Multi-station ship service winch with single-side centralization operating function

An operating function, multi-station technology, applied in the direction of the clockwork mechanism, hoisting device, etc., can solve the problems of uneven force on the brake belt, damage, cost increase of small and medium-sized ships, etc., and achieve easy disassembly and assembly and simplified structure. , the effect of low maintenance threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

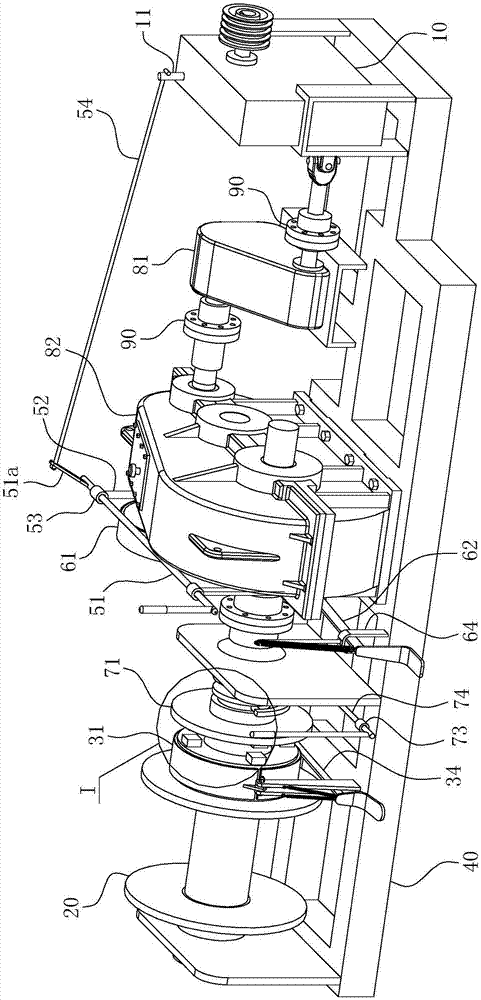

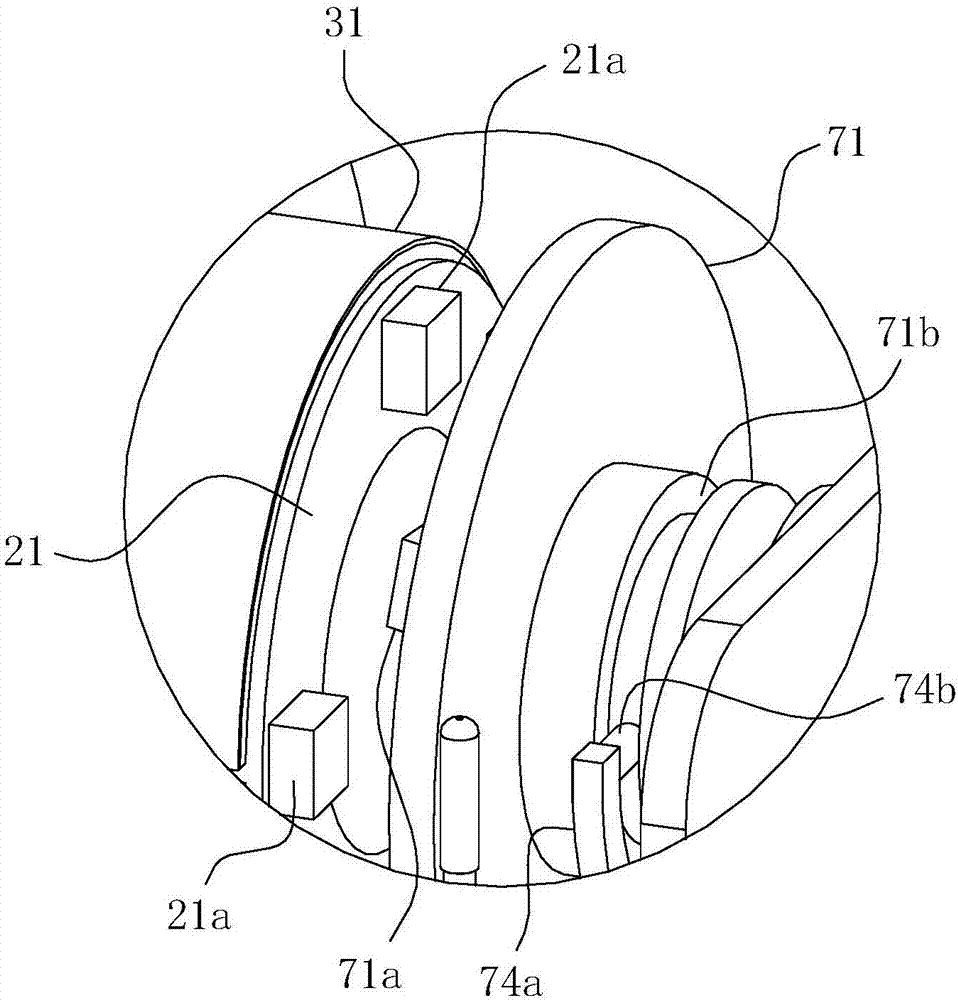

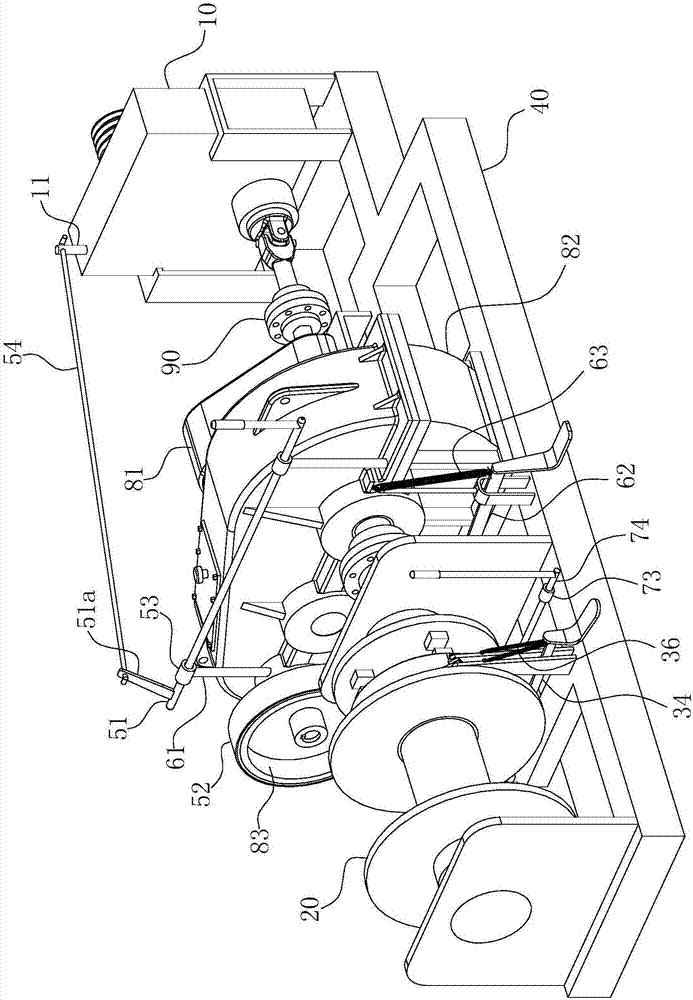

[0041] For ease of understanding, combined here Figure 1-7 , the concrete structure and working mode of the present invention are further described as follows:

[0042] as Figure 1-3 The specific structure shown is an example. The present invention mainly includes a gear box 10, a shaft coupling 90, a first gear box 81, a second gear box 82, a second brake assembly, a gear box 10 manual lever assembly, and a second gear box with a second gear box. The clutch control assembly of the lever 74, the first brake assembly and the winch 20. in:

[0043] 1), gear box and reduction box

[0044] Gear box 10 selects marine gear box for use, and the output shaft of gear box 10 is connected belt pulley. like Figure 1-2 As shown, between the input shaft of the first reduction box 81 and the output shaft of the gearbox 10, between the input shaft of the second reduction box 82 and the output shaft of the first reduction box 81, and between the input shaft of the guide column and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com