Aesthetic effect display swatch for porcelain veneer repaired discolored teeth with different technologies and manufacturing method

A technology of effect display and production method, applied in dentistry, medical science, manufacturing tools, etc., can solve the problem of diverse and complex color information of discolored teeth, and achieve the effect of improving patient satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

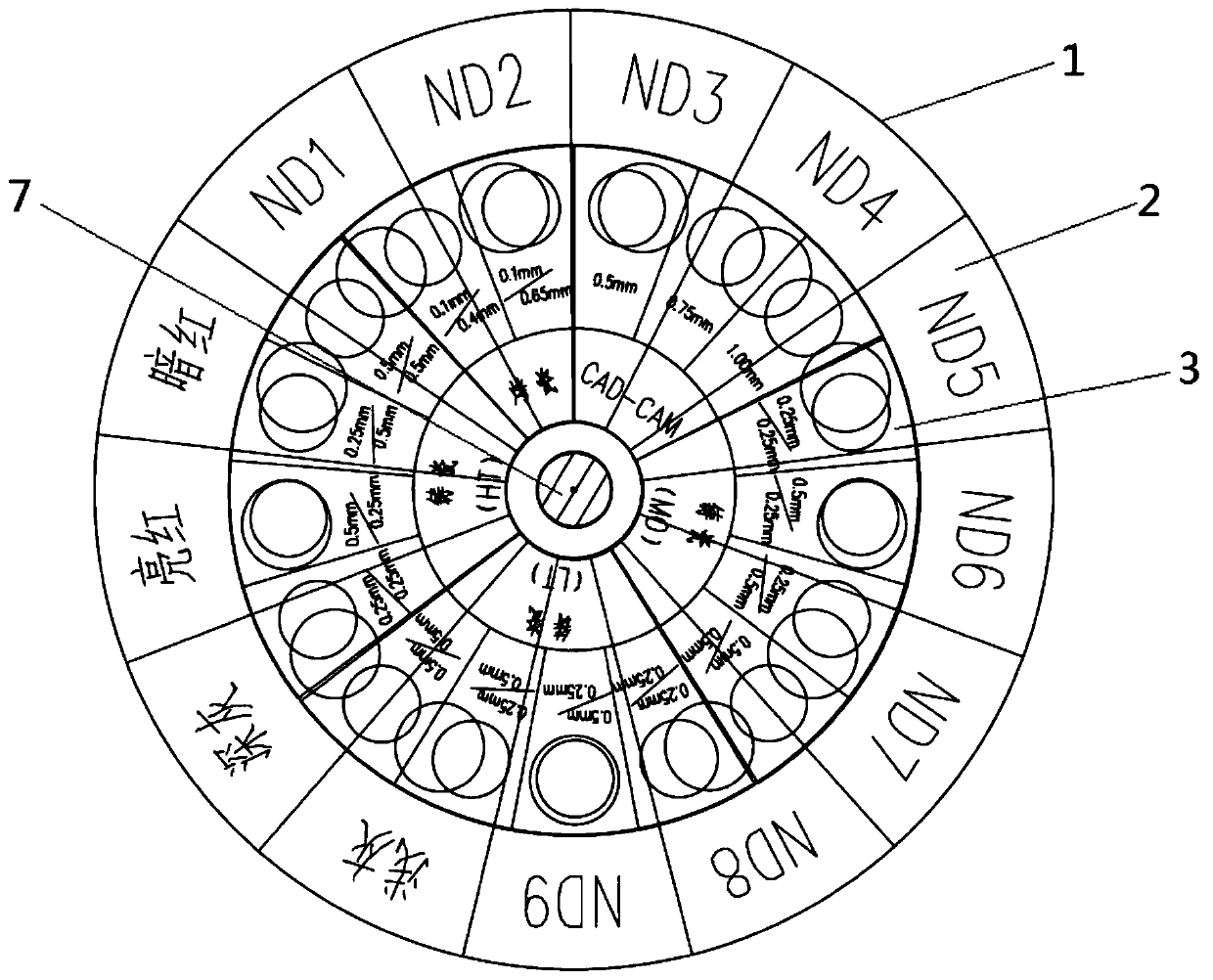

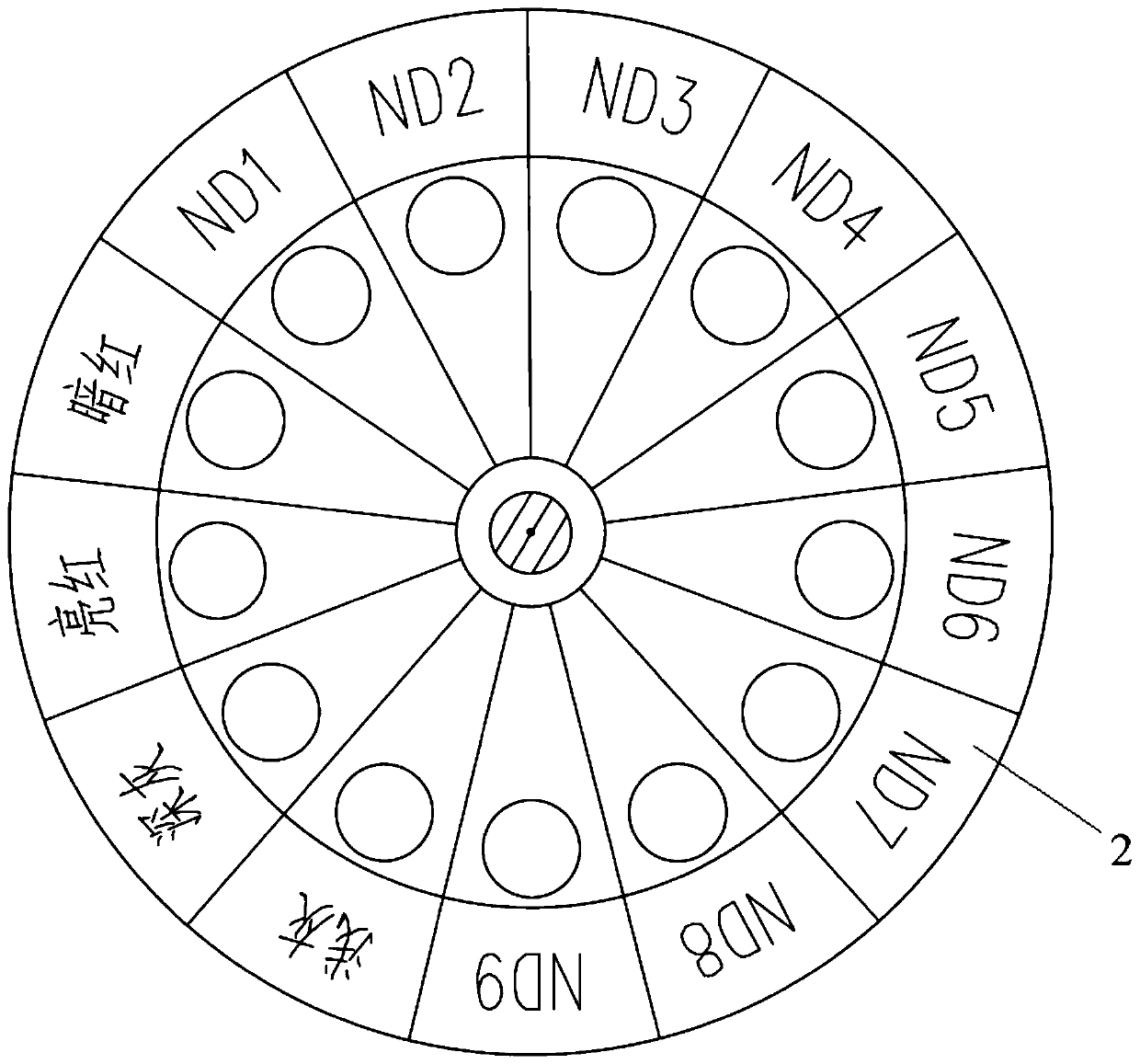

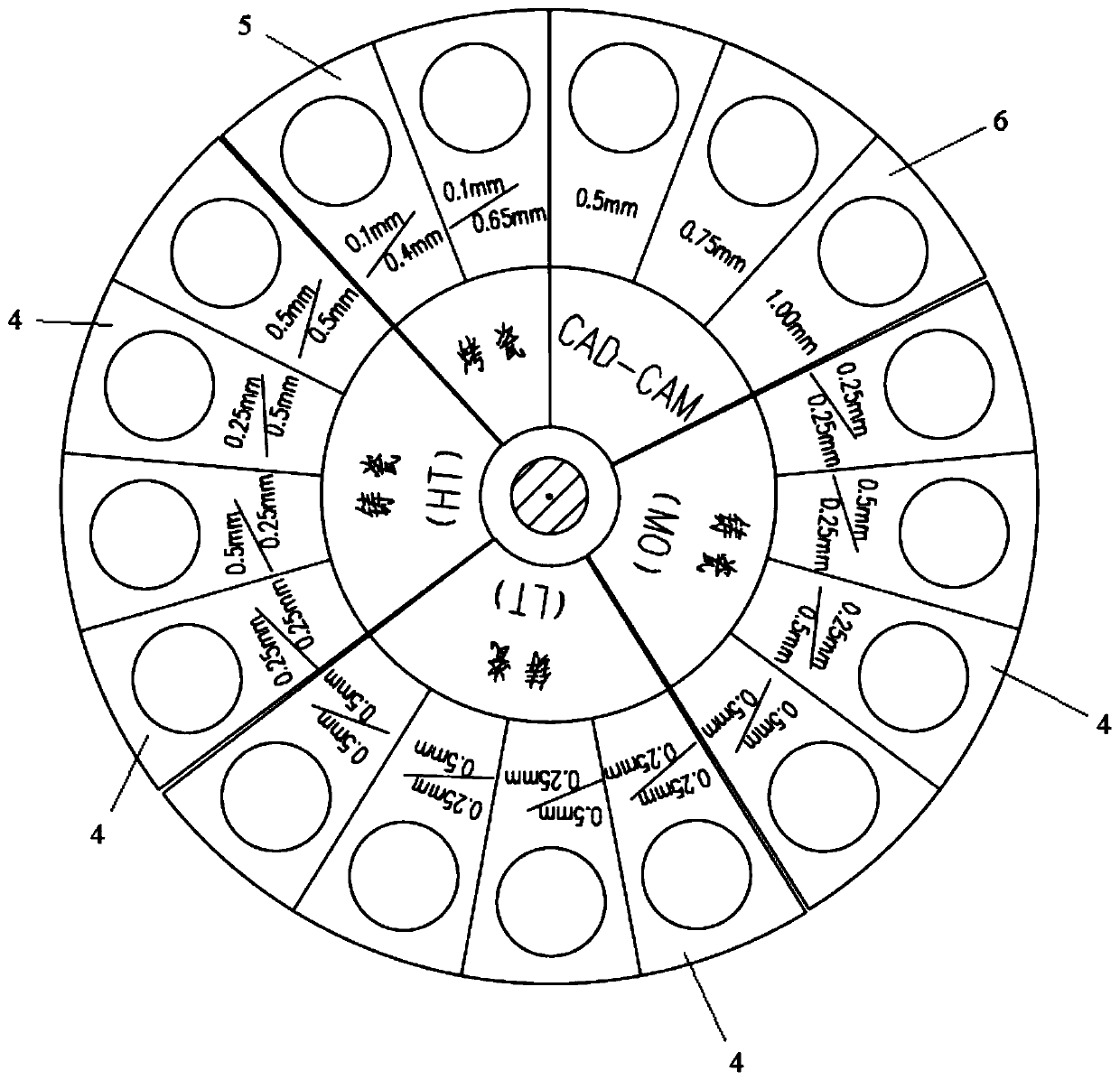

[0062] Embodiment 1—making of cast porcelain tiles

[0063] A cylindrical stainless steel custom-made mold is used to press GC resin sheets with an inner diameter of 12mm, a thickness of 0.35mm and 0.60mm, and three kinds of transparent nuclear porcelain specimens of A3 color IPS e.maxPressHT, LT and MO are produced by the lost wax-die casting method. Use 240#-1200# water sandpaper to polish the nuclear porcelain pieces to 0.25mm and 0.50m respectively, with an error of ±0.02mm; after the finished nuclear porcelain surface is sandblasted, pile A3 color decorative porcelain IPS.e.max cream dentin, The decorative porcelain is sintered in three times, and the decorative porcelain layer is polished to 0.25mm or 0.50mm with 240#-1200# water sandpaper, and the error is ±0.05mm.

[0064] Finally, 4 pieces of each kind of transparent cast porcelain pieces are produced, and the thicknesses of decorative porcelain / core porcelain are 0.25mm / 0.25mm, 0.5mm / 0.25mm, 0.25mm / 0.5mm and 0.5mm / 0....

Embodiment 2

[0065] Embodiment 2—production of ceramic tiles

[0066] Use silicone rubber impression material to make an impression of a cylindrical stainless steel mold with a diameter of 12 mm, fill the model with Shofeng refractory material, and polish both ends of the model smooth with water sandpaper. The layered molding method is used to successively build up IPSd.SIGN A3 color low-temperature opaque porcelain powder and body porcelain powder on the refractory model. The thickness of the opaque porcelain is 0.10mm, and the error is ±0.05mm. The body porcelain is fired three times. After the production is completed, use 240#-1200# water sandpaper to polish the total thickness of the porcelain tile to 0.50mm and 0.75mm.

Embodiment 3

[0067] Embodiment 3--CAD-CAM tile making

[0068] Choose A3 color VitablocsMarkII LT porcelain blocks, use CEREC software to design and manufacture three CAD-CAM tiles with a diameter of 12mm and a thickness of 0.50mm, 0.75mm and 1.00mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com