. The smoke exhaust speed is fast and the efficiency is high. The sides of the two smoke exhausters 4, 5 are respectively installed There are water cannons 6 and foam cannons 7. The water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com