On-instant-heating quick heat generating wire

A heating wire, instant heating technology, applied in the direction of the heating element shape, etc., can solve the problems of large safety hazards, slow heating wire heating, etc., to achieve the effects of reducing energy consumption, reducing health effects, and shortening heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

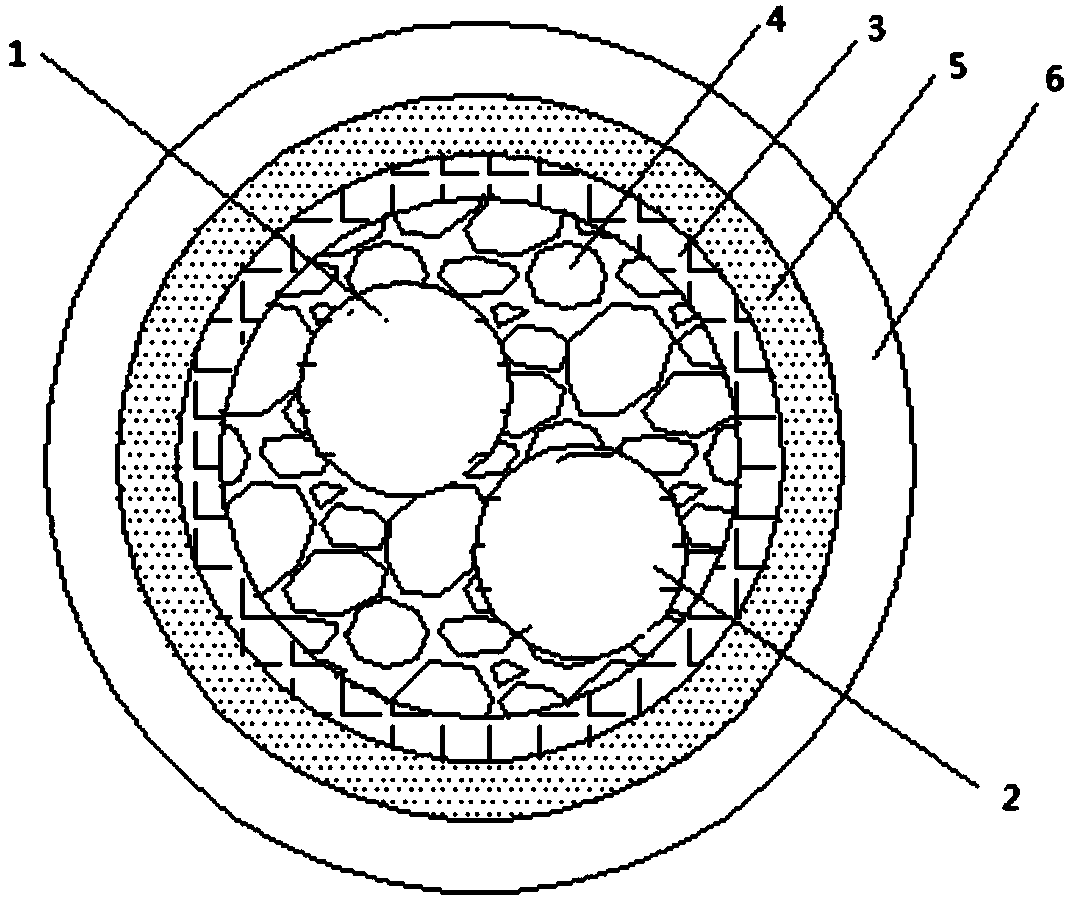

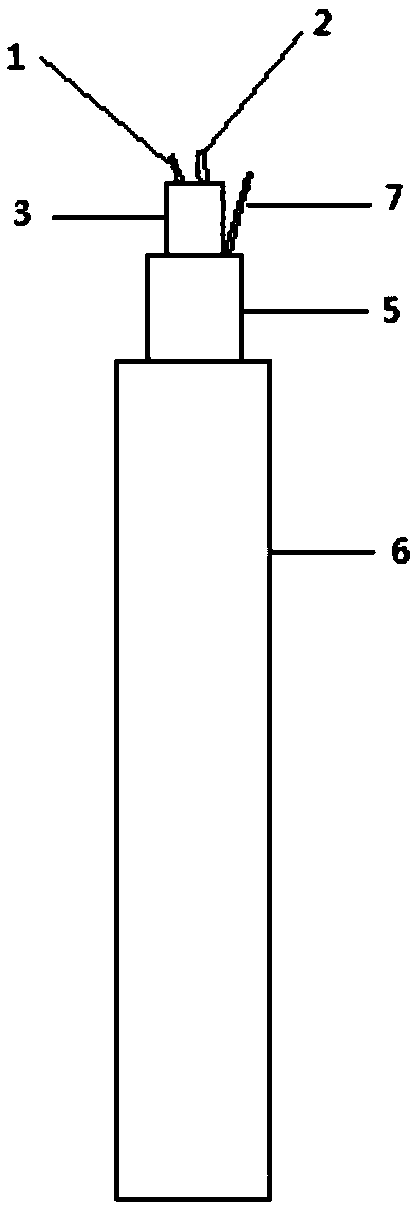

[0032] Embodiment 1 provides a kind of instant heating type rapid heating wire, such as figure 1 and figure 2 As shown, the schematic diagram of the section structure of the heating wire and the schematic diagram of the overall structure, including the heating wire 1, the insulating layer 3, the grounding wire, the shielding layer 5 and the sheath 6, the heating wire 1 is divided into a cold wire 8 and a hot wire 9, and the cold wire 8 is plated Tin-copper wire, the hot wire 9 is chromium-nickel alloy, the weight percentage in the chromium-nickel alloy is chromium: nickel = 3:7, the cold wire 8 and the hot wire 9 are connected by twisting, and the pitch ratio of the twisting is not less than 12; The outer layer of the heating wire 1 is also provided with a power cord 2, the power cord 2 and the heating wire 1 are arranged in parallel in the insulating layer 3, the insulating layer is arranged in the shielding layer, the shielding layer is arranged inside the sheath, the power...

Embodiment 2

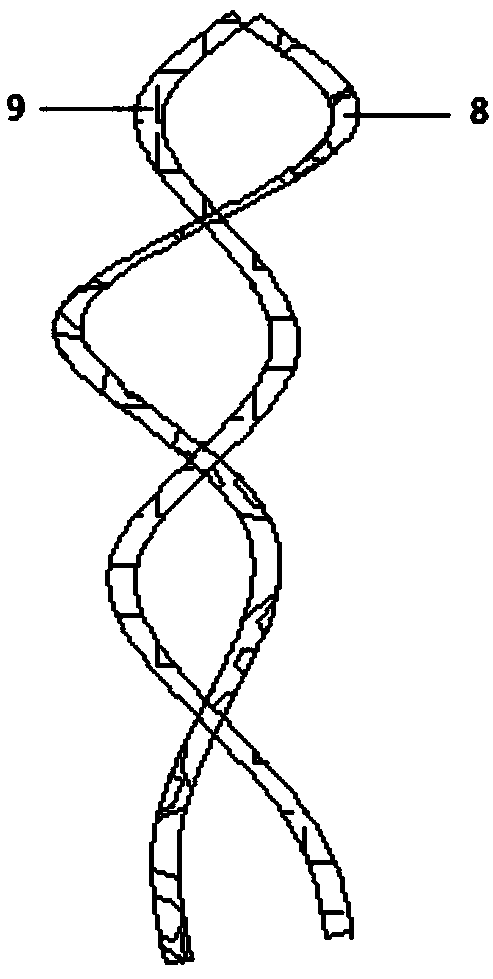

[0037] Embodiment 2 provides a kind of energized instant heating type rapid heating wire, including heating wire 1, insulating layer 3, grounding wire, shielding layer 5 and sheath 6, such as image 3Shown is the structural diagram of the hot wire. The heating wire 1 is divided into a cold wire 8 and a hot wire 9. The cold wire 8 is a tinned copper wire, and the hot wire 9 is a chromium-nickel alloy. The weight percentage in the chromium-nickel alloy is chromium: nickel = 3 : 7, the cold wire 8 and the hot wire 9 are connected by twisting, and the pitch ratio of the twisting is not less than 12; the outer layer of the heating wire 1 is also provided with a power wire 2, and the power wire 2 and the heating wire 1 are arranged in parallel on an insulating In layer 3, a leakage protection switch is provided at the interface between the power line 2 and the power supply. When the heating wire is damaged, the shielding layer 5 will conduct electricity, and the leakage protection sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com