Crusher structure for tempered glass

A tempered glass and breaker technology, applied in vehicle safety arrangements, life-saving equipment, pedestrian/occupant safety arrangements, etc., can solve the problems of high risk, increased casualties, delayed escape timing, etc., to achieve operational safety and improve personnel. Escape probability, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

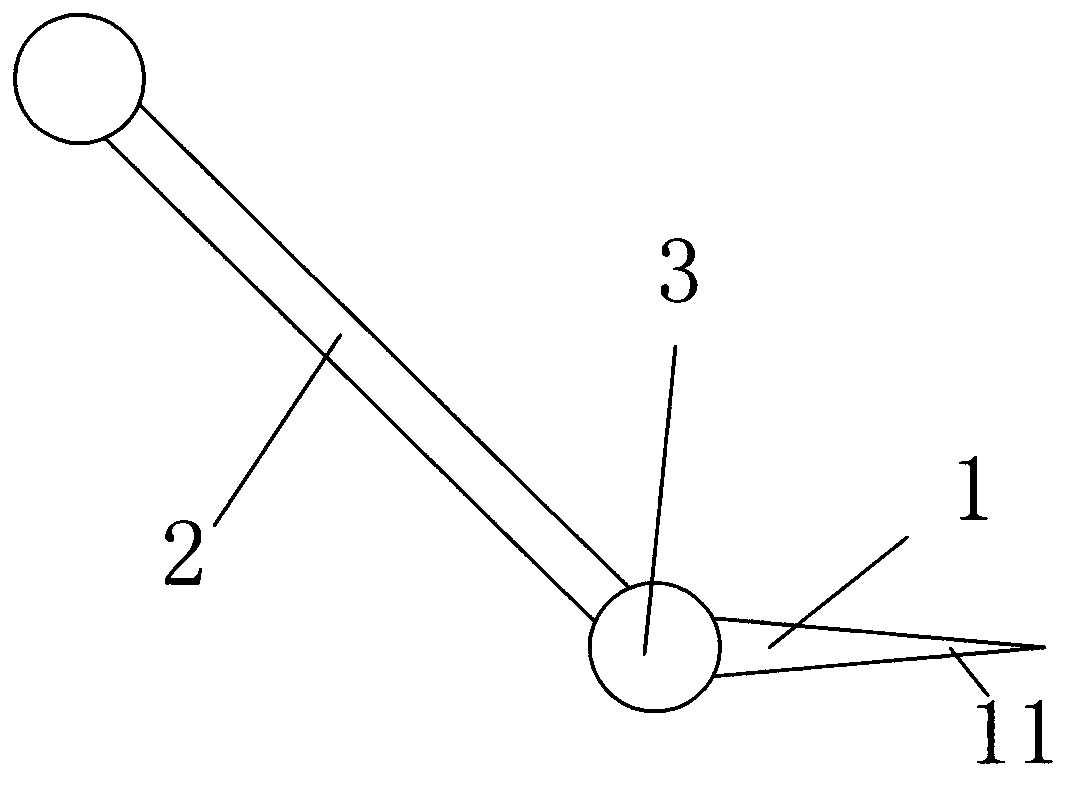

[0016] see figure 1 , as shown in the figure: a tempered glass breaker structure, including an impact assembly and a knife body 1 cooperating with the impact assembly, the impact assembly includes a drive rod 2, the front end of the drive rod 2 is installed in cooperation with the drive shaft 3, The body 1 is installed in cooperation with the drive shaft 3, and the tail end of the drive rod 2 is provided with a handle 8. After the structure of the toughened glass breaker is installed, the position of the tip 11 of the knife body 1 is corresponding to the edges or corners of the toughened glass.

Embodiment 2

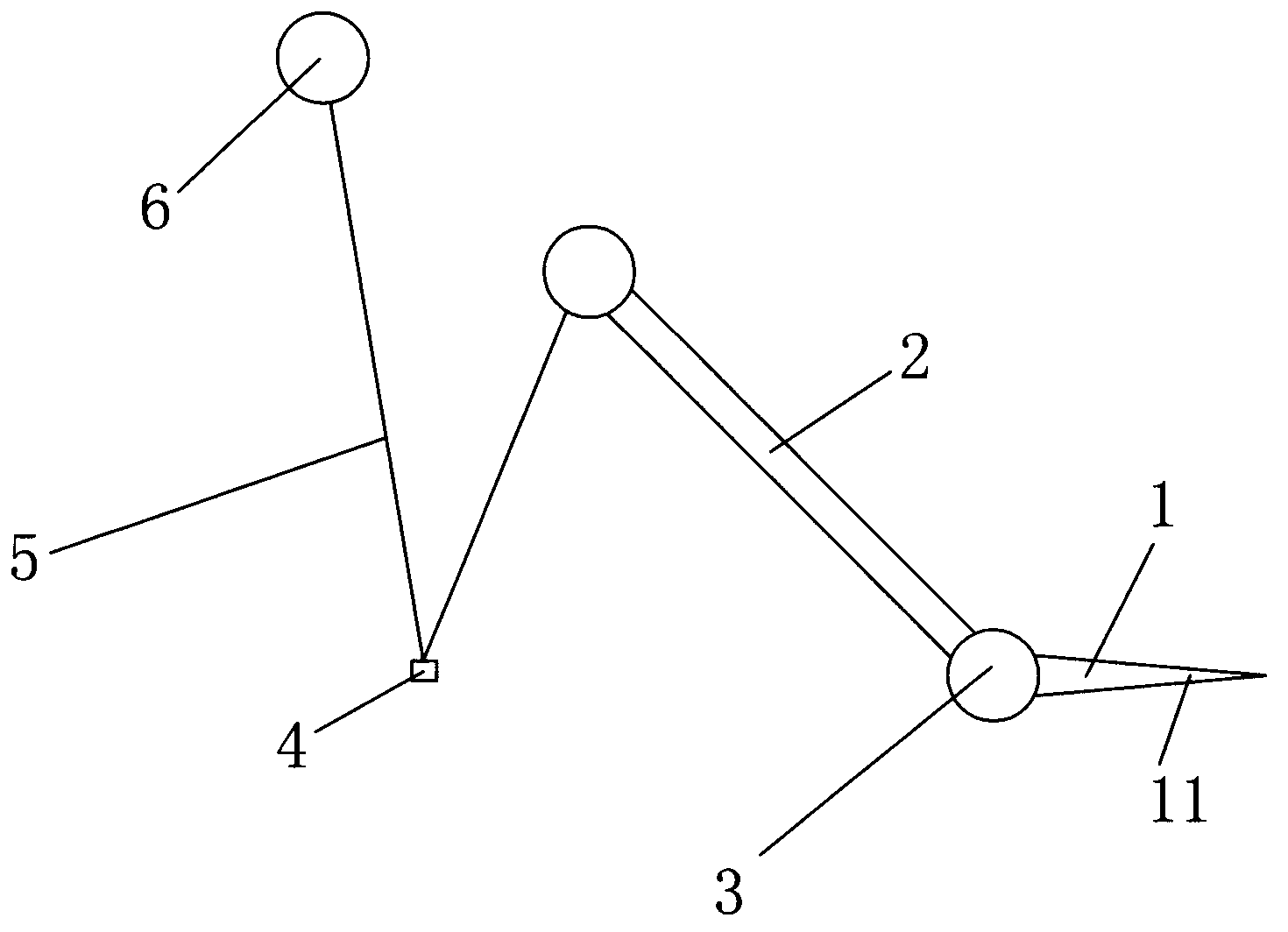

[0018] see figure 2 , as shown in the figure: a tempered glass breaker structure, including an impact assembly and a knife body 1 cooperating with the impact assembly, the impact assembly includes a drive rod 2, the front end of the drive rod 2 is installed in cooperation with the drive shaft 3, The body 1 is installed in cooperation with the drive shaft 3, and the tail end of the drive rod 2 is provided with a traction device. The traction device includes a fixed support point 4, a steel wire rope 5 installed in cooperation with the fixed support point 4, and a pull ring arranged at the front end of the steel wire rope 5. 6. After the structure of the toughened glass breaker is installed, the position of the tip 11 of the knife body 1 is corresponding to the edges or corners of the toughened glass.

Embodiment 3

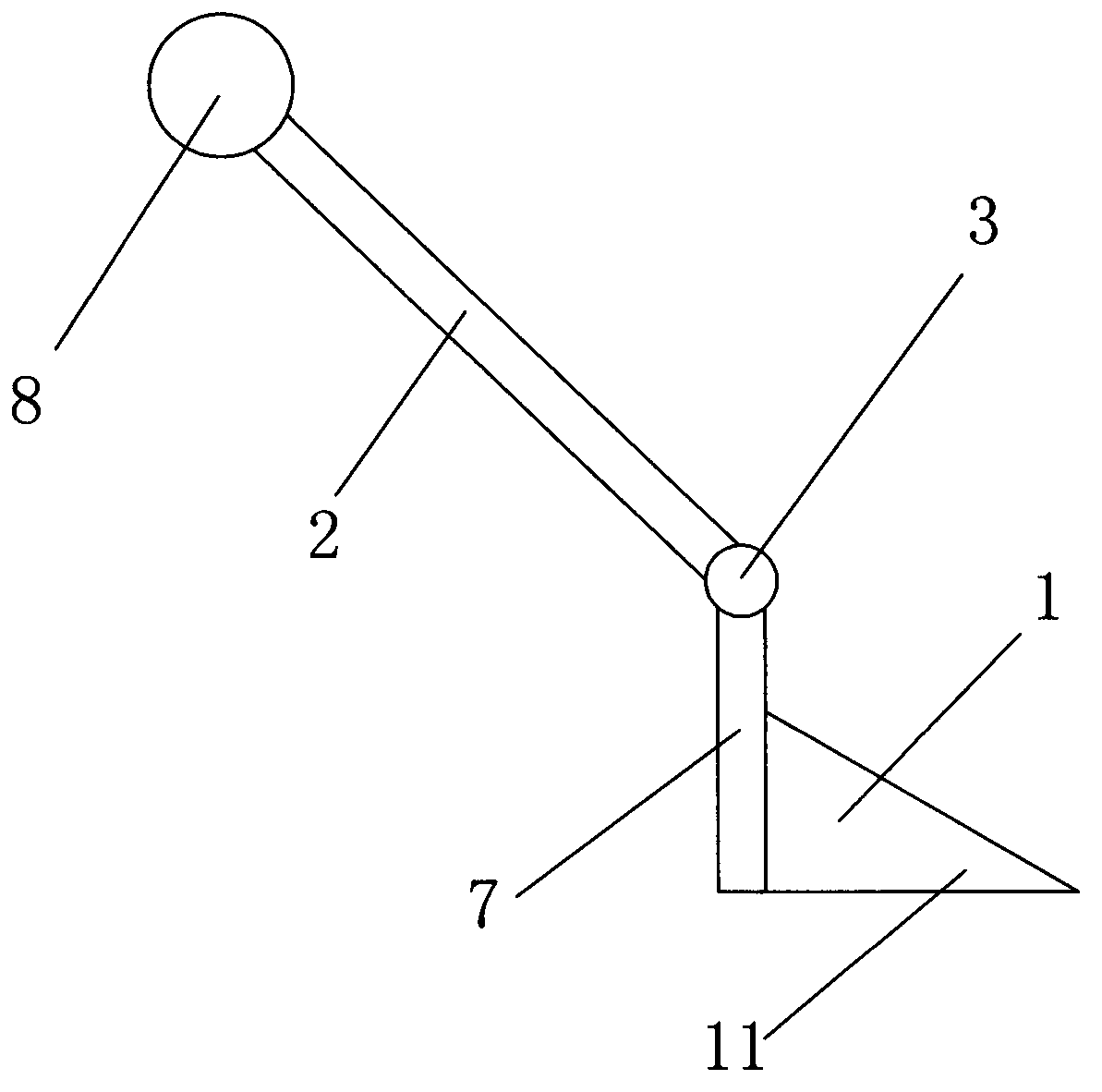

[0020] see image 3 , as shown in the figure: a tempered glass breaker structure, including an impact assembly and a knife body 1 cooperating with the impact assembly, the impact assembly includes a drive rod 2, the front end of the drive rod 2 is installed in cooperation with the drive shaft 3, The body 1 is installed in cooperation with the drive shaft 3, the impact assembly further includes a connecting rod 7, the connecting rod 7 is installed in cooperation with the drive shaft 3, the cutter body 1 is installed in cooperation with the front end of the connecting rod 7, and the tail end of the driving rod 2 is provided with a handle 8 . After the structure of the toughened glass breaker is installed, the position of the tip 11 of the knife body 1 is corresponding to the edges or corners of the toughened glass.

[0021] working principle:

[0022] According to the physical characteristics of tempered glass, the higher the strength of the glass after tempering, the more fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com