Household food garbage processor

A food waste treatment and household technology, applied in grain processing and other directions, can solve the problems of inability to recycle, difficult to handle and store food waste, etc., and achieve the effect of solving easy blockage, quick kitchen cleaning, and optimizing the home environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

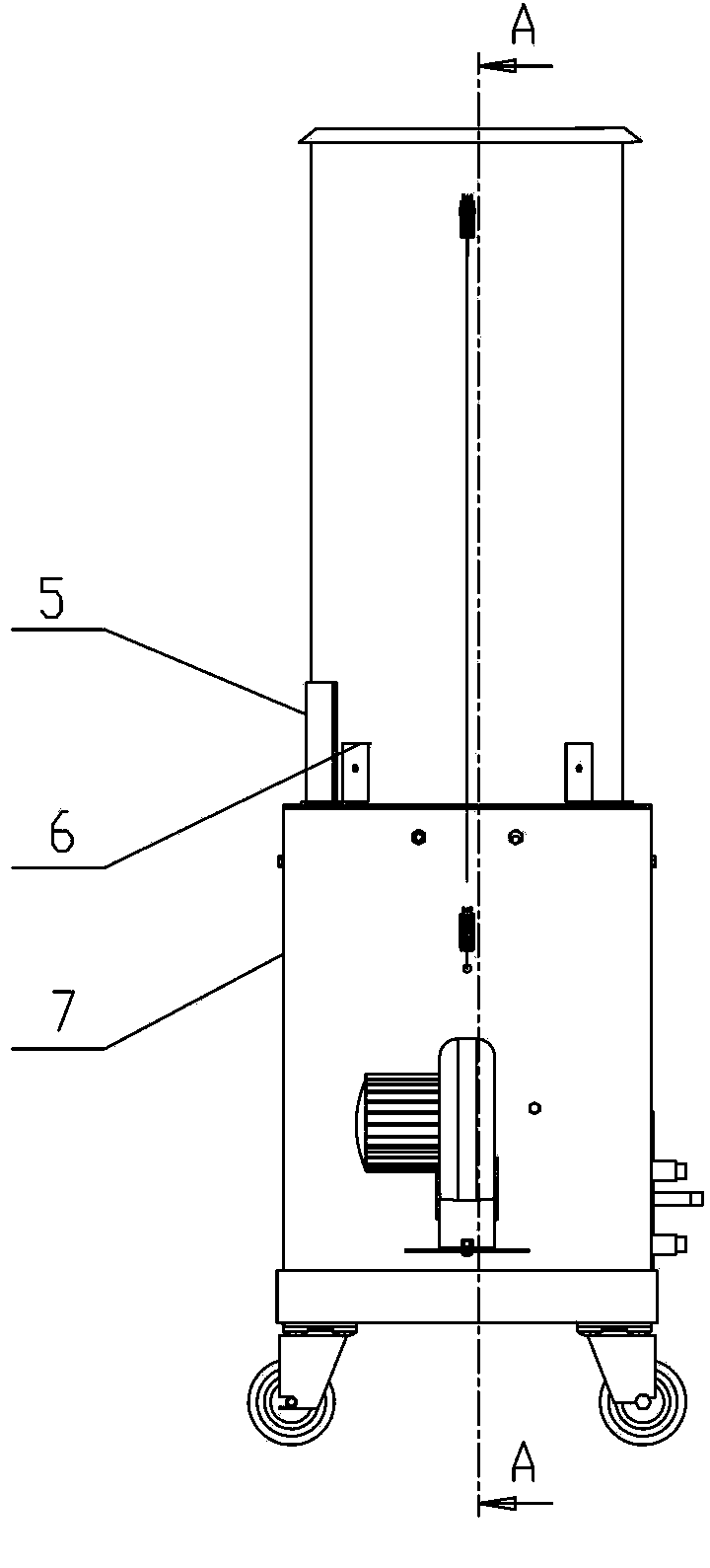

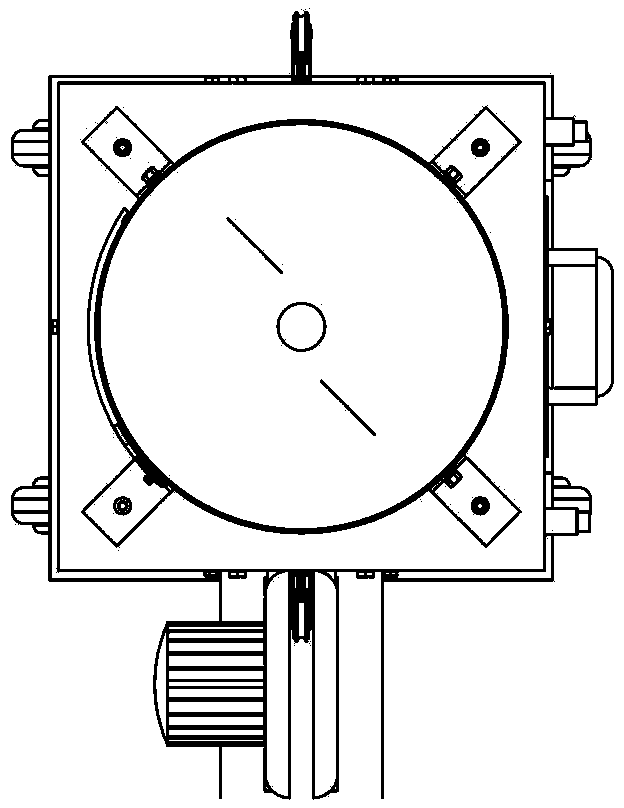

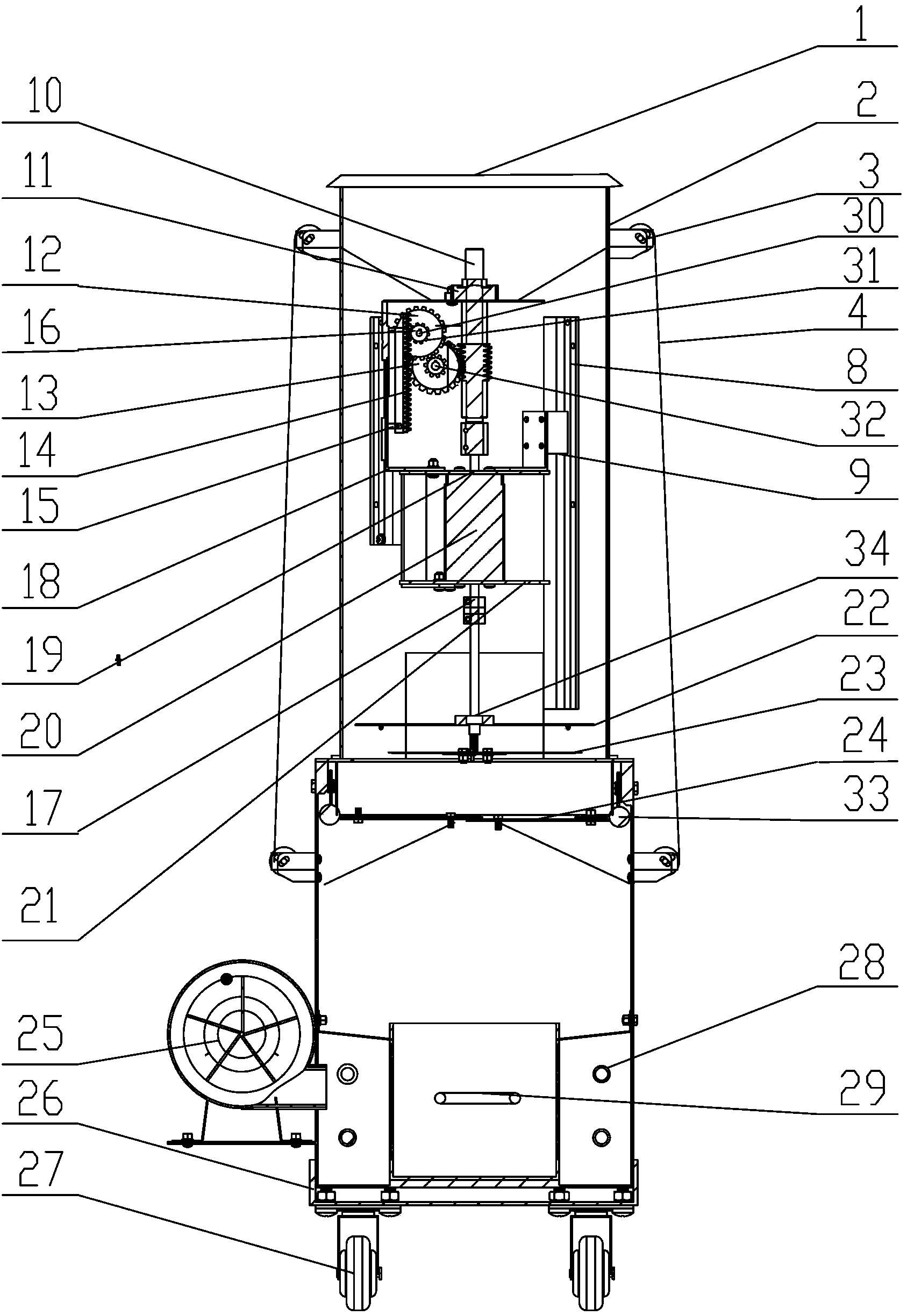

[0027] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

[0028] Figure 1 to image 3 As shown, the food waste disposer is composed of three parts, the top end is a grinding device, and then the bottom is a grinding cavity, the shell of the grinding cavity is a round barrel 2, the shell of the storage room is a square barrel 7, and the shell of the square barrel 7 On the barrel wall, a slide rail 8 is vertically installed every 90 degrees, and the slide rail 8 is evenly arranged, and the slide rail 8 and the barrel wall of the circular barrel 2 are fixed by bolts; , both sides of the upper and lower ends of the rack 14 are drilled, and bolts are inserted into the holes to fix them on the clamp 15. Small holes are installed on both sides of the clamp 15, and these small holes are used to connect the rack 14 with bolts and fix it on the clamp 15. The circular barrel has 2 barrel walls.

[0029] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com