Preparation method of wear-resistant and abrasion-resistant WC-CoCr coating

A corrosion-resistant and coating technology, which is applied in the field of preparation of wear-resistant and corrosion-resistant WC-CoCr coatings, can solve the problems of limited wear-resistant and corrosion-resistant properties and uneven dispersion of coatings, and achieve improved wear-resistant and corrosion-resistant properties, Reduced wear rate, effect of high corrosion potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

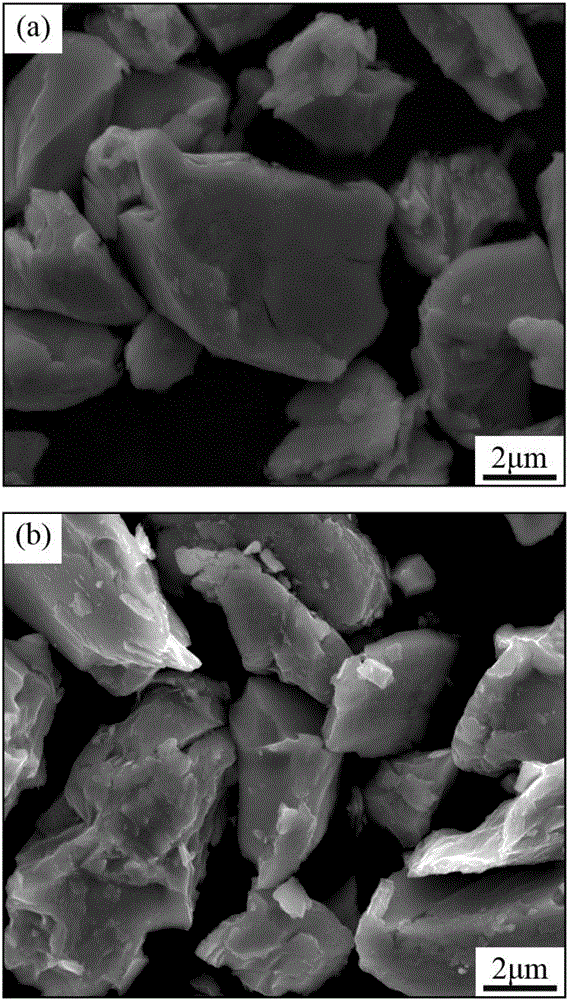

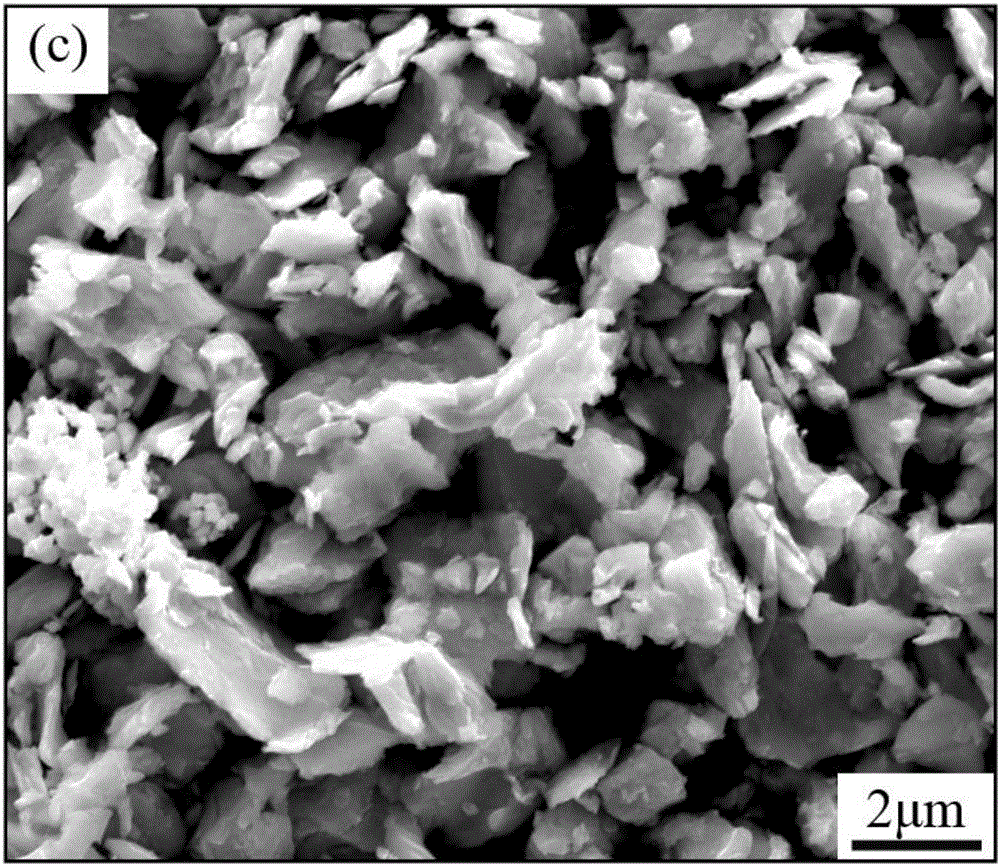

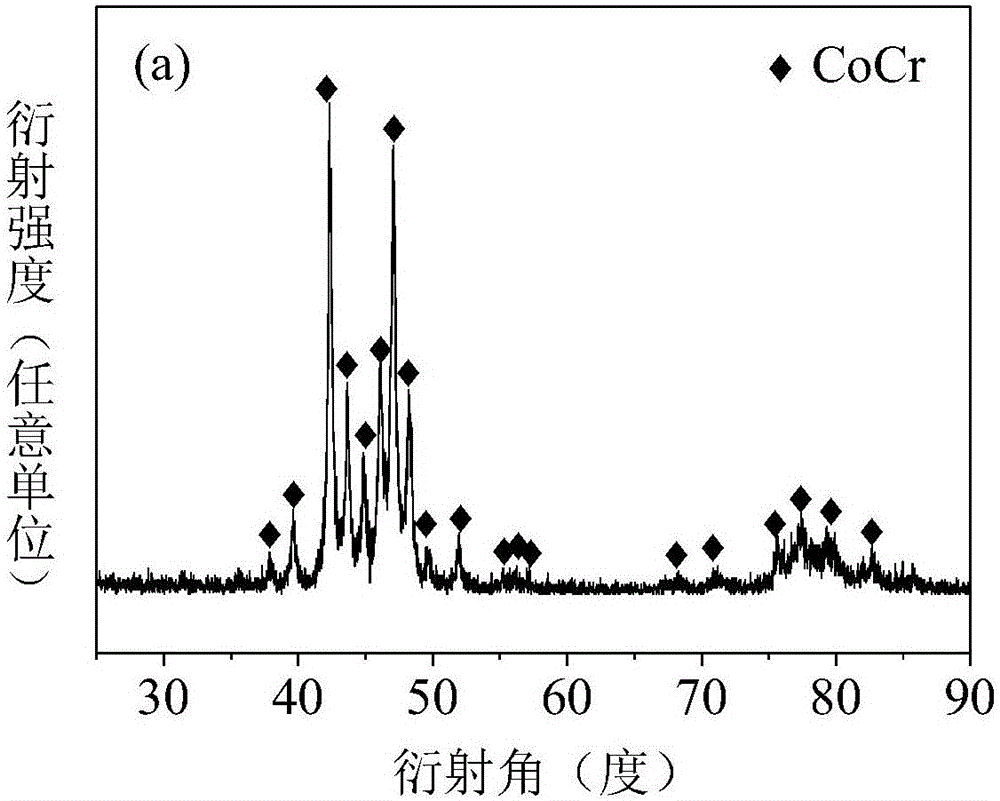

[0018] Mix cobalt ingots and chromium ingots in proportion, put argon as a protective gas in an induction suspension melting furnace for melting and mixing, in which the mass fraction of cobalt is 33%, and the power of the melting furnace is first increased to 3kW, kept for 1min, and then every 10s , the power of the smelting furnace was increased by 2kW until it reached 17kW, and the power was adjusted to zero after 5 minutes of heat preservation. After the sample was naturally cooled, an ingot of cobalt-chromium intermetallic compound was obtained. The cobalt-chromium intermetallic compound ingot was ball-milled and crushed, the ball-milling medium was absolute ethanol, the ball-to-material ratio was 3:1, and the ball-milling time was 15 h, the flaky CoCr intermetallic compound powder with an average thickness of about 0.8 μm was obtained (its apparent Micromorphology such as figure 1 a). The WC powder with an average particle size of 480nm and the CoCr intermetallic compou...

Embodiment 2

[0020] Mix cobalt ingots and chromium ingots in proportion, put argon as a protective gas in an induction suspension melting furnace for melting and mixing, in which the mass fraction of cobalt is 40%, first increase the power of the melting furnace to 4kW, keep it warm for 1min, and then , the power of the smelting furnace was increased by 2kW until it reached 18kW, and the power was adjusted to zero after 4 minutes of heat preservation. After the sample was naturally cooled, an ingot of cobalt-chromium intermetallic compound was obtained. The cobalt-chromium cast intermetallic compound ingot was ball-milled and crushed, the ball-milling medium was absolute ethanol, the ball-to-material ratio was 4:1, and the ball-milling time was 40 h, the flake CoCr intermetallic compound powder with an average thickness of about 0.6 μm was obtained (its apparent Micromorphology such as figure 1 b). The WC powder with an average particle size of 230nm and the CoCr intermetallic compound po...

Embodiment 3

[0022] Mix cobalt ingots and chromium ingots in proportion, put argon as a protective gas in an induction suspension melting furnace for melting and mixing, in which the mass fraction of cobalt is 46%, first increase the power of the melting furnace to 5kW, keep it warm for 1min, and then , the power of the smelting furnace was increased by 2kW until it reached 19kW, and the power was adjusted to zero after 3 minutes of heat preservation. After the sample was naturally cooled, an ingot of cobalt-chromium intermetallic compound was obtained. The cobalt-chromium intermetallic compound ingot was ball-milled and crushed, the ball-milling medium was absolute ethanol, the ball-to-material ratio was 5:1, and the ball-milling time was 60 h, the flake CoCr intermetallic compound powder with an average thickness of about 0.2 μm was obtained (its apparent Micromorphology such as figure 1c). The WC powder with an average particle size of 90nm and the CoCr intermetallic compound powder we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com