Individualized tooth preparation substep indicating guide plate manufactured by digital design

A guide plate and tooth body technology, applied in design optimization/simulation, dentistry, filling teeth, etc., can solve the problems of inaccurate guide plate and insufficient visualization of veneer repair, reduce medical disputes, improve the quality of veneer repair and patients Satisfaction and the effect of reducing the difficulty of clinical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

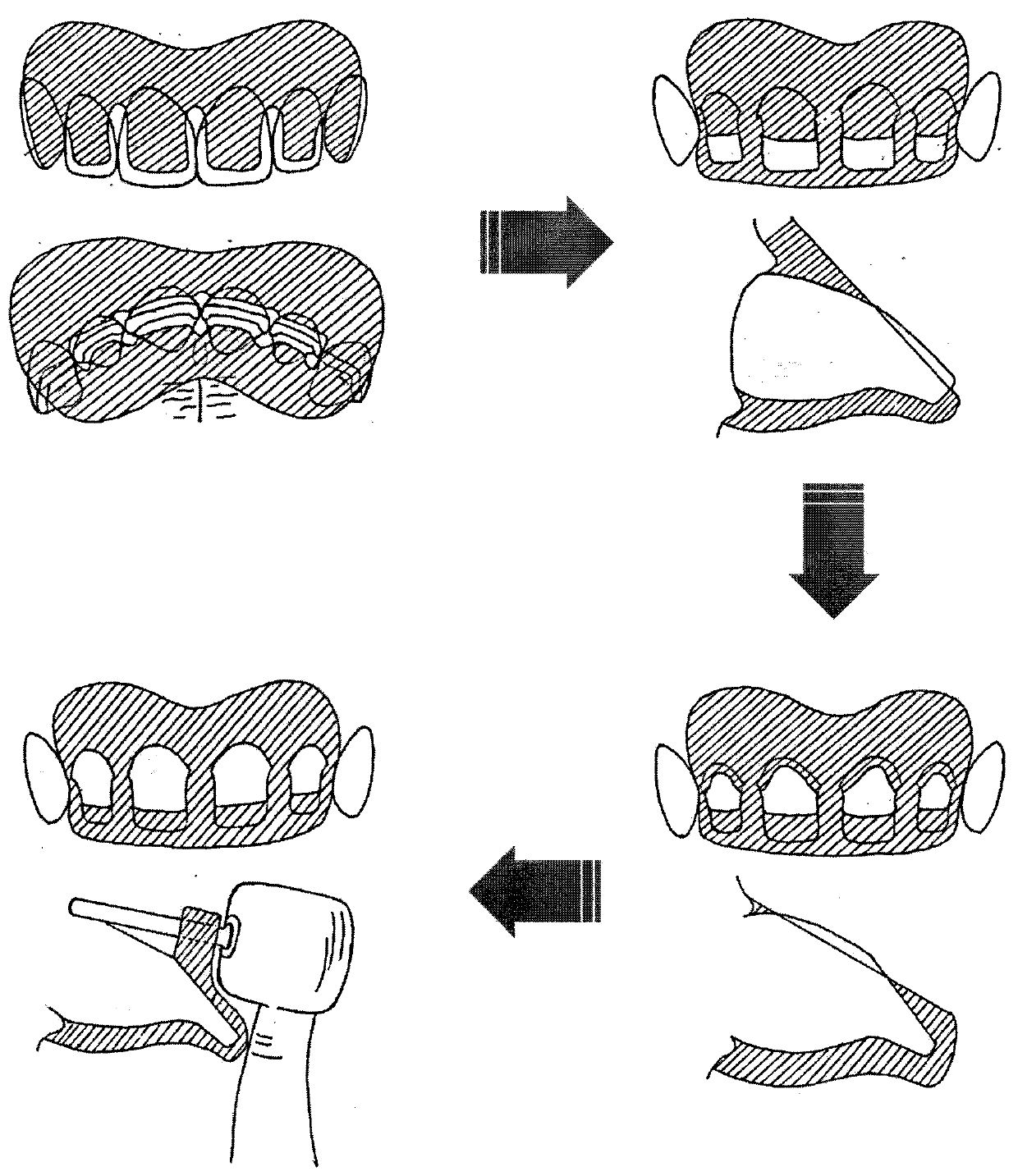

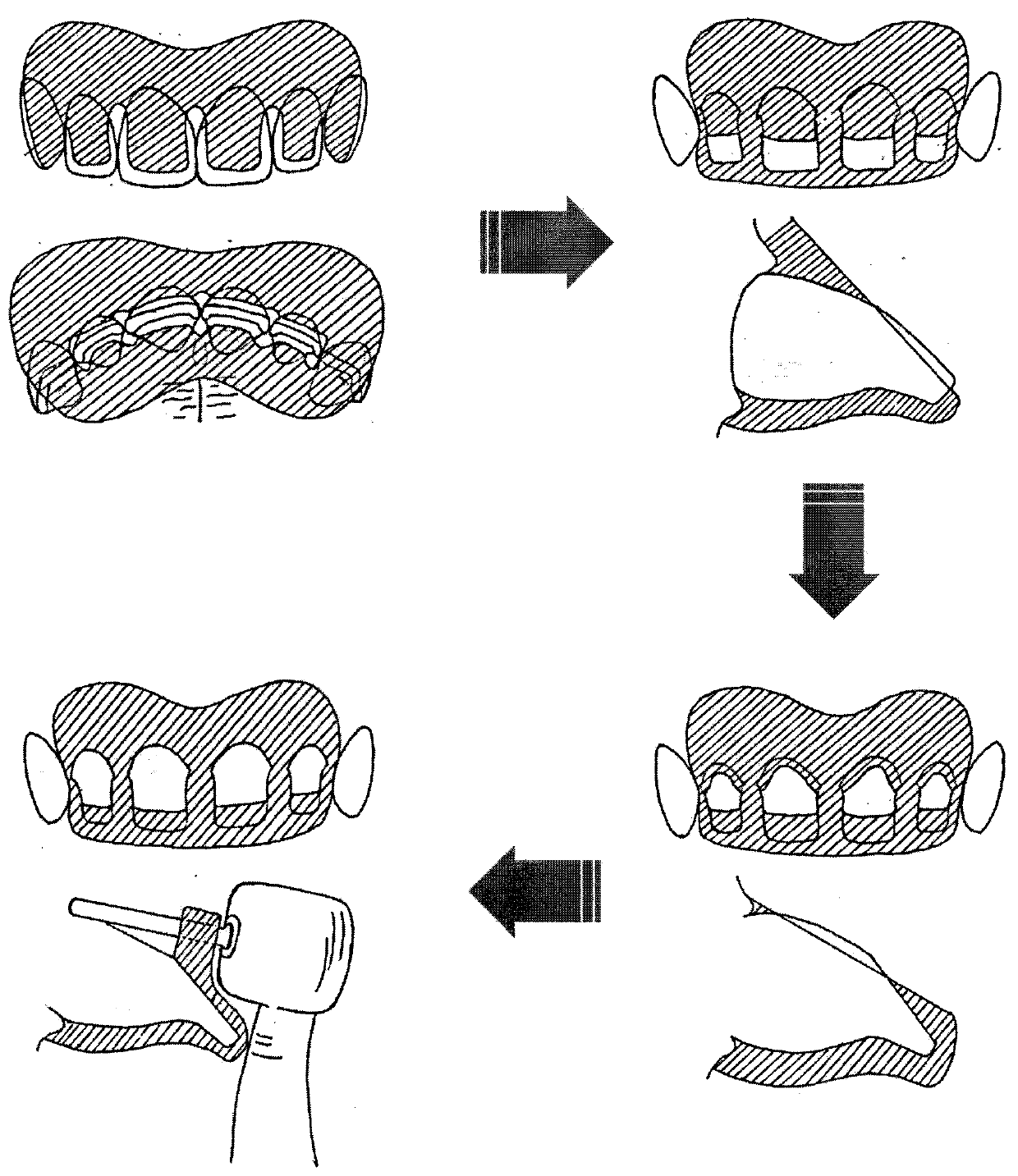

[0018] A digitally designed and manufactured personalized step-by-step instruction guide plate for tooth preparation, characterized in that the ideal anterior tooth shape is reconstructed through three-dimensional modeling, the guide plate is divided into three parts, the incisal guide plate-used for the incisal end and the adjacent surface Preparatory steps, labial guides - steps for labial preparations (subdivided into two subsections), gingival margin guides - steps for gingival margin preparations.

[0019] Taking the butt-type proximal extended veneer restoration of four maxillary anterior teeth including right upper lateral incisor, right upper central incisor, left upper central incisor, and left upper lateral incisor as an example, a digitally designed and manufactured personalized tooth preparation The implementation of the step-by-step instruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com