Hydraulic multistage composite roller crusher

A composite roller and crusher technology, applied in grain processing and other directions, can solve the problems of affecting the service life of the crushing device, damage to the crushing device, and different material sizes, and achieve the effects of high cost performance, improved efficiency and large crushing ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and embodiments.

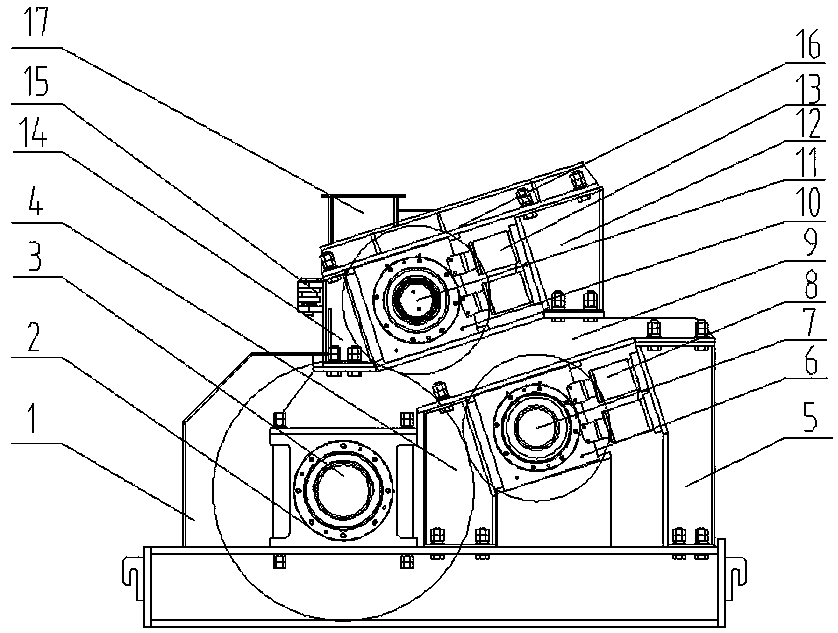

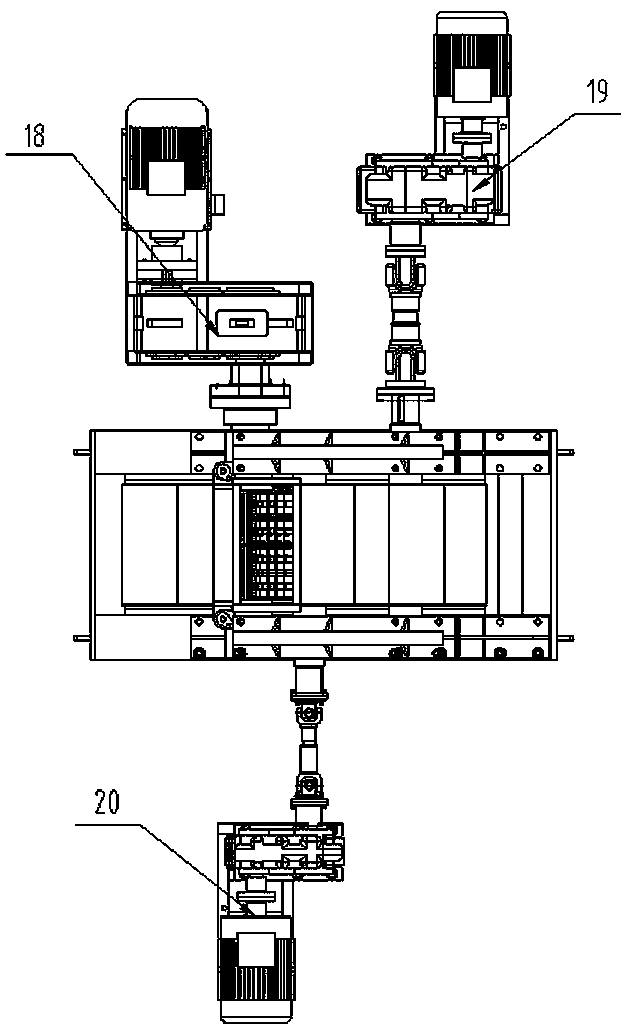

[0015] Such as figure 1 with figure 2 As shown, a hydraulic multi-stage composite roll crusher includes a frame 1, on which a fixed roller 3 is arranged, and the two ends of the fixed roller 3 are fixedly supported on the frame 1 through a fixed bearing seat 2, and the frame The outer side of 1 is provided with an upper pressing plate 16 and a lower pressing plate 9, and the upper pressing plate 16 and the lower pressing plate 9 are obliquely fixedly connected with slideways, and all slideways are inclined from the end far away from the fixed roller 3 to the end close to the fixed roller 3. The bottom is set, the upper movable bearing seat 10 is arranged in the slideway connected with the upper pressing plate 16, and the upper movable bearing seat 10 supports the upper movable roller 11, and the lower movable bearing seat 6 is arranged in the slideway connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com