Glass ceramic veneer and processing method thereof

A glass-ceramic and processing method technology, applied in dentures and other directions, can solve the problems of cumbersome embedding and casting process, poor processing accuracy, low tooth fit, etc., and achieve the effect of shortening the delivery cycle, improving the production accuracy, and shortening the preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Present embodiment is a kind of processing method of glass-ceramic veneer, and the steps are as follows:

[0070] (1) Scanning to obtain three-dimensional data: use a three-dimensional scanner to scan the tooth model to obtain a three-dimensional image;

[0071] (2) On the virtual three-dimensional image, adopt CAD design software to design an ultra-thin veneer with a thickness of 0.3mm to obtain stl data;

[0072] (3) Output the stl data to the numerical control equipment, and use the numerical control equipment to cut the glass ceramic material and process it into a veneer body;

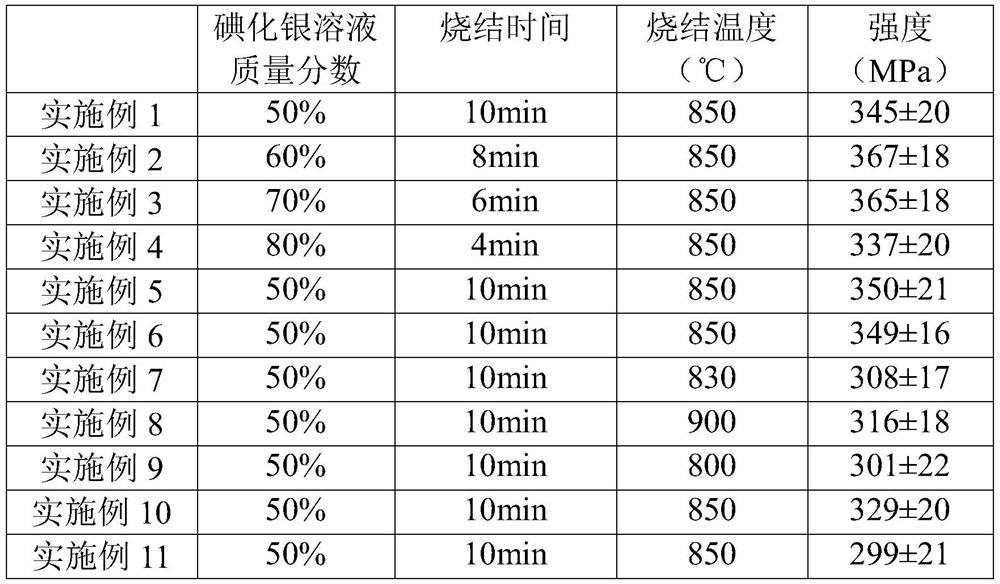

[0073] (4) Prepare a saturated aqueous solution of potassium iodide, dissolve silver iodide in the solution, and prepare a silver iodide solution with a mass fraction of 50%; brush the silver iodide solution with a mass fraction of 50% on the surface of the veneer body, and then put it into sintering In the furnace, bake at 850°C for 10 minutes to obtain a sintered body;

[0074] (5) After...

Embodiment 2

[0076] This embodiment is a processing method for glass-ceramic veneer, the raw materials and steps it adopts are the same as those in Embodiment 1, the difference is that in step (4), a silver iodide solution with a mass fraction of 60% is prepared; the roasting time is 8 min.

[0077] Specific steps are as follows:

[0078] (1) Scanning to obtain three-dimensional data: use a three-dimensional scanner to scan the tooth model to obtain a three-dimensional image;

[0079] (2) On the virtual three-dimensional image, adopt CAD design software to design an ultra-thin veneer with a thickness of 0.3mm to obtain stl data;

[0080] (3) Output the stl data to the numerical control equipment, and use the numerical control equipment to cut the glass ceramic material and process it into a veneer body;

[0081] (4) Prepare a saturated aqueous solution of potassium iodide, dissolve silver iodide in the solution, and prepare a silver iodide solution with a mass fraction of 50%; brush the s...

Embodiment 3

[0084] This embodiment is a processing method for glass-ceramic veneer, the raw materials and steps it adopts are the same as those in Embodiment 1, the difference is that in step (4), a silver iodide solution with a mass fraction of 70% is prepared; the roasting time is 6 min.

[0085] Specific steps are as follows:

[0086] (1) Scanning to obtain three-dimensional data: use a three-dimensional scanner to scan the tooth model to obtain a three-dimensional image;

[0087] (2) On the virtual three-dimensional image, adopt CAD design software to design an ultra-thin veneer with a thickness of 0.3mm to obtain stl data;

[0088] (3) Output the stl data to the numerical control equipment, and use the numerical control equipment to cut the glass ceramic material and process it into a veneer body;

[0089] (4) Prepare a saturated aqueous solution of potassium iodide, dissolve silver iodide in the solution, and prepare a silver iodide solution with a mass fraction of 50%; brush the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com