Polishing solution for cobalt-chromium metal electrolyte plasma polishing

A technology of electrolyte and polishing fluid, which is applied in the field of metal processing, can solve problems such as gaps, unsatisfactory results, and burnt black, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

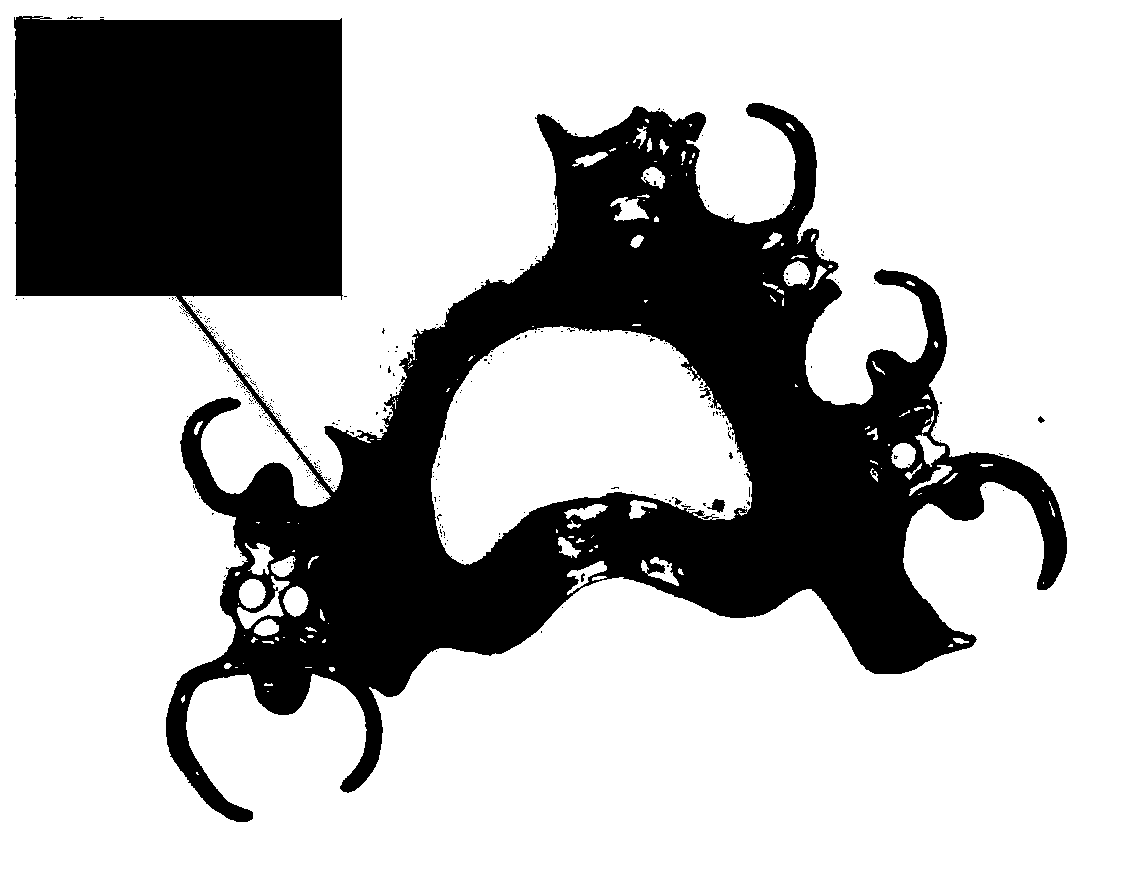

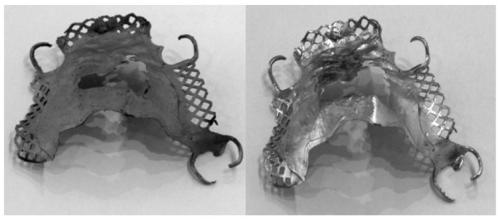

Image

Examples

preparation example Construction

[0046] The second aspect of the present invention provides a method for preparing the above-mentioned polishing solution for cobalt-chromium metal electrolyte plasma polishing, comprising the following steps: mechanically blending sulfate and organic acid at room temperature, and then stirring and dissolving in water, That is the polishing solution.

[0047] The third aspect of the present invention provides a method for using the above-mentioned polishing solution for cobalt-chromium metal electrolyte plasma polishing, comprising the following steps: adding the polishing solution into the polishing tank of the electrolyte plasma polishing machine, heating to 93-98°C, and then Put the cobalt-chromium metal connected to the DC power supply into the polishing solution, the polishing voltage is 330-380V, the polishing time is 500-700 seconds, take out the cobalt-chromium metal, and the polishing is completed.

[0048] In some preferred embodiments, the method for using the polish...

Embodiment 1

[0053] Embodiment 1 provides a polishing solution for cobalt-chromium metal electrolyte plasma polishing, and its preparation raw materials include: 7 parts of sulfate, 1 part of organic acid, and 210 parts of water in parts by weight.

[0054] The sulfate is potassium sulfate and ammonium sulfate, and the weight ratio of potassium sulfate and ammonium sulfate is 1:2.5.

[0055] The organic acid is citric acid; the citric acid is citric acid monohydrate.

[0056] This example also provides a method for preparing the above-mentioned polishing liquid for cobalt-chromium metal electrolyte plasma polishing, which includes the following steps: mechanically blending sulfate and organic acid at room temperature, and then stirring and dissolving in water to obtain the polishing liquid.

[0057] This example also provides a method for using the above-mentioned polishing liquid for cobalt-chromium metal electrolyte plasma polishing. The cobalt-chromium metal workpiece is put into the p...

Embodiment 2

[0061] Embodiment 2 provides a polishing solution for cobalt-chromium metal electrolyte plasma polishing, and its preparation raw materials include: 7 parts of sulfate, 1 part of organic acid, and 210 parts of water in parts by weight.

[0062] Described sulfate is ammonium sulfate.

[0063] The organic acid is citric acid; the citric acid is citric acid monohydrate.

[0064] This example also provides a method for preparing the above-mentioned polishing liquid for cobalt-chromium metal electrolyte plasma polishing, which includes the following steps: mechanically blending sulfate and organic acid at room temperature, and then stirring and dissolving in water to obtain the polishing liquid.

[0065] This example also provides a method for using the above-mentioned polishing liquid for cobalt-chromium metal electrolyte plasma polishing. The cobalt-chromium metal workpiece is put into the polishing solution, the polishing voltage is 340V, the polishing time is 600 seconds, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com