Aluminum base printed circuit board and preparation method thereof

A printed circuit board, aluminum-based technology, applied in the direction of printed circuit manufacturing, printed circuit, circuit substrate materials, etc., can solve the problems of conductive copper foil etched lines can not be too thin, can not meet the requirements, low adhesion, etc. Overcome easy breakdown by high voltage, achieve high power and high integration, and improve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

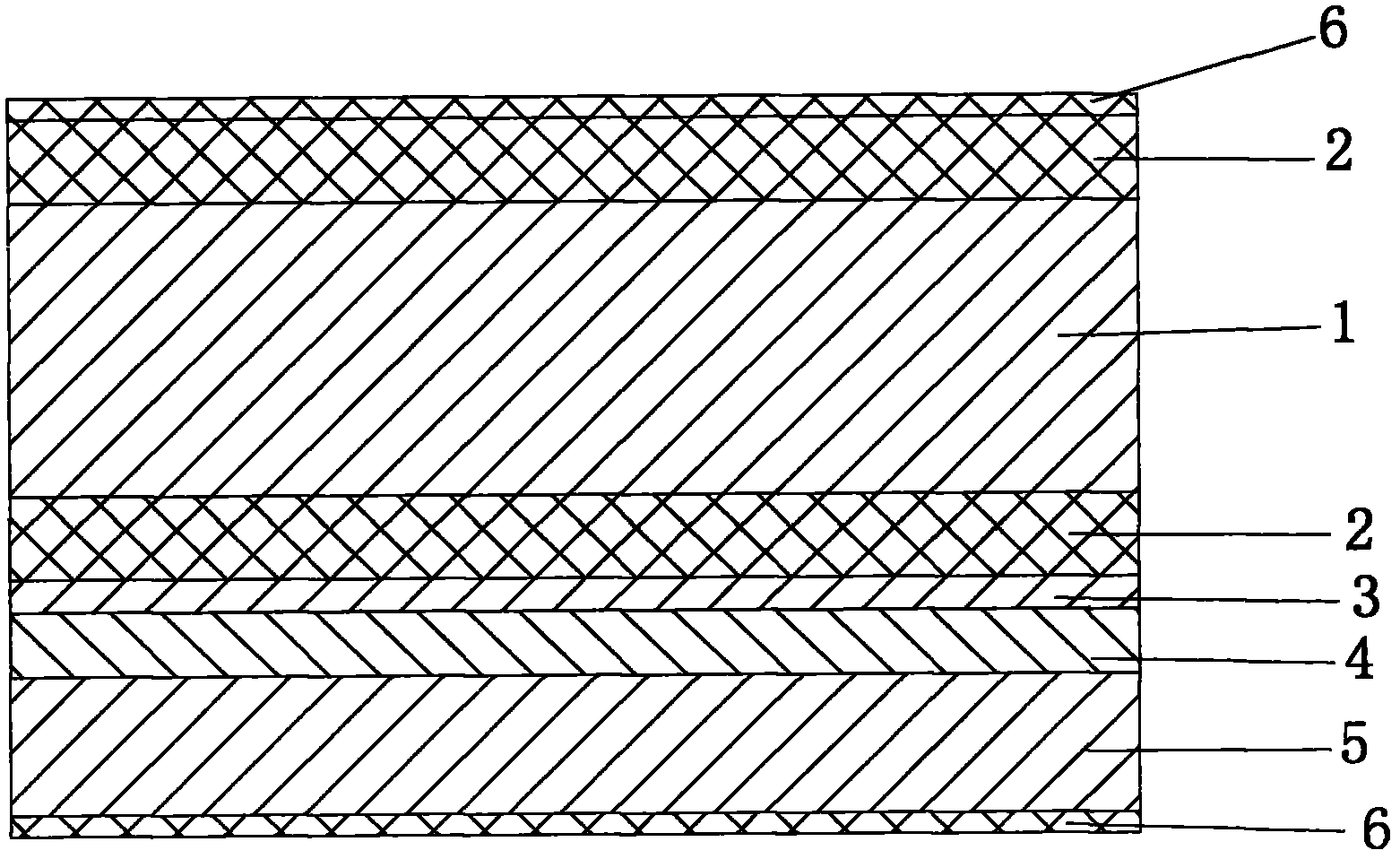

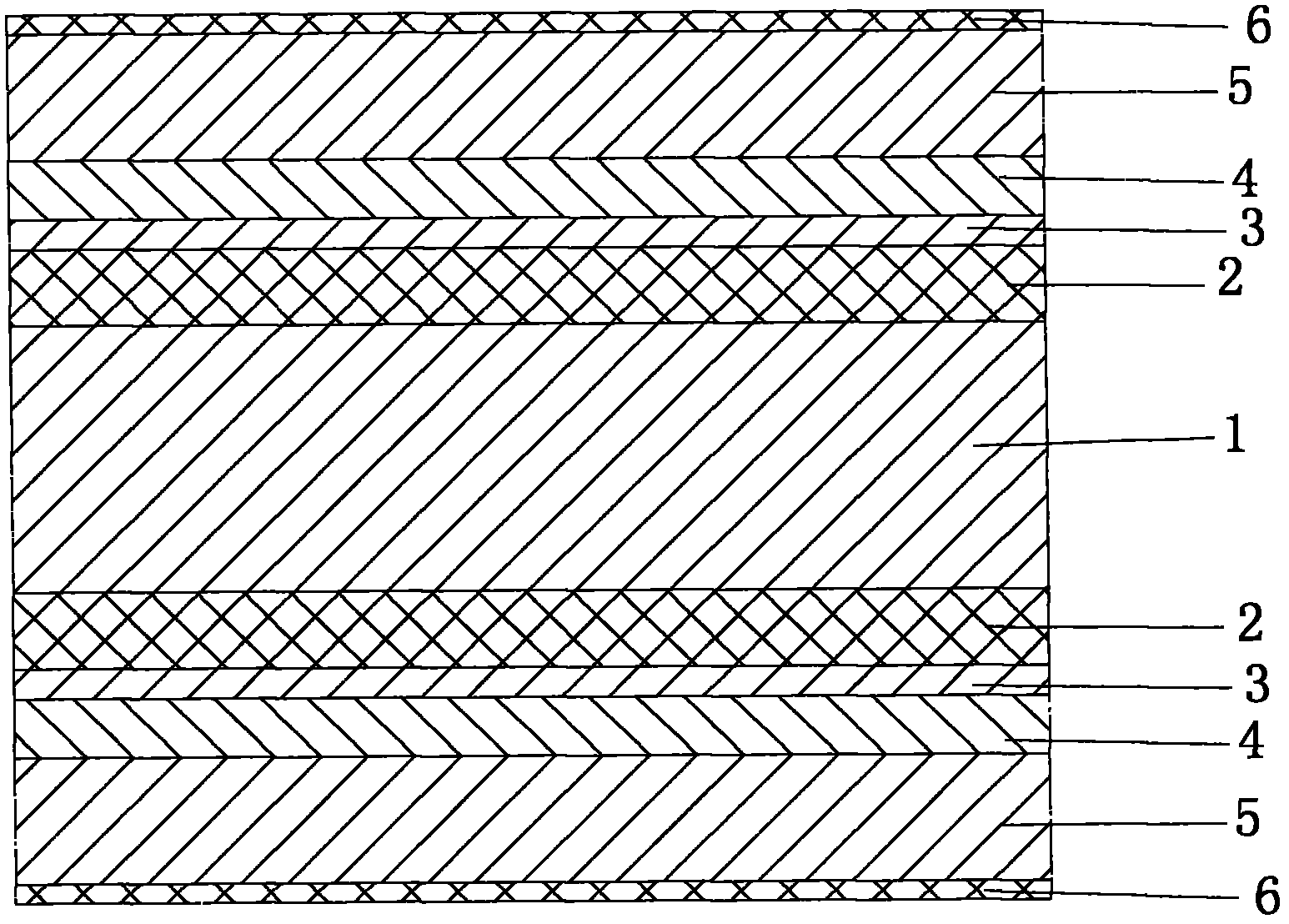

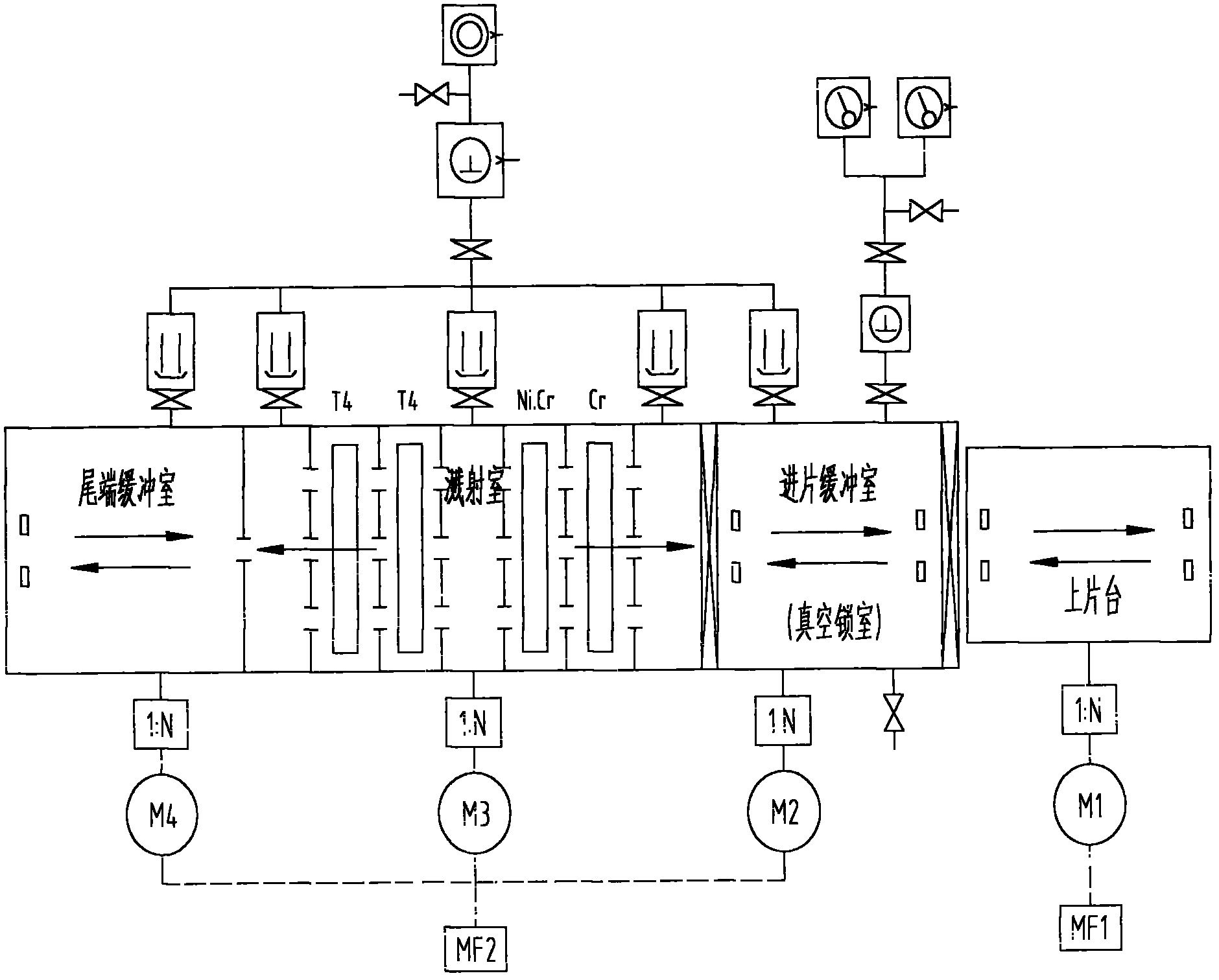

[0019] Such as figure 1 As shown, the aluminum-based printed circuit board of the present invention is provided with an aluminum substrate 1 with a thickness of 1.5 mm to 5 mm when the circuit board is printed on one side. Form dense, high-temperature-resistant, corrosion-resistant and insulating Al2O3 with a thickness of 10 μm to 20 μm 2 o 3 The ceramic insulating layer 2 is coated with a transition layer 3 by a vapor deposition process on the surface of the insulating layer 2 on one side. The vacuum evaporation, vacuum magnetron sputtering or vacuum ion plating process of physical vapor deposition can be used, and the transition layer 3 has a thickness of A 30nm to 80nm chromium, nickel or chromium-nickel alloy film is coated with a copper conductive film 4 with a thickness of more than 300nm on the transition layer 3 by a vapor deposition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com