Building waste recovery equipment based on construction cost control

A technology for construction waste and recycling equipment, which is applied in construction waste recycling, recycling technology, solid waste management and other directions, can solve the problems of saving time and cost of sand screening, inconsistent size, and inability to automatically separate metal objects, so as to save screening sand. time cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

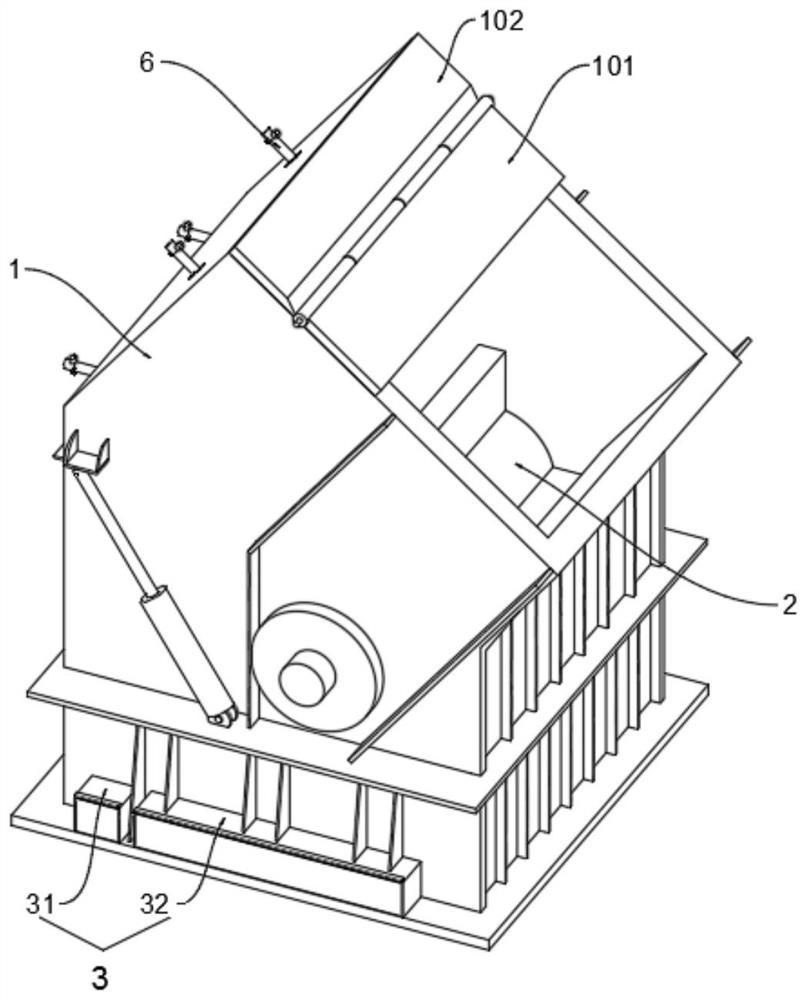

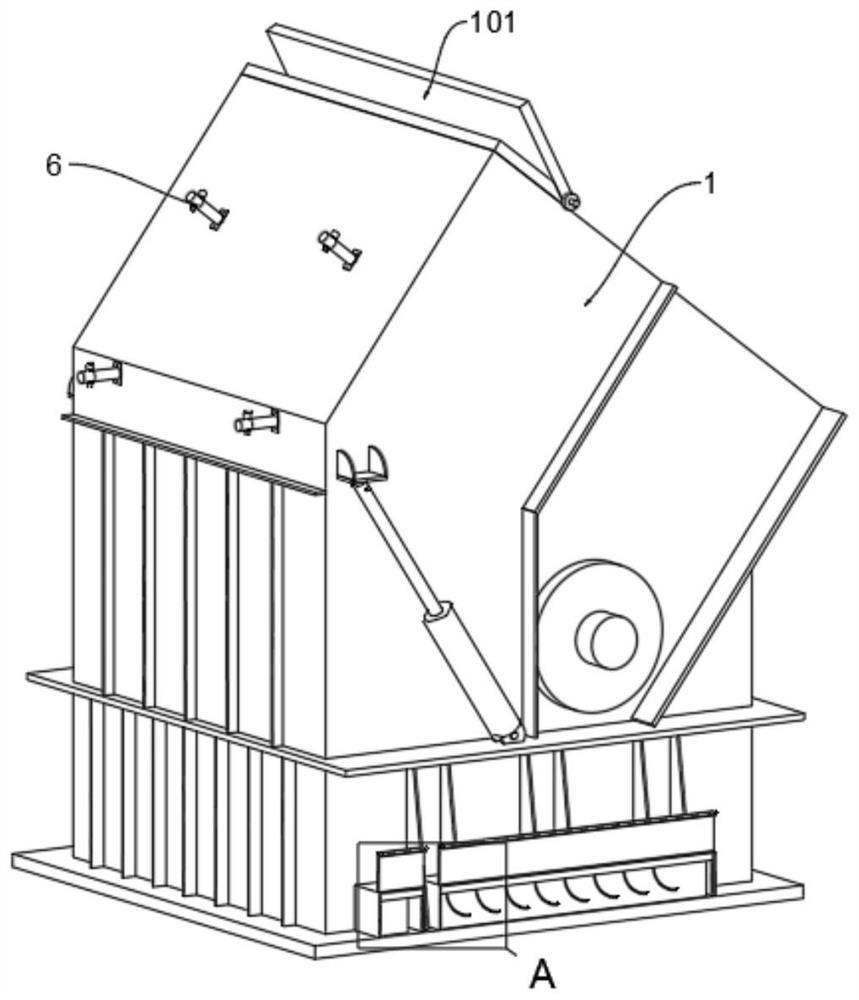

[0034] Example 1: Please refer to Figure 1 to Figure 9 :

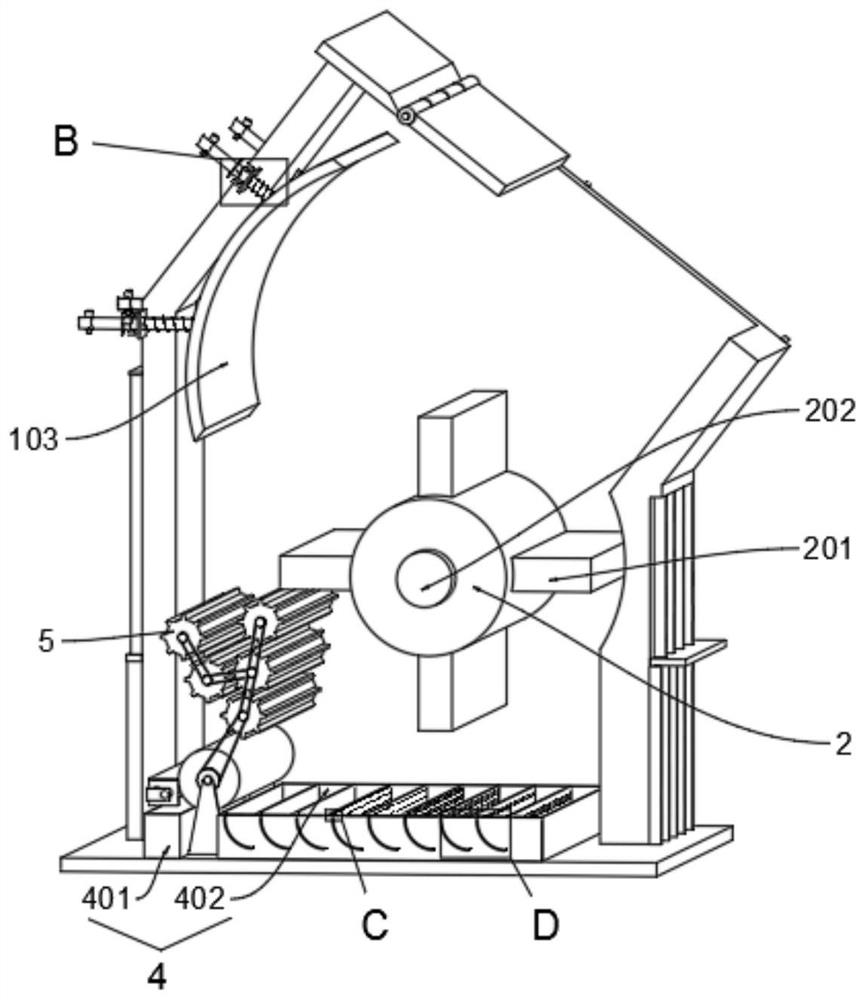

[0035] The present invention proposes a construction waste recycling device based on construction cost control, comprising: a main body 1; a rotor 2 is movably connected inside the main body 1; the outer left bottom surface of the main body 1 is fixedly connected to a sealing box group 3; The box group 4, the gear group 5 and the magnet wheel 7 are installed inside the main body 1, and the upper part of the main body 1 is movably connected to the counterattack plate 103 through the hanger 6; the sealed box group 3 includes a small outer box 31 and a large outer box 32; The box group 4 includes a metal box 401 and a powder box 402, and the left outer end of the metal box 401 is placed inside the small outer box 31, and the left outer end of the powder box 402 is placed inside the large outer box 32; the rear side of the magnet wheel 7, the main body 1. The scraper 8 is fixedly connected internally; the front side of t...

Embodiment 2

[0045] On the basis of the first embodiment, a sealing cover can be added to the top of the main body 1, and an atomizer can be added to the bottom of the sealing cover. 1. The air at the top feed is physicochemically treated to reduce the outward flow of dust and avoid environmental pollution.

[0046] The specific usage and function of this embodiment: In the present invention, when the waste material enters the interior from the top of the main body 1, all the waste material will be dumped above the rotor 2 due to the difference in angle, and will not fall off the front side of the baffle 201. After the rotor 2 rotates, the waste is driven upwards and flipped by the baffle 201 to achieve impact crushing;

[0047] When the magnet wheel 7 rotates with the linkage shaft 701 , the gear set 5 is driven to rotate by the batch machine, so that the scrap particles falling from the rear side of the rotor 2 are further smashed through the gear set 5 , and the metal objects in it are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com