Cobalt-chromium alloy powder and preparation method and application thereof

A cobalt-chromium alloy and powder technology, which is applied in the field of cobalt-chromium alloy powder and its preparation, can solve the problems of powder particle size range, bulk density physical and chemical parameters matching, affecting performance, high oxygen content and nitrogen content of cobalt-chromium powder, etc. Achieve the effects of enhancing biocompatibility, ensuring performance, and reducing alloy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

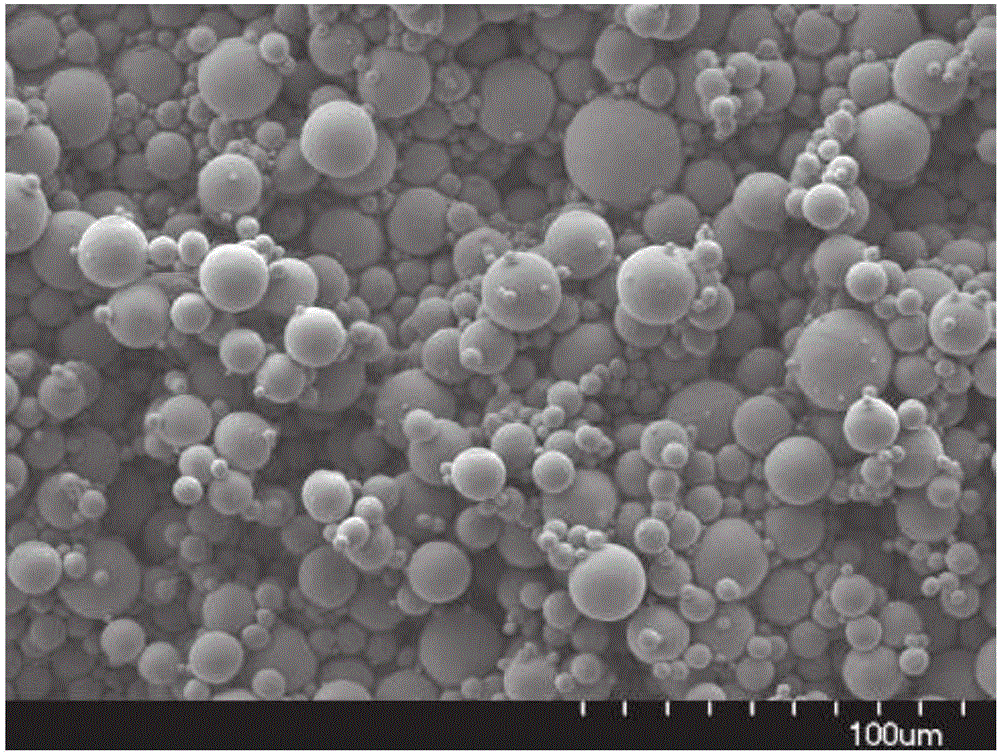

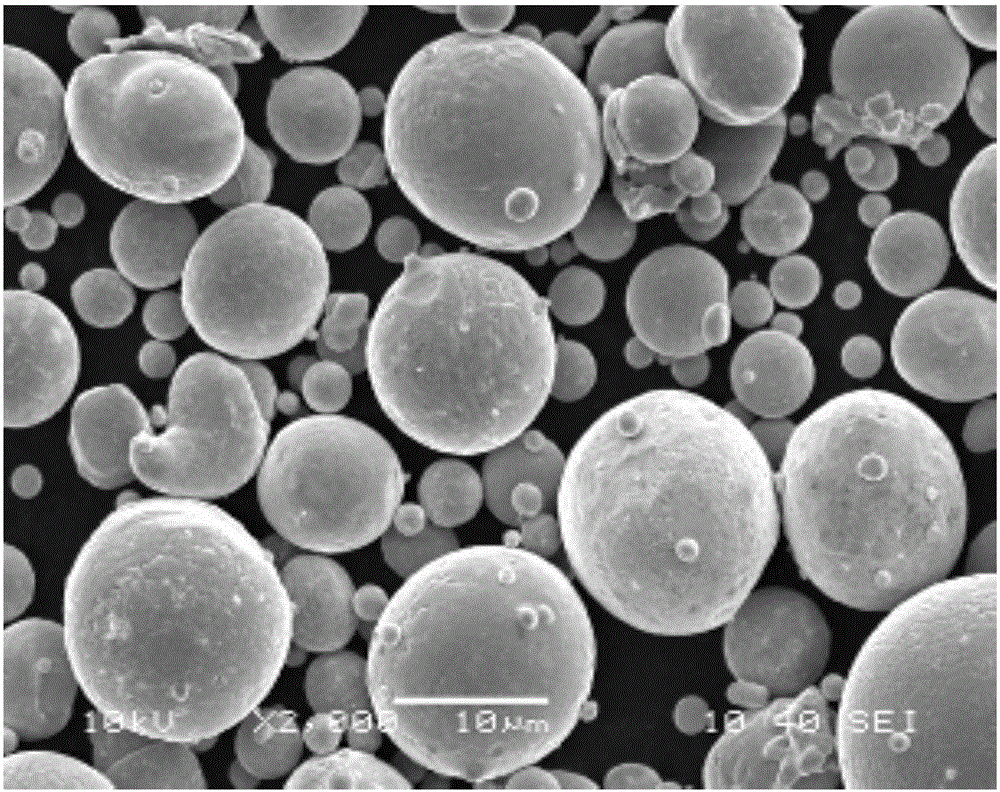

Image

Examples

preparation example Construction

[0038] The preparation method of cobalt-chromium alloy powder of the present invention comprises the steps:

[0039] a. Melting and atomization: In the powder-making chamber in an inert gas atmosphere, a plasma torch is used to melt and atomize the cobalt-chromium alloy wire to form high-temperature small droplets;

[0040] b. Cooling: Pass an inert gas flow with a temperature of 300-500°C into the powder-making chamber, and laminarly cool the high-temperature small droplets to obtain cobalt-chromium alloy powder;

[0041] Wherein, the inert gas in step a and the inert gas flow in step b are both argon or helium.

[0042] Wherein, the diameter of the cobalt-chromium alloy wire is preferably 3-20 mm.

[0043]The method of the invention can adopt industrialized cobalt-chromium alloy wire as raw material. However, in order to obtain a cobalt-chromium alloy composition that is more suitable for dental restorations, the cobalt-chromium alloy wire of the present invention is prefe...

Embodiment 1

[0063] a. Raw material preparation stage

[0064] The high-purity elemental alloy powder is uniformly mixed according to the composition requirements, and then pressed into a pre-alloyed block by hot isostatic pressing. Wherein the conditions of hot isostatic pressing are 1050° C., 140 Mpa, and heat preservation for 160 minutes.

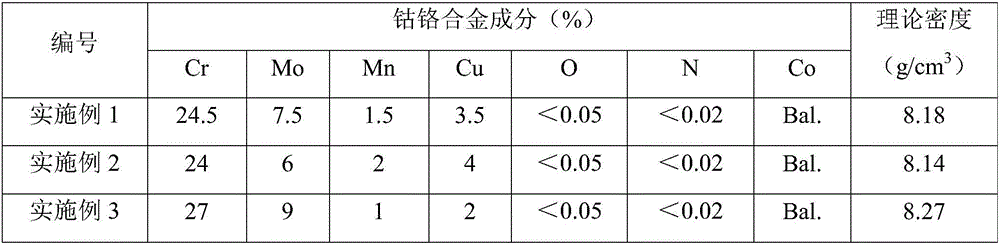

[0065] The dental cobalt chromium alloy is proportioned according to the following chemical composition:

[0066] Cr: 24.5%, Mo: 7.5%, Cu: 3.5%, Mn: 1.5%, and the balance is Co.

[0067] Next, a sliding wire drawing machine was used to process the cobalt-chromium alloy block into a uniform wire with a diameter of 10 mm.

[0068] b. Plasma melting and atomization stage

[0069] During the powder making process, the wire material flows into the powder making chamber at a uniform speed, and after reaching the plasma torch processing melting zone with argon as the working gas, the metal wire is instantly melted by the plasma, and then atomized into a ...

Embodiment 2

[0080] According to the method of embodiment 1, only change the composition of cobalt-chromium alloy, carry out proportioning according to following chemical composition:

[0081] Cr: 24%, Mo: 6%, Cu: 4%, Mn: 2%, and the balance is Co.

[0082] The chemical composition of the prepared cobalt-chromium alloy powder is shown in Table 1, and the bulk density and fluidity data are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com