A kind of water-based composite coating material and its preparation method and application

A composite coating, water-based technology, used in coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve problems such as the inability to fully utilize the characteristics of silicone, potential safety hazards, VOC emissions, etc., achieve good sealing, convenient construction, and improve adhesion. focus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

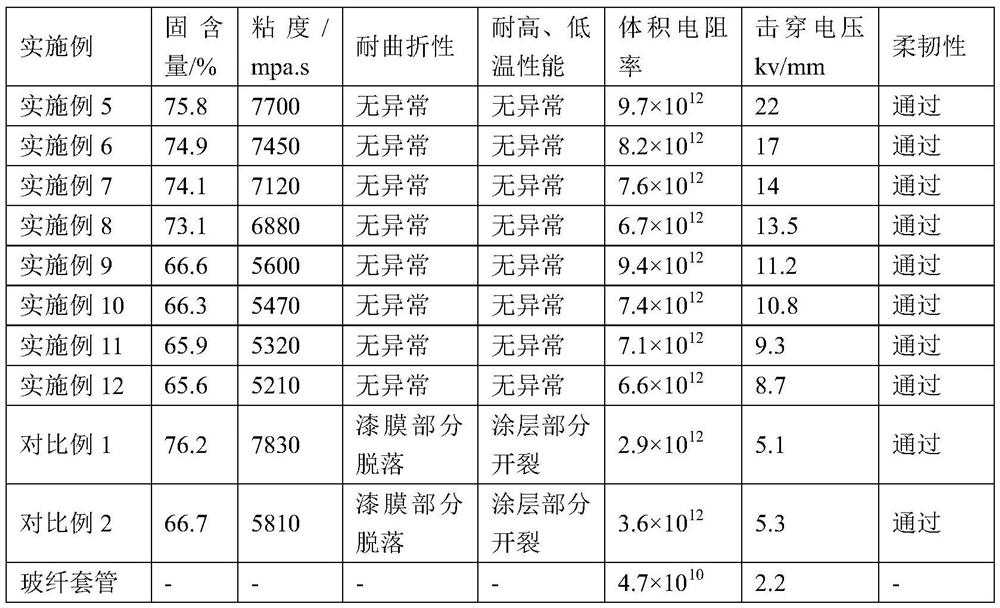

Examples

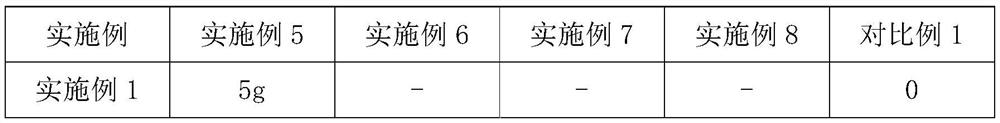

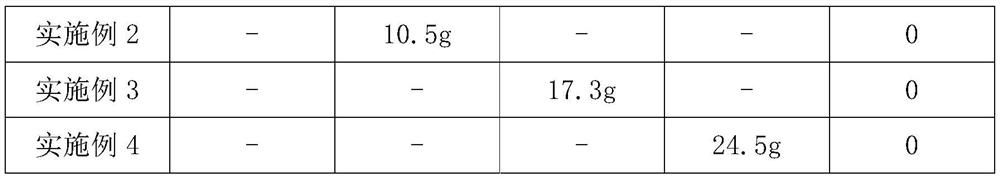

Embodiment 1

[0055] The preparation method of composite functional material is as follows:

[0056] A. Add 12g of aluminum isopropoxide, 87g of deionized water, and 1.5g of hydrochloric acid (37% in mass fraction) into the reactor, and heat up to 75°C while stirring. After the reactants are completely dissolved, keep the temperature at 75°C for 4 hours. , transfer the reaction product into a rotary evaporator, heat up to 85° C. and rotary evaporate to remove isopropanol and water to obtain a crystalline material, cool down to room temperature, dissolve the crystalline material with an aqueous solution of hydrochloric acid at PH=1, and obtain a crystalline material with a solid content of 15%. Aluminum sol solution;

[0057] B. Under the condition of nitrogen protection, put 100g of hydroxy silicone oil (the number average molecular weight is 340, and the hydroxyl content is 10%), 0.1g of stannous octoate, and 100g of absolute ethanol into the stainless steel reaction kettle, stir and mix a...

Embodiment 2

[0059] The preparation method of composite functional material is as follows:

[0060] A. Weigh 18g of aluminum sec-butoxide, 96g of deionized water, and 1g of hydrochloric acid (37% by mass) into the reactor, and heat up to 80°C while stirring. After the reactants are completely dissolved, react at a constant temperature of 80°C for 5h , transfer the reaction product into a rotary evaporator, raise the temperature to 90°C, and completely evaporate the sec-butanol and water to a crystal state to obtain a crystalline material, lower it to room temperature, dissolve the crystalline material with a hydrochloric acid aqueous solution of PH=2, and prepare Obtaining an aluminum sol solution with a solid content of 25%;

[0061] B. Under the condition of nitrogen protection, put 100g of hydroxy silicone oil (the number average molecular weight is 566, and the hydroxyl content is 6.8%), 0.05g of stannous oleate, and 100g of absolute ethanol into the stainless steel reaction kettle, st...

Embodiment 3

[0063] The preparation method of composite functional material is as follows:

[0064] A. Add 12g of aluminum isopropoxide, 87g of deionized water, and 1.5g of hydrochloric acid (37% in mass fraction) into the reactor, and heat up to 75°C while stirring. After the reactants are completely dissolved, keep the temperature at 75°C for 4 hours. , transfer the reaction product into a rotary evaporator, heat up to 85°C and rotary evaporate to remove isopropanol and water to obtain a crystalline material, cool down to room temperature, dissolve the crystalline material with an aqueous hydrochloric acid solution with pH=1, and obtain a crystalline material with a solid content of 20%. Aluminum sol solution;

[0065] B, under the condition of nitrogen protection, 100g hydroxy silicone oil (number average molecular weight 883, hydroxyl content 5.6%), 0.1g stannous octoate, 100g absolute ethanol are dropped into stainless steel reaction kettle, stirred and mixed at room temperature for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com