A crushing system and crushing method for harmless separation of swill

A crushing system and technology for separating swill, applied in chemical instruments and methods, solid separation, grain processing, etc., can solve the problems of low utilization rate of crushing energy, low crushing efficiency, easy damage of crushing motor, etc., to speed up processing speed, improve Crushing efficiency, the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

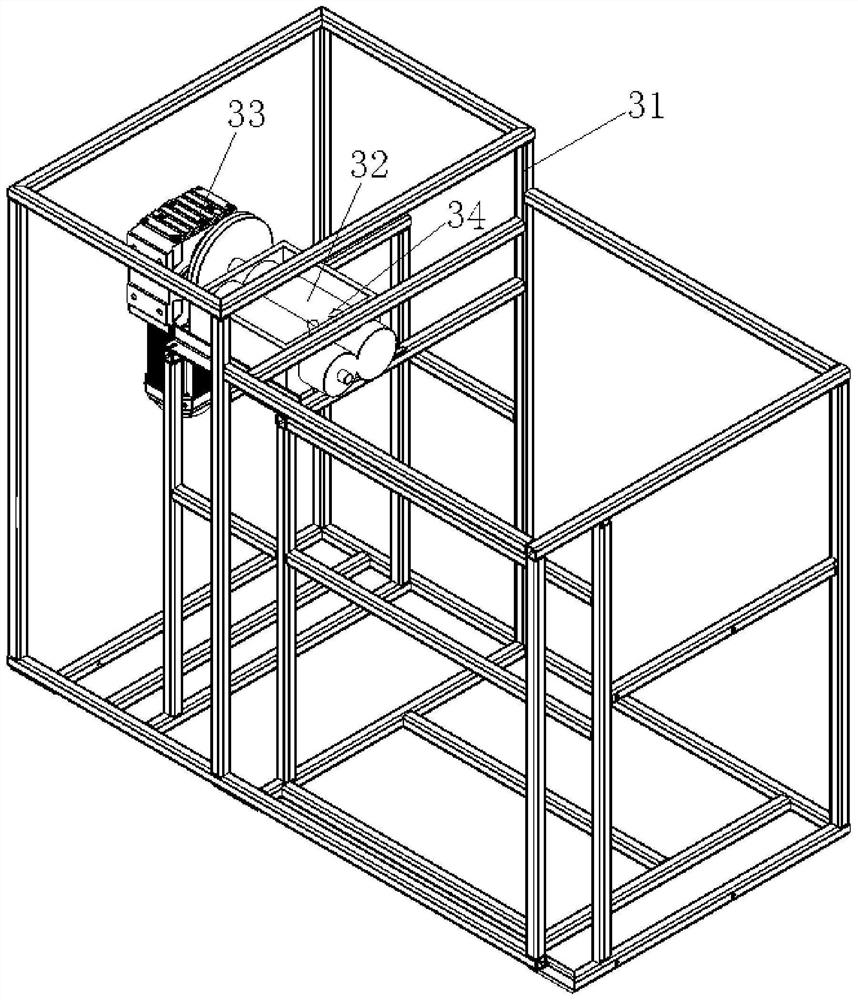

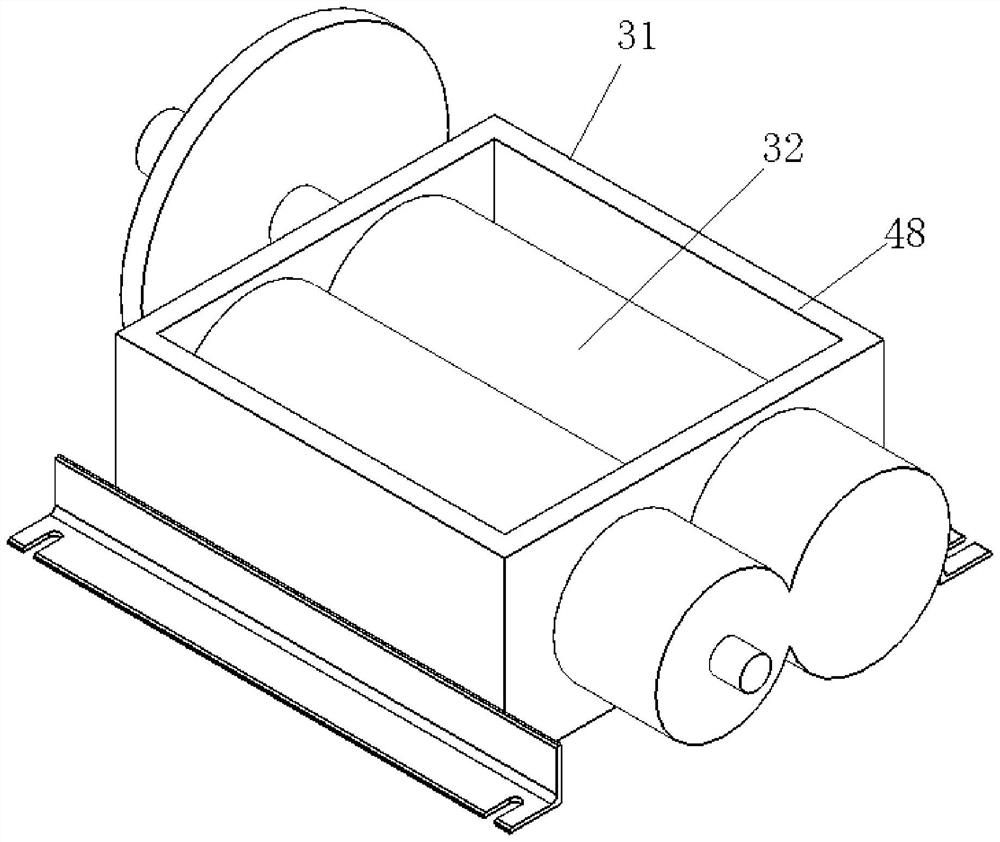

[0080] see figure 1 as well as figure 2 , This embodiment provides a crushing system for harmless separation of swill, the system is used for crushing wet garbage sorted from kitchen swill. The crushing system can be used as a part of the kitchen swill treatment equipment, or it can be set up as an independent system. Wherein, the crushing system includes a frame body 31, a crushing roller 32, a crushing motor 33, a flushing mechanism, a statistics mechanism and a crushing controller.

[0081] The frame body 31 is composed of a plurality of square tubes spliced together, and the splicing method can be welding, clamping, screwing, etc., and of course it can also be integrally formed. The bottom end of the frame body 31 can be provided with structures such as pulleys, so that the frame body 31 can move on the ground. At the same time, the bottom of the frame body 31 can also be provided with a limiting structure, which can limit the movement of the frame body 31 on the gro...

Embodiment 2

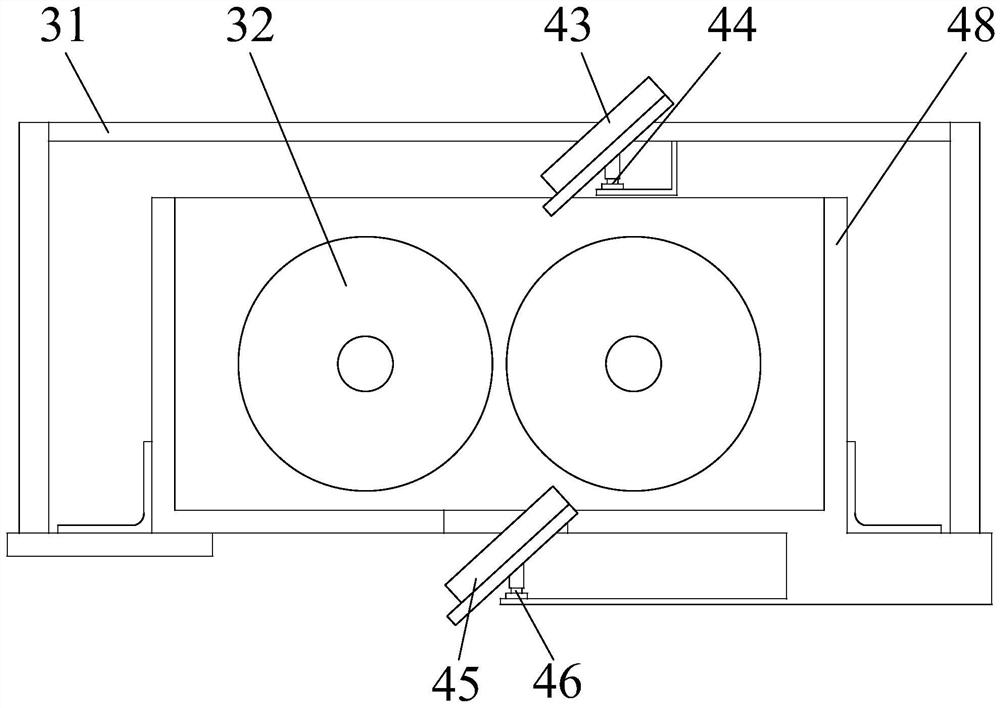

[0090] see image 3 , this embodiment provides a crushing system for harmless separation of swill (the flushing mechanism is not shown in the figure), which refines the statistical mechanism on the basis of embodiment 1.

[0091] The detection component one includes a slide plate one 43 and a load cell one 44 . The first slide plate 43 is installed on the frame body 31 and arranged obliquely, and one end inclined downward faces the preset rolling space. The wet garbage slides from the slide plate one 43 into the preset rolling space. The load cell one 44 is installed between the frame body 31 and the slide plate one 43, and is used for detecting the weight of the wet garbage positioned on the slide plate one 43. In this embodiment, it is assumed that the sliding speed of the wet garbage on the sliding plate 43 is a fixed value, which can be measured in advance, and the sliding length of the wet garbage on the sliding plate 43 is also a fixed value, then the calculation formu...

Embodiment 3

[0102] see Figure 4 , this embodiment provides a crushing system for harmless separation of swill, the flushing mechanism is not shown, and a screening mechanism is added on the basis of embodiment 1. The screening mechanism includes a vibrating motor 36 and a screen one 35 , and may also include a rubber block 30 , a mounting plate 29 and at least two springs 50 . Screen one 35 is installed on the frame body 31 and is located above the two crushing rollers 32 . In this embodiment, one end of the screen one 35 is connected to the same end of all the springs 50 , and the same other end of all the springs 50 is fixed on the frame body 31 , so that the screen one 35 can be indirectly installed on the frame body 31 . The bottom end of the mounting plate 29 is connected with the rubber block 30 , and the rubber block 30 is installed on the frame body 31 . Wherein, the vibrating motor 36 is installed on the frame body 31 through the rubber block 30 and the mounting plate 29, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com