Ultra-pure dual smelting formula applied to semiconductor valve

A semiconductor and formula technology, applied in the field of ultra-pure double smelting formula, can solve problems such as intensified corrosion holes, easy pollution of pipelines, and rough flow channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

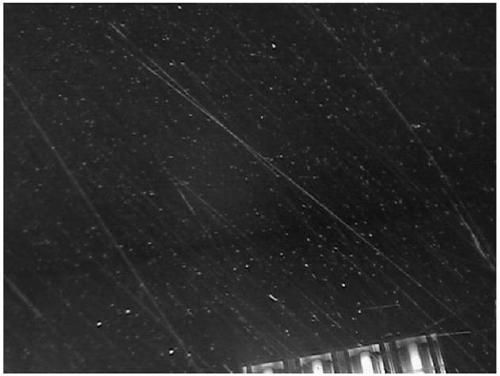

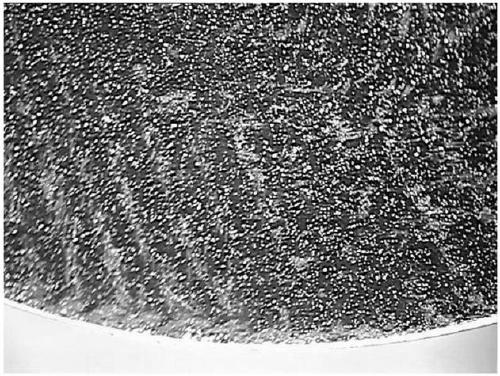

Image

Examples

Embodiment 1

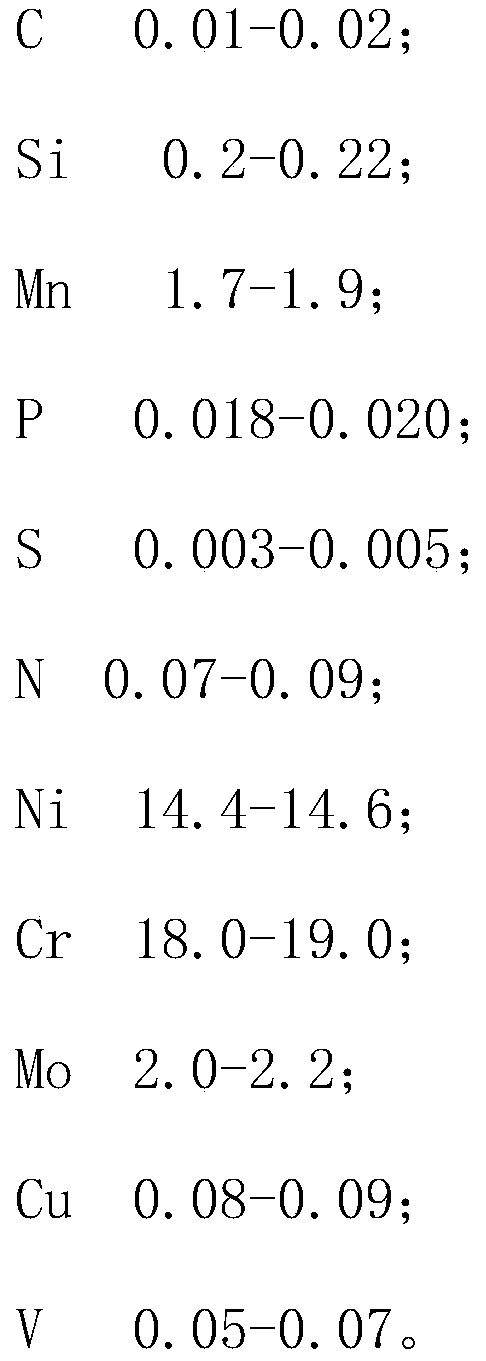

[0036] An ultra-pure dual smelting formula applied to semiconductor valves, including the following elemental formulas by mass ratio:

[0037] C 0.01;

[0038] Si 0.2;

[0039] Mn 1.7;

[0040] P 0.018;

[0041] S 0.003;

[0042] N 0.09;

[0043] Ni 14.6;

[0044] Cr 18.0;

[0045] Mo 2.0;

[0046] Cu 0.08;

[0047] V 0.05.

Embodiment 2

[0049] An ultra-pure dual smelting formula applied to semiconductor valves, including the following elemental formulas by mass ratio:

[0050] C 0.015;

[0051] Si 0.21;

[0052] Mn 1.8;

[0053] P 0.019;

[0054] S 0.004;

[0055] N 0.08;

[0056] Ni 14.5;

[0057] Cr 18.5;

[0058] Mo 2.1;

[0059] Cu 0.085;

[0060] V 0.06.

Embodiment 3

[0062] An ultra-pure dual smelting formula applied to semiconductor valves, including the following elemental formulas by mass ratio:

[0063] C 0.02;

[0064] Si 0.22;

[0065] Mn 1.9;

[0066] P 0.020;

[0067] S 0.005;

[0068] N 0.09;

[0069] Ni 14.6;

[0070] Cr 19.0;

[0071] Mo 2.3;

[0072] Cu 0.09;

[0073] V 0.07.

[0074] The following table 1 is compared with other company's formulations.

[0075]

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com