Metal part surface repair material and metal part surface processing technology and application

A technology for metal parts and surface repair, applied in the direction of metal material coating process, coating, fusion spraying, etc. problems, to achieve the effects of excellent self-melting performance, excellent high temperature wear resistance and corrosion resistance, prolonging service life and maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

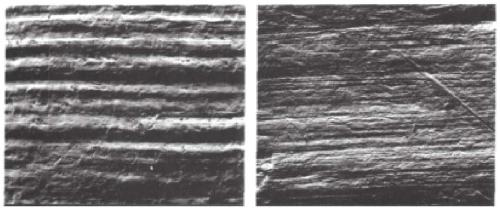

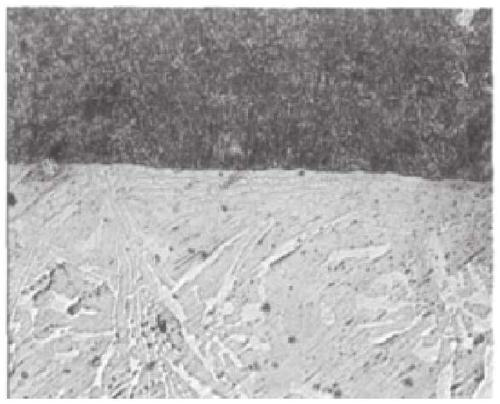

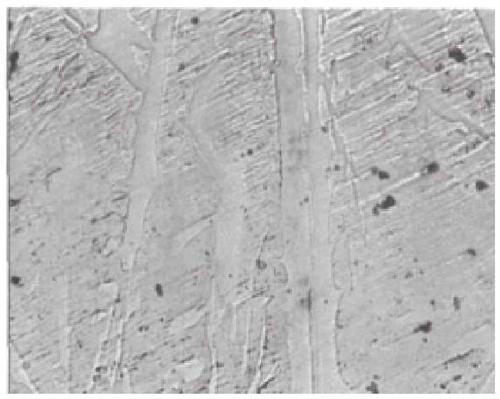

Image

Examples

no. 1 example

[0033] A surface treatment process for metal parts, comprising the steps of:

[0034] (1) Pretreatment: first use a degreasing agent to remove oil stains and other pollutants on the surface of the workpiece; then use 20 mesh white corundum to sandblast and polish the surface to a roughness of 90um; remove scale, rust and other attachments on the surface of the workpiece to achieve surface cleanliness Sa3.0; After the grinding is completed, repair the surface of the workpiece without visible grease, dirt, scale, rust and other attachments, so that the metal matrix of the part is exposed and ready for use;

[0035](2) Flame thermal spraying: The following powder alloys are used as repair materials for spraying (particle size is 30-100 μm): by mass percentage, Cr 16%, Si 4%, B 4%, Cu 3%, Mo 3%, Fe 2.5%, C 0.5%, WC 11%, Ni balance. The specific process and parameters of flame spraying: first heat the workpiece to make the surface temperature of the workpiece reach 120°C; then use...

no. 2 example

[0043] A surface treatment process for metal parts, comprising the steps of:

[0044] (1) Pretreatment: first use degreaser to remove oil stains and other pollutants on the surface of the workpiece; then use 20 mesh white corundum to sandblast and polish the surface to a roughness of 125um; remove scale, rust and other attachments on the surface of the workpiece to achieve surface cleanliness Sa3.0; After the grinding is completed, repair the surface of the workpiece without visible grease, dirt, scale, rust and other attachments, so that the metal matrix of the part is exposed and ready for use;

[0045] (2) Flame thermal spraying: The following powder alloys are used as repairing materials for spraying (particle size is 30-100 μm): by mass percentage, Cr: 10%, Si: 1%, B: 10%, Cu: 10%, Mo: 1%, Fe: 5%, C: 3%, WC: 20%, Ni balance. The specific process and parameters of flame spraying: first heat the workpiece to make the surface temperature of the workpiece reach 100°C; then u...

no. 3 example

[0047] A surface treatment process for metal parts, comprising the steps of:

[0048] (1) Pretreatment: first use degreaser to remove oil stains and other pollutants on the surface of the workpiece; then use 20 mesh white corundum to sandblast and polish the surface to a roughness of 75um; remove scale, rust and other attachments on the surface of the workpiece to achieve surface cleanliness Sa3.0; After the grinding is completed, repair the surface of the workpiece without visible grease, dirt, scale, rust and other attachments, so that the metal matrix of the part is exposed and ready for use;

[0049] (2) Flame thermal spraying: The following powder alloys are used as repair materials for spraying (particle size is 30-100 μm): by mass percentage, Cr 20%, Si 10%, B 1%, Cu 1%, Mo 10%, WC 1%, Ni balance. The specific process and parameters of flame spraying: first heat the workpiece to make the surface temperature of the workpiece reach 80°C; then use the oxygen-propane high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com