Concrete circulating crushing device

A cyclic crushing and concrete technology, applied in external electrostatic separators, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as affecting the health of workers, unable to guarantee the accuracy of concrete crushing, and affecting the efficiency of concrete recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

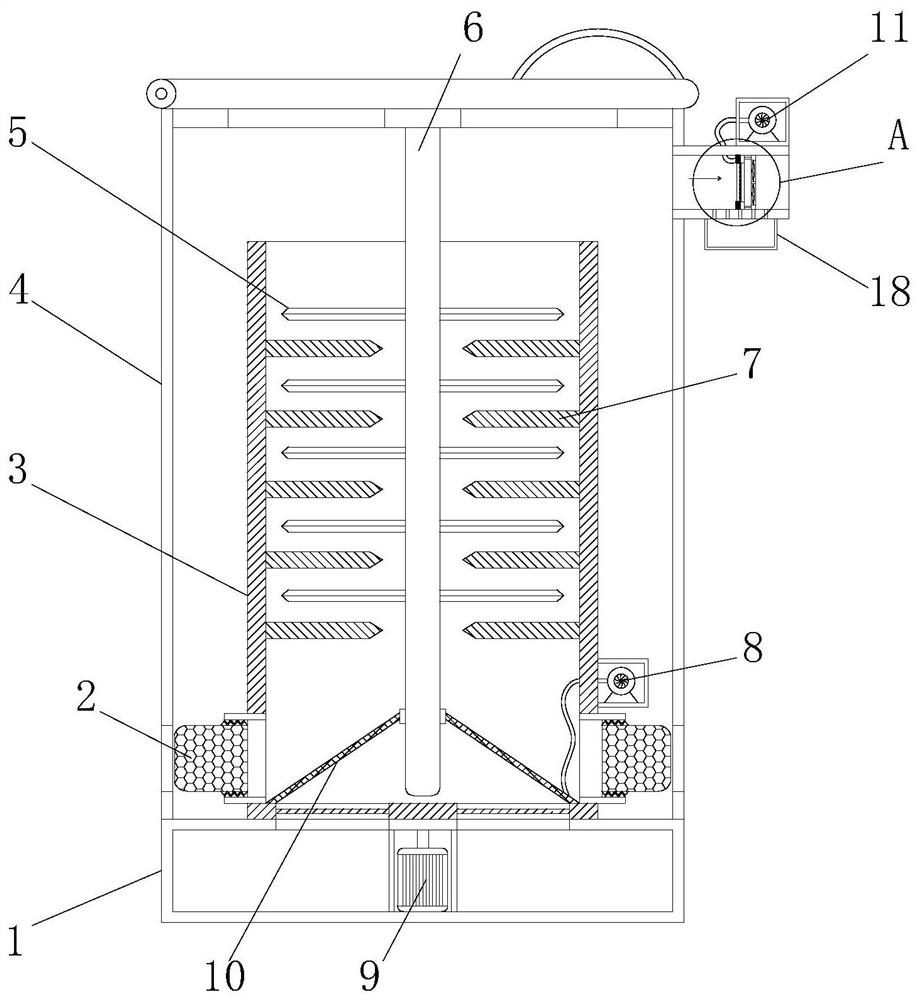

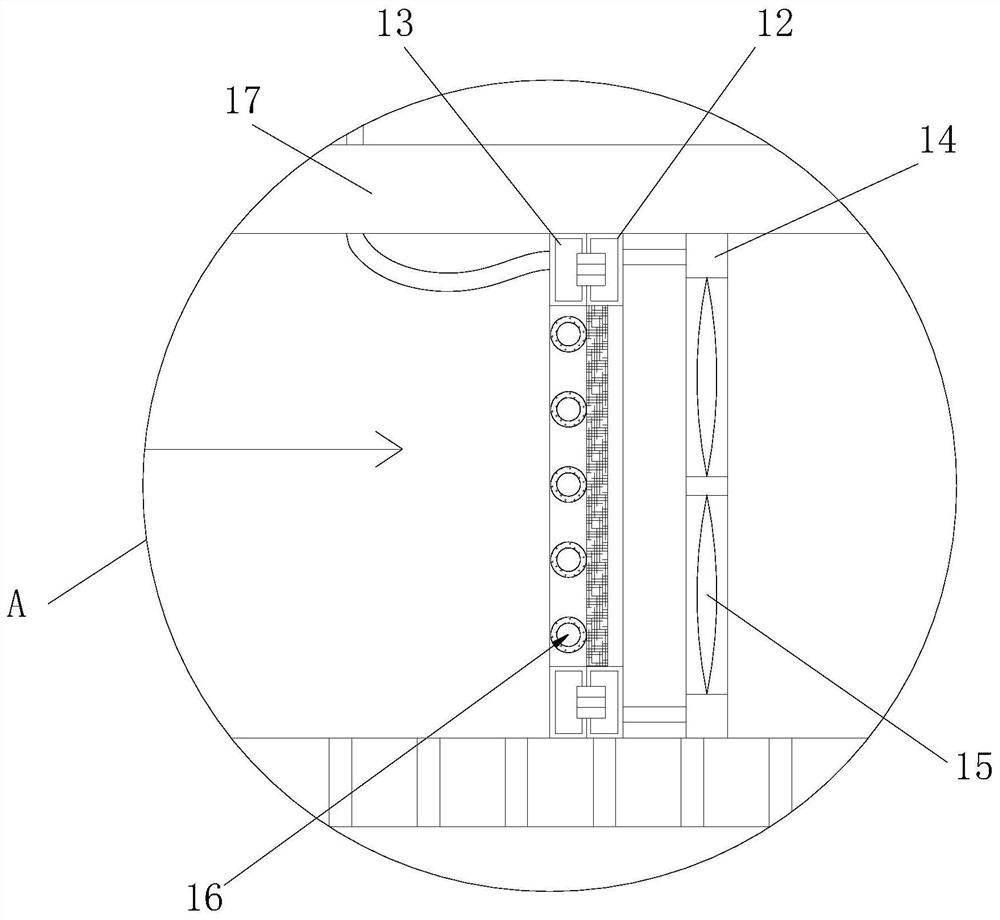

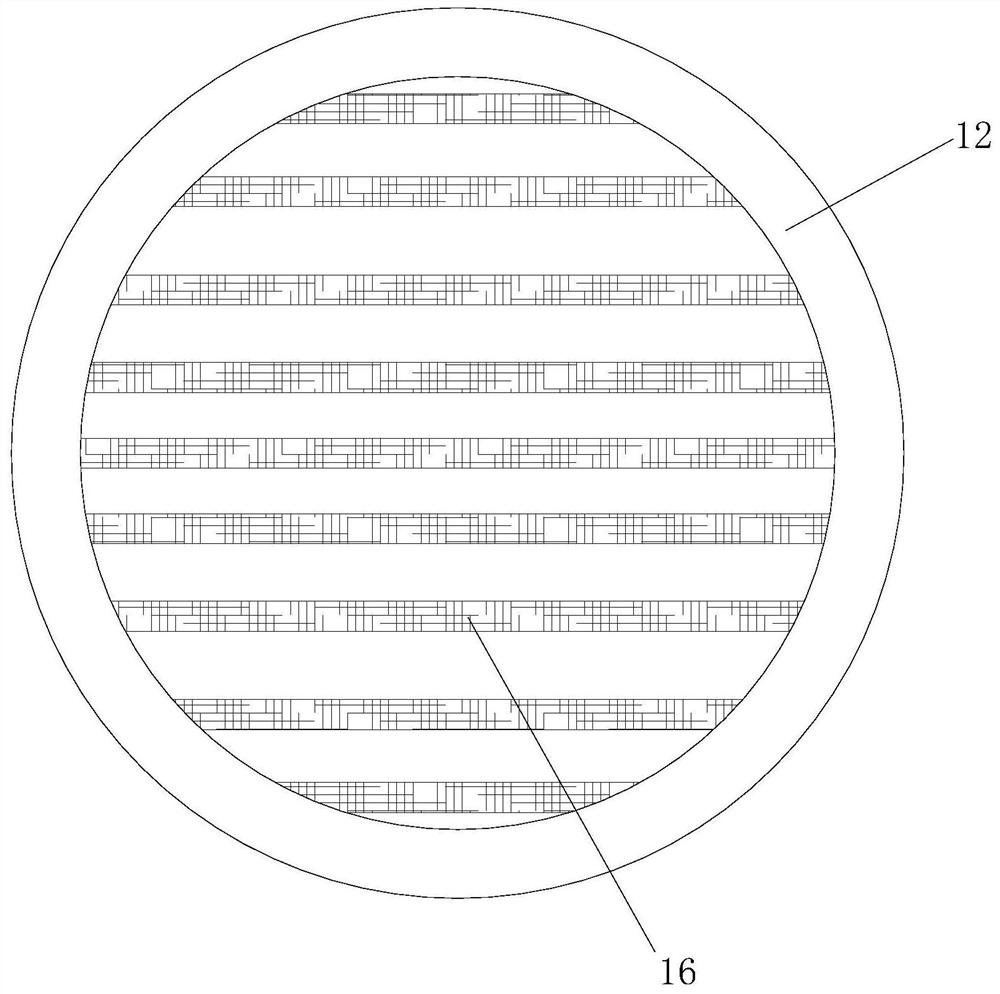

[0041] see figure 1 and figure 2 , a concrete circulation crushing device, comprising a recovery box 1, the top of the recovery box 1 is fixedly connected with a protective box 4, the inner bottom of the protective box 4 is rotatably connected with a crushing box 3, and the inner surface of the crushing box 3 is fixedly connected with a plurality of The second crushing knife 7, the inner top of the protective box 4 is fixedly connected with a column 6, and one end of the column 6 extends into the crushing box 3, and a plurality of first crushing knives 5 are fixedly connected around the crushing box 3, and the column 6 is rotatably connected. There is an installation ring, and a filter screen 10 is fixedly connected around the installation ring, and the bottom end of the filter screen 10 is fixedly connected with the inner bottom end of the crushing box 3, and a material leakage port is provided between the recovery box 1 and the crushing box 3, and the recovery box 1 The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com