Bean stick rapid molding and production equipment

A kind of production equipment and bean stick technology, applied in the field of bean stick rapid prototyping production equipment, can solve the problems of low production efficiency, unfulfilled hygienic requirements, high labor cost, etc., and achieve a large and uniform heating area, strong practicability, and convenient assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

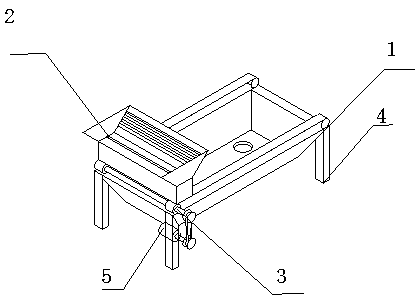

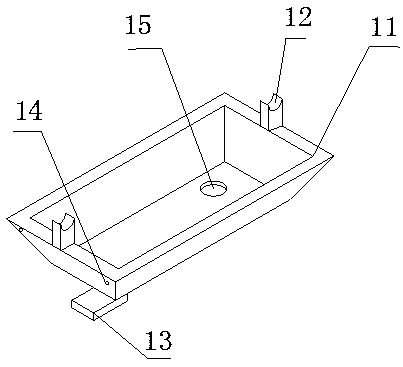

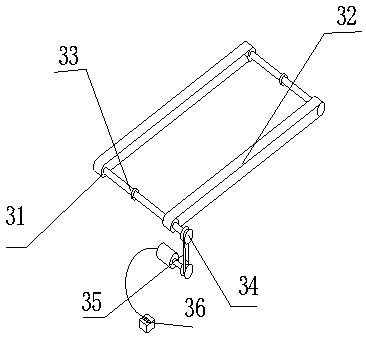

[0025] Specific implementation method: when installing, first install the four sets of supporting legs 4 screws on the lower end of the bean curd pot, weld the transmission rod base 12 on the upper end of the trapezoidal shell 11, install the fixing plate 13 on the bottom end of the trapezoidal shell 11 with bolts, and set up waste Recovery port 15 is at the bottom of trapezoidal shell 11, motor 5 is installed on the fixed plate 13, connects motor 5 and belt pulley 34 with belt 35, bean stick groove 22 is arranged on dustproof shell 21 inside, U-shaped plate 23 is screwed Fix it at the lower end of the dust-proof casing 21, install the micro motor 24 on the left end of the U-shaped plate 23, fix the rolling wheel 1 25 and the rolling wheel 2 26 at the bottom of the U-shaped plate 23, and install the two sets of bearings on the transmission rod 33 At the middle position, transmission wheel 31 is installed on transmission rod 33 two ends, conveyor belt 32 is enclosed within trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com