Tool for manufacturing water-cooling bearing pedestal blank model by one-time molding

A water-cooled bearing seat, white mold technology, applied in casting and molding equipment and other directions, can solve the problems of easily consumable spare parts, high labor intensity, high work intensity, etc., and achieve the effect of ensuring safety, flexibility and reliability, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

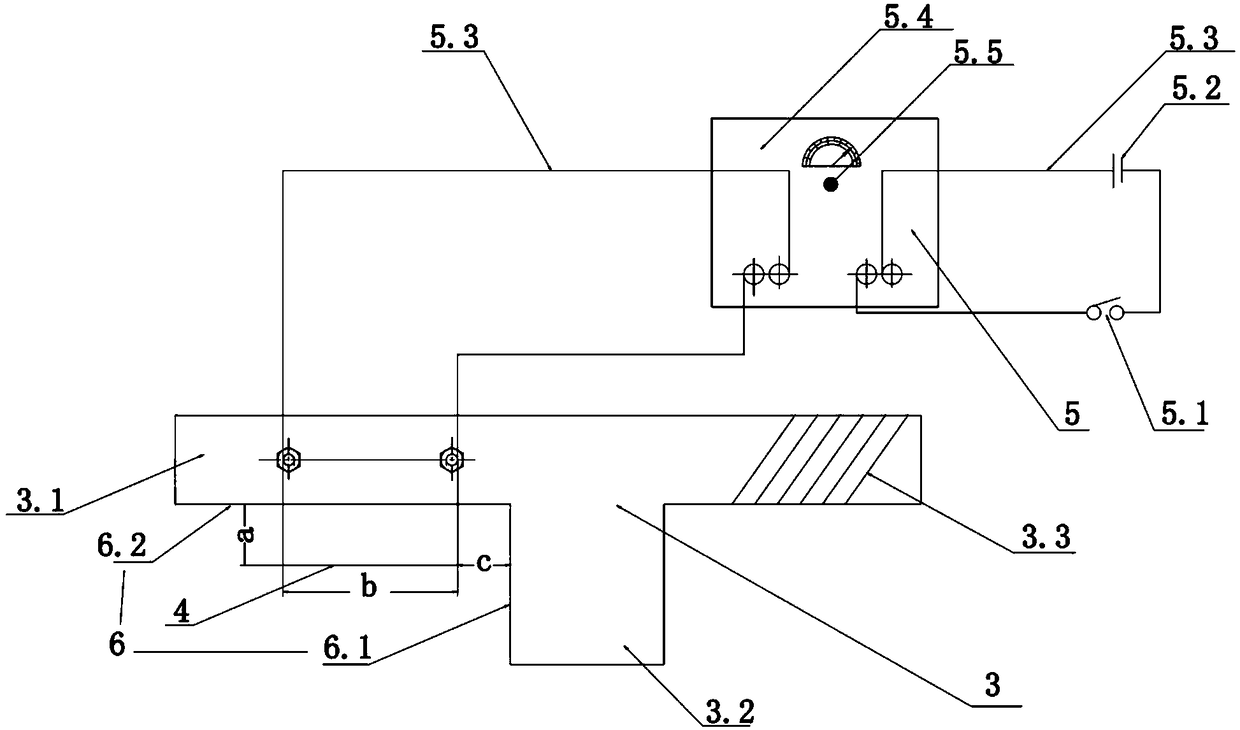

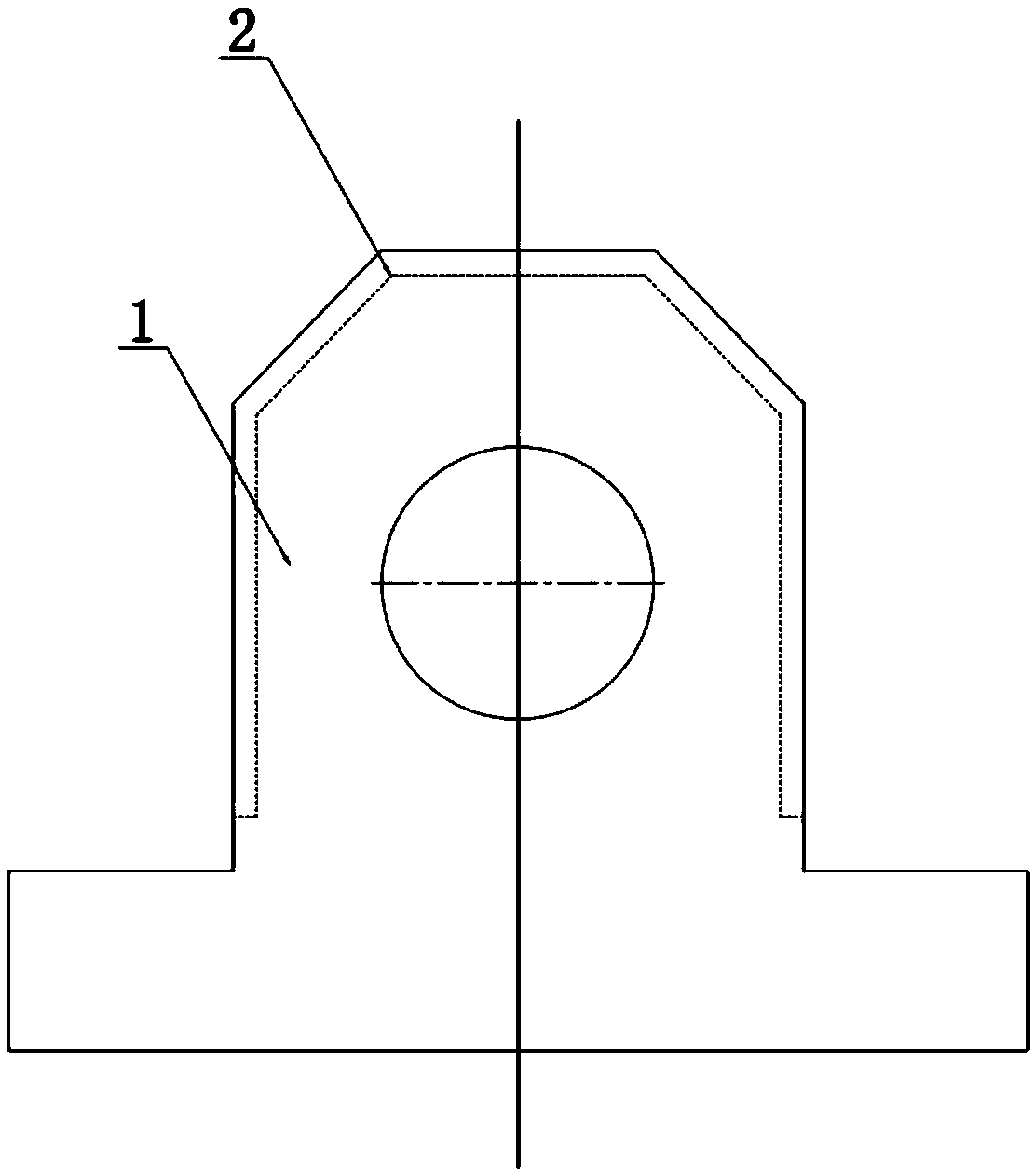

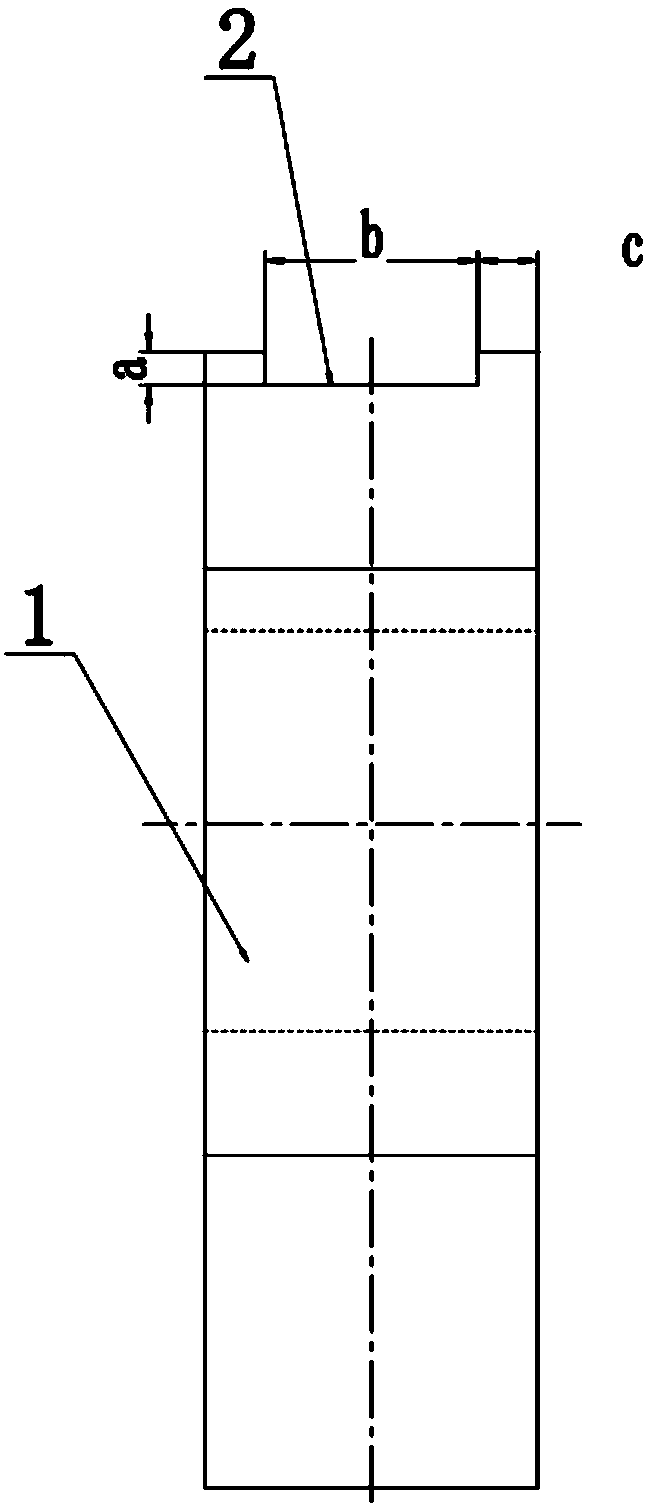

[0020] Example: By adjusting the contact voltage regulator knob 5.5 to change the current in the loop connected to the wire 5.3, the control current is 16.9A-19.5A, the cutting effect is the best, and then the temperature of the heating resistance wire 4 on the top plate 3.1 is controlled. Hold the handle 3.3 at the part 3 of the work group, and contact the side surface of the tooling 6.1 with the side of the white mold 1 of the water-cooled bearing housing, and the top surface of the tooling 6.2 contacts the top surface of the white film 1 of the water-cooled bearing housing. Carry out cutting and grooving at the slotted area. The heating resistance wire 4 adopts a nickel-chromium wire with a diameter of 3mm, which can ensure the required strength for cutting. The width a of the heating resistance wire 4 and the distance between the heating resistance wire 4 and the top surface of the tooling b are 6.2. , The distance c between the heating resistance wire 4 and the side surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com