Fireproof thermal insulation decorative board and manufacturing method thereof

A technology of fire-proof heat preservation and decorative boards, which is applied in the direction of chemical instruments and methods, manufacturing tools, laminating devices, etc. It can solve the problems of affecting the construction effect and construction progress, poor heat preservation effect of heat preservation materials, and difficulty in monitoring construction quality. Construction operation, improved fire prevention effect, good decoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

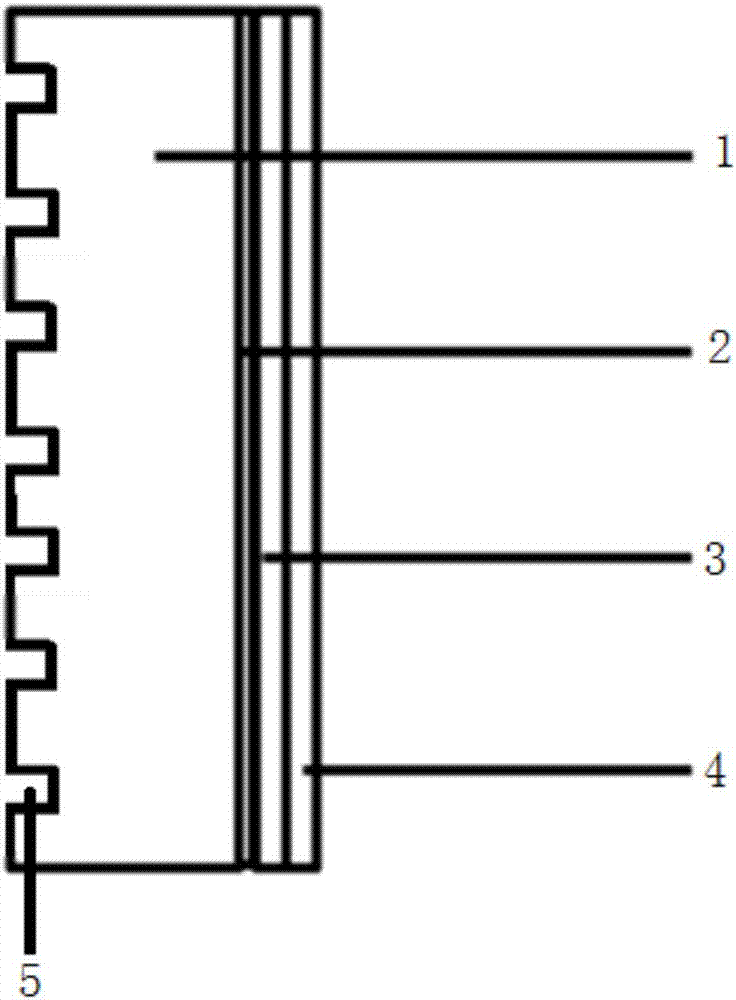

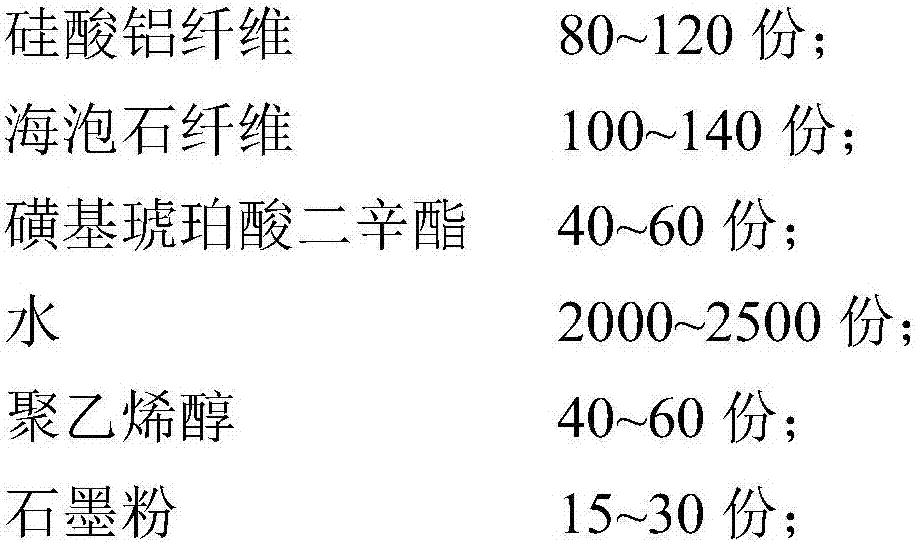

[0054] The invention provides a fireproof heat preservation decorative board, which comprises an inorganic fiber modified heat preservation board 1, a bonding layer 2, a calcium silicate board layer 3, and a soft porcelain veneer layer 4 arranged sequentially from the inside to the outside; Board 1 is made of fireproof and thermal insulation materials, and the fireproof and thermal insulation materials include component A and component B; wherein, the components included in component A and the parts by weight of each component are:

[0055]

[0056] The component that B component comprises and the parts by weight of each component are:

[0057] 600 parts of sulphoaluminate cement;

[0058] Hydrophobic agent 5 parts.

[0059] in:

[0060] The water repellent is one of calcium stearate, zinc stearate, aluminum stearate, preferably zinc stearate.

[0061] The inorganic fiber modified insulation board also needs to add a hydrogen peroxide foaming agent, and the weight part o...

Embodiment 2

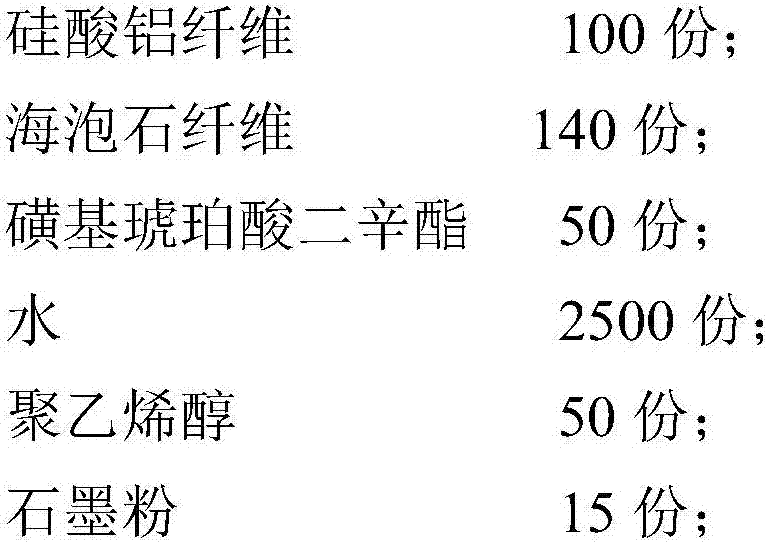

[0063] The invention provides a fireproof heat preservation decorative board, which comprises an inorganic fiber modified heat preservation board 1, a bonding layer 2, a calcium silicate board layer 3, and a soft porcelain veneer layer 4 arranged sequentially from the inside to the outside; Board 1 is made of fireproof and thermal insulation materials, and the fireproof and thermal insulation materials include component A and component B; wherein, the components included in component A and the parts by weight of each component are:

[0064]

[0065] The component that B component comprises and the parts by weight of each component are:

[0066] 700 parts of sulphoaluminate cement;

[0067] Water repellent 8 parts.

[0068] in:

[0069] The water repellent is one of calcium stearate, zinc stearate, aluminum stearate, preferably zinc stearate.

[0070] The inorganic fiber modified insulation board also needs to add a hydrogen peroxide foaming agent, and the weight part of th...

Embodiment 3

[0072] The invention provides a fireproof heat preservation decorative board, which comprises an inorganic fiber modified heat preservation board 1, a bonding layer 2, a calcium silicate board layer 3, and a soft porcelain veneer layer 4 arranged sequentially from the inside to the outside; Board 1 is made of fireproof and thermal insulation materials, and the fireproof and thermal insulation materials include component A and component B; wherein, the components included in component A and the parts by weight of each component are:

[0073]

[0074] The component that B component comprises and the parts by weight of each component are:

[0075] 800 parts of sulphoaluminate cement;

[0076] 10 parts of water repellent.

[0077] in:

[0078] The water repellent is one of calcium stearate, zinc stearate, aluminum stearate, preferably zinc stearate.

[0079] The inorganic fiber modified insulation board also needs to add a hydrogen peroxide foaming agent, and the weight part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com