Rake head for rapidly and automatically excavating seabed mud

A technology of automatic excavation and seabed mud, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of unfavorable waterway dredging effects, low loading and unloading efficiency, and inconvenient disassembly, etc., to achieve Avoid the low efficiency of rake suction, reduce the difficulty of crushing, and facilitate the effect of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

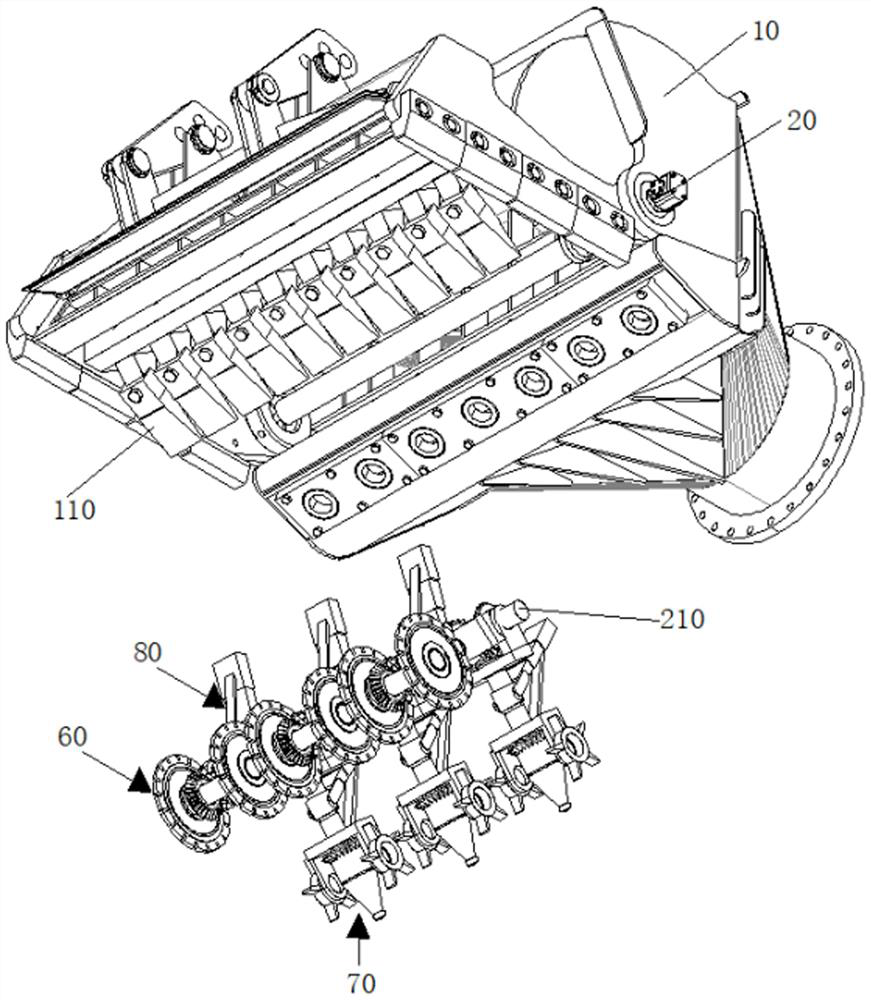

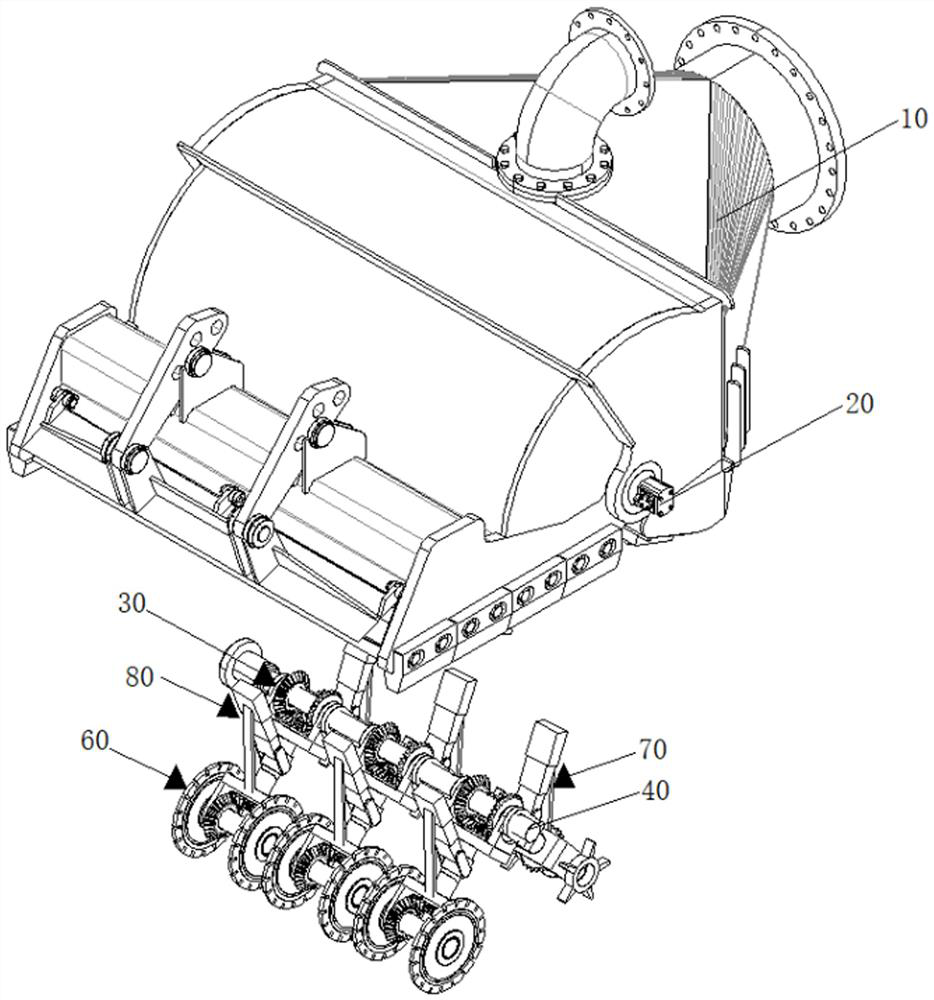

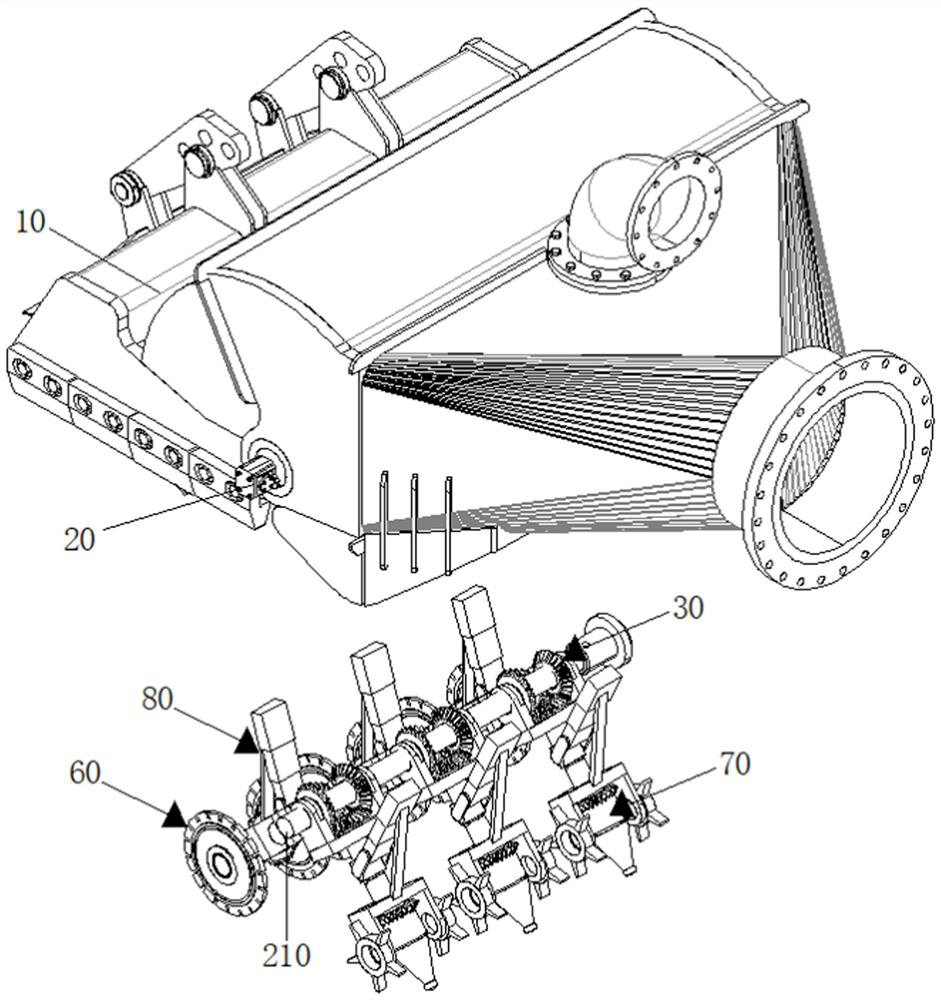

[0046] refer to Figure 1-8 , a rake head for rapid and automatic excavation of seabed mud, comprising a rake head cover 10, rake teeth 110 installed at the front end of the rake head cover 10, an underwater deceleration motor 20 installed on the side wall of the rake head cover 10, and an underwater deceleration motor The transmission shaft 210 at the output end of the 20 and located in the cavity of the rake head cover 10 also includes,

[0047] The first transmission bevel gear set 30 is equidistantly set on the outer wall of the transmission shaft 210, and is used to convert the axial rotation of the transmission shaft 210 into a direction-adjustable radial rotation;

[0048] The transmission rod 40 is installed on the transmission end of the first transmission bevel gear set 30;

[0049] The buffer adjustment mechanism 80 is installed in the middle section of the transmission rod 40, and is used for adjusting the angle between the transmission rod 40 and the transmission...

Embodiment 2

[0062] refer to Figure 5-10 , a rapid and automatic excavation drag head for seabed mud, which is basically the same as that of Embodiment 1. Furthermore, the pre-crushing mechanism 70 is rotatably connected to the third U-shaped frame 710 on the outer wall of the drive shaft 210, and is rotatably connected to the third U-shaped frame. 710 is the third driven bevel gear 720 that is horizontally sectioned and only meshes with one of the first driving bevel gears 310, and the breaking rod 730 that is fixedly installed on the driving end of the third driven bevel gear 720 is installed on the breaking rod 730 away from the third driven bevel gear. The crushing head 740 at one end of the bevel gear 720, the second collar 750 set in the middle of the crushing rod 730, the second connecting piece 760 movably connected to the outer wall of the second collar 750, and the second connecting piece 760 movably connected to the inner wall of the rake head cover 10 and the second link. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com