A pyroelectric infrared detector sensitive unit and its manufacturing method

A pyroelectric infrared and sensitive unit technology, which is applied in the direction of electrical components, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of difficult to prepare high-performance pyroelectric infrared detectors, weak absorption layer adhesion, Narrow absorption band and other problems, to achieve the effect of excellent heat transfer performance, small specific heat capacity and wide absorption band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

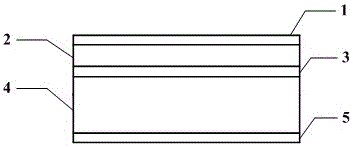

[0044] (1) Lithium tantalate (LiTaO 3 ) crystal surface treatment

[0045] 1) Cleaning LiTaO 3 wafer. to LiTaO 3 Surface A (first surface) and surface B (second surface) of the wafer are mechanically thinned and polished and chemically etched. Wet etching LiTaO 3 Wafer to remove defects and damage caused by thinning polishing.

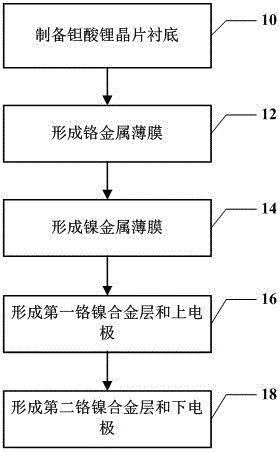

[0046] (2) Depositing an infrared absorbing layer and etching to form an electrode structure

[0047] 2) Clean LiTaO 3 The wafer is photolithographically patterned on the A side (that is, the pattern described above is formed).

[0048] 3) In LiTaO 3 Chromium metal film and nickel metal film are deposited on the A side of the wafer by magnetron sputtering process. Float cleaning. Among them, the thickness of the chromium metal film is 15nm, and the thickness of the nickel metal film is 60nm.

[0049] 4) In LiTaO 3 Photolithographic patterning of the A side of the wafer.

[0050] 5) In LiTaO 3 The magnetron sputtering process was used to d...

example 2

[0057] (1) LiTaO 3 surface treatment

[0058] 1) Cleaning LiTaO 3 wafer. to LiTaO 3 Surface A (first surface) and surface B (second surface) of the wafer are mechanically thinned and polished and chemically etched. Wet etching LiTaO 3 Wafer to remove defects and damage caused by thinning polishing.

[0059] (2) Deposit the infrared absorbing layer and etch to form the electrode structure

[0060] 2) Clean LiTaO 3 The wafer is photolithographically patterned on the A side.

[0061] 3) In LiTaO 3 Chromium metal film and nickel metal film are deposited on the A side of the wafer by magnetron sputtering process, and the float cleaning is carried out. Among them, the thickness of the chromium metal film is 20nm, and the thickness of the nickel metal film is 65nm.

[0062] 4) In LiTaO 3 Photolithographic patterning of the A side of the wafer.

[0063] 5) In LiTaO 3 The chromium-nickel alloy absorption layer was deposited on the A side of the wafer by thermal evaporation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com