Automatic separating device and method for domestic garbage

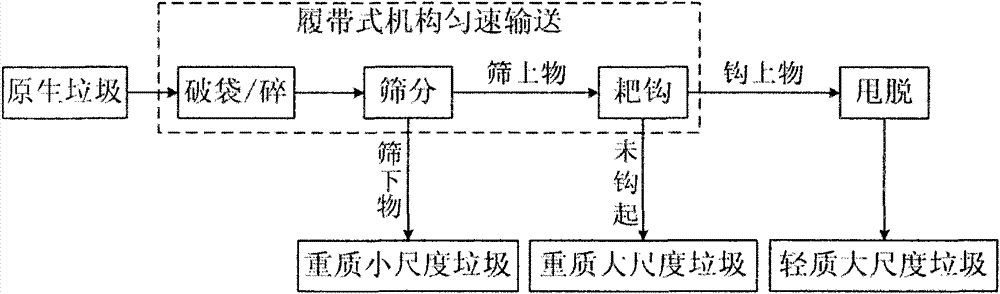

An automatic sorting technology for domestic garbage, applied in the direction of solid separation, solid waste removal, etc., can solve the problems of secondary environmental pollution, large resistance of winnowing system, low sorting efficiency, etc., achieve high degree of automation, no second Secondary pollution, great effect of sorting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

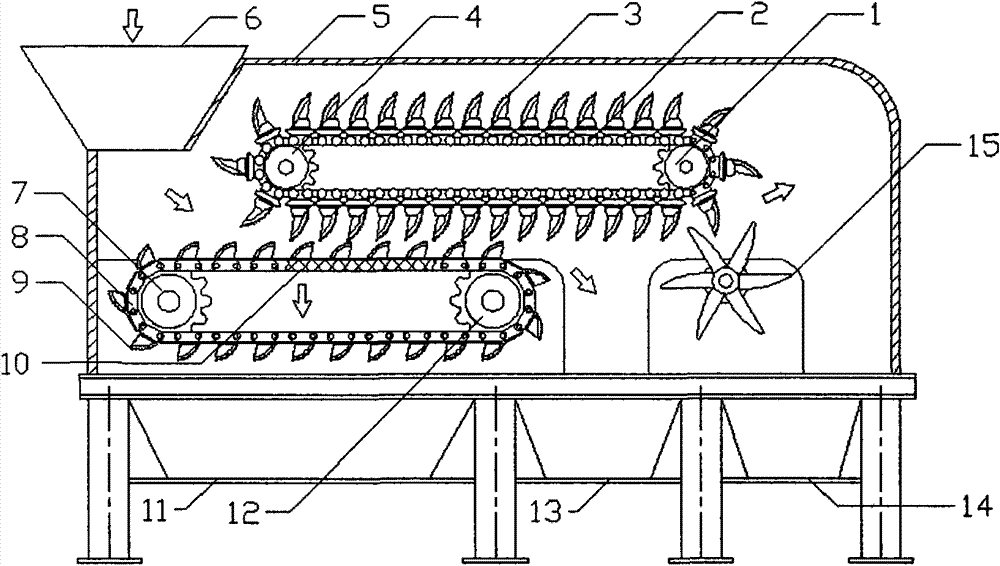

[0030] The domestic garbage automatic sorting equipment of the present invention adopts a differential crawler reciprocating structure. The crawler is divided into upper and lower stages. The upper crawler is composed of upper sprocket 1, upper sprocket 4 and upper chain group 2. The upper rake mechanism 3 is fixed on On the upper chain group 2, the lower track is composed of the lower sprocket 7, the lower sprocket 12, and the lower chain group 8. The lower rake mechanism 9 is fixed on the lower chain group 8; , the end of the upper crawler belt is provided with a throw-off mechanism 15; a material inlet 6 and a third-level discharge opening are provided, that is, the first-level output opening 11, the second-level output opening 13, and the third-level output opening 14. The whole device is fixed on the frame 5, and the upper sprocket 1, the lower sprocket 12 and the throwing off mechanism 15 are respectively driven by three variable frequency motors.

[0031] Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com