Farmland residual crop straw treatment equipment

A technology of crop straw and processing equipment, which is applied in the field of agricultural equipment and can solve the problems of large safety and hidden dangers of hanging baskets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

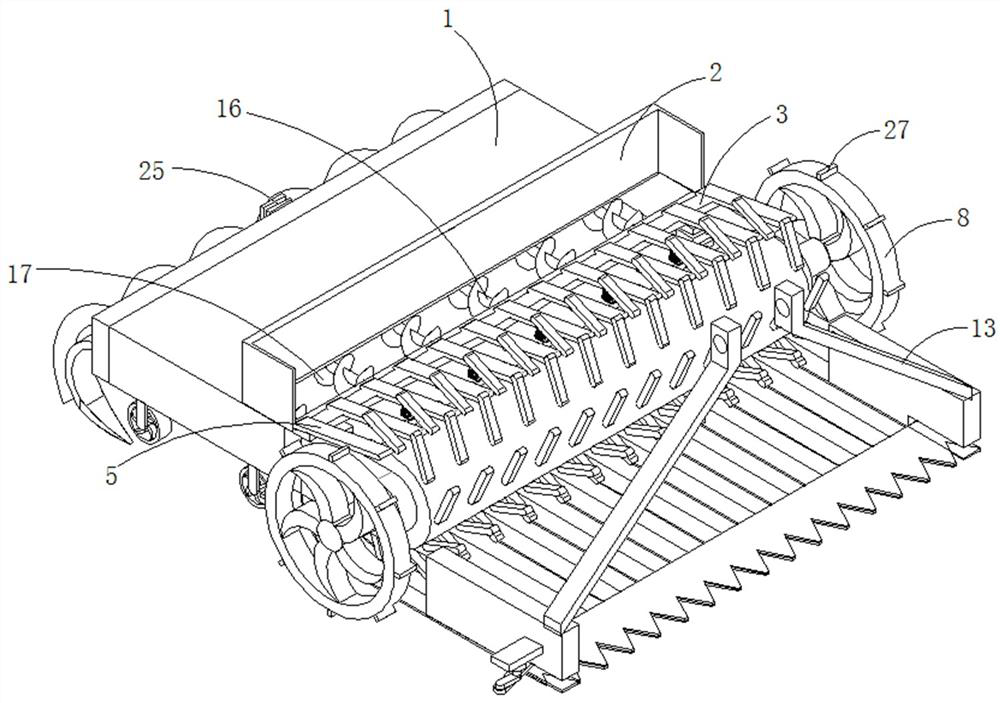

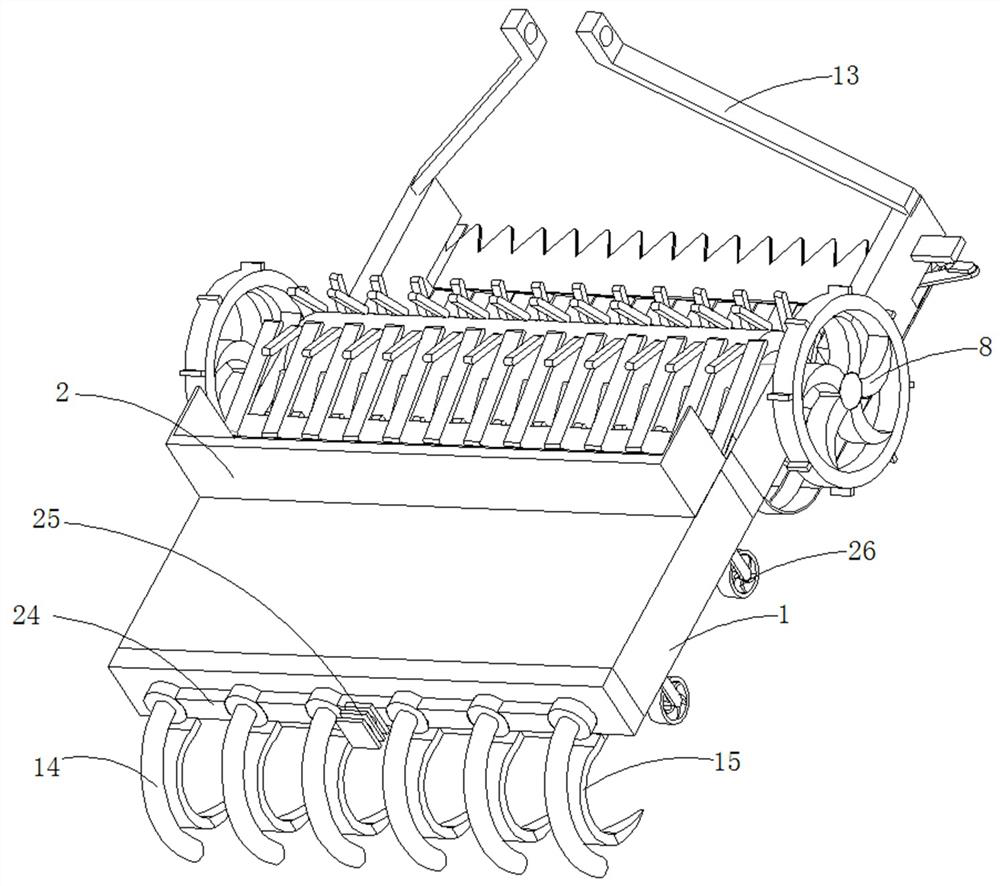

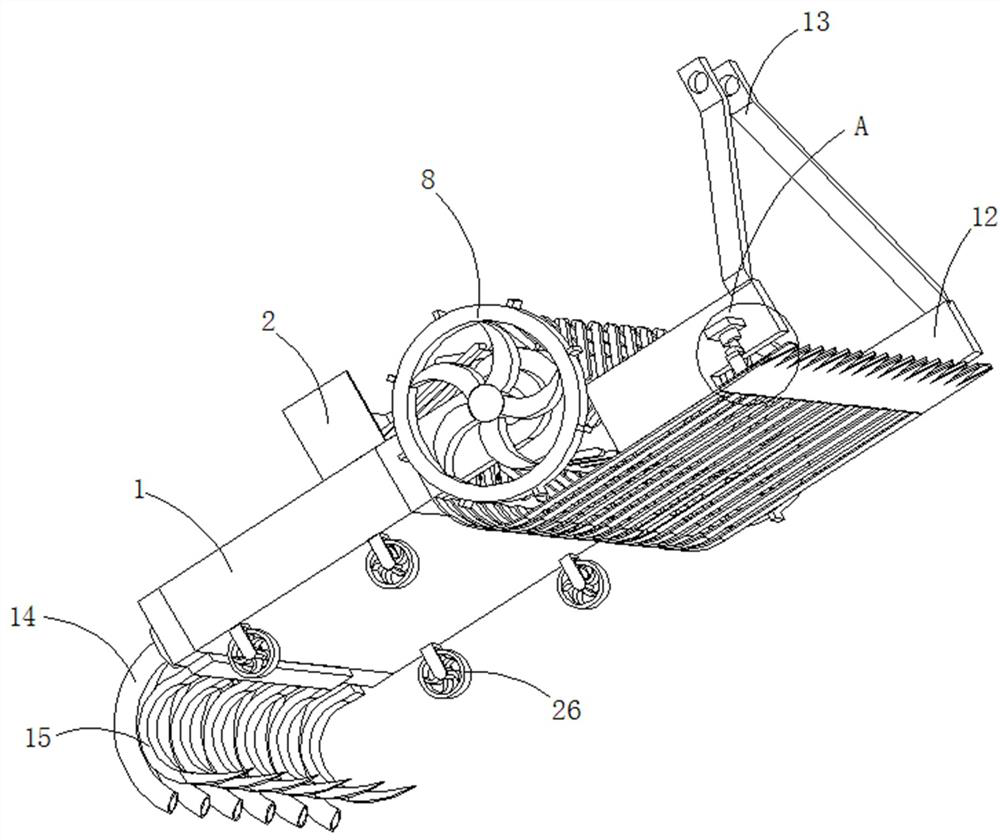

[0038] refer to Figure 1-6, a kind of equipment for processing residual crop straw in farmland, comprising a crushing box 1, a feeding port is opened on the top of the crushing box 1, a U-shaped feeding hopper 2 is arranged at the outlet of the feeding port, and a U-shaped feeding hopper 2 is arranged at the opening of the U-shaped feeding hopper 2 The triangular positioning plate 3 is fixedly connected with the first vibrating motor 4 on the outer wall of the crushing box 1, and the vibrating end of the first vibrating motor 4 is fixedly connected with the triangular positioning plate 3, and the inclined surface of the triangular positioning plate 3 is fixed with evenly distributed The material guide rod 5 and the outer wall of the pulverizing box 1 near the U-shaped feed hopper 2 are fixedly connected with symmetrically distributed connecting plates 6, and the rotating shaft 7 is connected between the connecting plates 6, and the end of the rotating shaft 7 passes through th...

Embodiment 2

[0048] refer to Figure 1-6 , a kind of equipment for processing residual crop straw in farmland, comprising a crushing box 1, a feeding port is opened on the top of the crushing box 1, a U-shaped feeding hopper 2 is arranged at the outlet of the feeding port, and a U-shaped feeding hopper 2 is arranged at the opening of the U-shaped feeding hopper 2 The triangular positioning plate 3 is fixedly connected with the first vibrating motor 4 on the outer wall of the crushing box 1, and the vibrating end of the first vibrating motor 4 is fixedly connected with the triangular positioning plate 3, and the inclined surface of the triangular positioning plate 3 is fixed with evenly distributed The material guide rod 5 and the outer wall of the pulverizing box 1 near the U-shaped feed hopper 2 are fixedly connected with symmetrically distributed connecting plates 6, and the rotating shaft 7 is connected between the connecting plates 6, and the end of the rotating shaft 7 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com