Knitted cloth with heat release function

A technology of knitting and thermal energy, applied in knitting, weft knitting, electric heating devices, etc., can solve the problems of hard texture, discomfort, poor moisture absorption and breathability, etc., and achieve the effect of soft hand feeling, fast heat diffusion, and soft warmth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention are described in detail below:

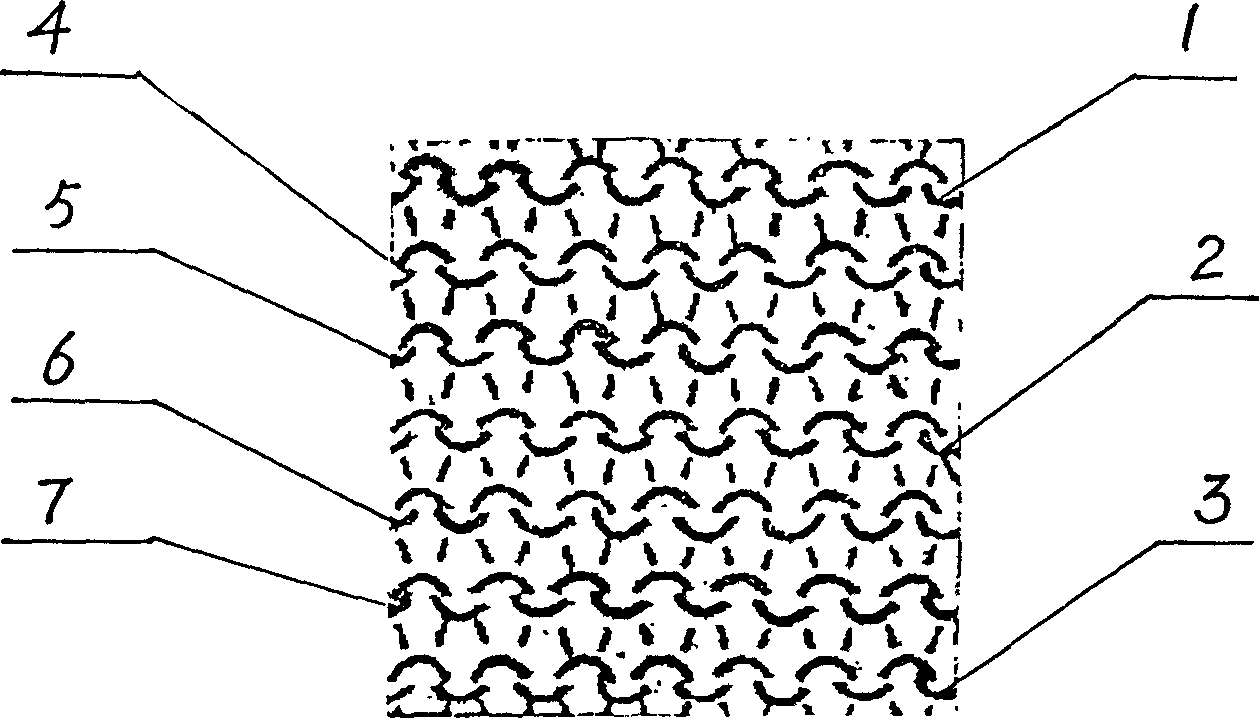

[0014] Ordinary yarn bobbins are placed on the yarn tray of the ordinary knitting machine, and heating yarn rolls are placed at intervals, ordinary yarns 4, 5, 6, 7 output from the ordinary yarn rolls and heating yarns 1, 2, 7 output from the heating yarn rolls 3. Common yarns 4, 5, 6, 7 and heating yarns 1, 2, 3 are bent into coils by the knitting machine through the conventional knitting process, and are interlaced with each other for knitting. The inner core of the heating yarn is a heating wire twisted from nickel-chromium alloy wire, and the inner core of the heating yarn is connected with a 12V DC power supply. The outer layer of the heating yarn is soybean fiber yarn. At present, there are 3 soybean fiber production enterprises in China, including Changshu Jianghe Tianrong Silk Fiber Co., Ltd. Soybean fiber is made of soybean meal extracted from soybean oil, and the globular protein in soybean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com