A tempered glass breaker

A tempered glass and breaker technology, applied in vehicle safety arrangement, life-saving equipment, pedestrian/occupant safety arrangement, etc., can solve the problems of high implementation cost, high risk, delayed escape timing, etc., to improve the escape probability and operation safety. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

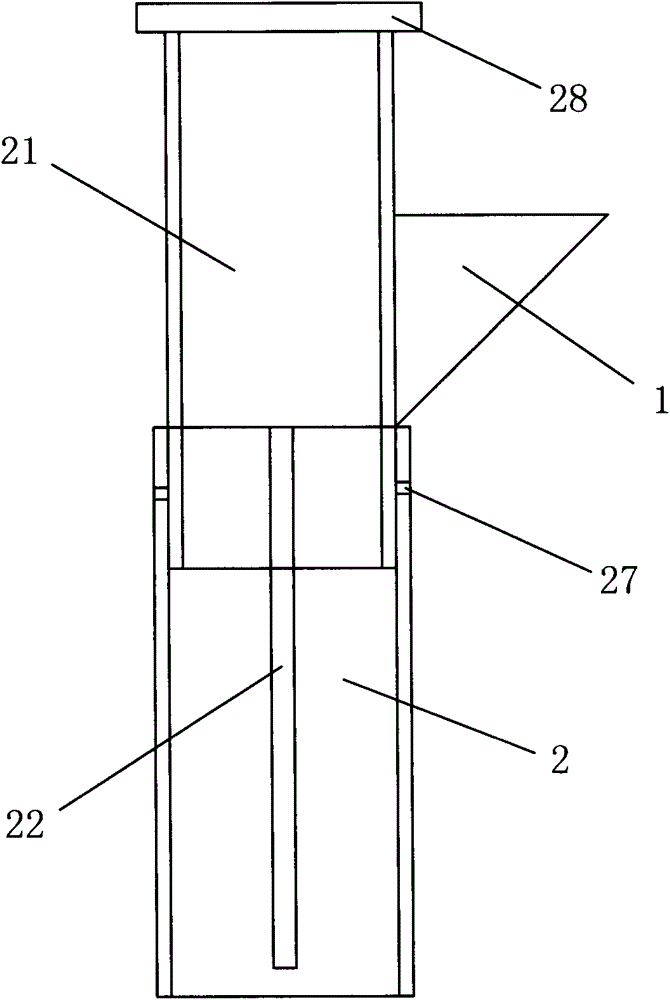

[0016] see figure 1 , as shown in the figure: a tempered glass breaker, including an impact assembly and a knife body 1 installed on the impact assembly, the impact assembly further includes a base 2 and is installed with the base 2 and can be installed in the base 2 The knife handle 21 that moves up and down, the knife body 1 is installed on the knife handle 21; The base 2 is provided with a knife groove 22 for the knife body 1 to move up and down and corresponding to the edge or corner position of the tempered glass, the knife handle 21 One end is placed in the base 2 , the other end of the handle 21 is provided with a handle 28 , and the handle 28 is located outside the base 2 . The base 2 is provided with a screw hole 27 for fixing the base 2

Embodiment 2

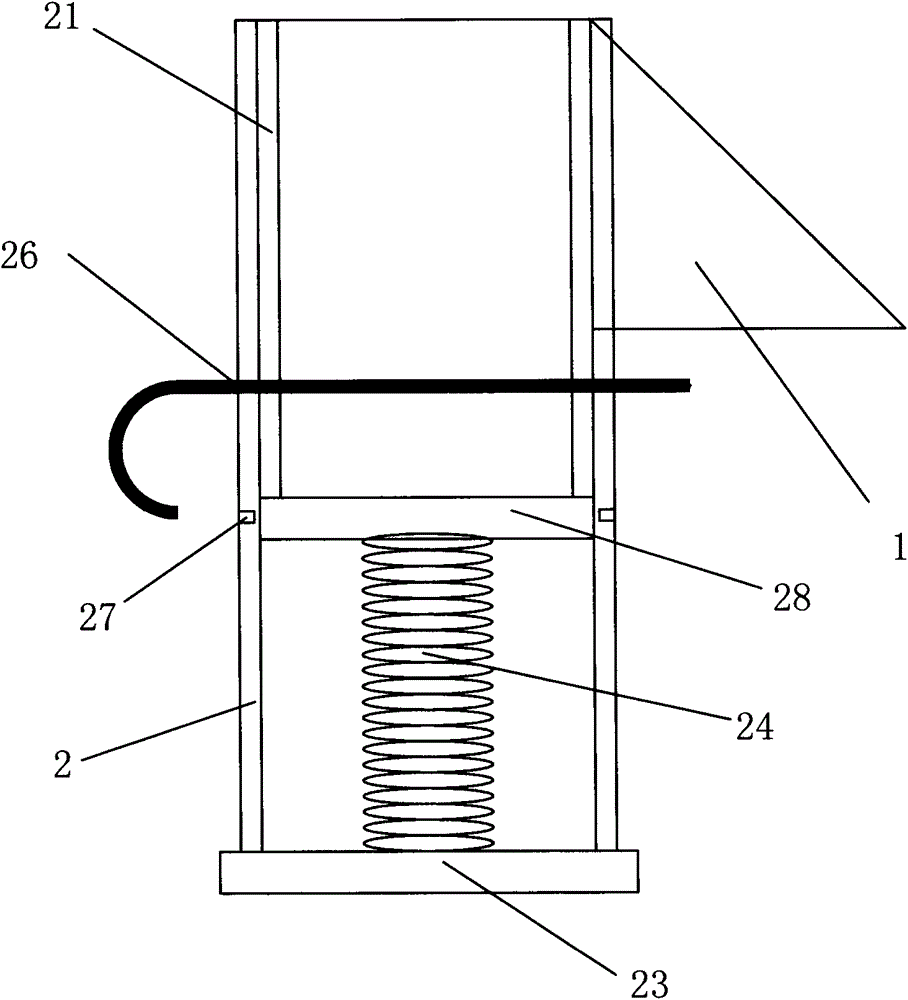

[0018] see figure 2 , as shown in the figure, a tempered glass breaker includes an impact assembly and a knife body 1 installed on the impact assembly. The impact assembly further includes a base 2 and is installed with the base 2 and can be installed in the base 2 The knife handle 21 that moves up and down, the knife body 1 is installed on the knife handle 21; The base 2 is provided with a knife groove 22 for the knife body 1 to move up and down and corresponding to the edge or corner position of the tempered glass, the knife handle 21 One end is placed in the base 2 , and one end of the knife handle 21 placed in the base 2 is provided with a handle 21 . An elastic assembly is also arranged in the base 2, and the elastic assembly further includes a spring seat 23 arranged at the end of the base 2, and a handle 28 arranged on the spring seat 23 and acting on the knife handle 21 arranged in the base 2 The spring 24 also includes a safety latch 26 that penetrates through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com