Patents

Literature

304 results about "Teeth grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

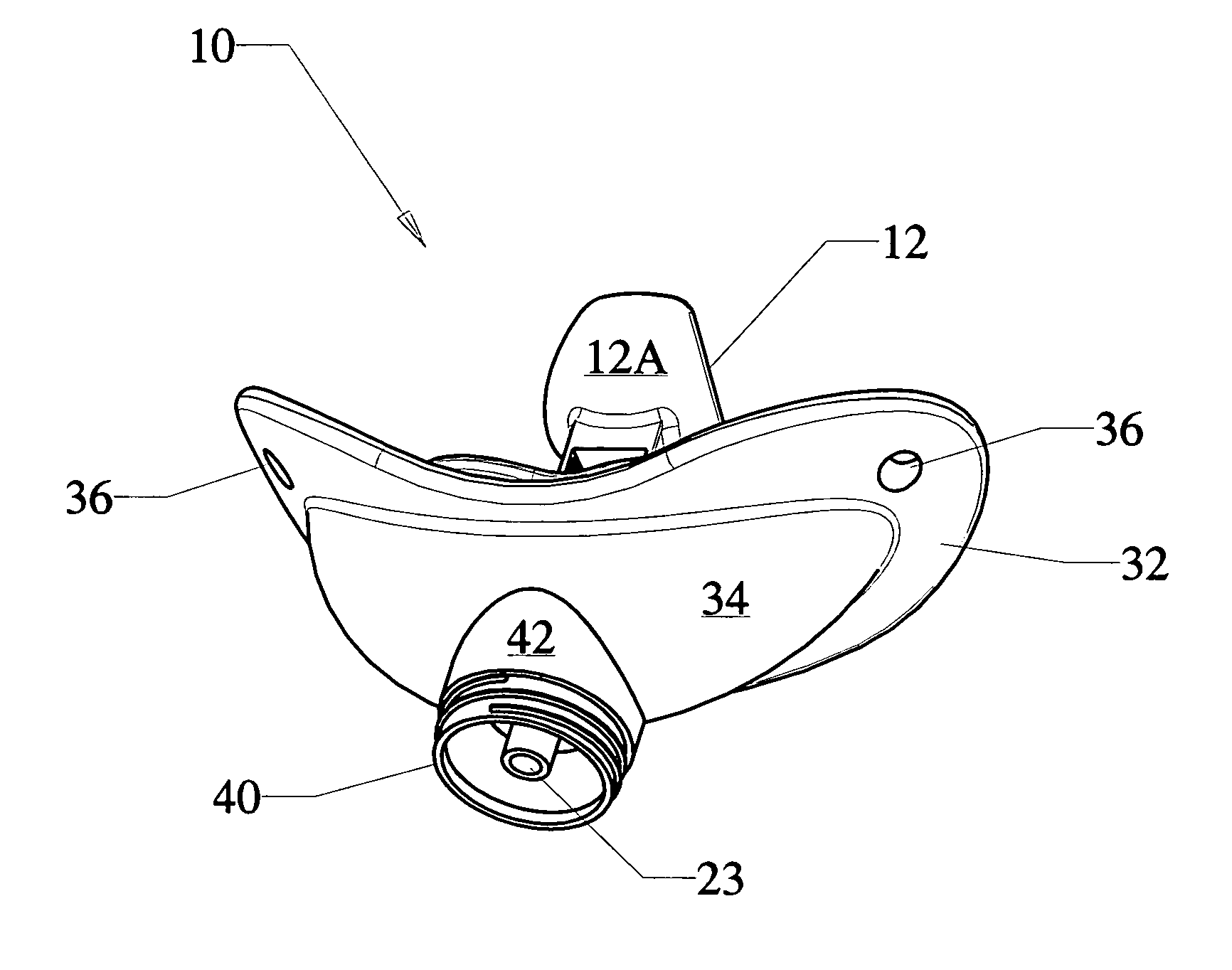

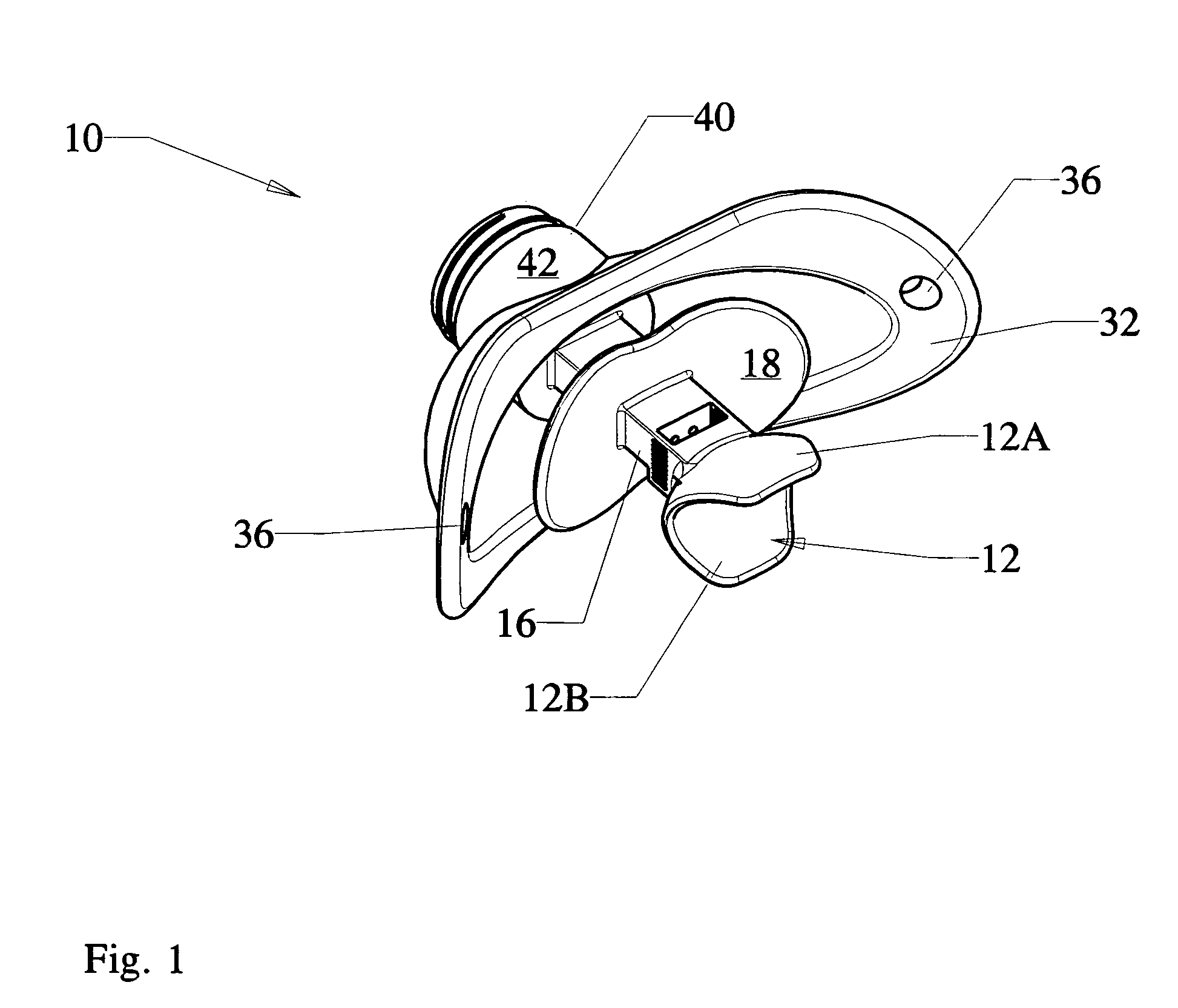

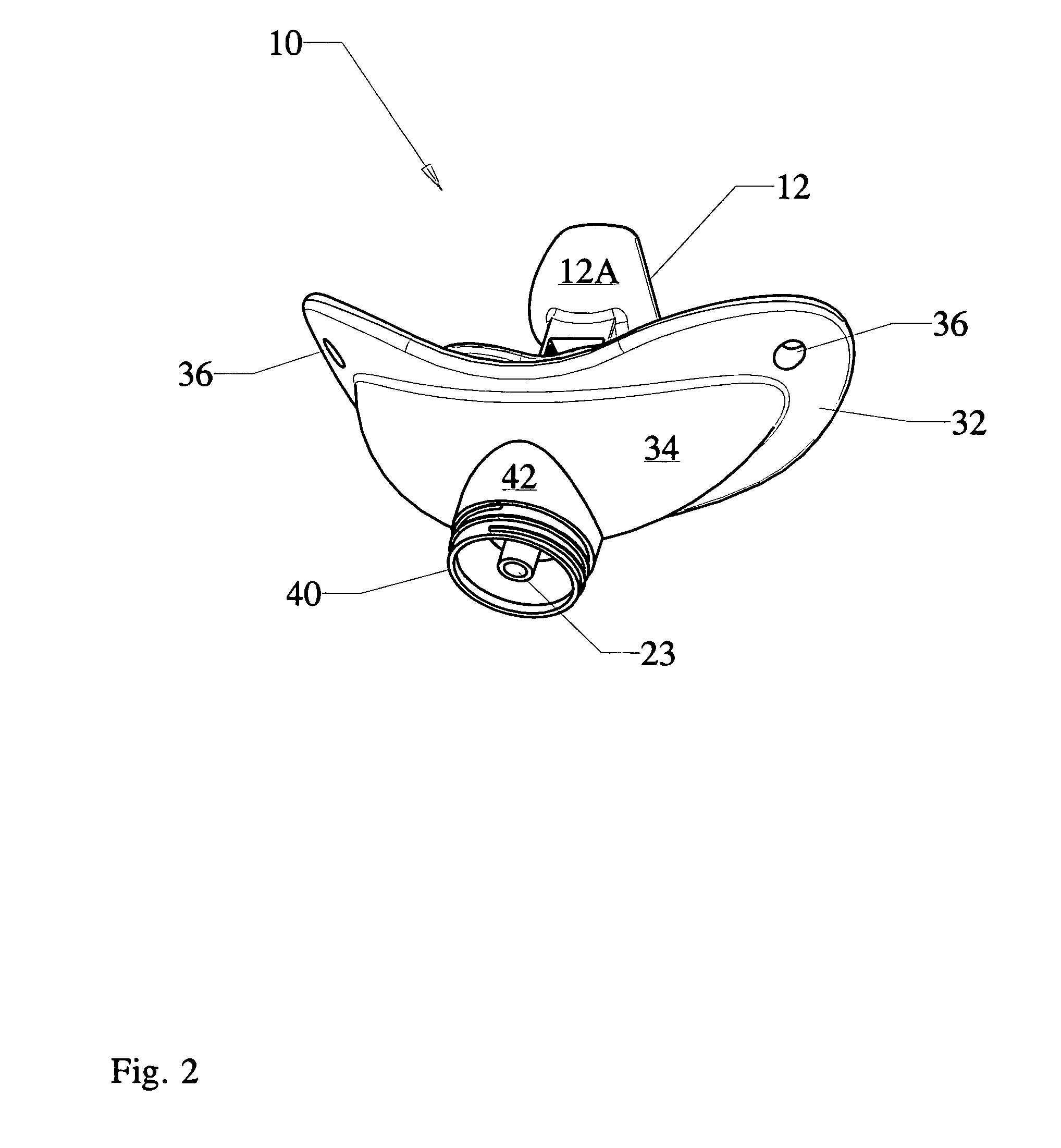

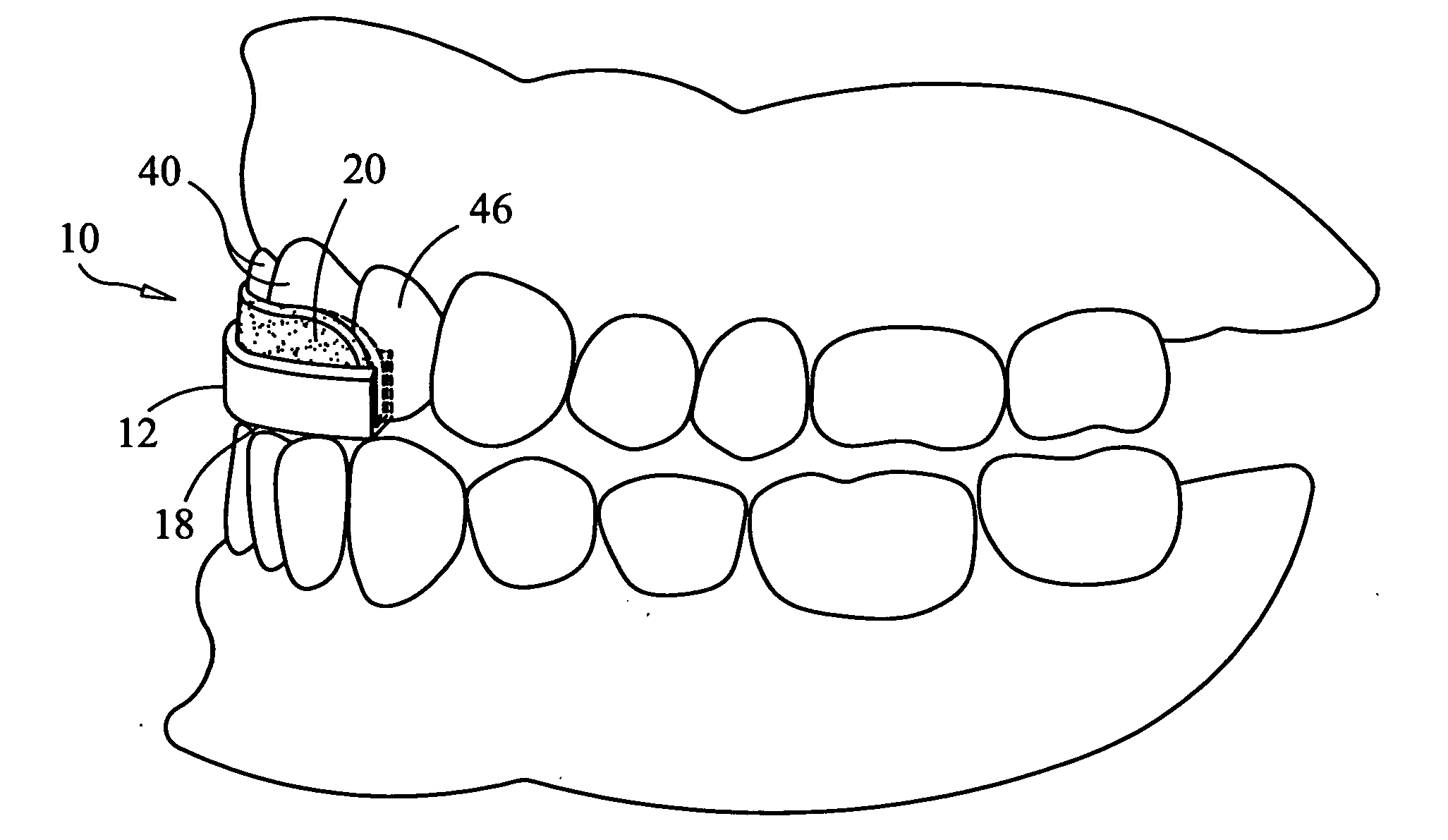

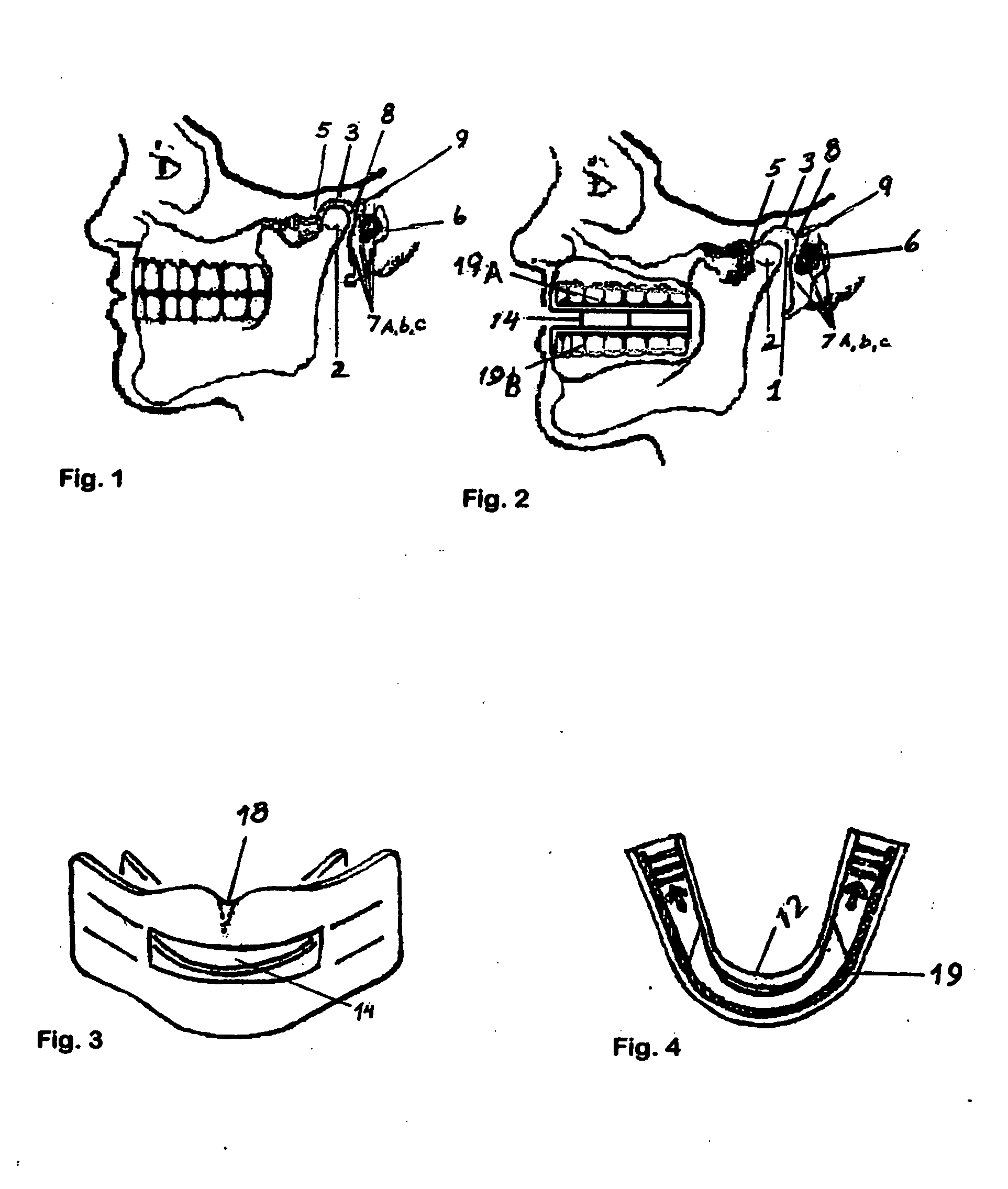

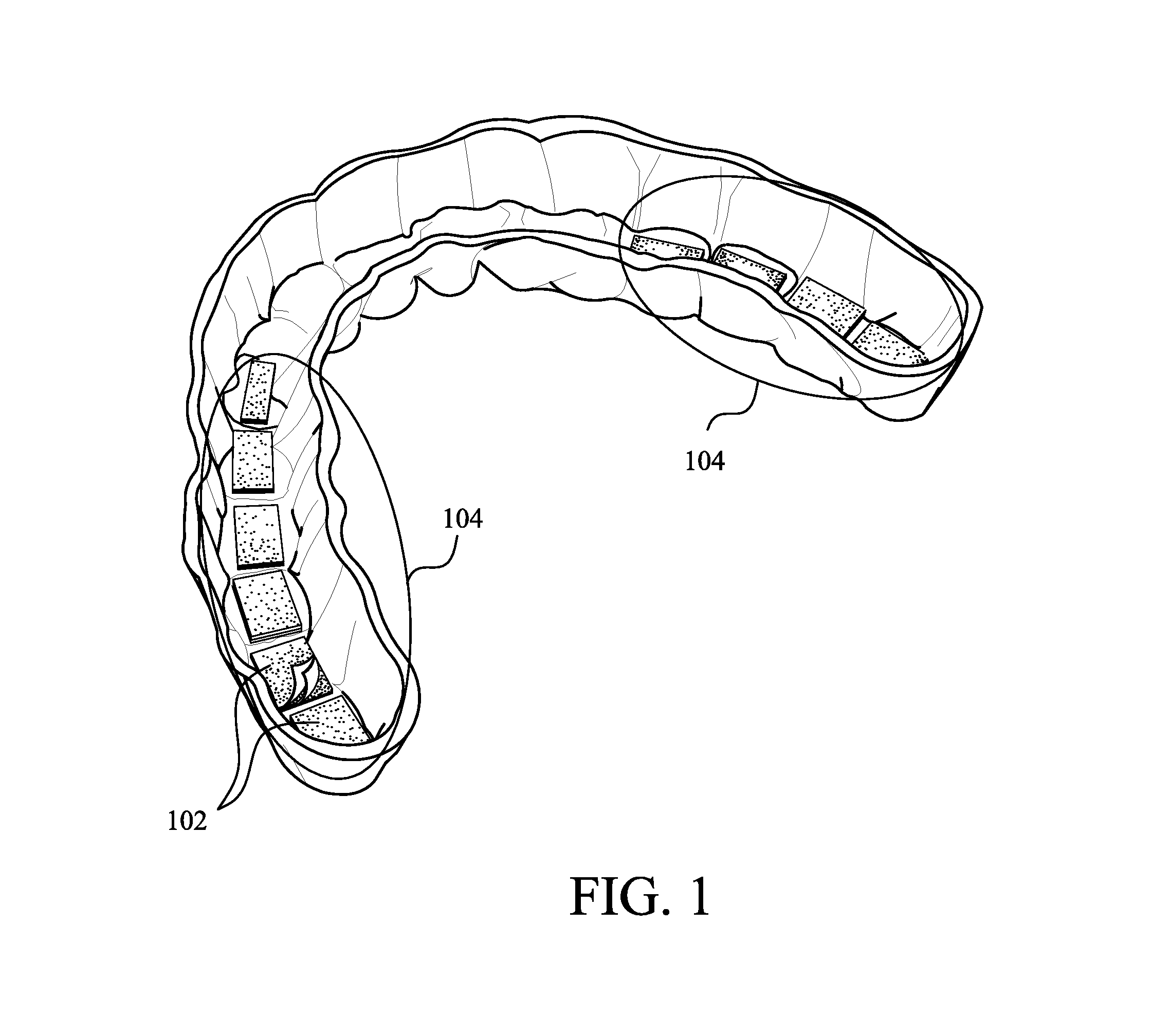

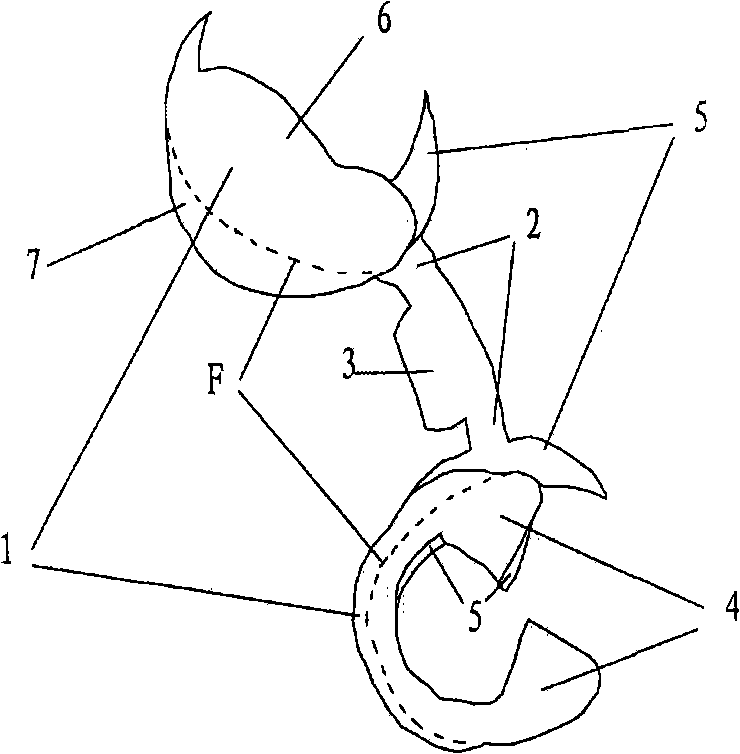

Breathing normalizer apparatus

InactiveUS7137393B2Reduce deliveryPrevent snoringTeeth fillingSnoring preventionOral medicationTeeth grinding

A breathing normalizer for partial insertion within the user's mouth for normalizing breathing patters, prevention of snoring, teeth grinding, and light forms of sleep apnea is disclosed. The device includes an outer plate which is positioned external to the user's mouth when in use, an elongated hollow shaft for connecting the structure to a lip plate adapted to be received between the user's lips and teeth, and a generally C-shaped multi-lobed structure adapted for receiving the user's tongue. The device is positioned within the oral cavity of the user in an operative configuration such that the tongue is retained within the multi-lobed structure, the teeth clamp down upon the connector with the lip plate positioned between the teeth and the inner portions of the upper and lower lips. The outer plate further defines a centrally disposed chamber having an inlet tube in fluid communication with the hollow tubular connector for providing an inlet for breathing air. The inlet tube is adapted for connection to a source of gas, such as oxygen, to assist in delivering the gas to the user through the lungs. In addition, the chamber includes a threaded peripheral edge adapted for threaded engagement with a container of medicine thereby facilitating the delivery of oral medications into the user's oral cavity and preferably the delivery of oral medications below the tongue. A medicine receiving chamber is further provided to allow for medicine received therein to be dispensed and / or evaporated in the user's mouth. As a result of proper application of the apparatus breathing at night is normalized, while snoring, grinding of the teeth, and apena are prevented, and further while medications may be simultaneously delivered orally.

Owner:PIVOVAROV ALEXANDER R

Dental appliance to prevent the negative effects of bruxism

InactiveUS20070023055A1Simple wayAvoid contactTeeth fillingSnoring preventionTemporomandibular disorderTeeth grinding

The present invention relates generally to dental appliances, and more specifically, to a unique bite guard that protects the teeth from the negative effects of teeth grinding or clenching, or other temporomandibular disorders which may include tension headaches, teeth fracture, cracking and / or loss. The application and configuration of the dental appliance is aesthetically superior to other configurations and arrangements and comprises of an outer shell that is small in configuration and is sized to fit the lower portion of a patient's lower front teeth. The dental appliance further includes an inner pliable layer that is in mating engagement with the inner anterior wall and the inner posterior wall of the outer shell. The inner pliable layer is also in mating engagement with the patient's front incisors and conforms to the patient's dentition.

Owner:ROTH STEVEN E

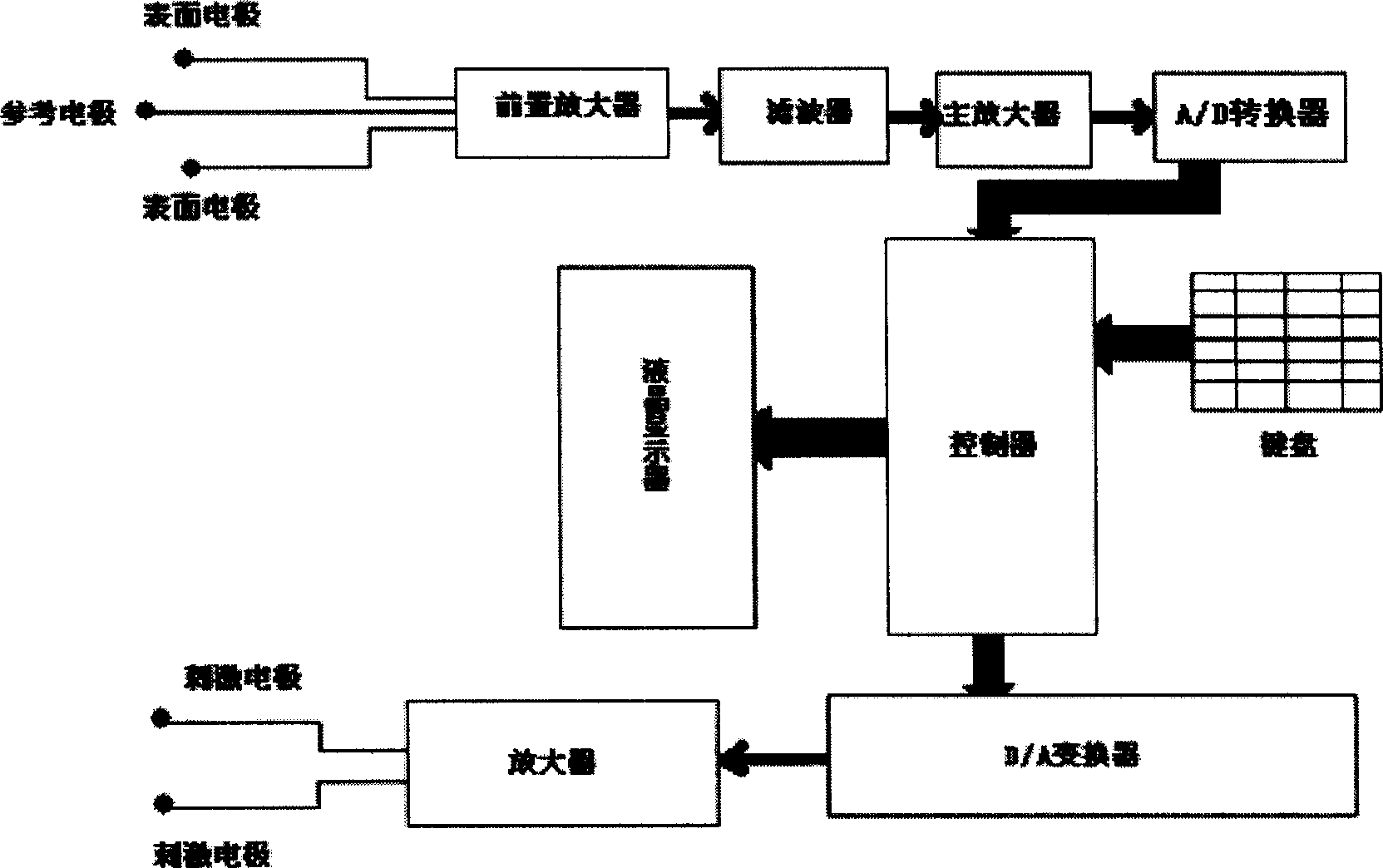

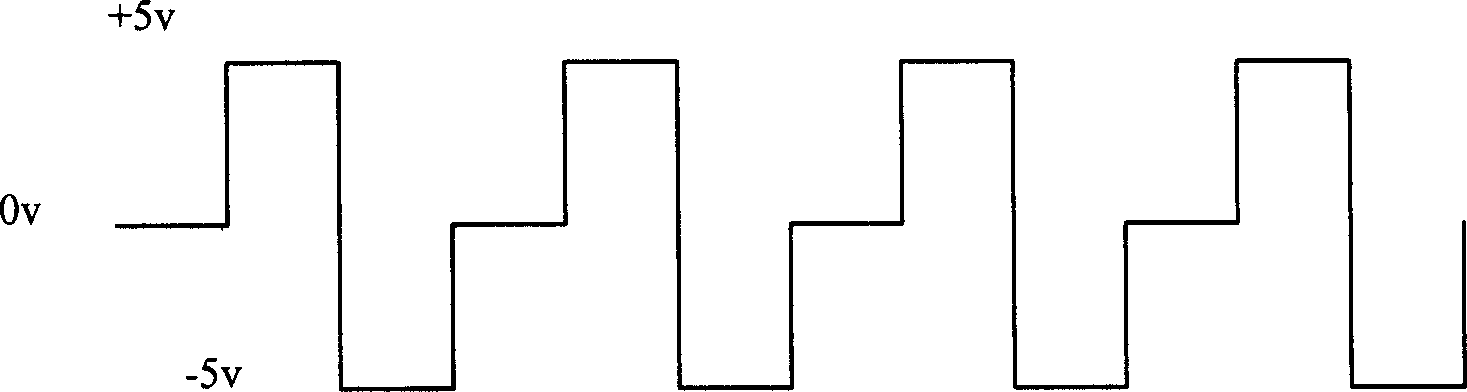

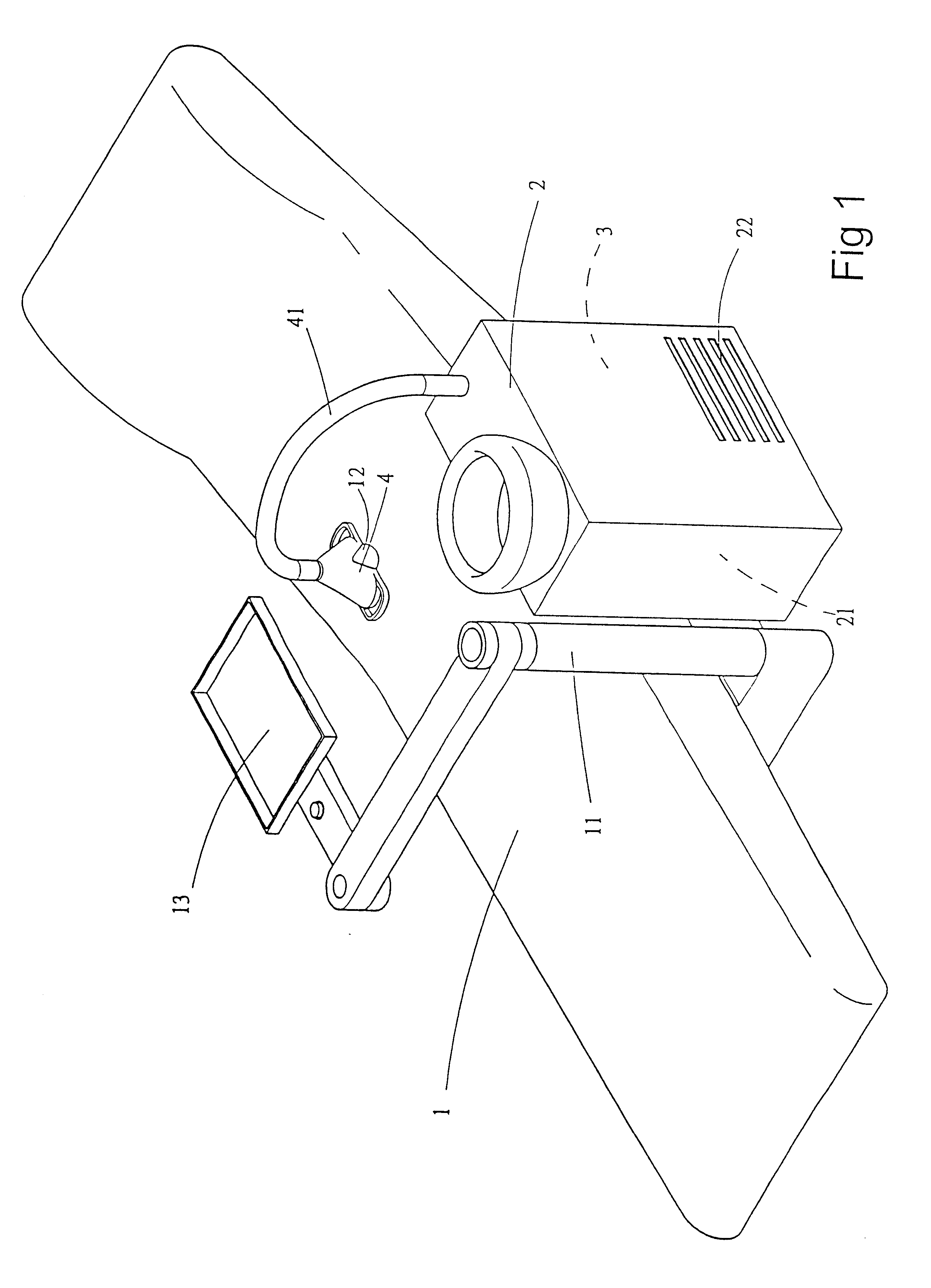

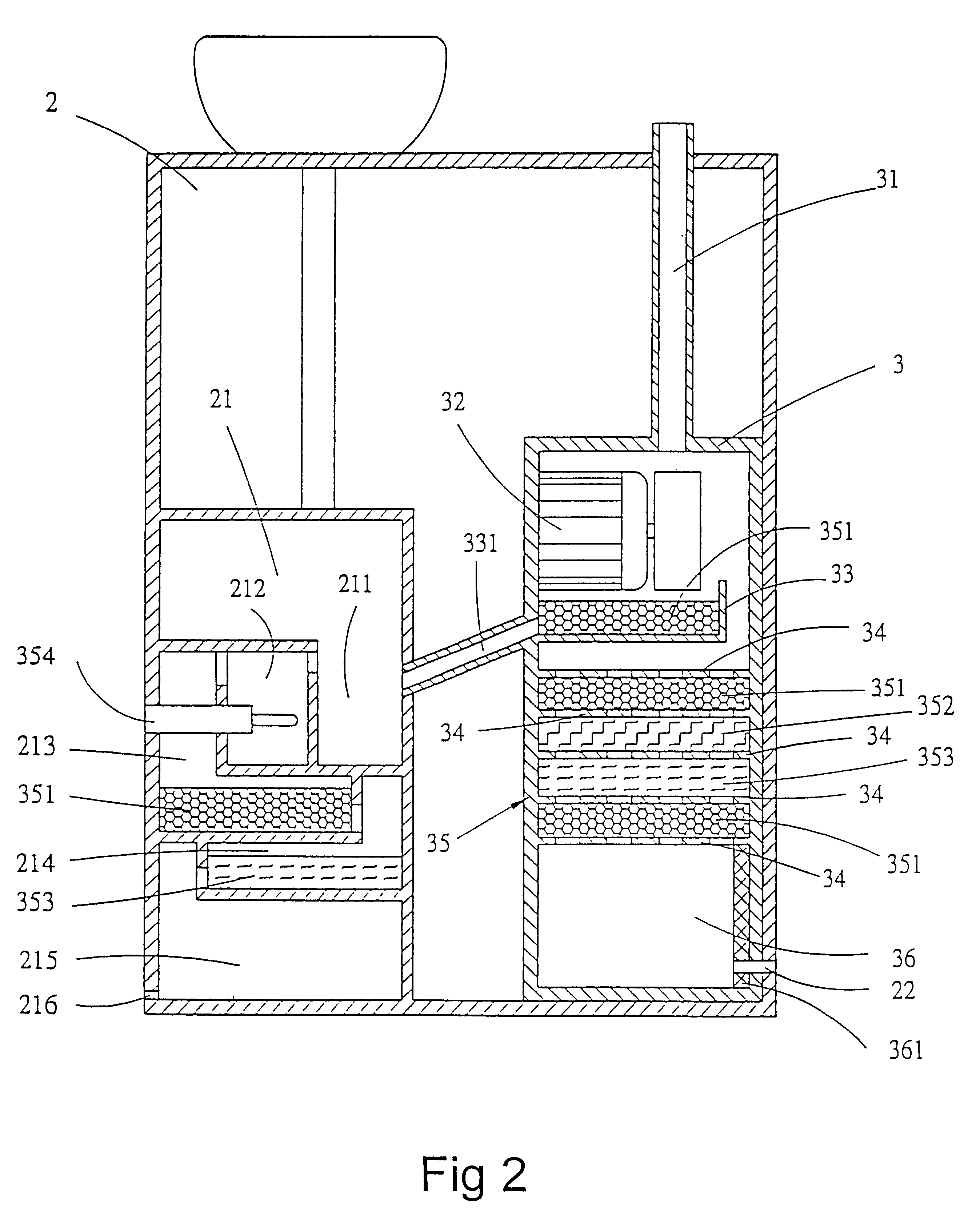

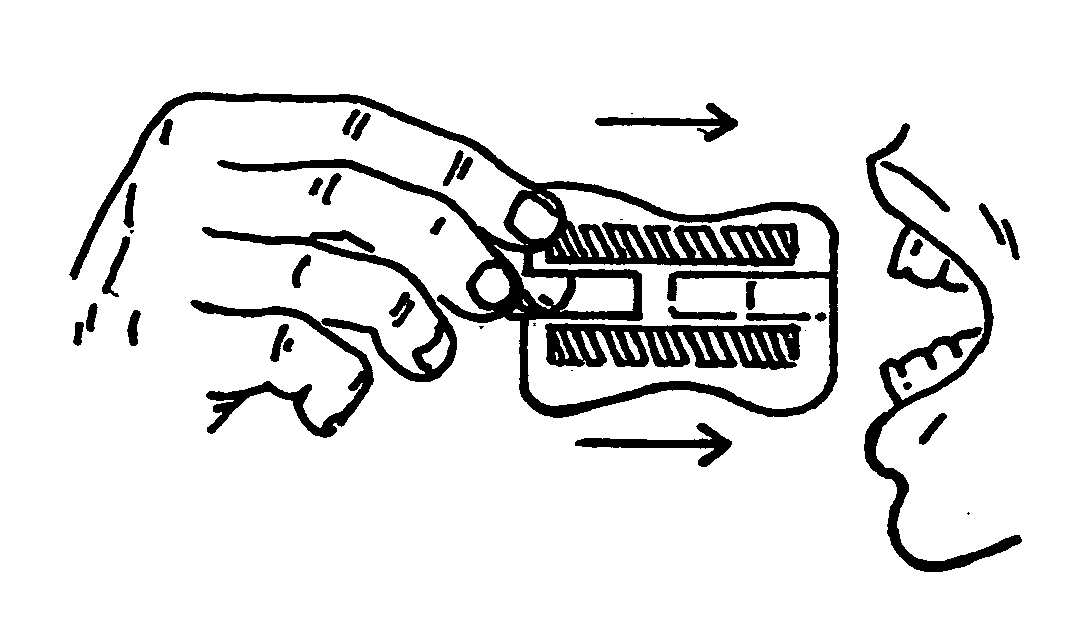

Electromechanical bruxism monitoring and treating equipment

InactiveCN1810319ADoes not affect normal sleepReduce volumeElectrotherapyDiagnostic recording/measuringElectricityElectrical impulse

The electromechanical bruxism monitoring and treating equipment consists of a measuring and recording part and a feedback treating part. The measuring and recording part has surface electrodes capable of recording the myoelectric action of abnormal masseter during sleep. When the myoelectric strength exceeds certain amplitude and the myoelectric signal period becomes greater than certain value, the controller has its counter started and the counting result including the average strength is shown in the display. Then, the feedback treating part generates stimulating electric pulse to regulate the myoelectric action so as to reach the aim of treating bruxism. The electromechanical bruxism monitoring and treating equipment can monitor the teeth grinding time and strength as treating reference and treating bruxism by means of weak electric stimulation.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

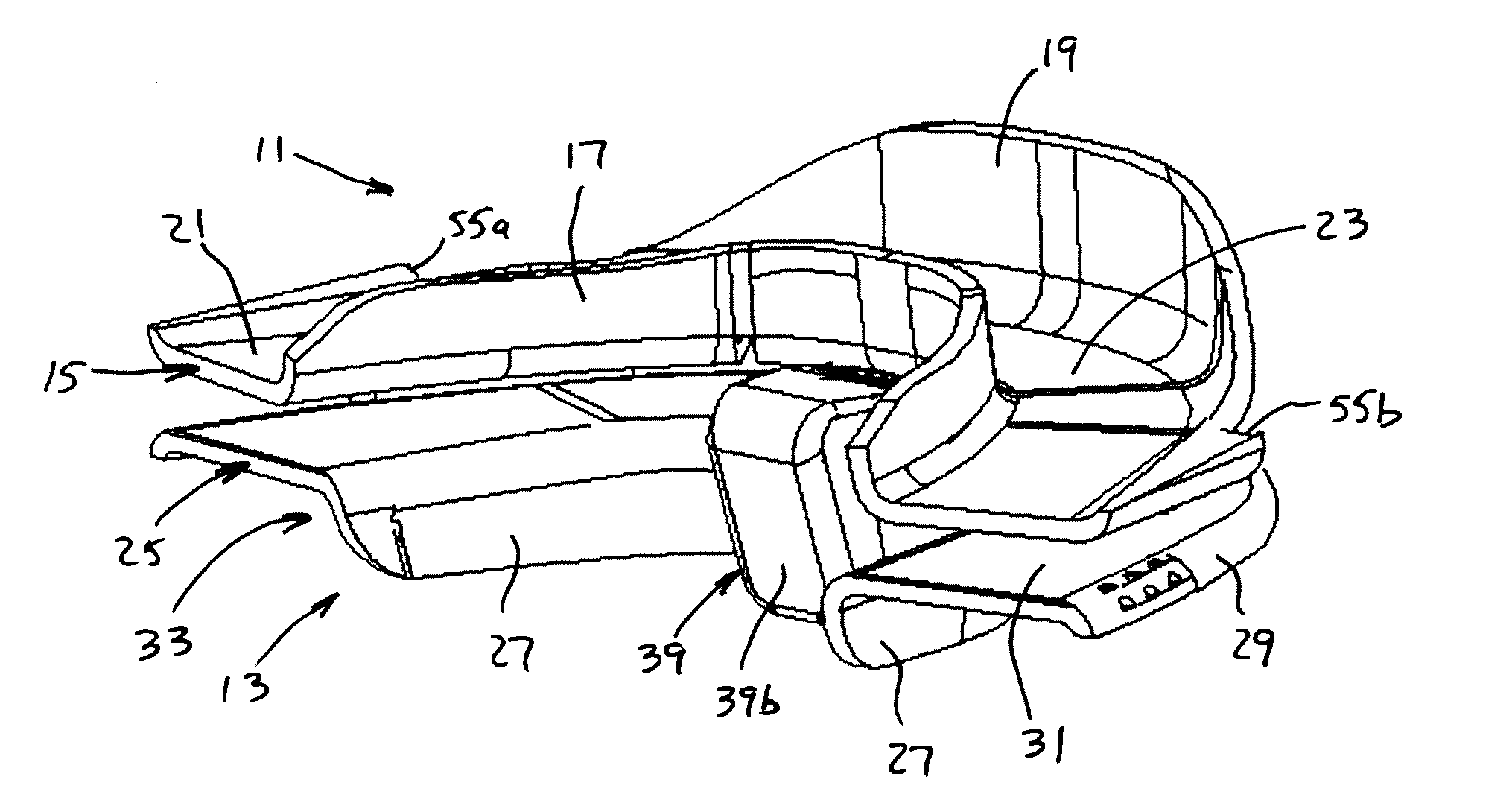

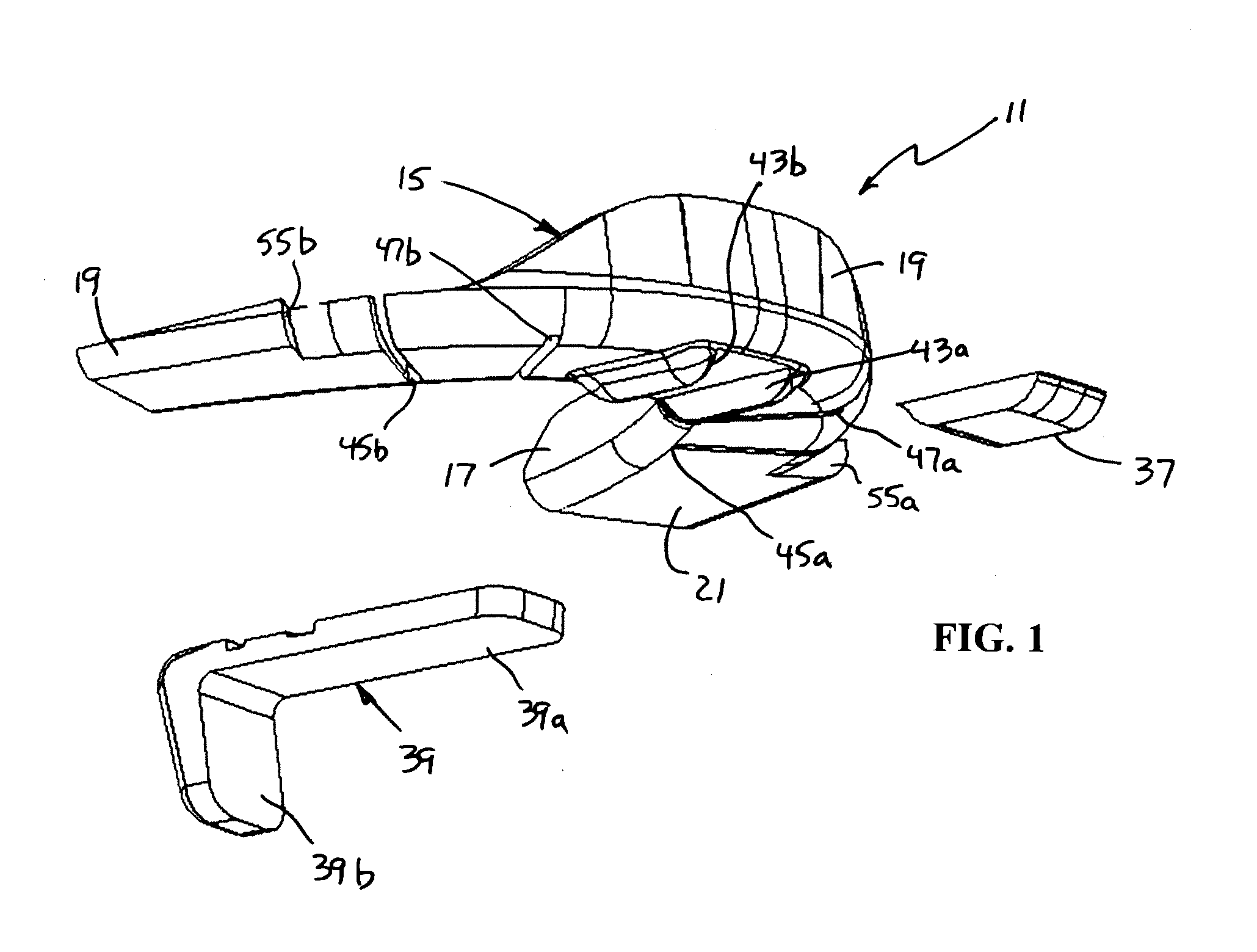

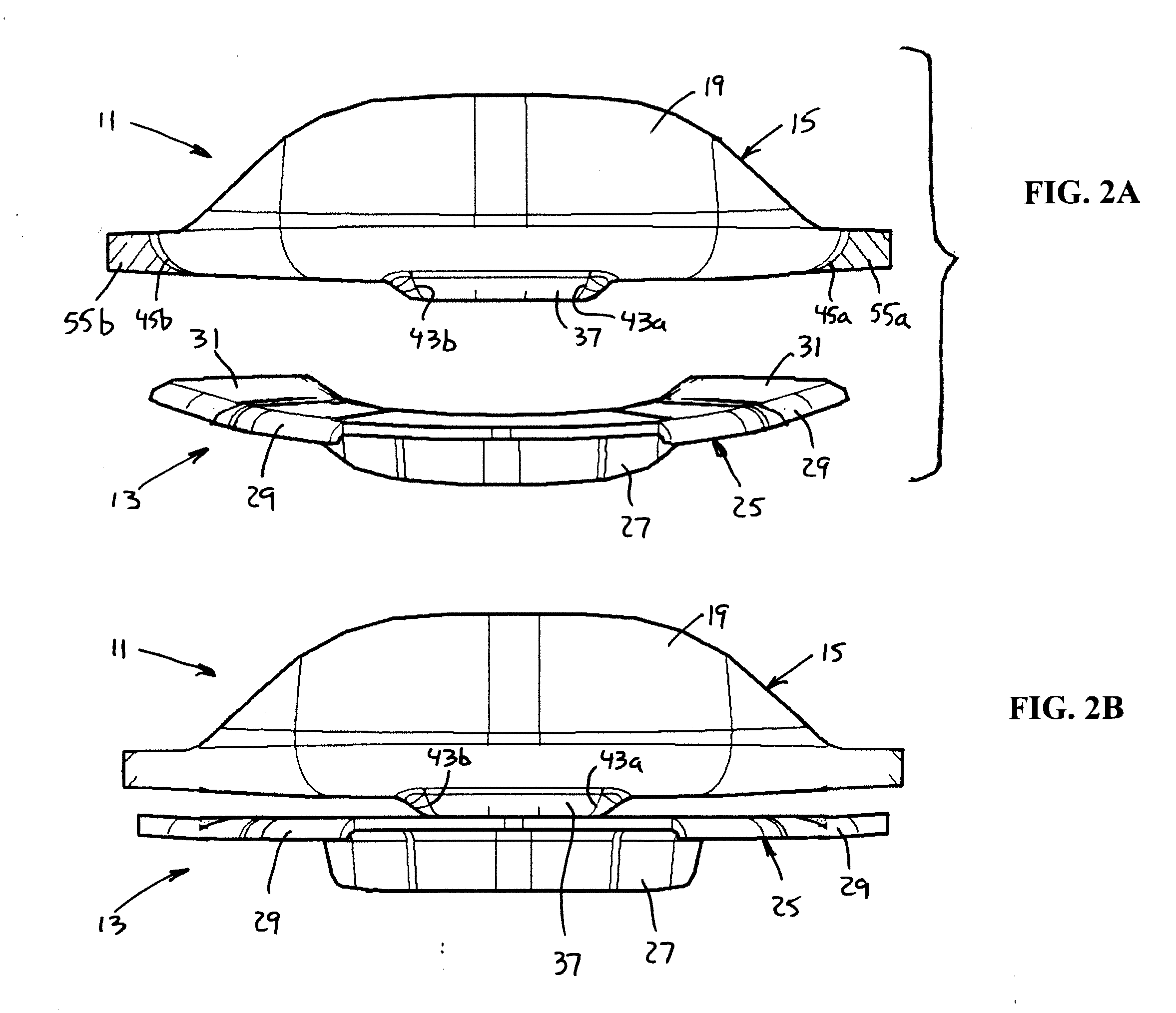

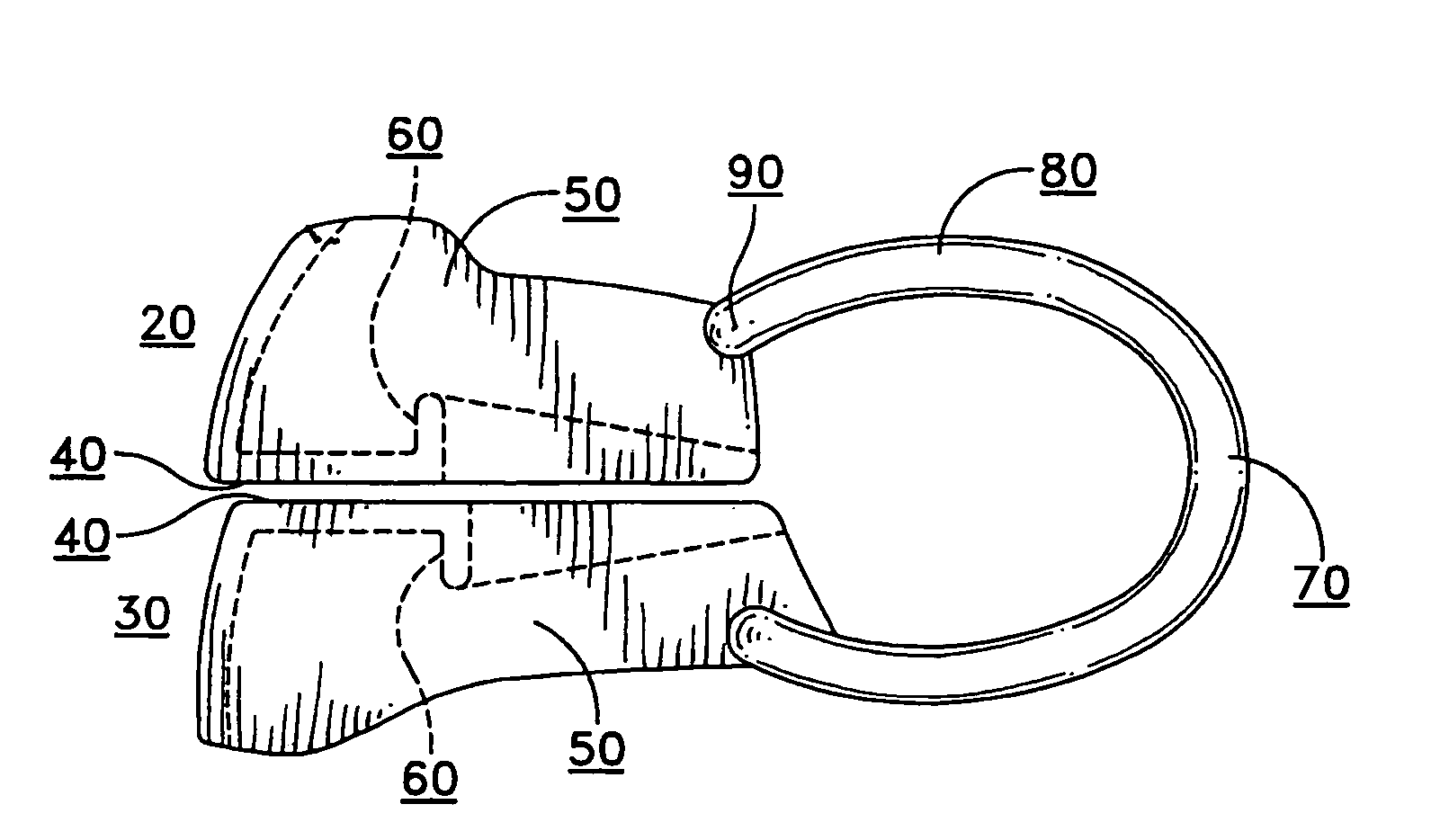

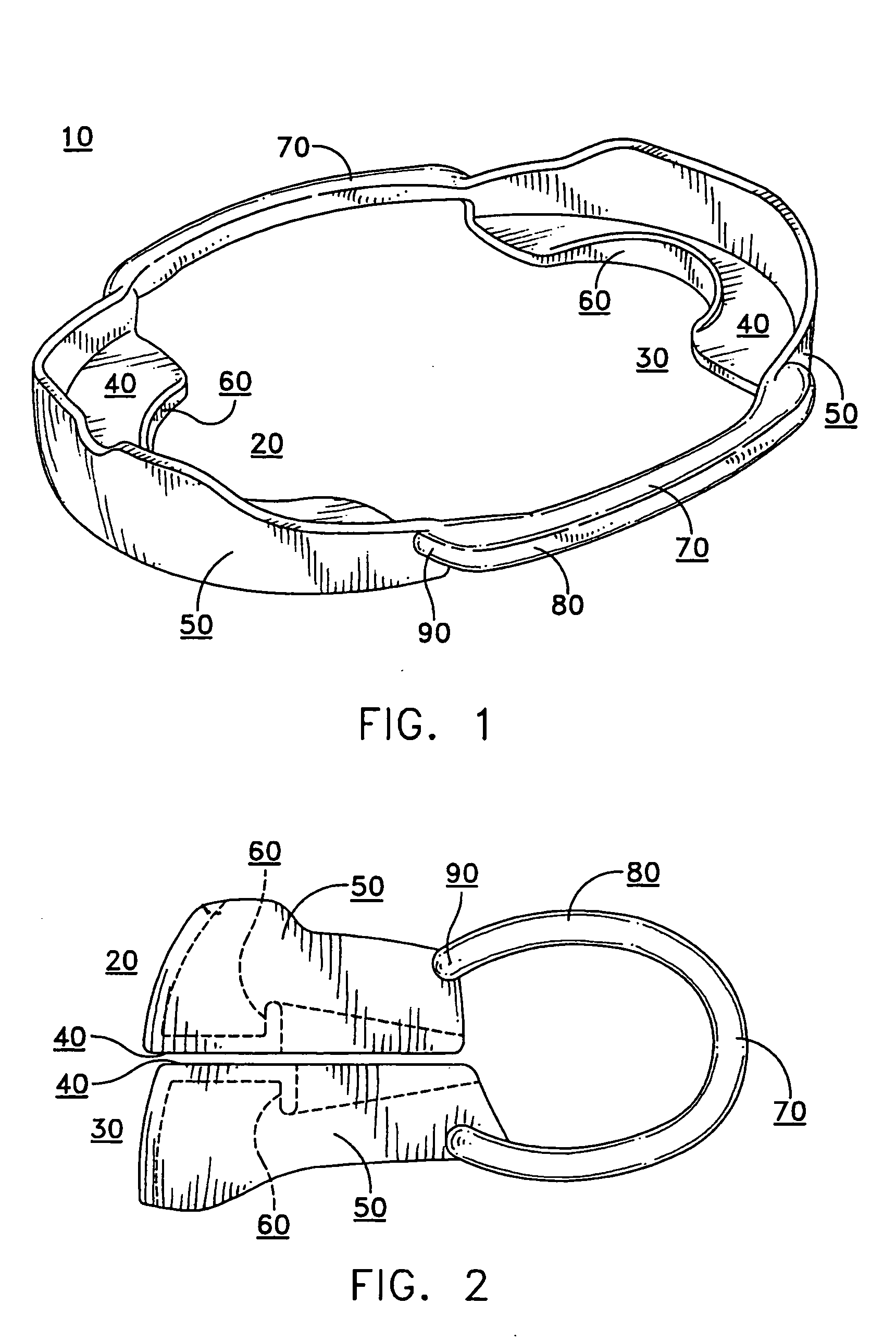

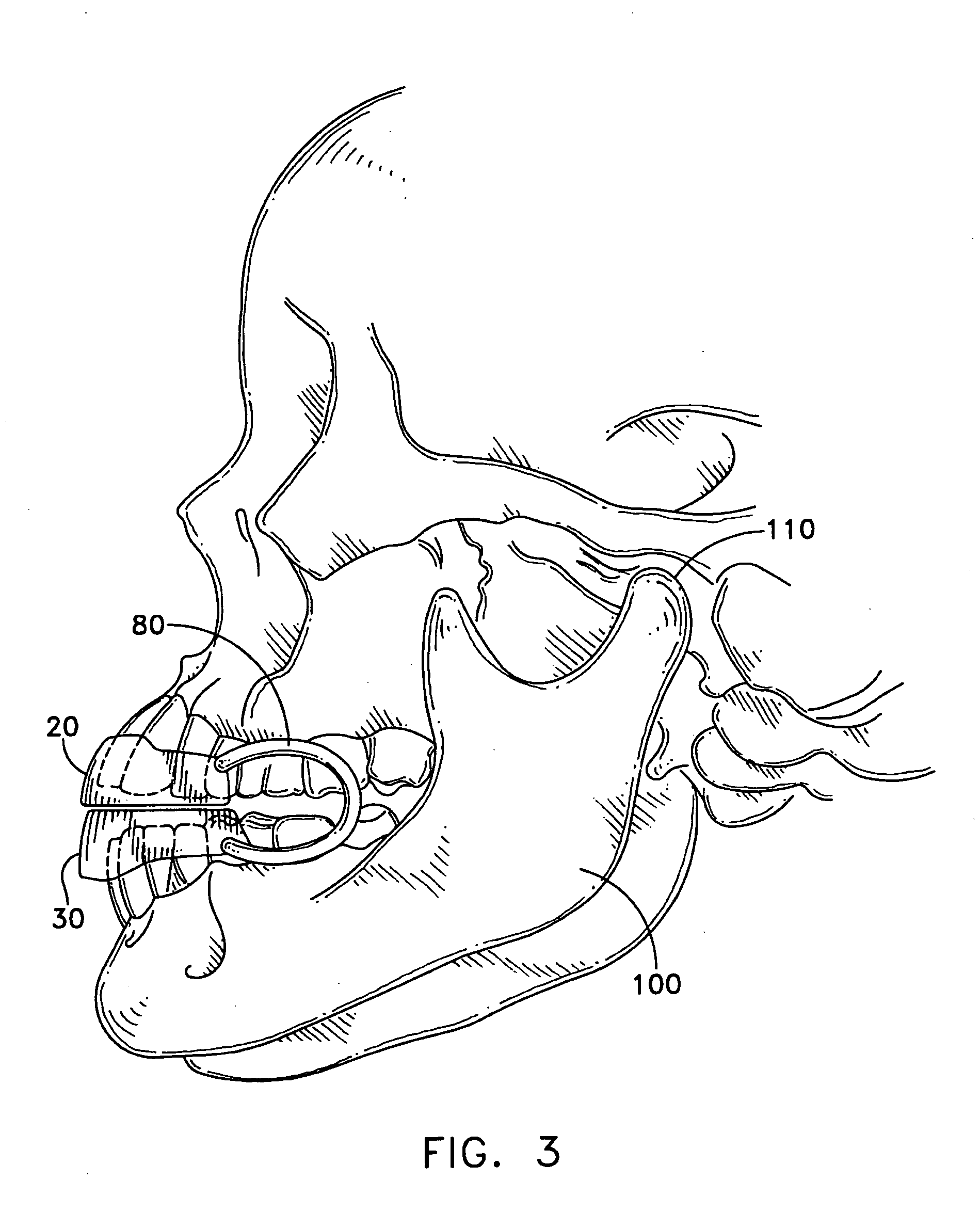

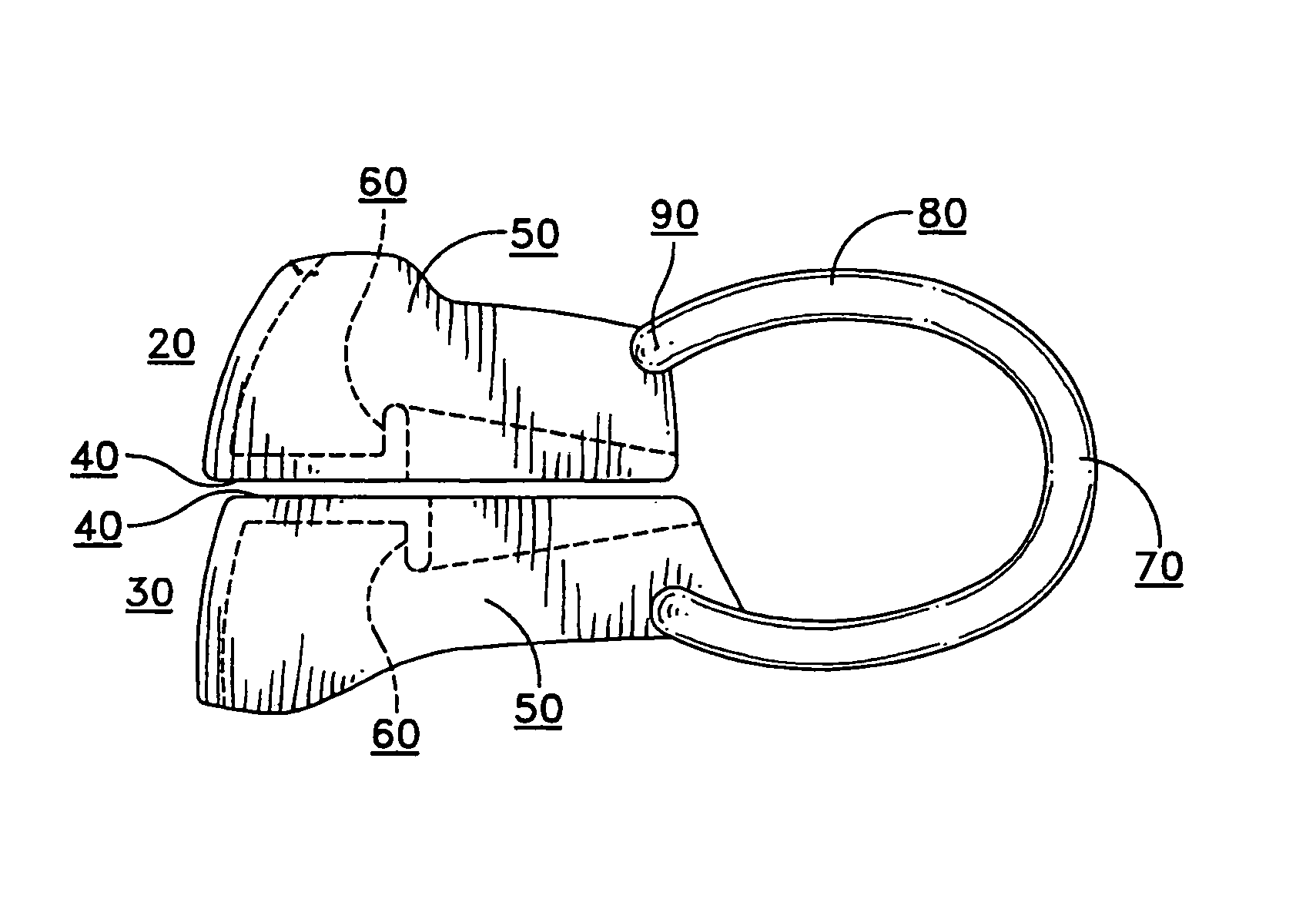

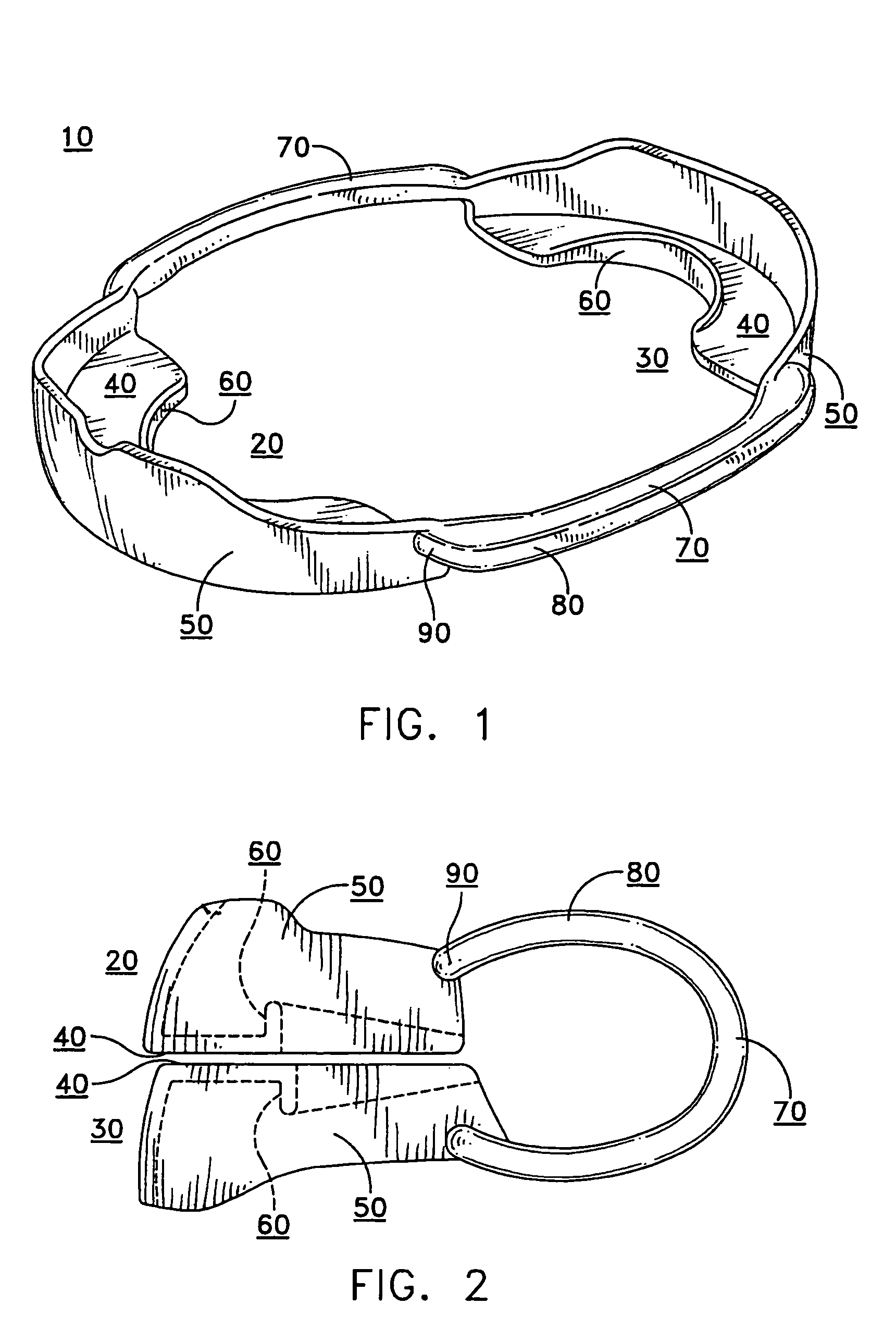

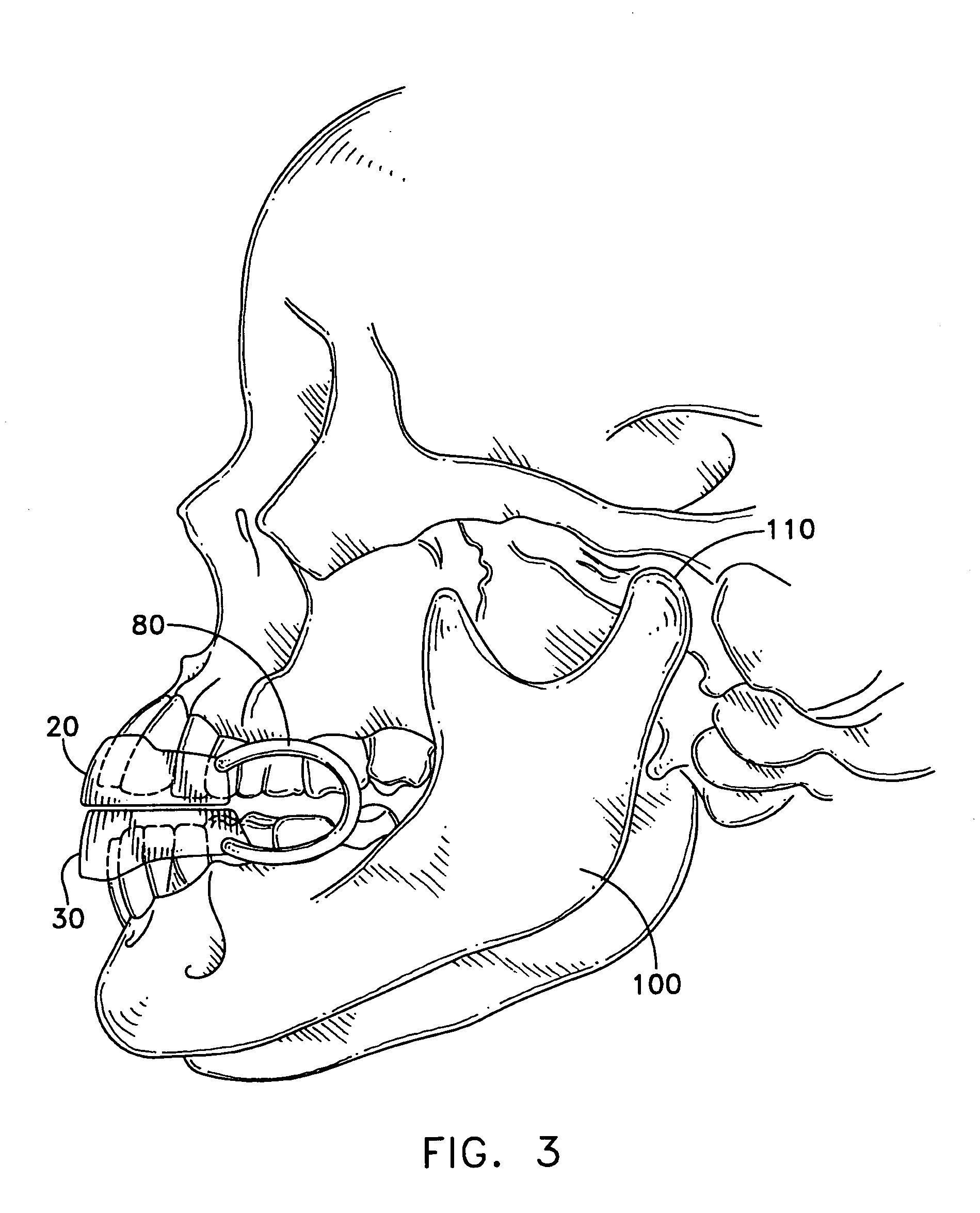

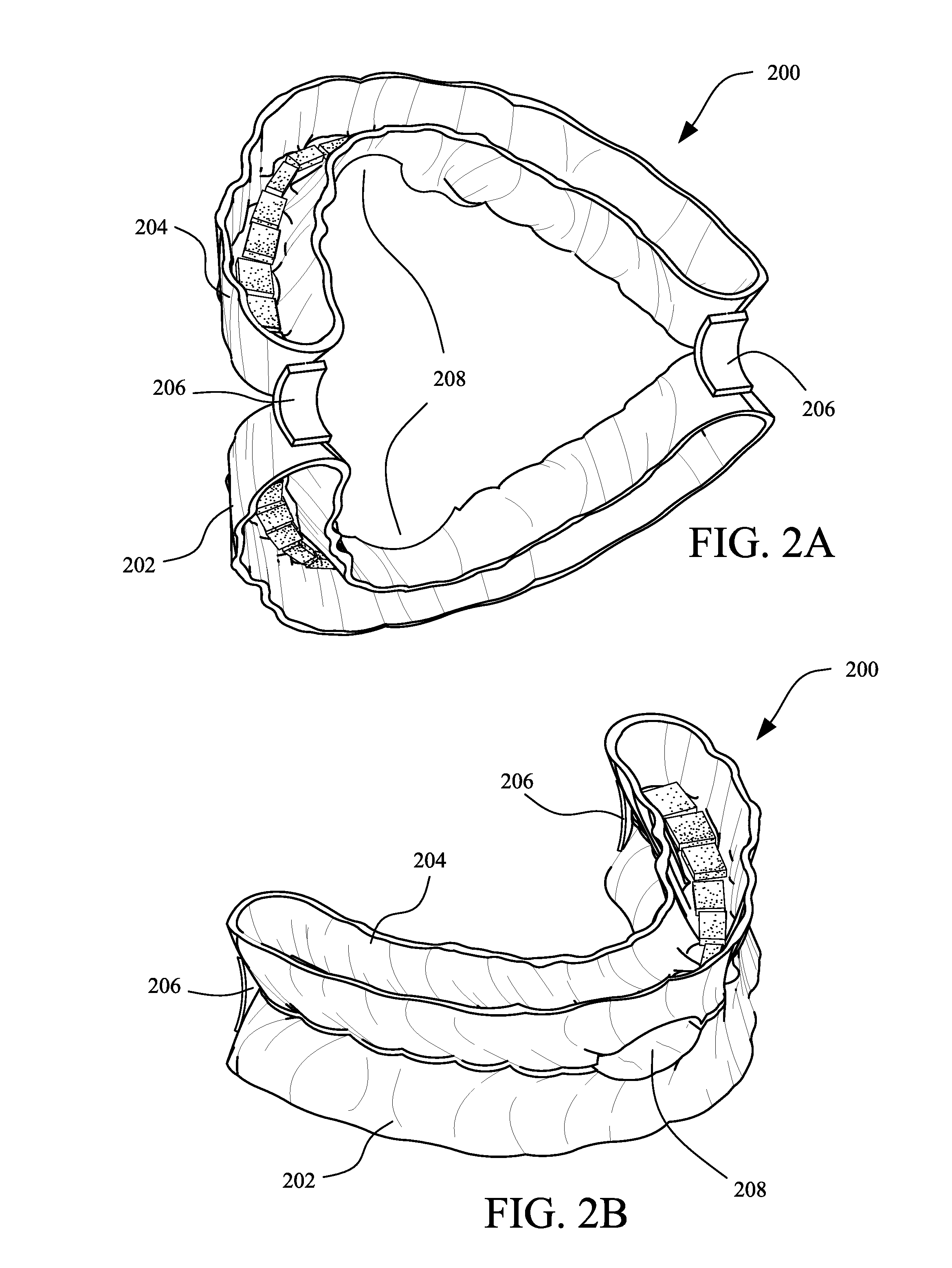

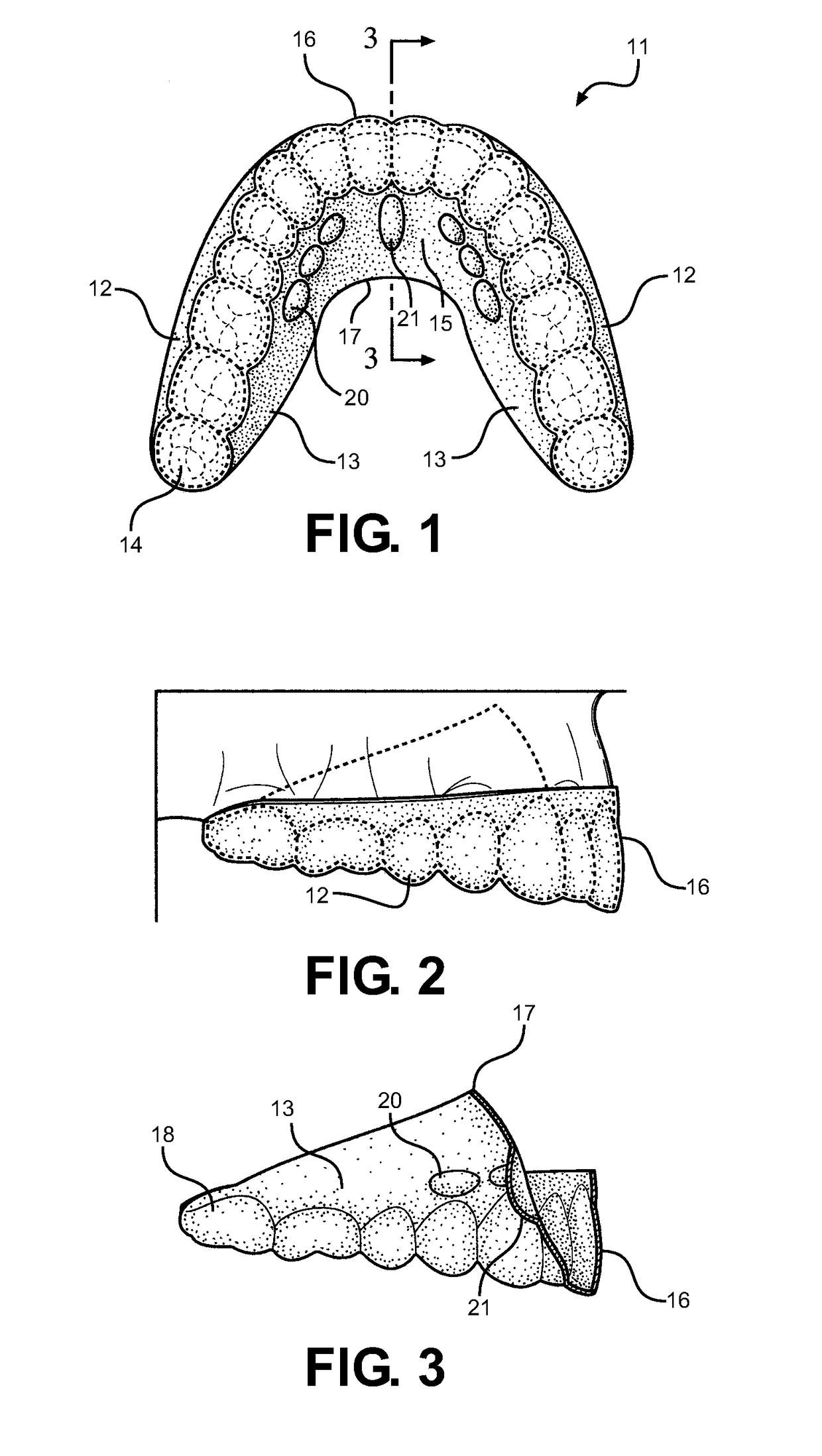

Multipurpose therapeutic mouthpiece assembly

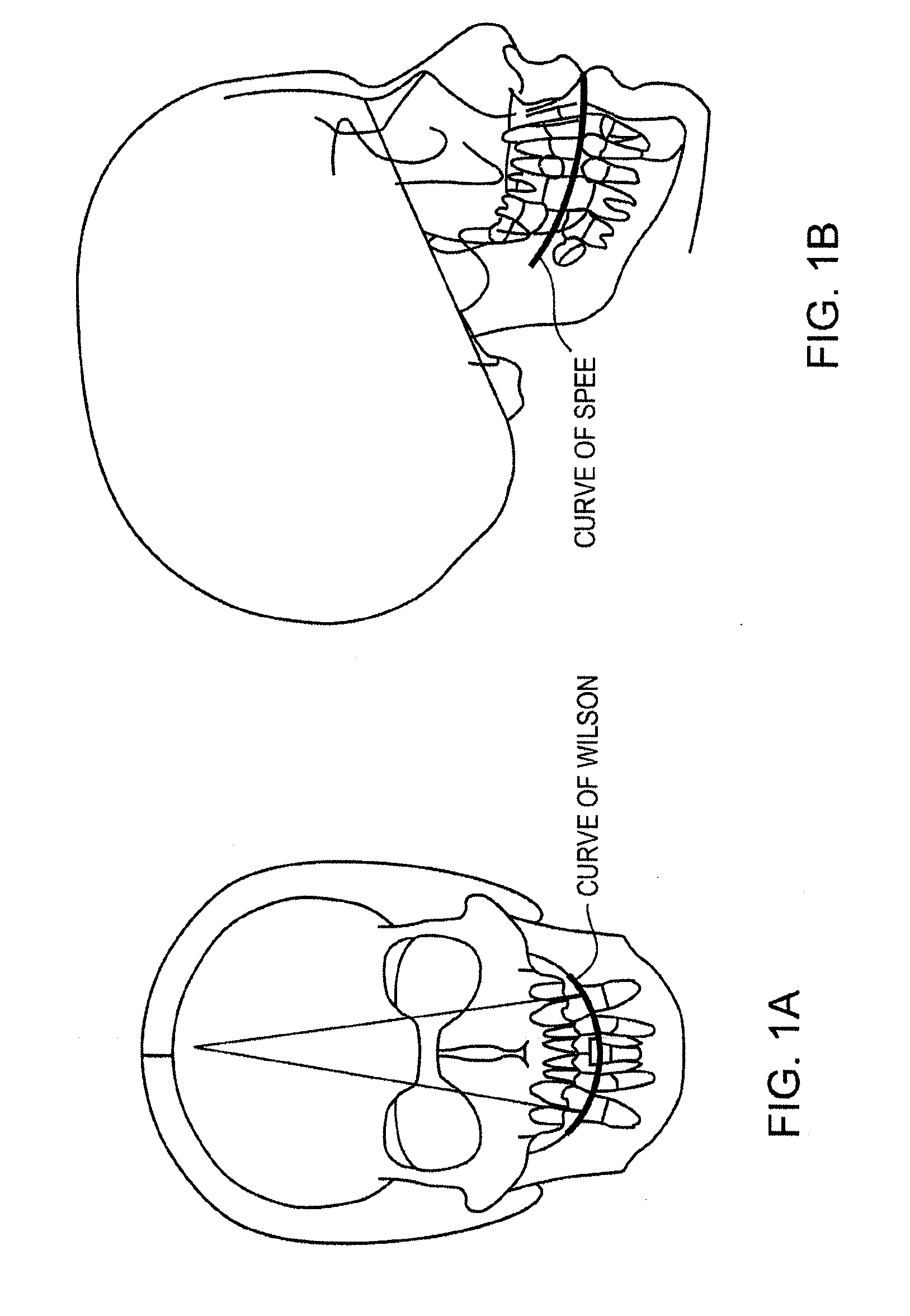

An multipurpose mouthpiece assembly is disclosed for use in diagnosing and treating a variety of termporomandibular disorders. The assembly can include both a maxillary appliance and a mandibular appliance that are optionally configurable to function as a discluder, for diagnosing and treating wearers suffering from bruxism, tension headaches, and common migraine headaches, by preventing contact between opposing canine and posterior teeth and thereby reducing the intensity of clenching of the wearer's temporalis muscles. Alternatively, the two appliances are optionally configurable for use as a mandibular advancement device, for diagnosing and treating wearers suffering from obstructive sleep apnea by preventing excessive retrusion of the wearer's mandible. Alternatively, either the maxillary appliance or the mandibular appliance can be used individually to protect the teeth from nocturnal asymptomatic teeth grinding. In all cases, the appliance(s) can be readily adjusted to accommodate wearers whose maxillary and mandibular arches have a variety of sizes and shapes.

Owner:BOYD RES

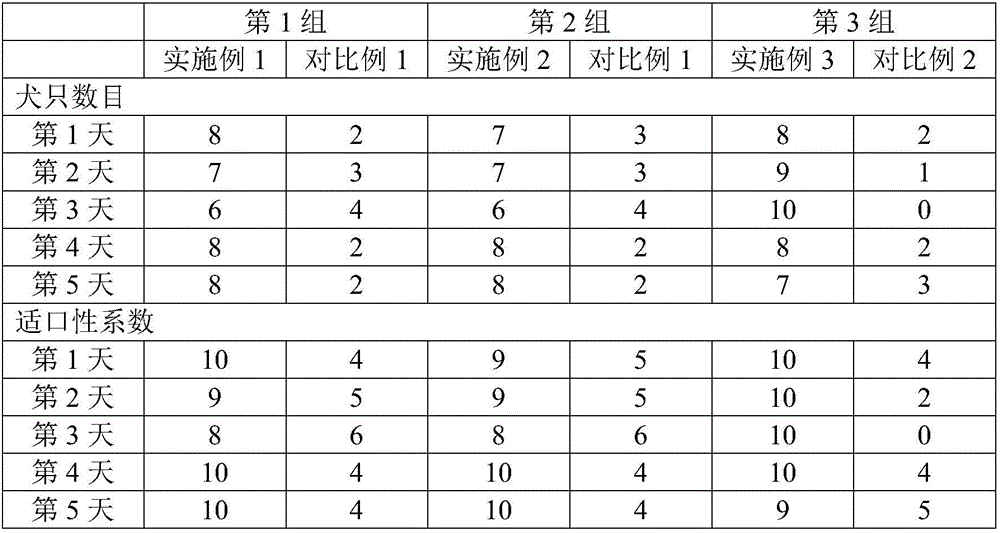

Pet chews containing coarse grains and preparation method of pet chews

The invention discloses pet chews containing coarse grains and a preparation method of the pet chews, belonging to the field of pet food processing. Particularly, the pet chews are prepared from the coarse grains and plants by a mechanical puffing process. The pet chews are characterized by comprising the following components in parts by weight: 30-42 parts of corn starch, 18-27 parts of flour, 15-22 parts of coarse grains, 5-7 parts of gelatin, 10-15 parts of glycerin, 0.01-0.05 part of xanthan gum, 0.02-0.05 part of potassium sorbate, 0.03-0.06 part of monoglyceride, 0.05-0.1 part of salt, 0.5-1.0 part of sugar, 3-5 parts of sorbitol, 0.3-0.5 part of a pet essence, and 0.01-0.05 part of sodium citrate. The pet chews are low in cost, the production of the pet chews is not affected by short supply of the raw materials and weather, and the pet chews are more suitable for large-scale production. The pet chews have teeth grinding and dental care functions, and are beneficial to promoting and improving pet intestine and digestive absorption by virtue of the contained coarse grains.

Owner:江苏贝甜宠物食品有限公司

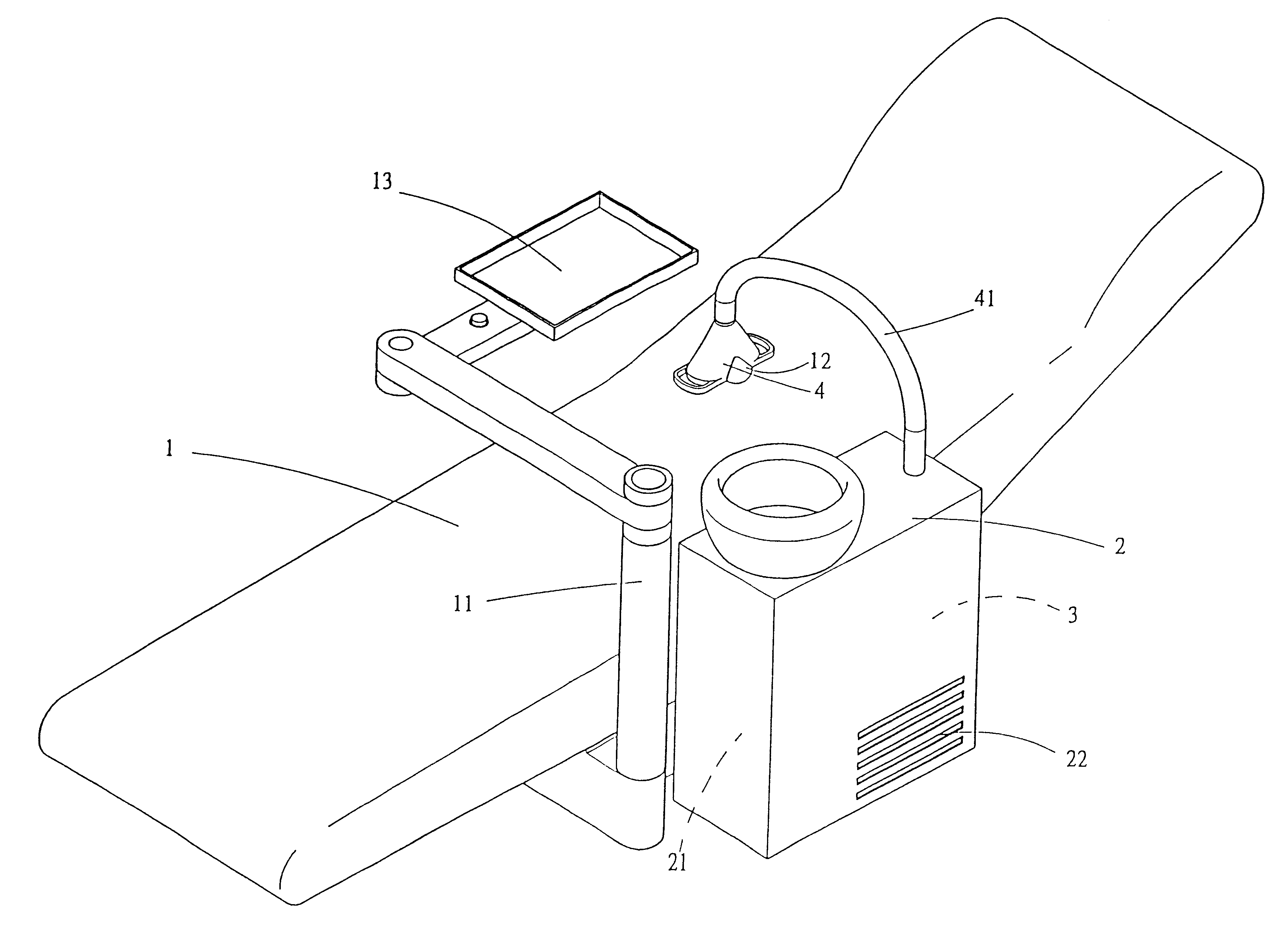

Air-sucking, sterilizing and wastewater treatment method for dental clinic bed

InactiveUS6464499B1Precise positioningAvoid contaminationOperating chairsDental toolsChemical solutionExhaust valve

This is an air-sucking, sterilizing and wastewater treatment method for dental clinic bed. It has an air-sucking and sterilizing device, and a wastewater-treating device below a gargle bench of a dental clinic bed. The air-sucking inlet of the air-sucking and sterilizing device is connected above the bench top to an air-sucking pipe that can be bent to form. At the other end of the air-sucking pipe is an air-sucking mask equipped with a clinical lamp. Utilizing the bendable property of the air-sucking pipe, the dentist can adjust the air-sucking mask with the clinical lamp to an optimum position, to collect germ-carrying flying saliva and volatile chemicals produced in the clinical process, or the flying moisture from the tooth grinding machine in the air-sucking and sterilizing device. Inside the air-exhaust valve is a ion device for purifying purpose to enhance hygienic quality of the entire clinical process, and avoid unnecessary contamination of flying saliva. The wastewater-treating device will clean the patient's mouth and chemical solutions and germ-carrying wastewater, filter and sterilize it thoroughly before discharging it, so the discharged wastewater will not pollute river sources.

Owner:LU LI CHOU

Dual use exercise whitener appliance

InactiveUS20130029291A1Facilitate breathing, expectorating, and speakingTeeth fillingSnoring preventionSacroiliac jointTeeth grinding

A jaw-joint protective device is provided for whitening and brightening a wearer's teeth while protecting the teeth, tongue, lips, jaw, and other delicate structures of the vital cranial triad (VCT) from injury and / or for supporting the condyle of the temporomandibular joint (TMJ) in a relatively fixed (stable) position thereby stabilizing the jaw and the VCT during head contact activity, exercise, physical rehabilitation, C-force acceleration, teeth grinding disorders and sleep apnea and or permit the components of a VCT disorder to be realigned for proper healing. This device is an over-the-counter purchased, boil and bite device for whitening at least one tooth while protecting the jaw-joint, providing maxillary and mandibular teeth seats for protection of the mouth and / or healing of the VCT. This invention provides a device for customized fitting that is purchased over-the-counter that is versatile for protecting not only the mouth but also a larger area, the vital cranial triad which includes the TMJ, while at the same time allows for audible speech, reduces sleep disorders of snoring, grinding and clenching of teeth with additional benefits.

Owner:WILLIAMS EDWARD D

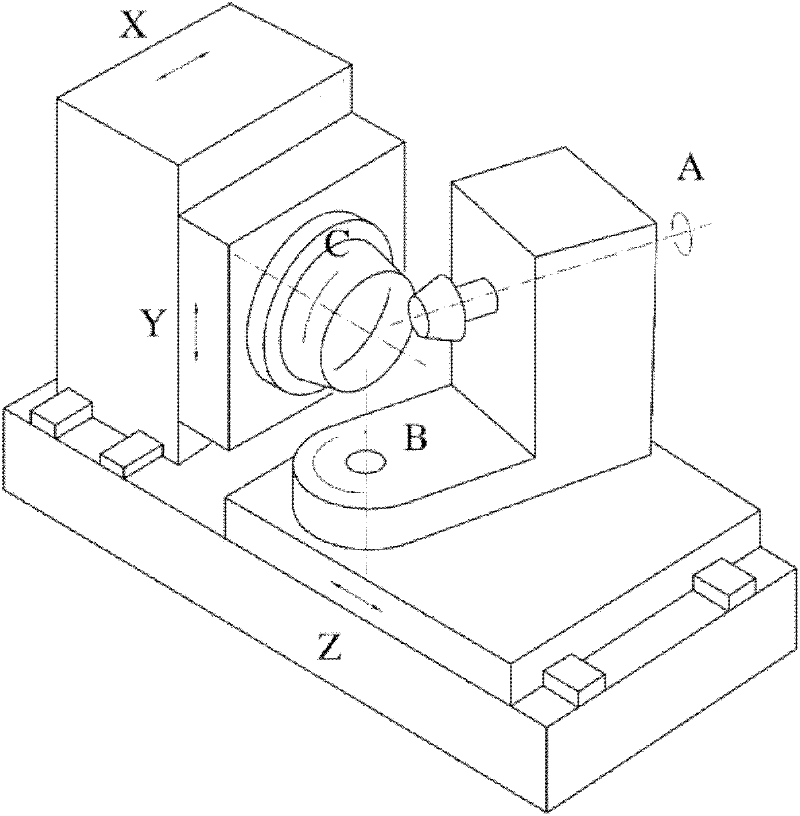

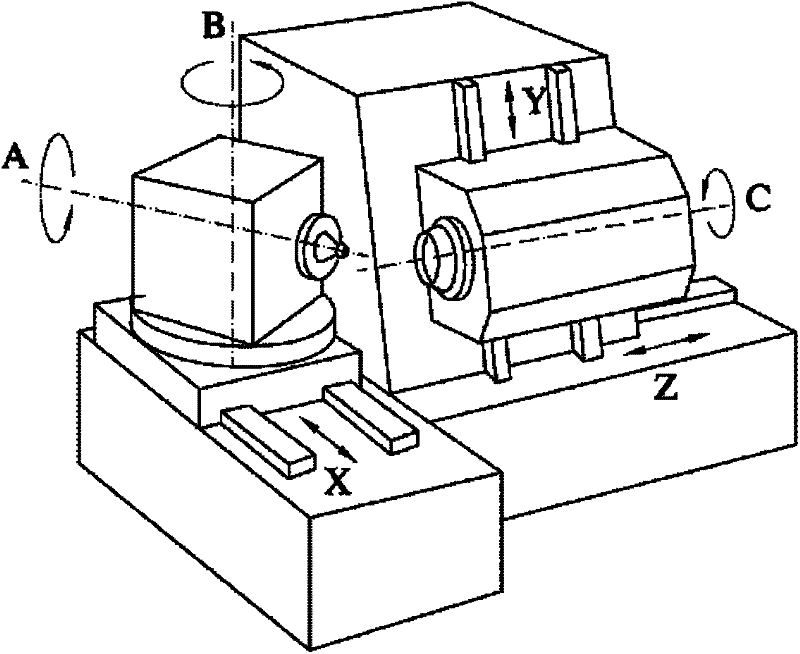

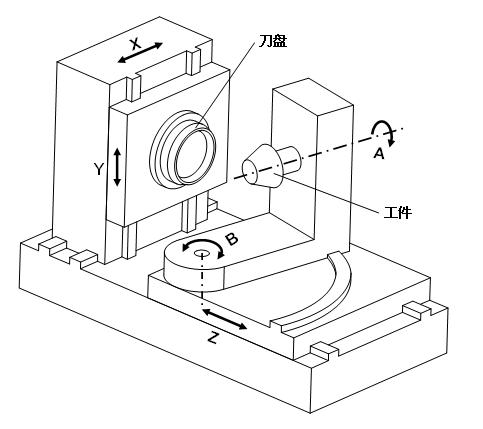

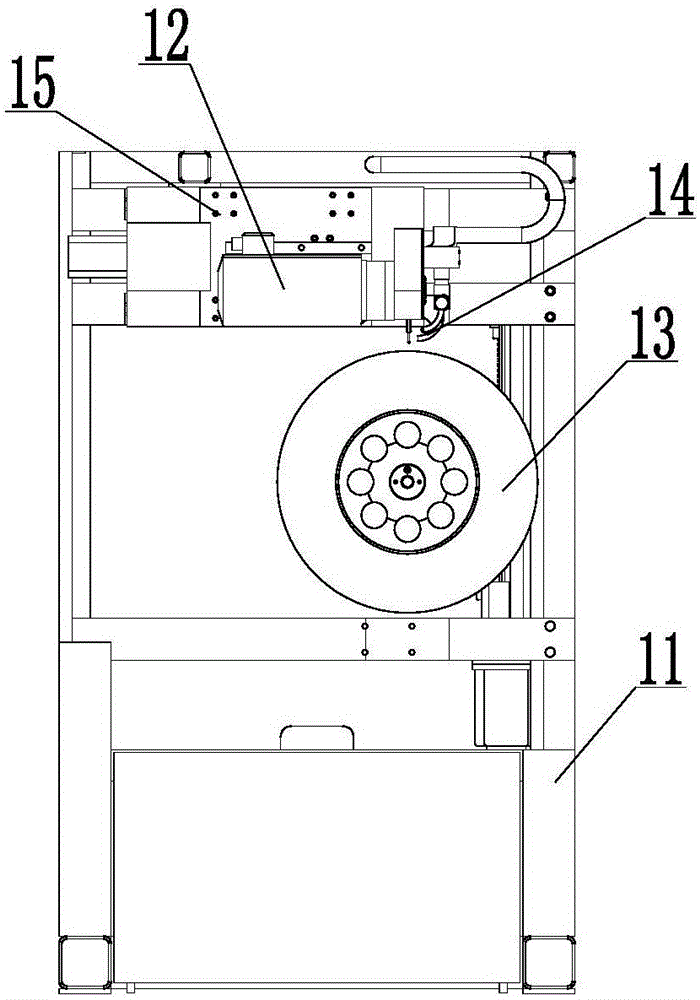

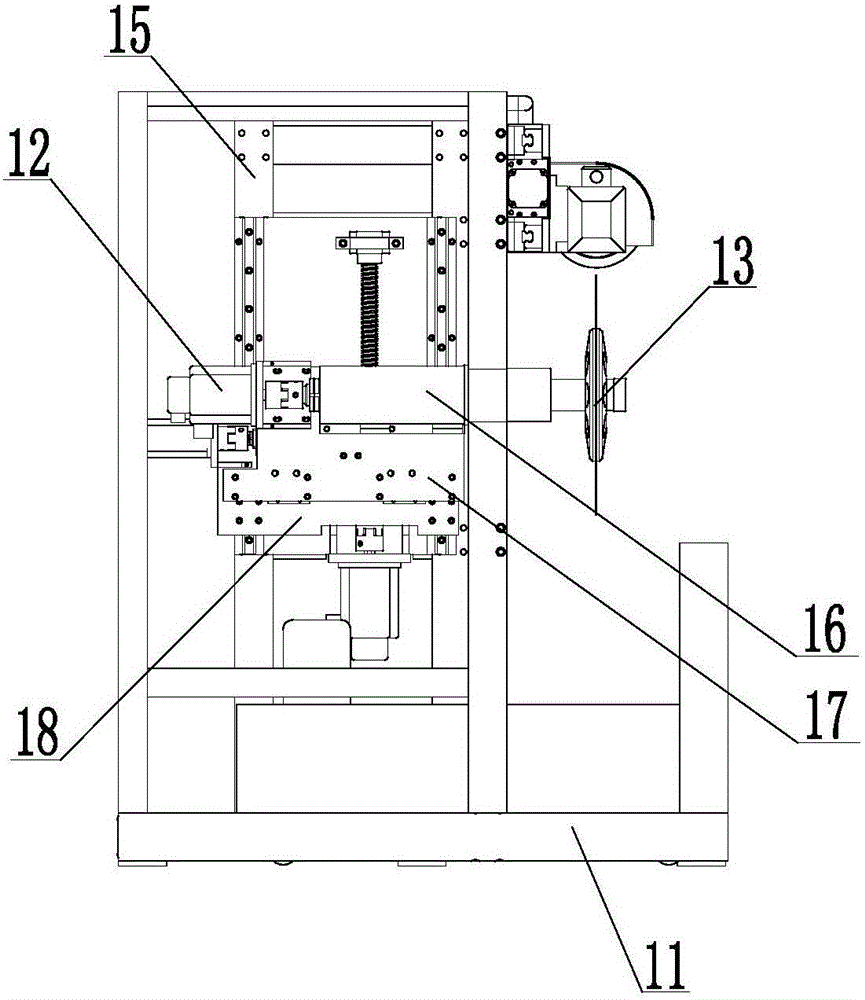

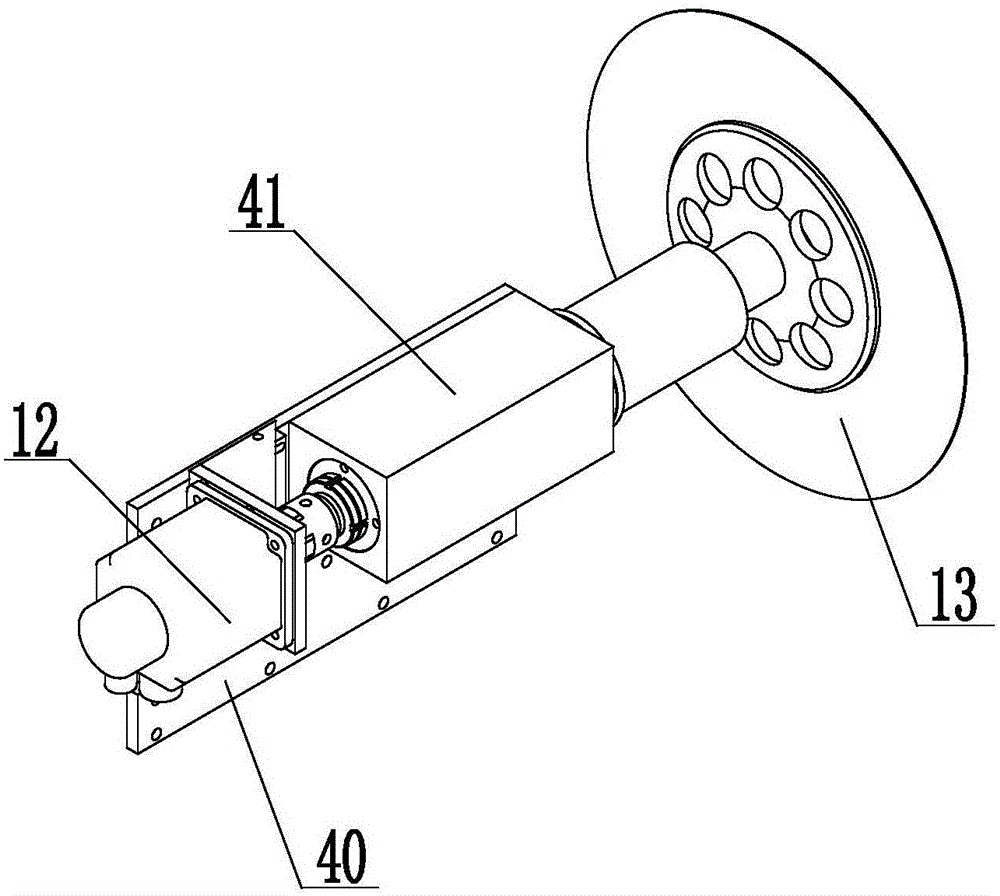

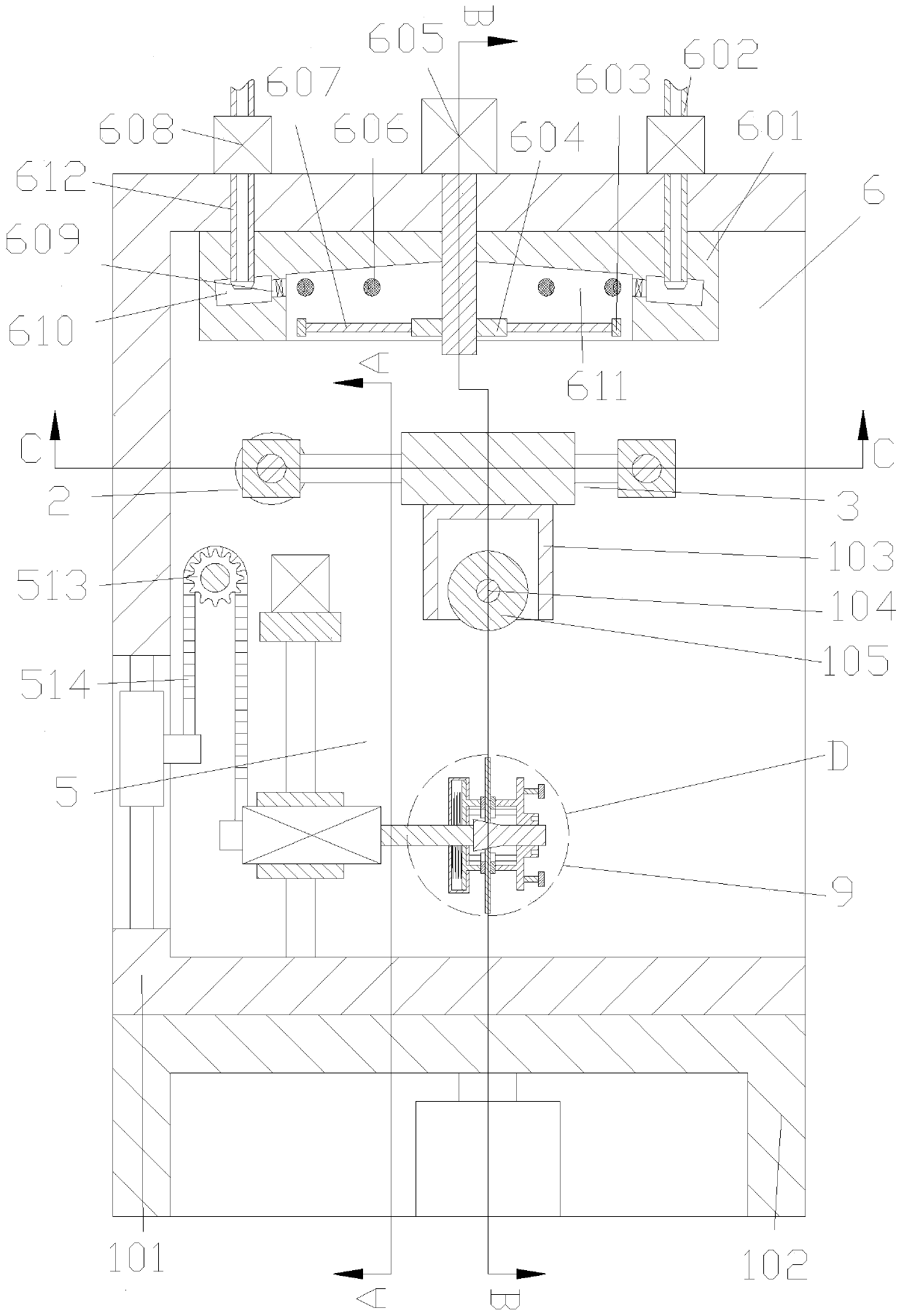

Machine tool and method for machining spiral bevel gear

The invention relates to numerical-control mechanical processing equipment and methods, in particular to a machine tool and a method for machining a spiral bevel gear. The machine tool is provided with a conveyer belt for automatically loading / unloading and a manipulator for loading / unloading the gear, thus, the full automation for machining the gear is realized. The machine tool has a simple structure and a small floor space, can be used for wet-cutting the spiral bevel gear, and can also be used for dry-cutting the spiral bevel gear; the machine tool can be used as a teeth-milling machine of the spiral bevel gear, and can also be used as a teeth-grinding machine of the spiral bevel gear; and the machine tool not only can carry out precision detection on machined gears, but also is provided with an automatic loading / unloading device.

Owner:CHANGSHA HALIANG KAISHUAI PRECISION MASCH CO LTD

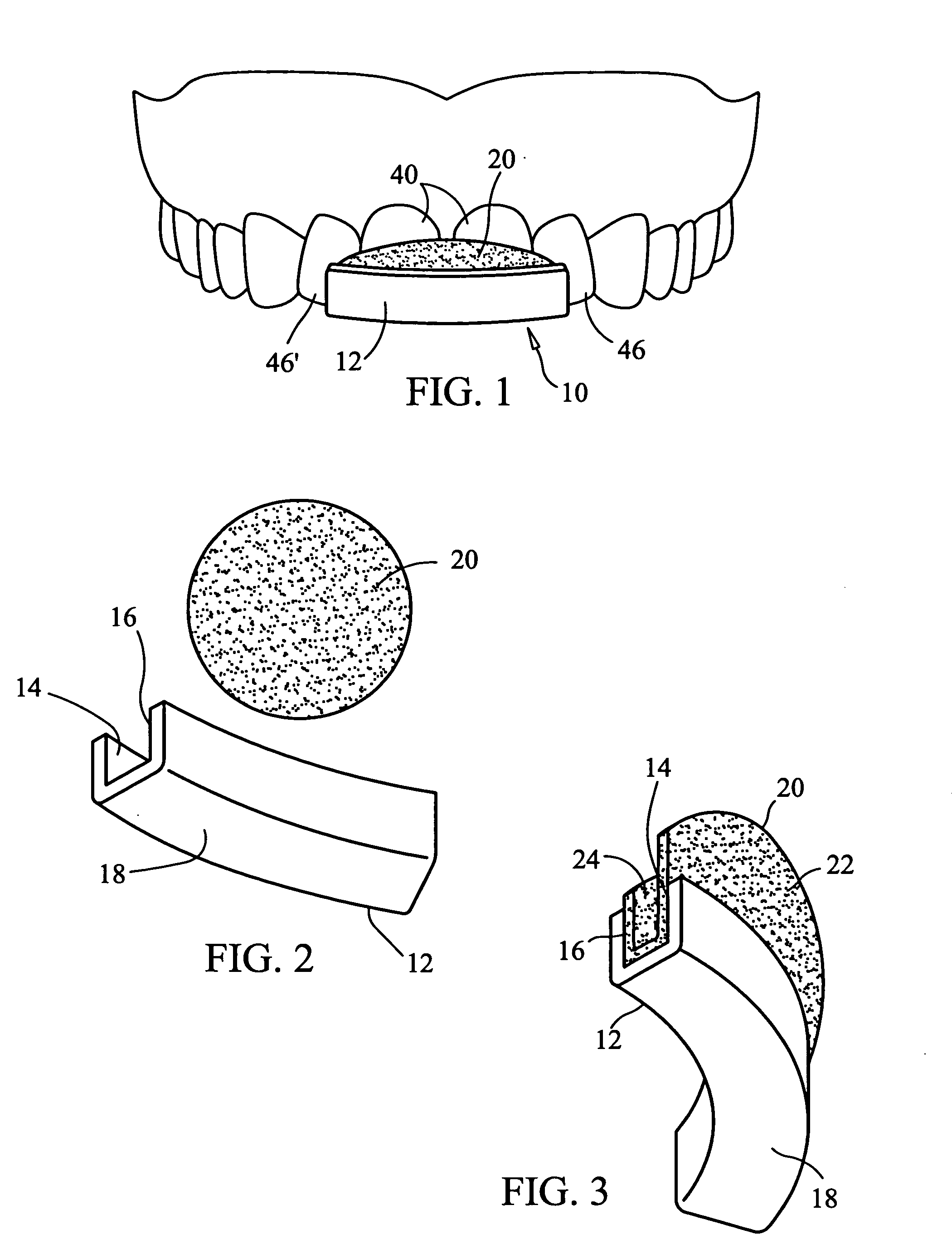

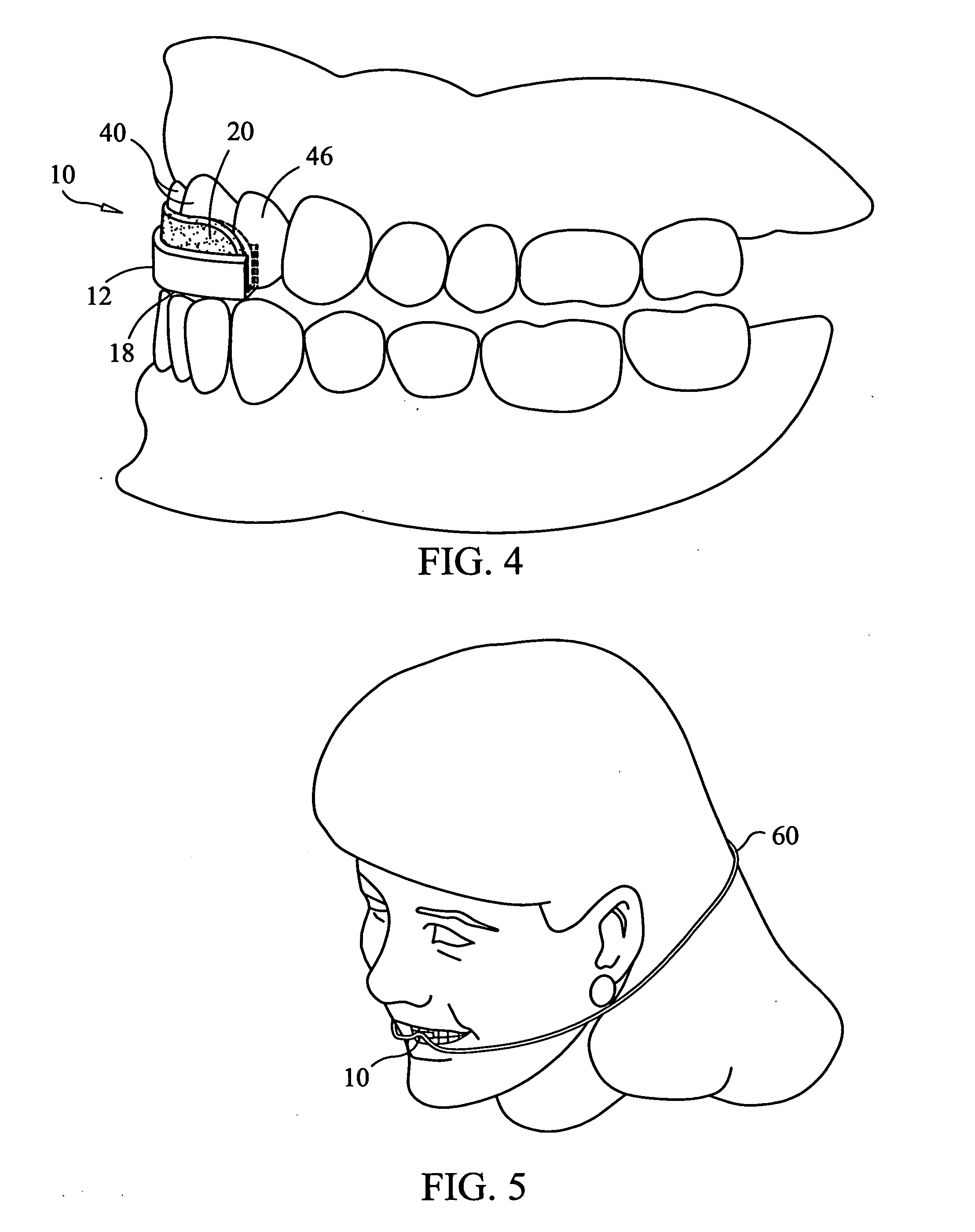

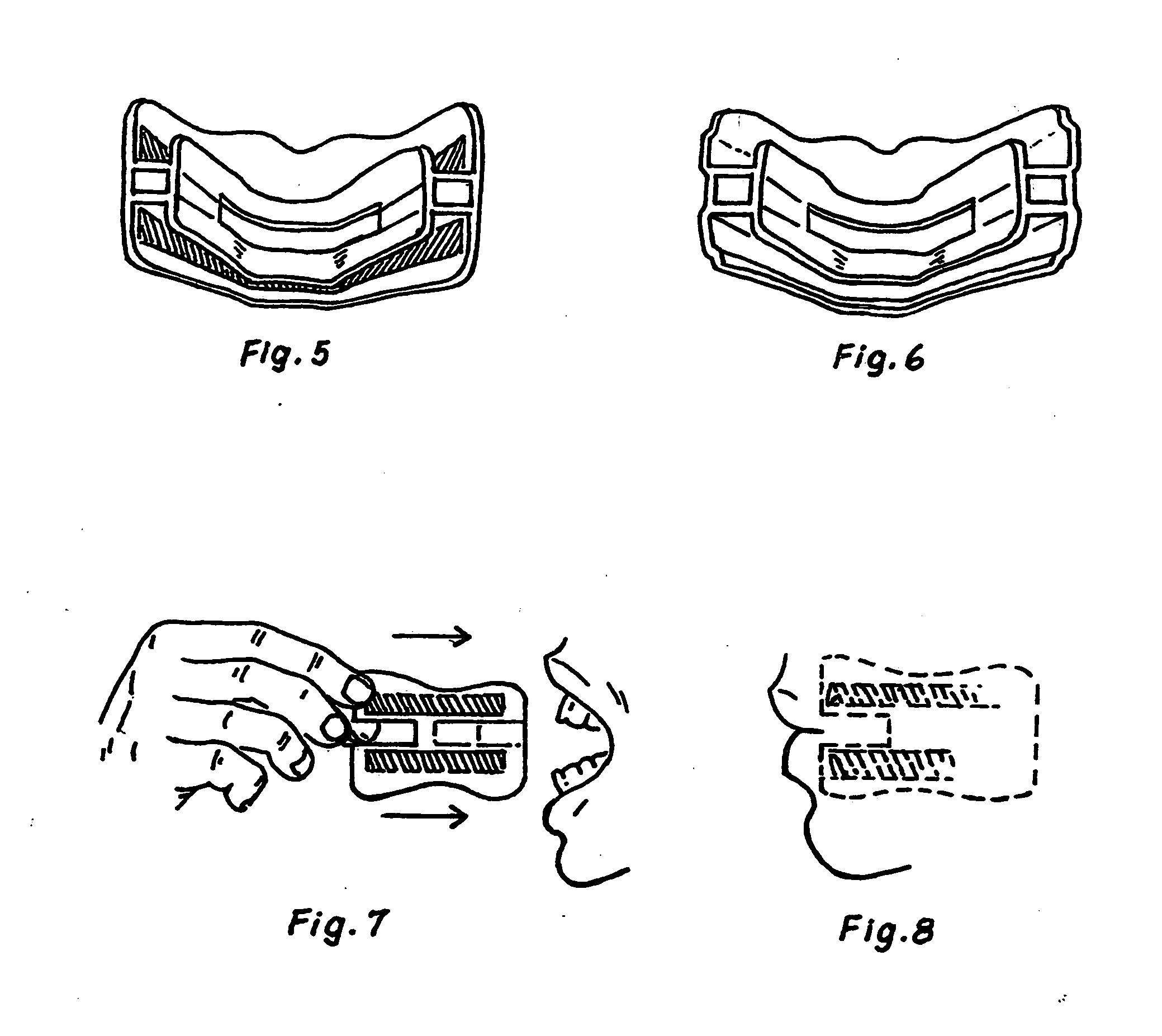

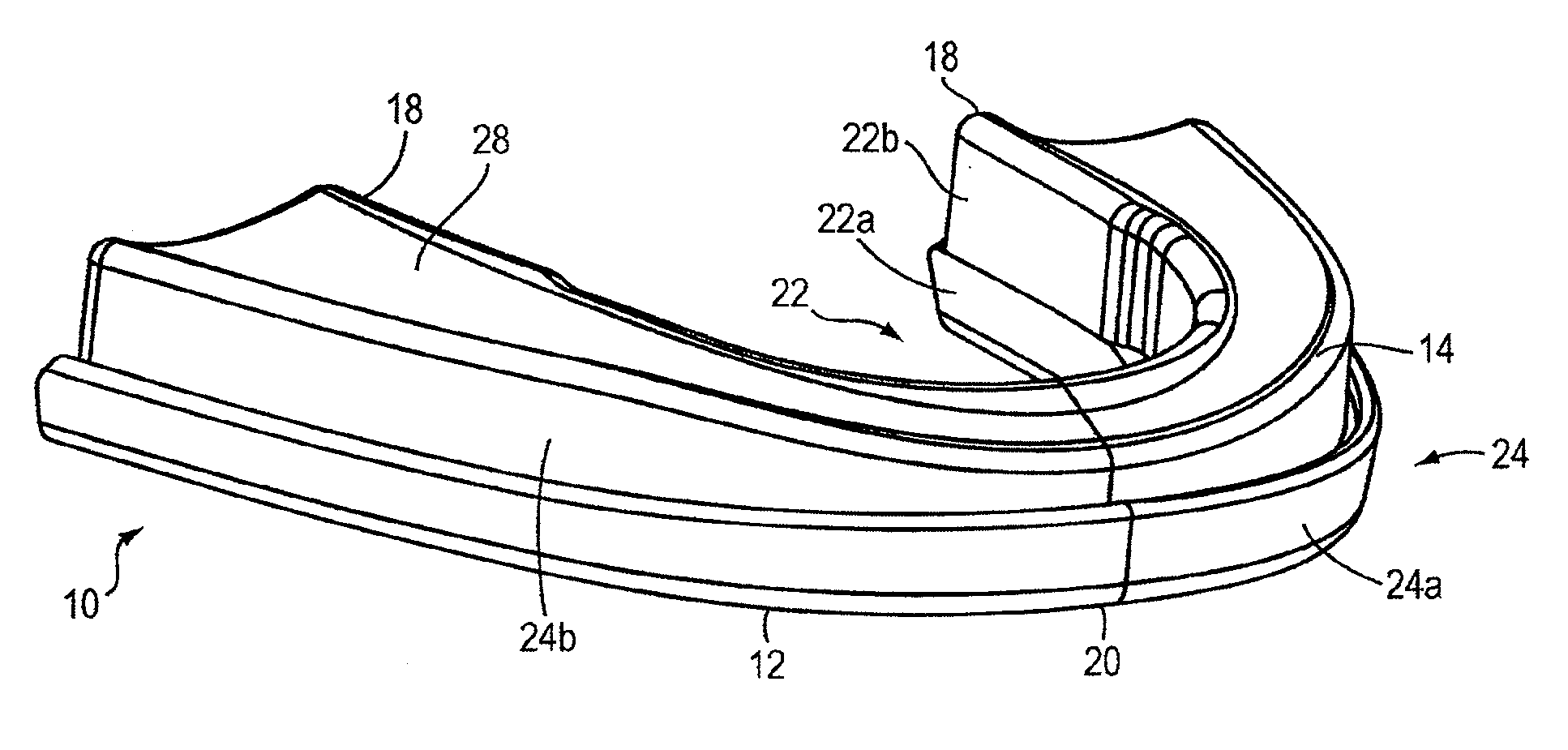

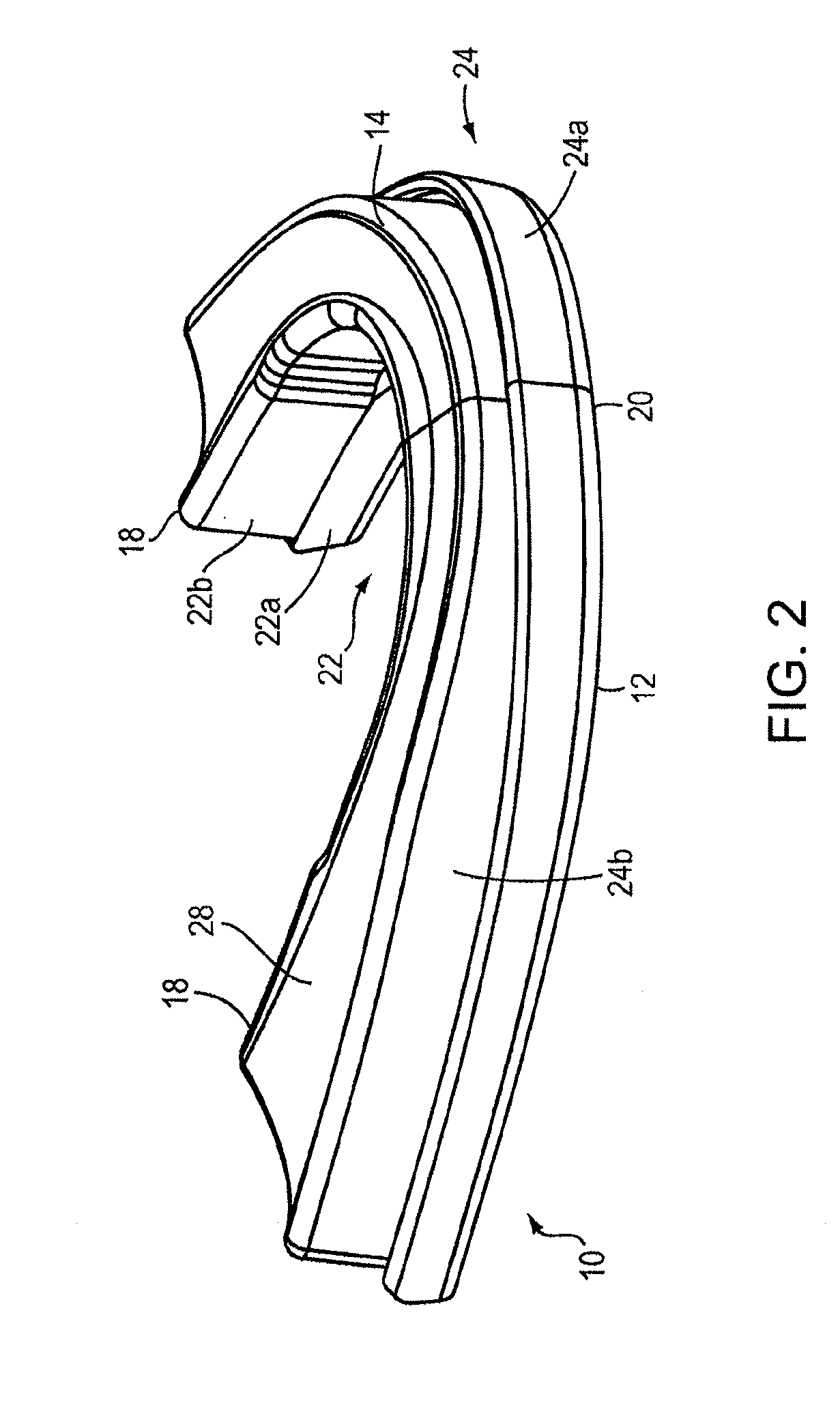

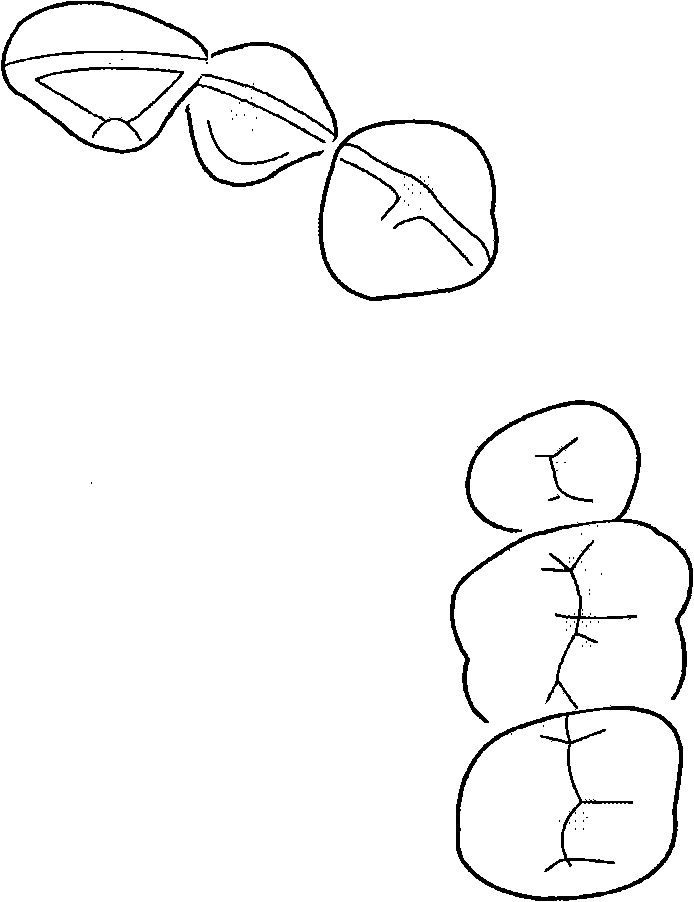

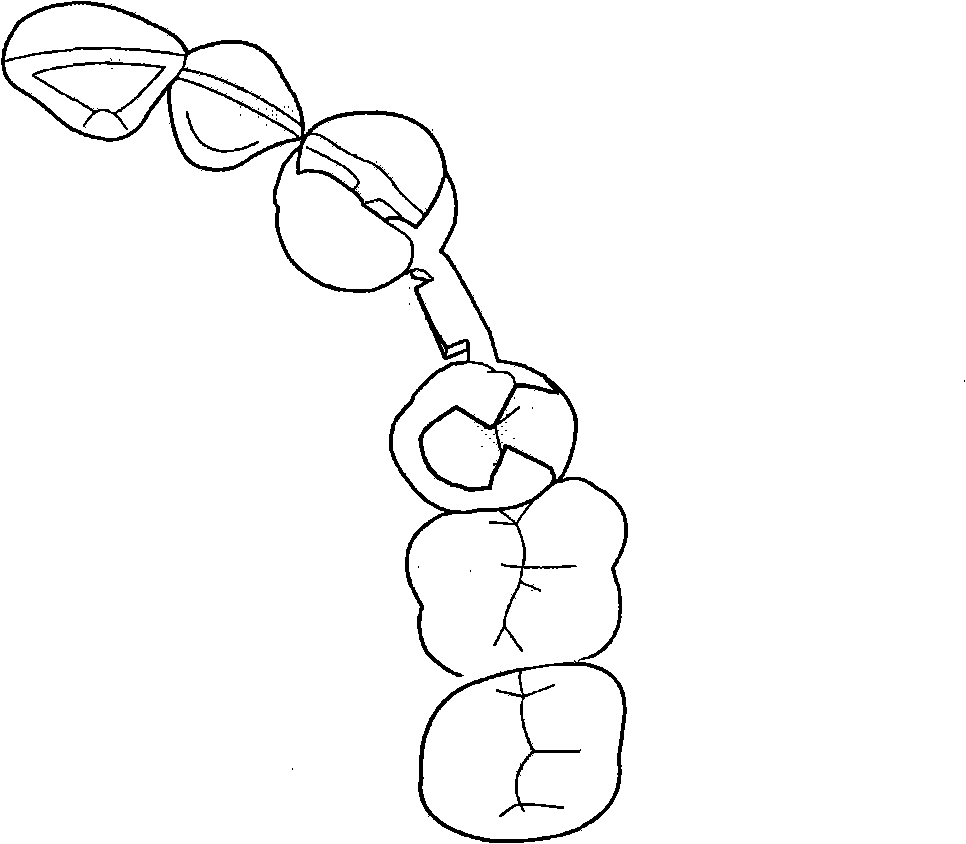

Anterior sextant dental bite tray apparatus

InactiveUS20050241650A1Thin materialInhibit orthodontic tooth movementOthrodonticsTeeth fillingTemporomandibular joint painTeeth grinding

An intraoral, flexible, hinged appliance which is an anterior resistance appliance, covering both anterior sextants of both arches (jaws), having the effect of an anterior bite plane, to facilitate orthodontic treatment. Each of the hinged sections consists of a roughly semicircular trough or tray that fits over the anterior sextant of a patient's teeth. The two troughs are hinged at the rear with a flexible material that when the troughs are flexed together and inserted in the mouth causes a force tending to lock the troughs against the patient's teeth, thereby helping to open a deep bite and protect teeth from the negative affects of bruxism or teeth grinding, and to relieve temporomandibular joint pain and dysfunction.

Owner:LBB ENTERPRISES

Night time dental protector

InactiveUS20110067711A1Preventing traumatic occlusion of upperPrecise alignmentTeeth fillingSnoring preventionOverbiteTeeth grinding

Owner:DENTEK ORAL CARE

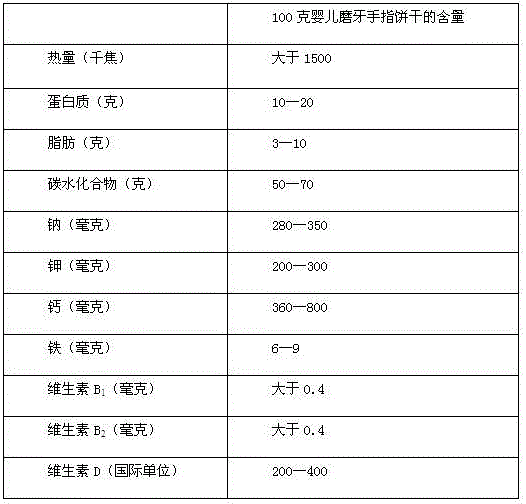

Tooth grinding food

The invention provides a tooth grinding food which is made of a composition comprising wheat meal, grease, sugar and a leavening agent at least. The tooth grinding food is characterized in that the wet gluten content of the wheat meal or the wheat meal and starch is below 20 percent, preferably below 18 percent; and on the basis of 100 parts by weight of the sum of the wheat meal and the starch, the tooth grinding food comprises 14-22 parts of grease, 18-26 parts of sugar and 0.05-0.1 part of leavening agent, and the expansion ratio is between 1.0 and 1.2. The tooth grinding food is produced by a crisp biscuit production process, has proper hardness, is difficult to break and drop, is suitable for an infant to grind teeth and is beneficial to the growth of the teeth of the infant.

Owner:贝因美股份有限公司 +1

Method for processing ultra-thin cast porcelain laminate veneer capable of preventing tooth grinding

The invention relates to the field of dental prosthesis, in particular to a method for processing ultra-thin cast porcelain laminate veneer capable of preventing tooth grinding. The method comprises the following steps: a three-dimensional scanner is adopted to scan a dental cast, a three-dimensional stereoscopic image is formed, an ultra-thin veneer with the thickness of less than 0.5 mm is designed on the virtual image, after the ultra-thin veneer is designed, data is output to a 3D (three-dimensional) resin wax forming machine, the ultra-thin veneer is formed in the manners of resin-spraying, irradiation curing and printing, and then the formed resin wax pattern is subjected to embedded casting, grinding adjustment, try-in and glazing. Compared with the prior art, the method adopts a computer to design, and the conventional hand-made wax pattern is replaced by the resin wax pattern processed by the digital resin wax spraying, irradiation curing and printing processing, so that fabrication of porcelain laminate veneer with the thickness of less than 0.5 mm is realized. An aesthetic seeking patient with discolored teeth does not need tooth grinding and can receive tooth-whitening treatment without hurting teeth.

Owner:深圳市金悠然科技有限公司

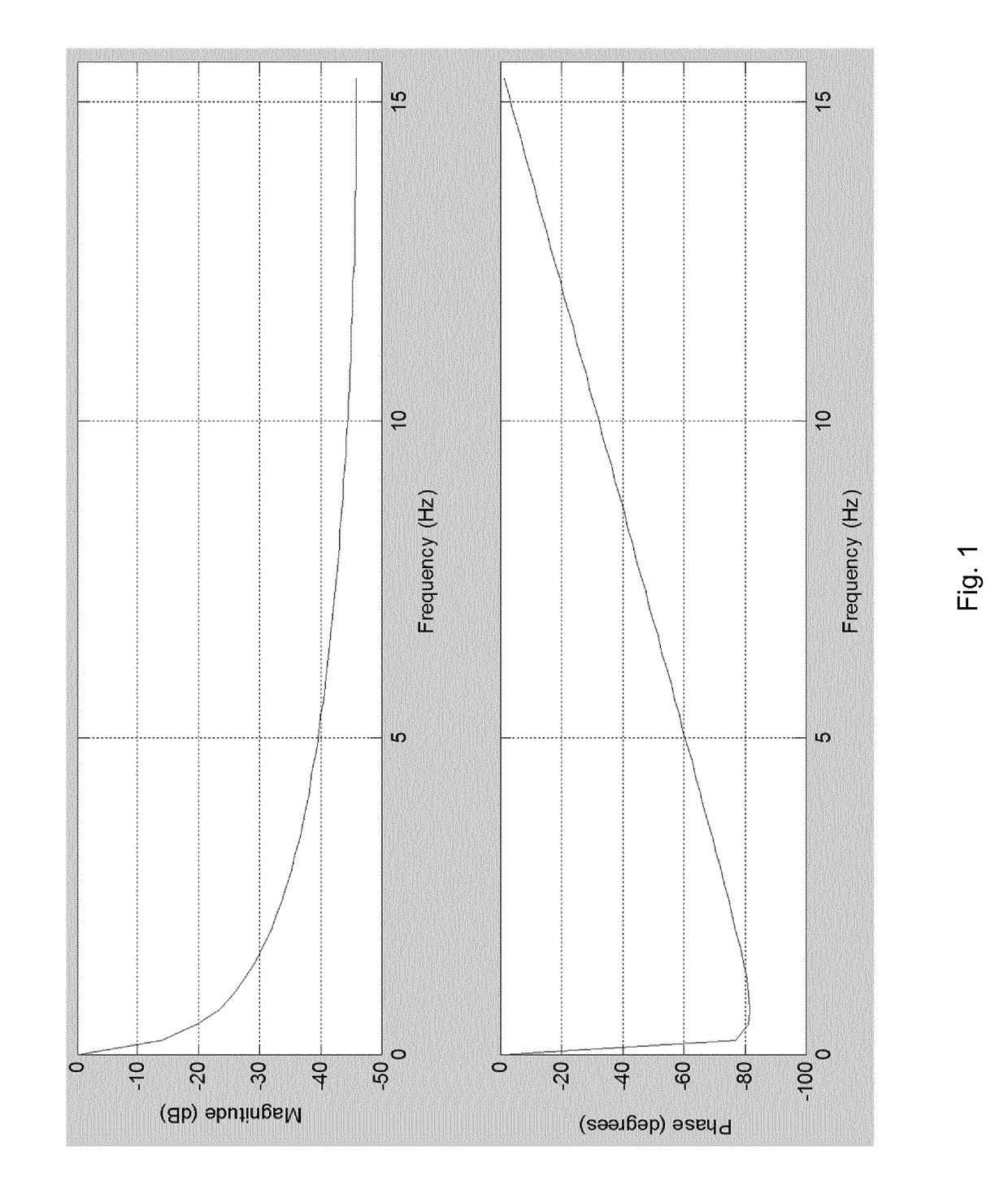

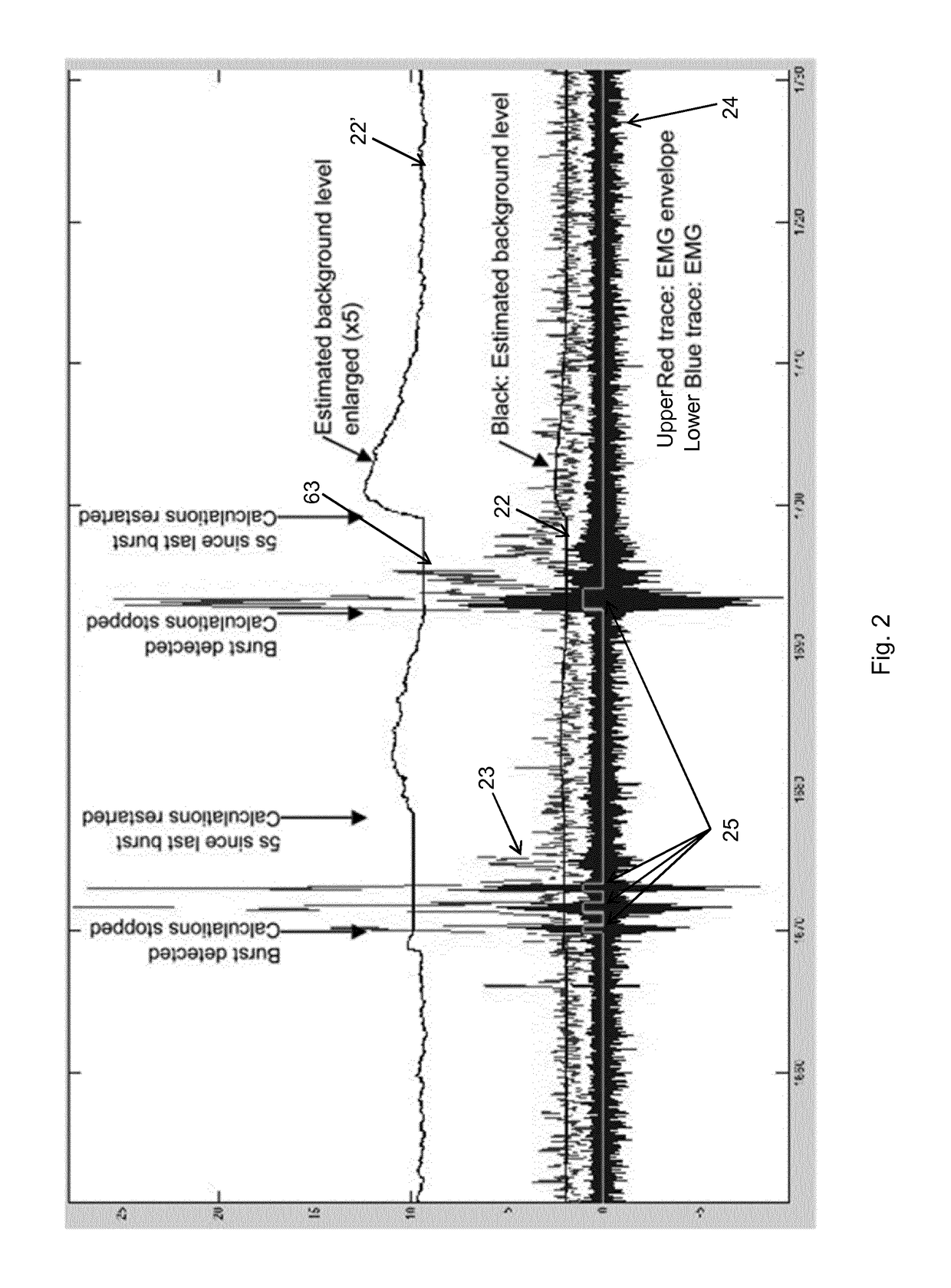

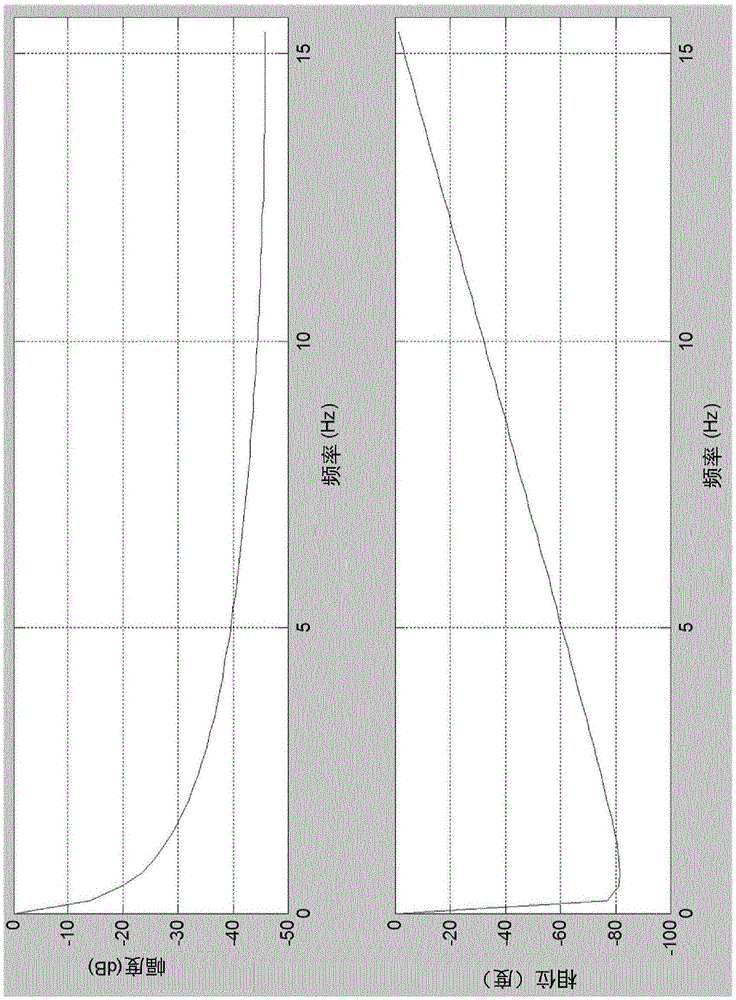

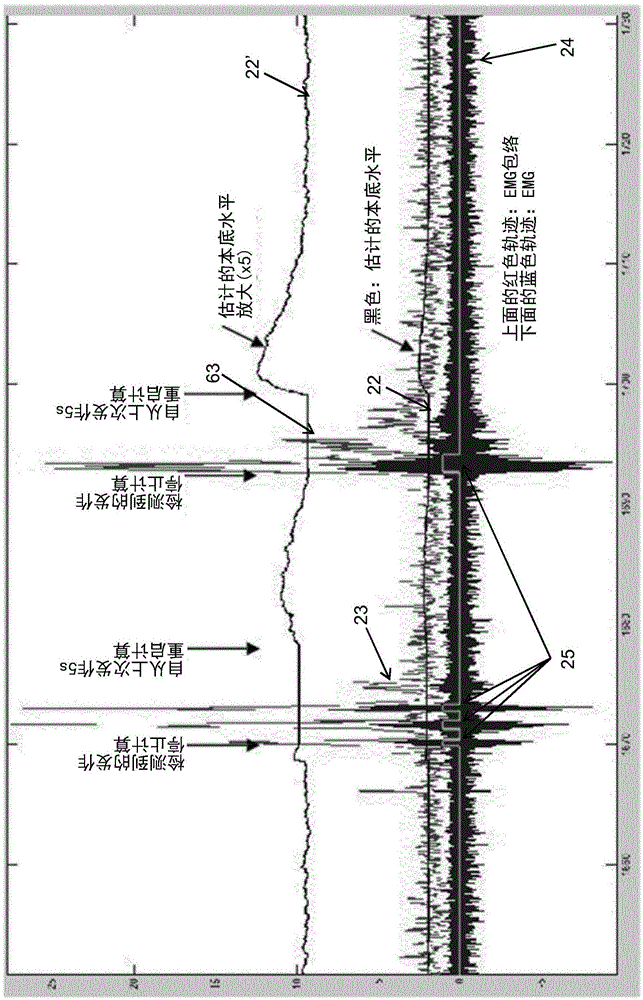

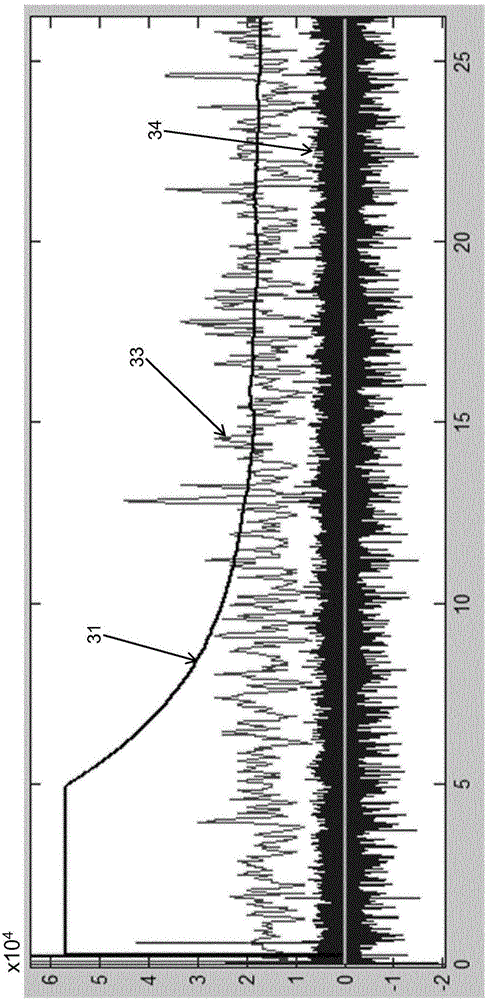

Automatic detection of teeth clenching and/or teeth grinding

ActiveUS20170071529A1Easy to useAvoid calibrationElectroencephalographyElectromyographyBite force quotientTeeth grinding

The present disclosure provides a computer implemented method for automatic detection of teeth clenching and / or teeth grinding in a dataset representing the level of biting force vs. time of a subject, the method comprising the steps of a) calculating a threshold level of biting force assigned to time t=t1 based on a background level determined from the dataset at a prior time t=t1−Tback, where Ttrack is a first predefined period of time,b) checking the level of biting,and if the level of biting force at time,t, exceeds the threshold level assigned to time t for a second predefined period of time, Tclench / grind, then assigning an event of teeth clenching to time t,c) if an event of teeth clenching has been assigned to time t, then either waiting a predefined period of time 10 Twait,or waiting until the level of biting is below the threshold for another predefined period of time Tend, d) if no events of teeth clenching and / or teeth grinding have been assigned for a third predefined period of time Tsilence, then repeating steps a)-c),e)if events of teeth clenching and / or teeth grinding have been assigned for a third predefined period of time Tsilence, then repeating only steps b)-c).

Owner:SUNSTAR SUISSE SA

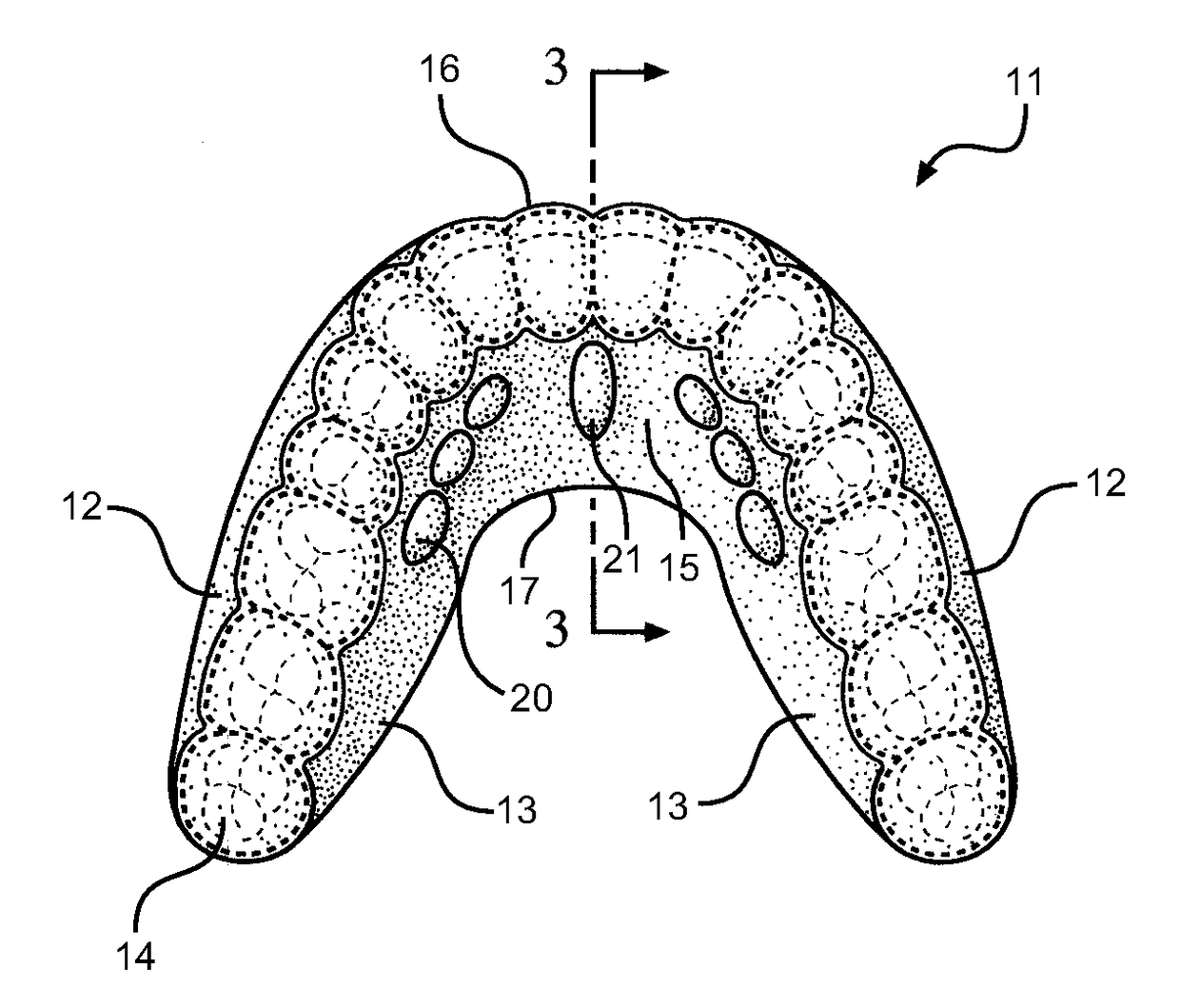

Anterior sextant dental bite tray apparatus

InactiveUS7404404B2Not inhibit orthodontic tooth movement and correctionThin materialOthrodonticsTeeth fillingTemporomandibular joint painTeeth grinding

An intraoral, flexible, hinged appliance which is an anterior resistance appliance, covering both anterior sextants of both arches (jaws), having the effect of an anterior bite plane, to facilitate orthodontic treatment. Each of the hinged sections consists of a roughly semicircular trough or tray that fits over the anterior sextant of a patient's teeth. The two troughs are hinged at the rear with a flexible material that when the troughs are flexed together and inserted in the mouth causes a force tending to lock the troughs against the patient's teeth, thereby helping to open a deep bite and protect teeth from the negative affects of bruxism or teeth grinding, and to relieve temporomandibular joint pain and dysfunction.

Owner:LBB ENTERPRISES

Infant molar rod biscuit containing soybean dietary fibers and production method thereof

InactiveCN105660791AImprove developmentPromote digestionDough treatmentBakery productsSodium bicarbonateFiber

The invention belongs to the field of foods and in particular relates to an infant molar rod biscuit containing soybean dietary fibers and a production method thereof. The infant biscuit disclosed by the invention contains soybean dietary fibers and also contains flour, white granulated sugar, eggs, grease, starch, whole milk powder, soy isolate protein, sodium bicarbonate, water and other raw materials, wherein the content of the soybean dietary fibers accounts for 2.5 to 9.3 percent of the weight of the biscuit. According to the invention, the soybean dietary fibers added into the formula have the characteristics of high protein and high fiber, the protein content of quality is improved, soybean protein and wheat protein can be well combined, and formation and structure of gluten can be improved, so that the product is higher in hardness. The soybean dietary fibers have good water absorption properties and can maintain 7-8 times of water, the viscosity of the product is improved, and the measured water absorption amount is less than 10 percent. Therefore, a quality surface layer is wetted and softened to absorb water, and the aims of guaranteeing long-term sucking of the infant and improving the tooth grinding and oral cavity practicing skills are achieved.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

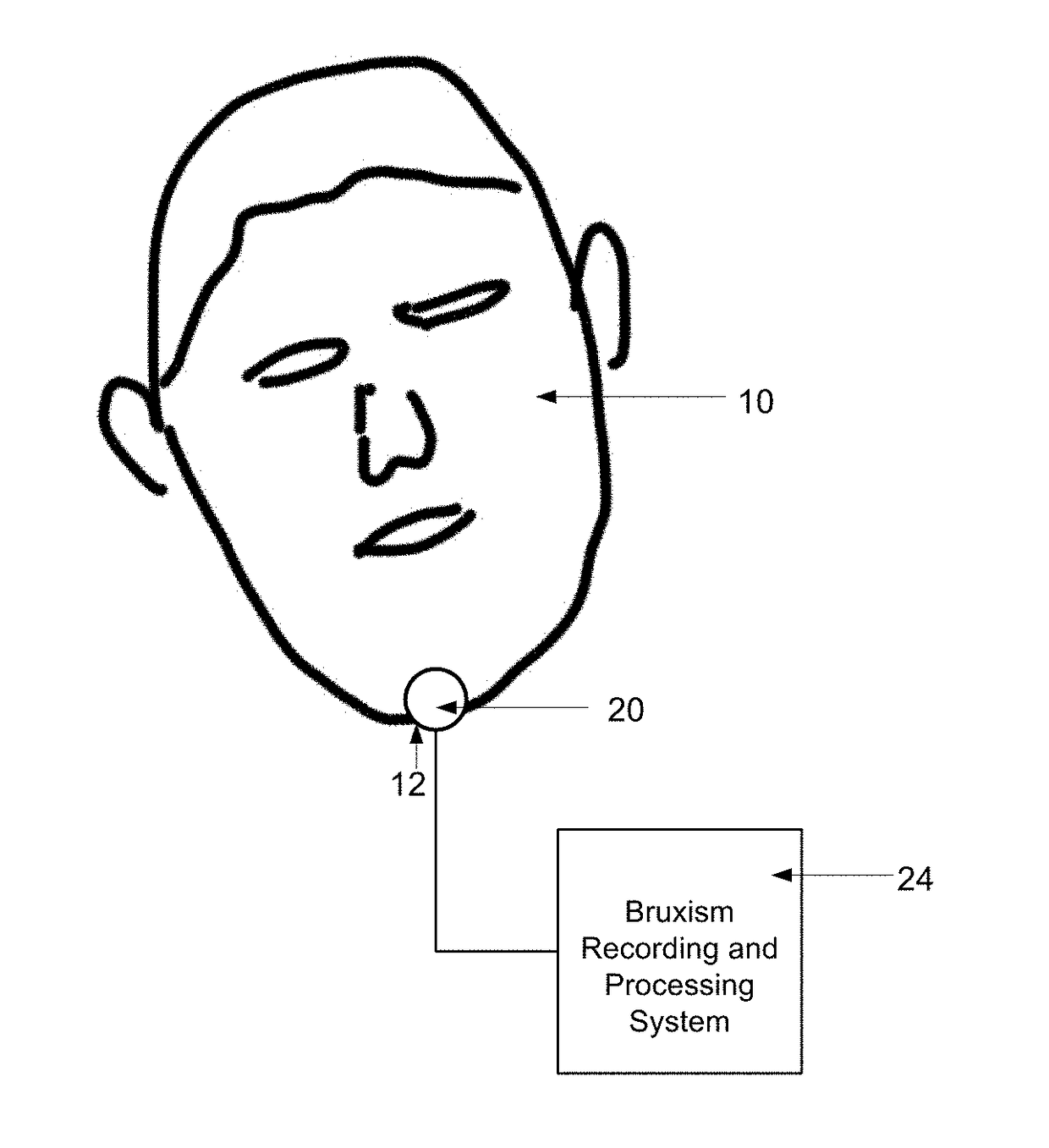

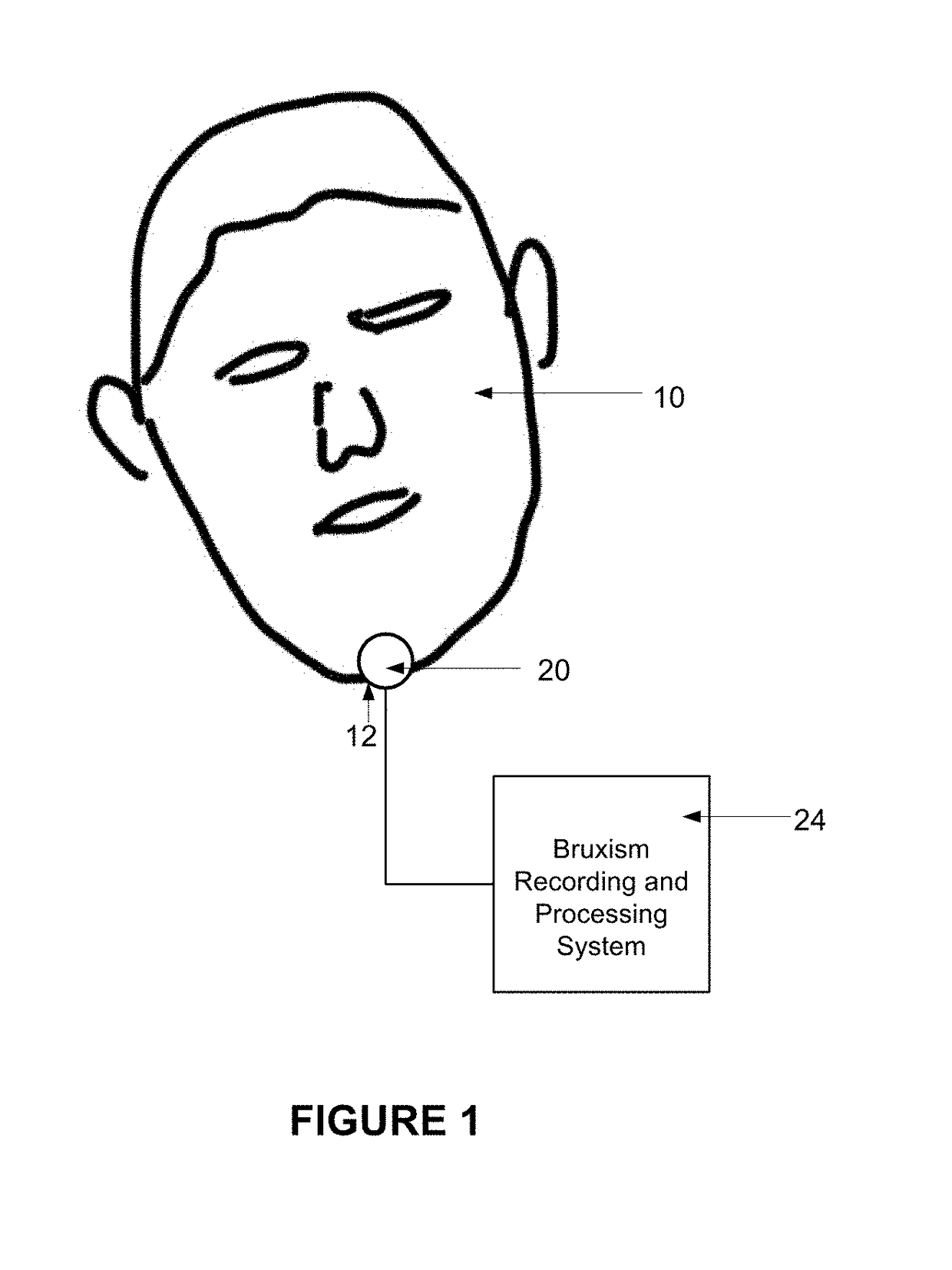

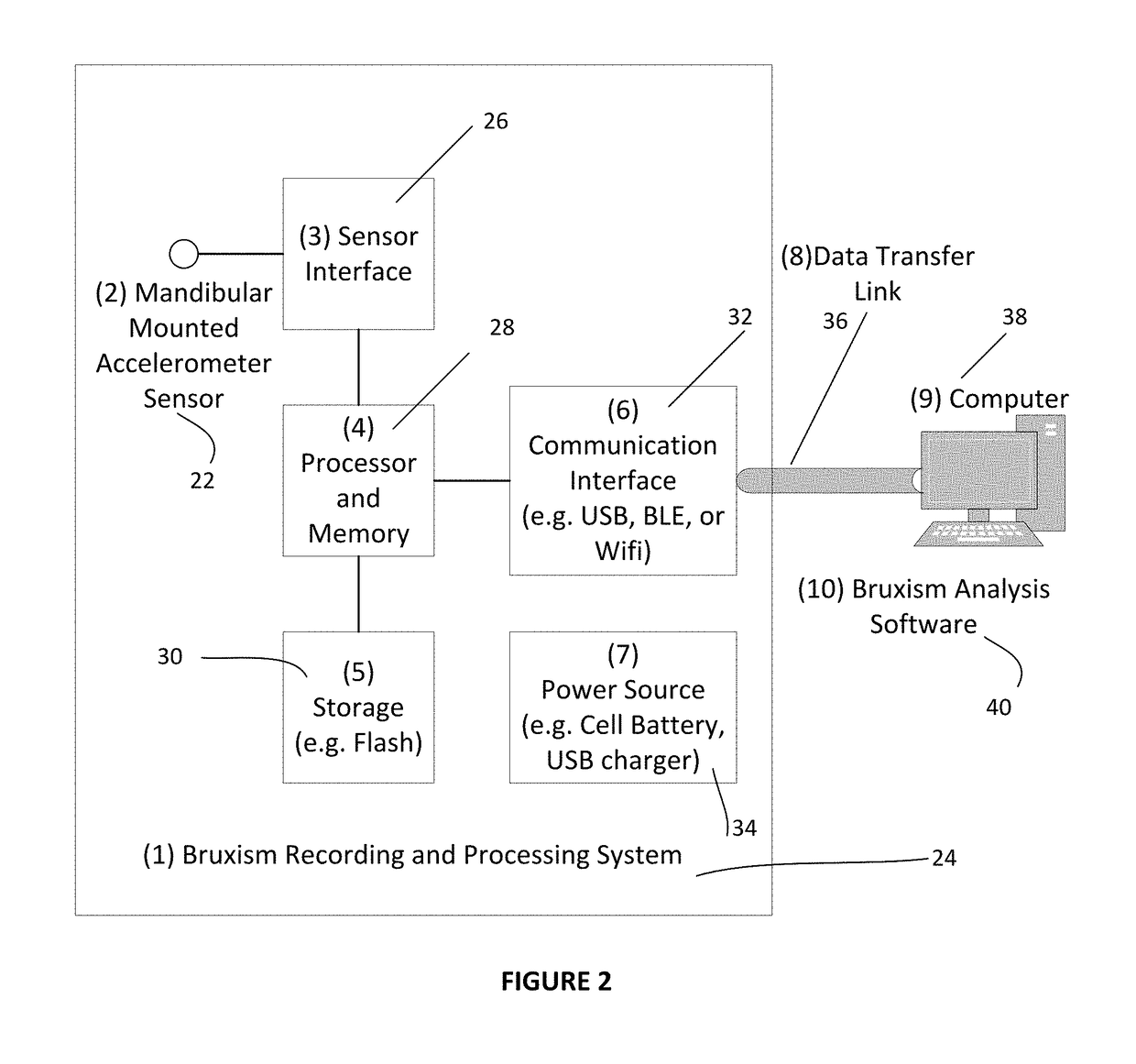

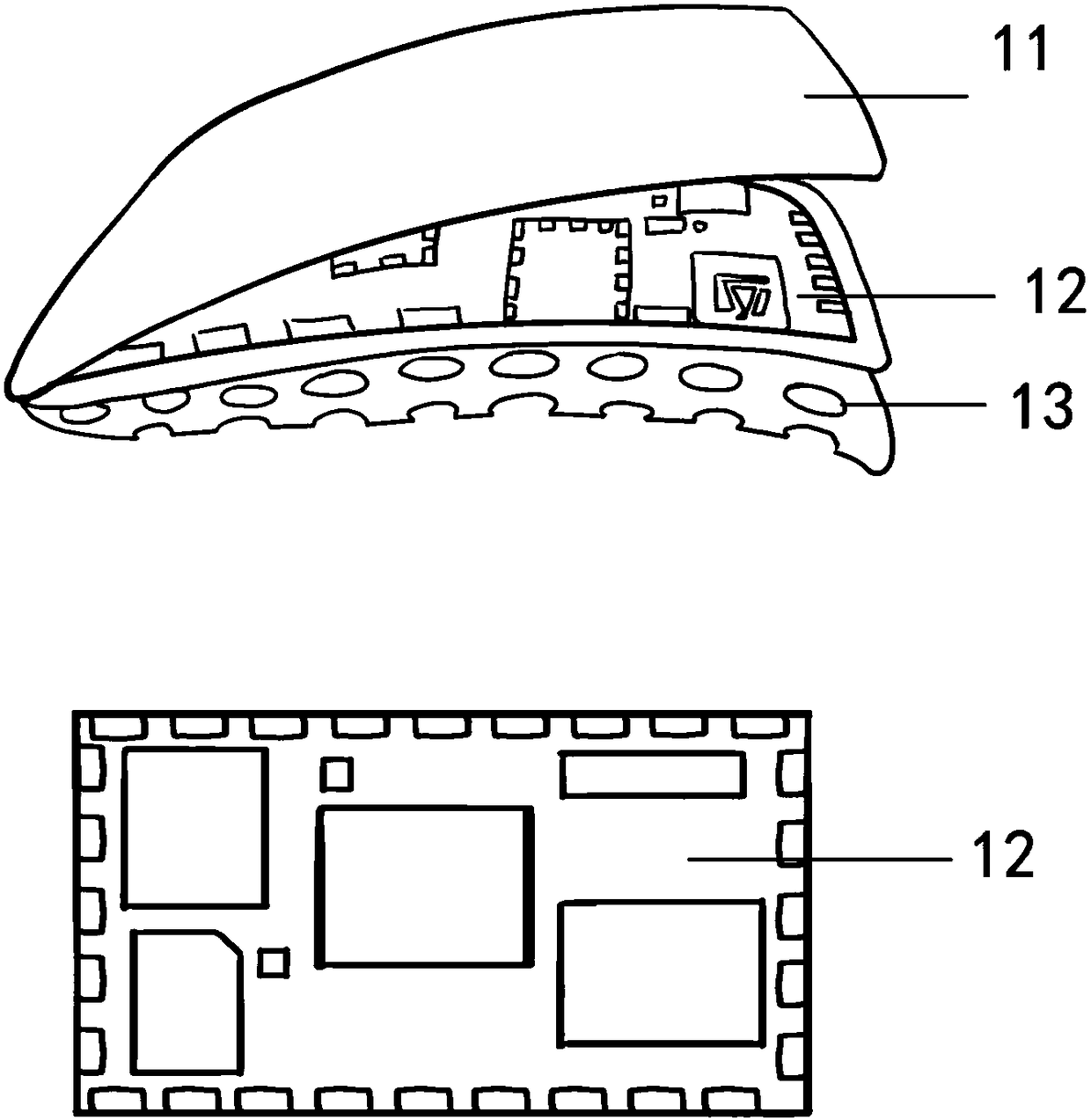

Bruxism Detection System With Chin-Mounted Accelerometer Sensor

InactiveUS20170265801A1Limiting energy/battery useMaximum flexibilityInertial sensorsDiagnostic recording/measuringChinAccelerometer

A bruxism detection system is provided that includes a chin-mounted acceleration sensor for detection of teeth grinding and teeth tapping. The system generally includes an acceleration sensor that is adapted to be removably and externally mounted with respect to an individual's chin, a bruxism recording and processing system operable on a local processor, and bruxism analysis software that is operable on the local processor or an adjoint processor (or a combination thereof). The system is designed to be used in any convenient location, including an individual's home, and is generally reusable by multiple people, thus reducing the cost of bruxism diagnosis and bringing a reliable and effective diagnosis tool to the general public.

Owner:PATWA AALOK NITAL +1

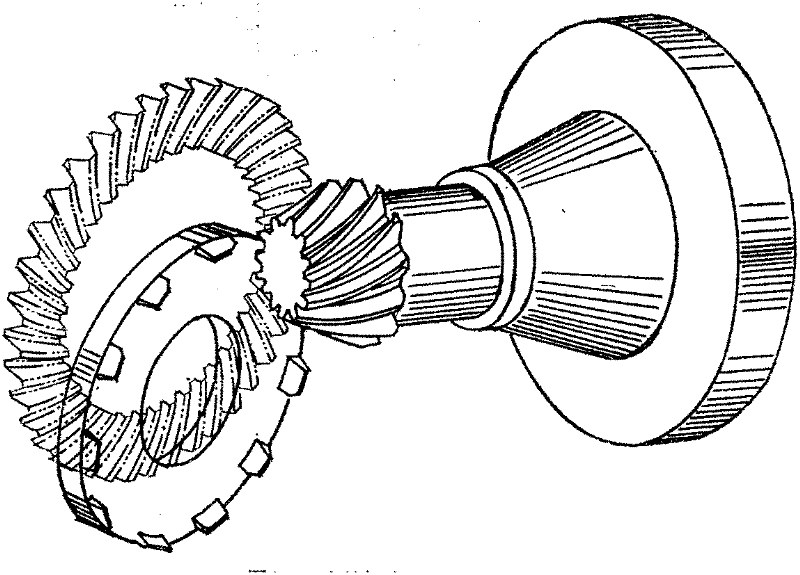

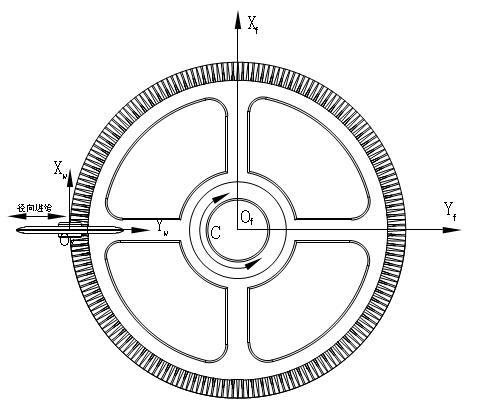

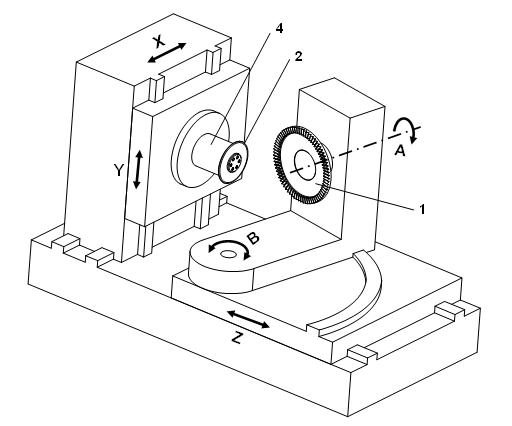

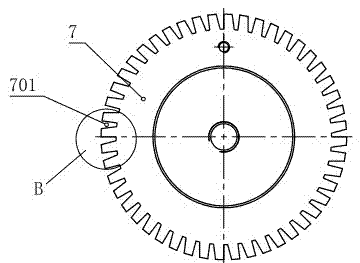

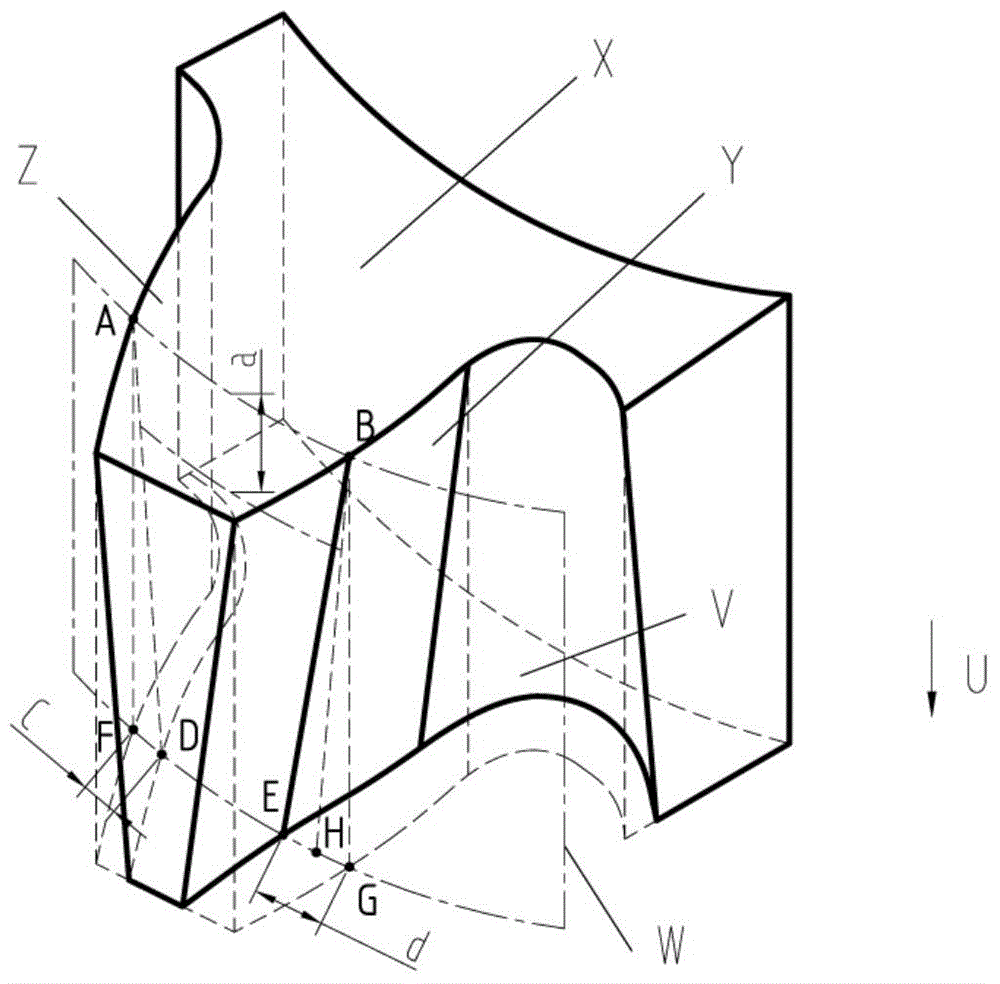

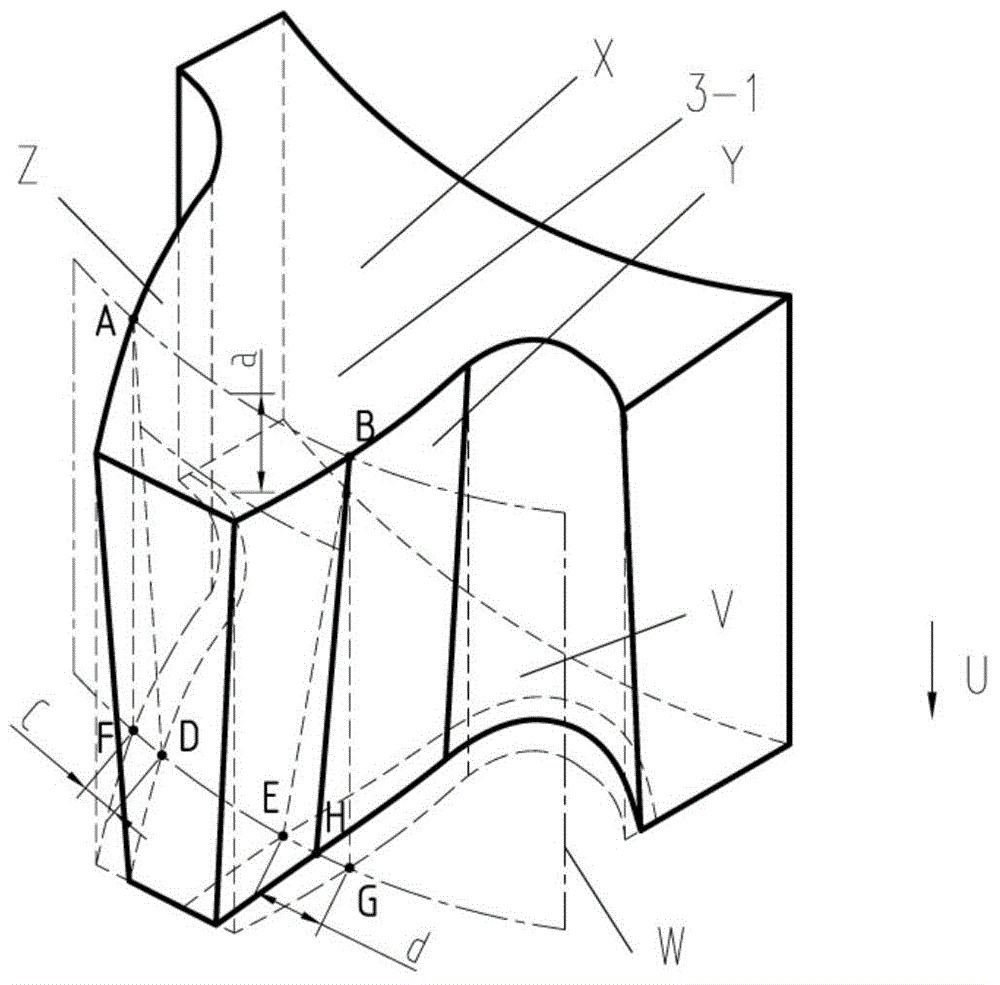

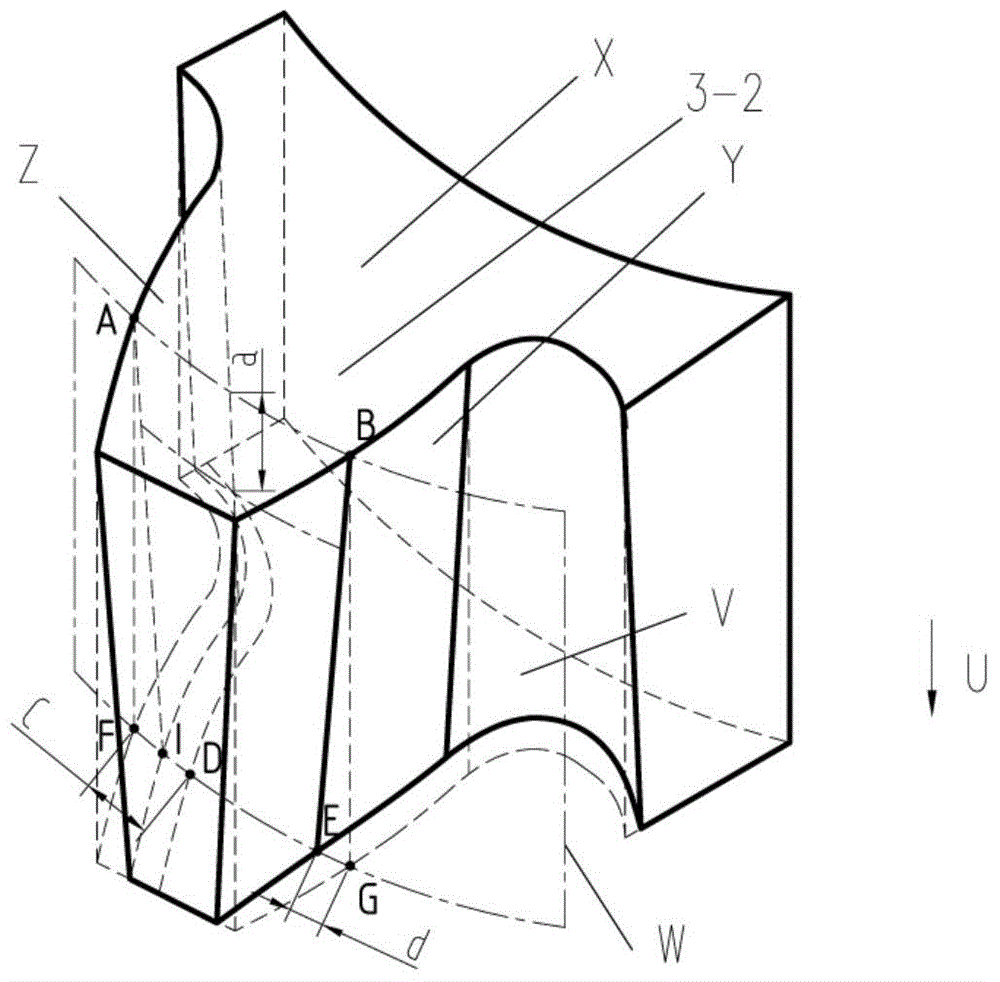

Method for processing face gear

The invention discloses a processing method for realizing face gear teeth milling and high-precision teeth grinding by use of a disc cutter on an existing numerically controlled lathe, which is characterized in that a face gear 1 is installed on a working platform of the lathe, an extended grinding wheel set 4 is installed on top of a lathe spindle, the disc cutter 2 is installed on top of the extended grinding wheel set 4; during processing, the face gear 1 rotates around its axis along with a lathe A rotating shaft while swinging with a lathe B rotating shaft, the disc cutter 2 rotates at a high speed around its axis along with the spindle while making a reciprocating feed movement in the radial direction of the face gear; because of the lathe B-shaft travel limitation, a single-face processing way is adopted, a right tooth face of the face gear is processed firstly, after one whole tooth face is processed, the face gear makes an indexing motion to process the next tooth face till the whole right tooth face of the face gear is processed, and then a left tooth face of the face gear 1 is processed on another station till the whole face gear is processed. By using the existing numerically controlled lathe and the disc cutter, the face gear teeth milling and the high-precision teeth grinding can be processed at the same time without additionally designing or manufacturing a face gear special processing lathe, the manufacturing cost is reduced and the development period is shortened greatly.

Owner:唐进元

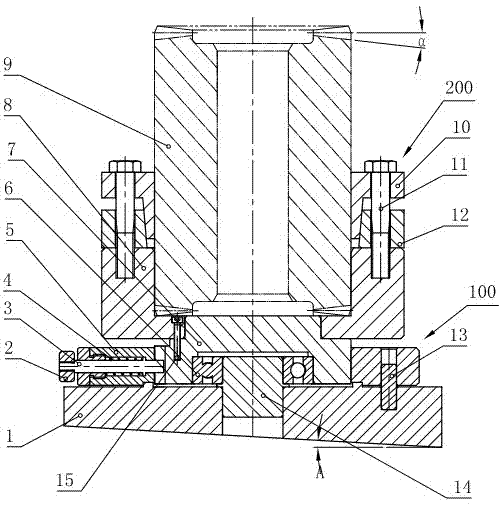

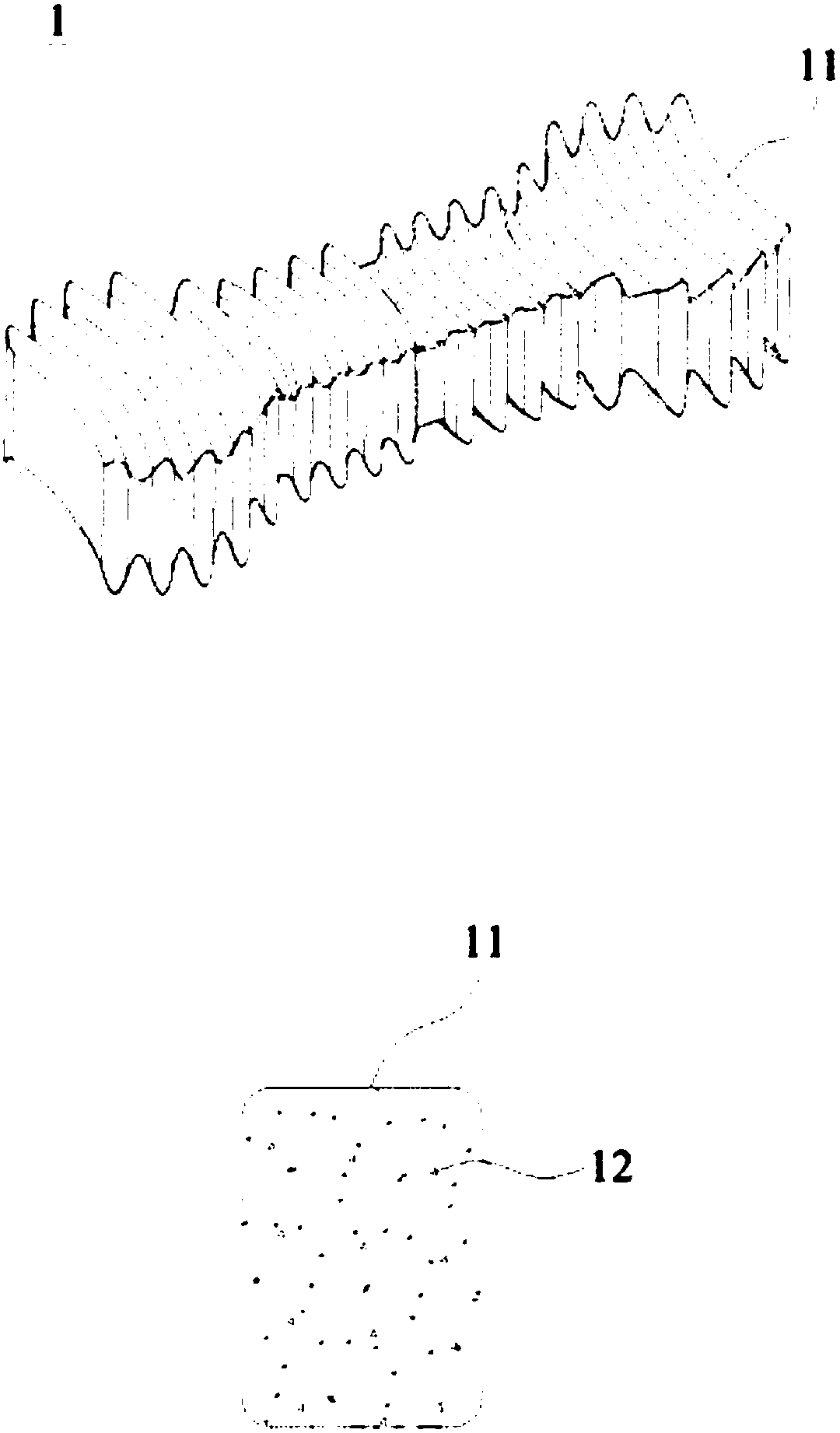

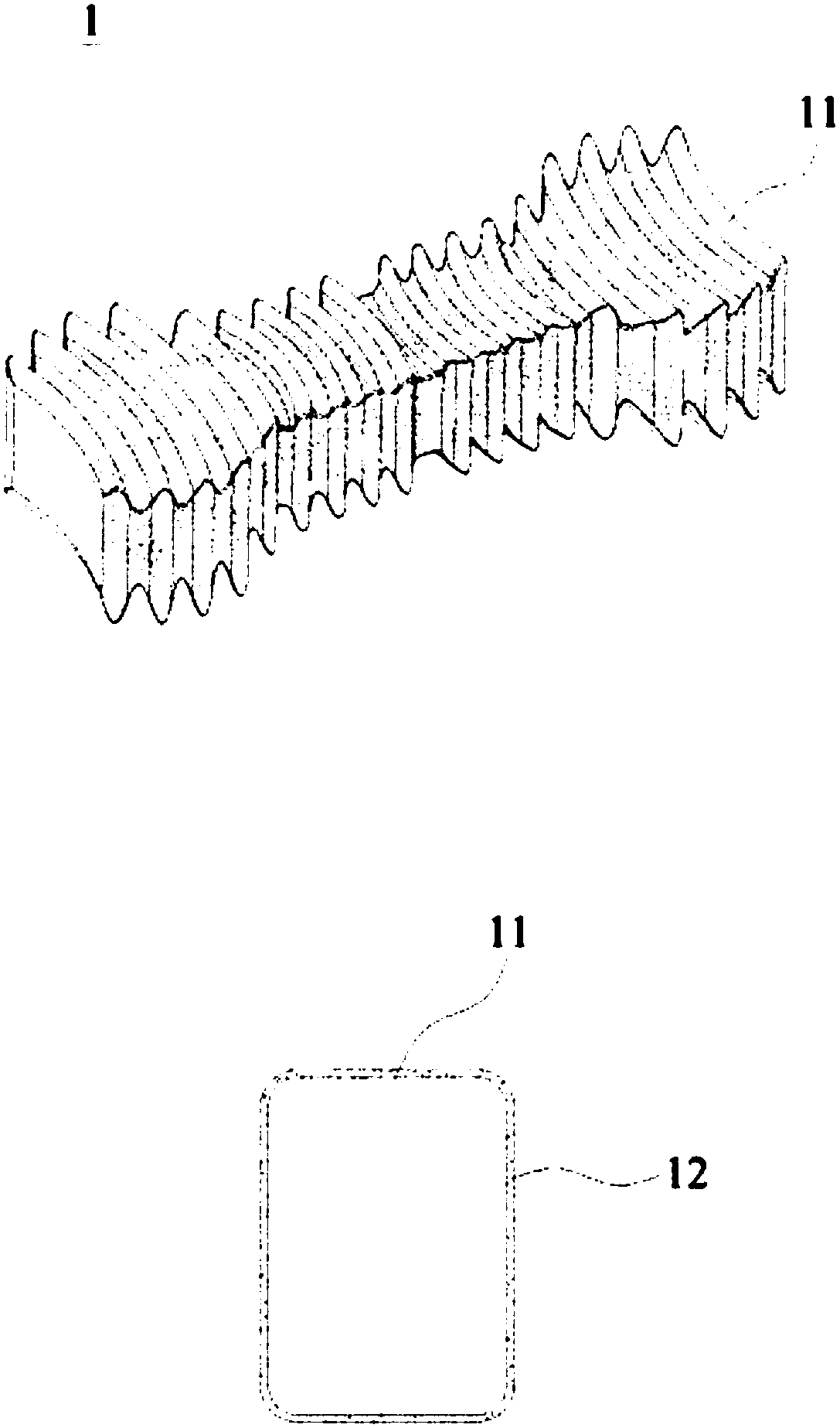

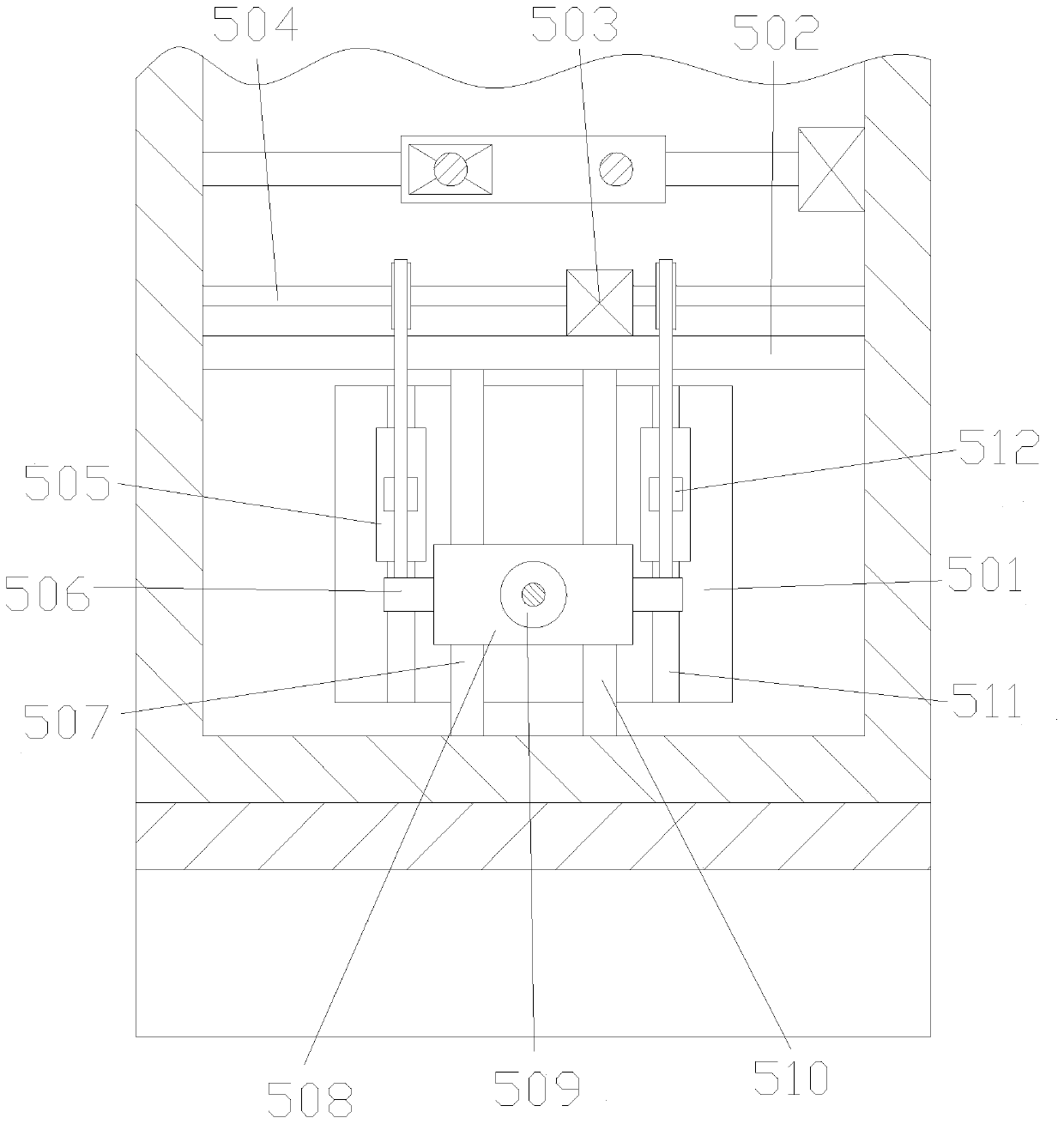

Face tooth grinding fixture

InactiveCN102248229AGuaranteed meshing accuracyExtended service lifeGear-cutting machinesGear teethLine of actionEngineering

The invention relates to a face tooth grinding fixture characterized by comprising a bottom support plate, wherein a dividing device is installed on the bottom support plate, a positioning sleeve is fixedly installed on the dividing device, the positioning sleeve and the dividing device are coaxially installed, a clamping device is arranged at the upper end of the positioning sleeve, an inclined surface is formed on the bottom surface of the bottom support plate, and the angle of the inclined surface is equal to the included angle between the root of the processed face tooth and the theoretical line of action. The face tooth grinding fixture has a simple and compact structure, low manufacturing cost and convenience in operation, can realize grinding of the face tooth only by a common tool grinder without needing extra special equipment, provides a means for grinding the face tooth, meets the requirement on the roughness of the face tooth surface, improves the tooth form accuracy, ensures the accuracy of mesh of the face tooth, prolongs the service life of the face tooth and reduces waste.

Owner:WUXI RL PRECISION MACHINERY

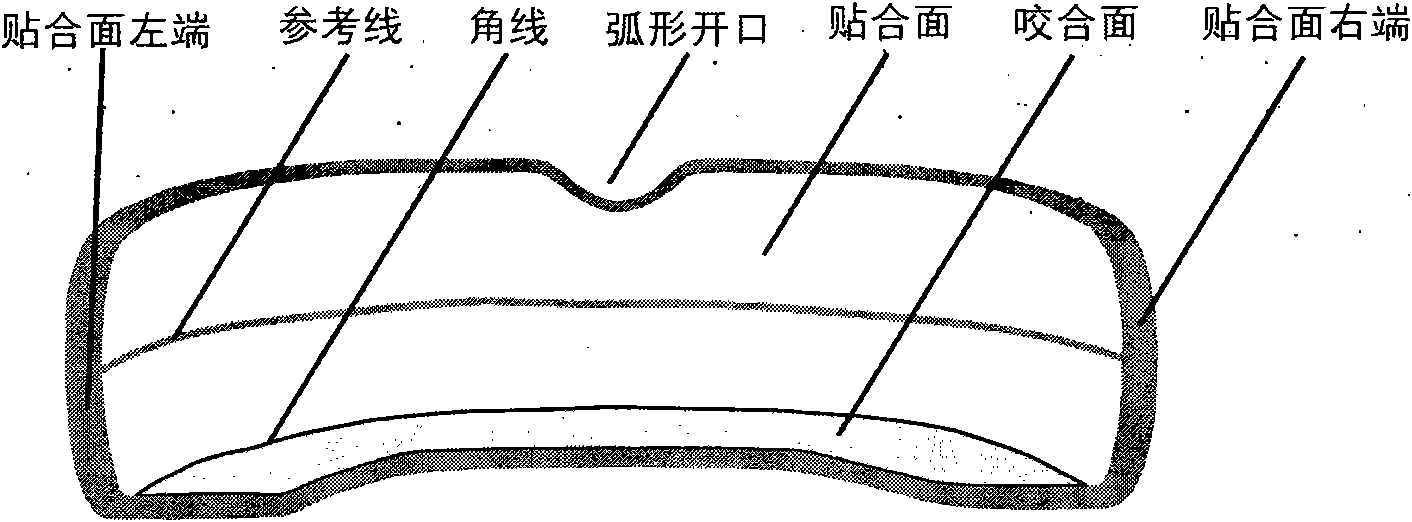

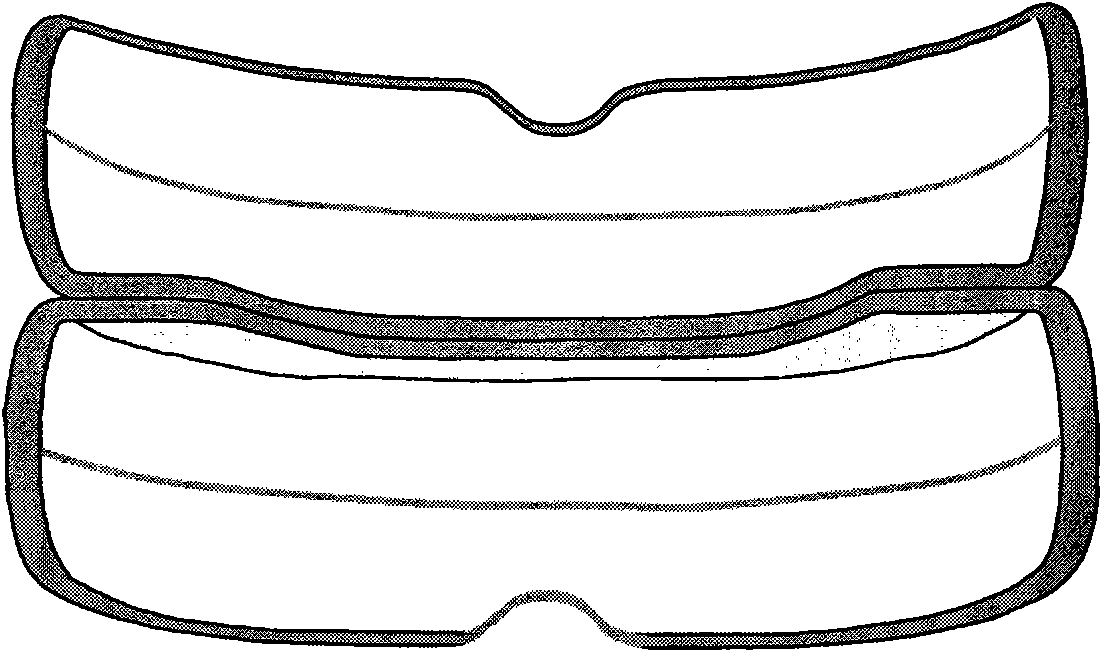

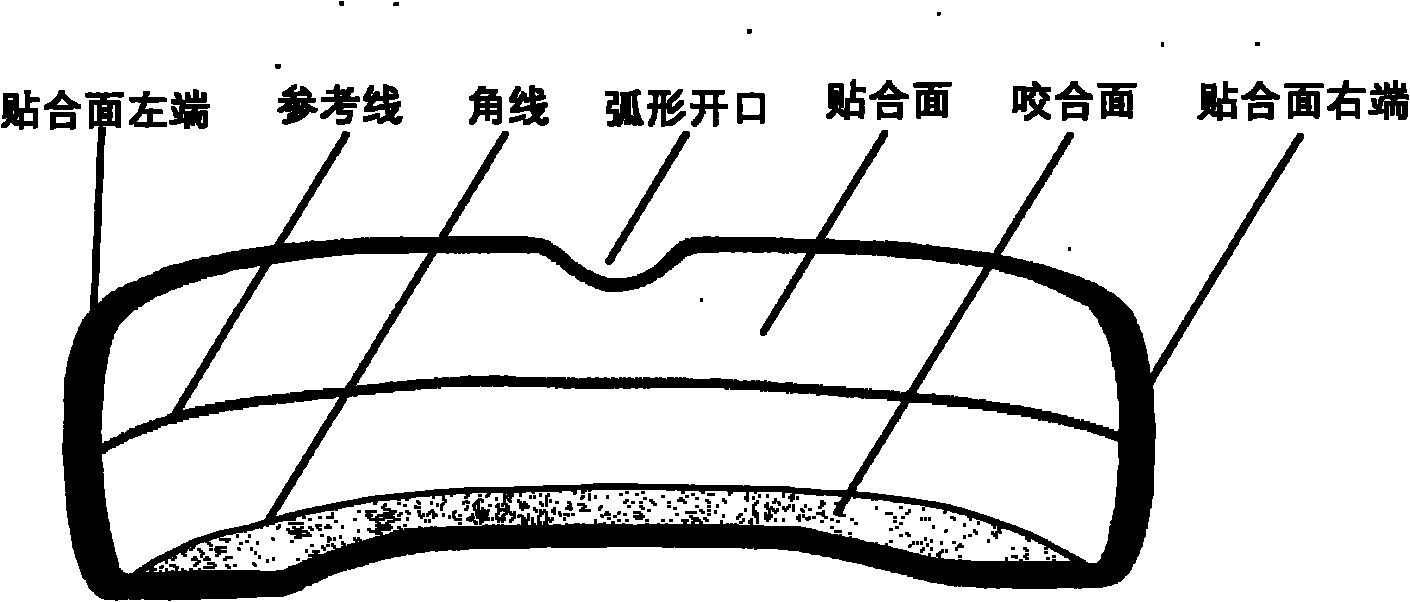

Denture for oral care and topical application of drug

The invention discloses a denture for oral care and topical application of drug, belonging to the technical field of medical care instruments. The denture can be used for both upper teeth and lower teeth, and comprises a binding surface, a left end of the binding surface, a right end of the binding surface, an occlusal surface, an arc opening, an angular line and a reference line. The denture hassimple structure and convenient operation, can be used for topical application of drug for teeth, can serve as the carrier of a preparation for cleaning teeth stains, and can also be used for teeth protection (such as teeth protection in boxing) and prevention of teeth grinding. The denture avoids the problems of non sanitation and the like brought by complex operation of the existing denture, and is especially suitable for children.

Owner:李少君

Automatic detection of teeth clenching and/or teeth grinding

ActiveCN106455989AEasy to useAvoid calibrationStrain gaugeInertial sensorsBite force quotientTeeth grinding

The present disclosure provides a computer implemented method for automatic detection of teeth clenching and / or teeth grinding in a dataset representing the level of biting force vs. time of a subject, the method comprising the steps of a) calculating a threshold level of biting force assigned to time t=t1 based on a background level determined from the dataset at a prior time t=t1-Tback, where Tback is a first predefined period of time,b) checking the level of biting,and if the level of biting force at time,t, exceeds the threshold level assigned to time t for a second predefined period of time, Tclench / grind, then assigning an event of teeth clenching to time t,c) if an event of teeth clenching has been assigned to time t, then either waiting a predefined period of time 10 T wait,or waiting until the level of biting is below the threshold for another predefined period of time Tend, d) if no events of teeth clenching and / or teeth grinding have been assigned for a third predefined period of time Tsilence, then repeating steps a)-c),e)if events of teeth clenching and / or teeth grinding have been assigned for a third predefined period of time Tsilence, then repeating only steps b)-c).

Owner:太阳星瑞士有限公司

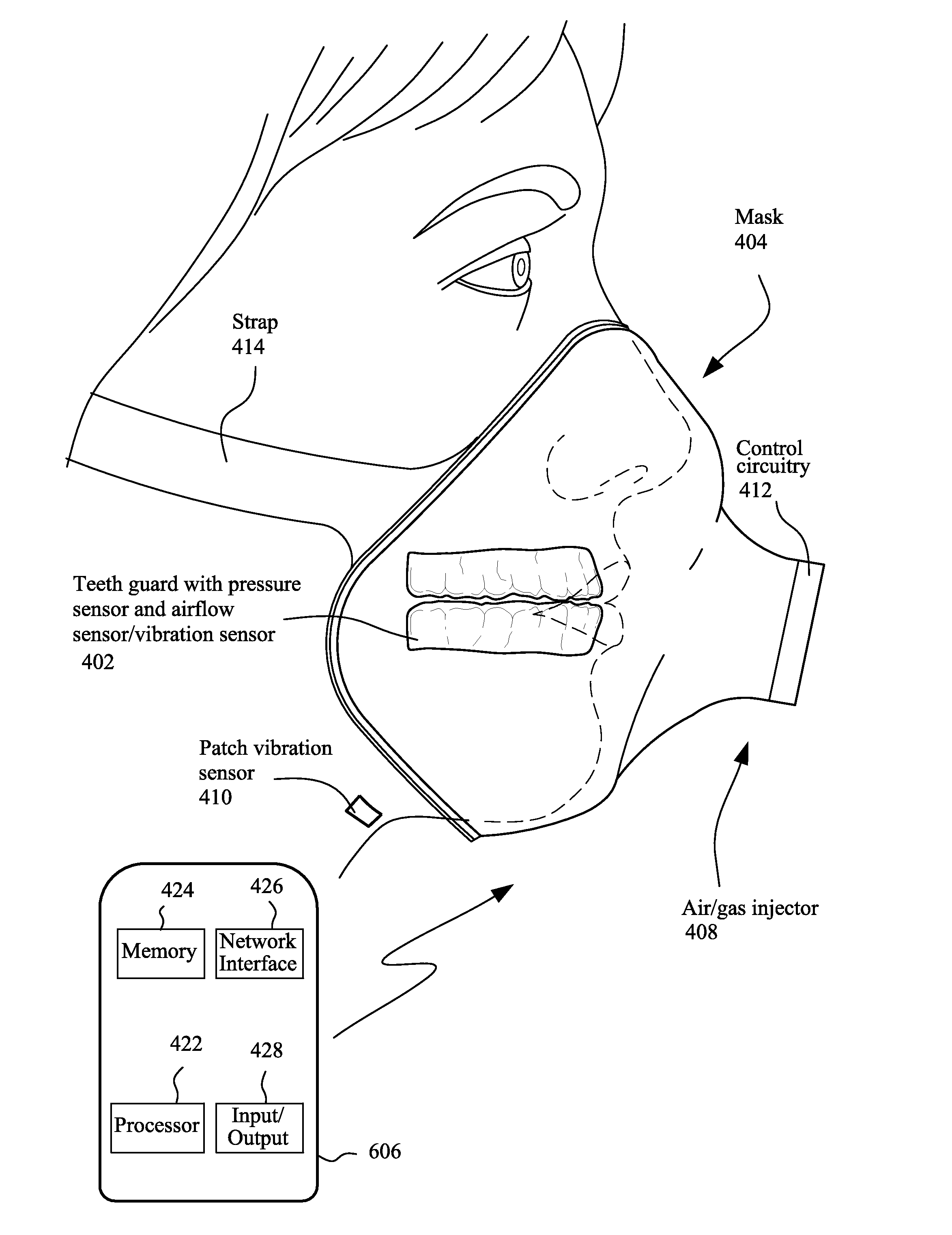

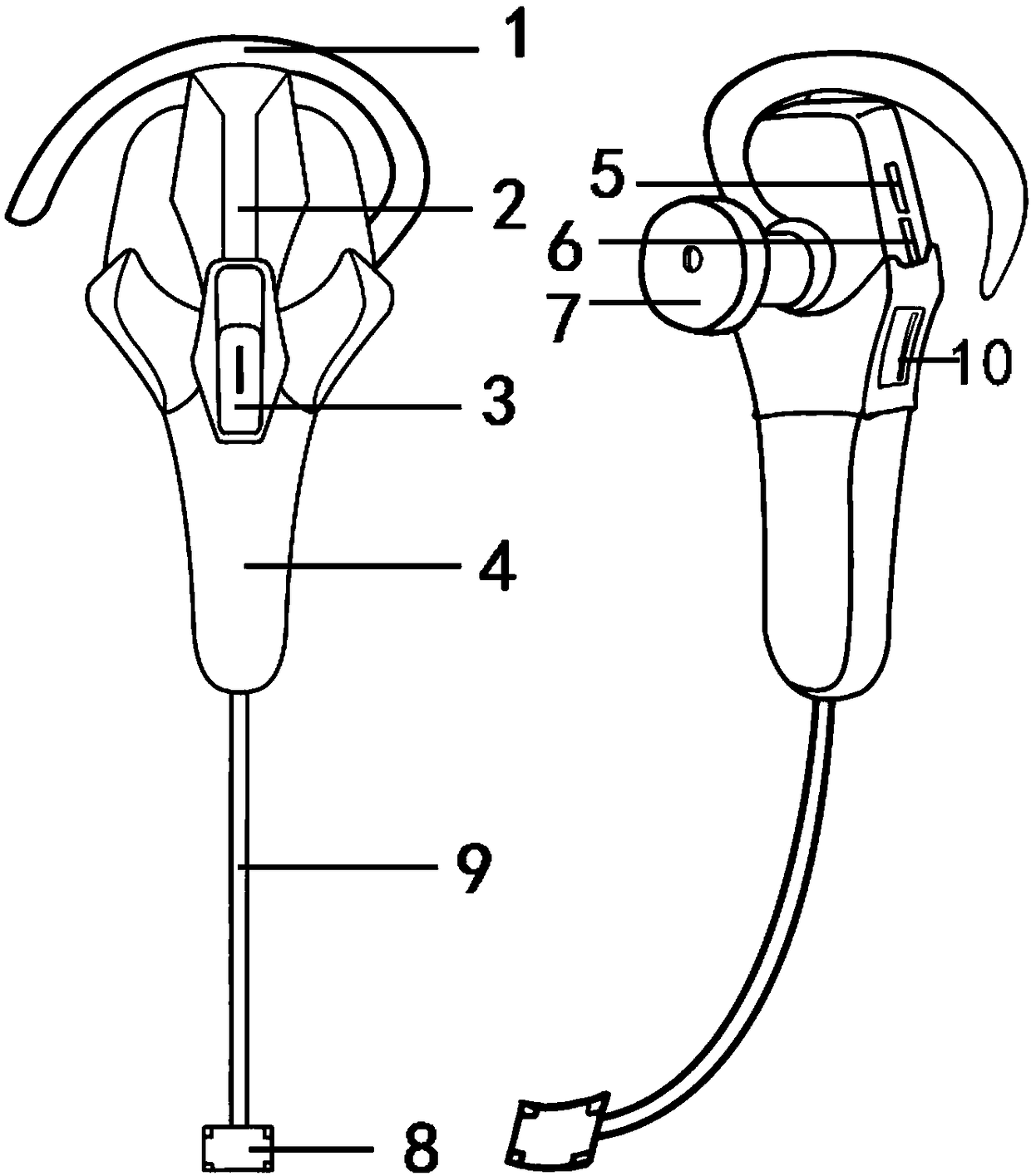

Methods and devices for monitoring bruxism and/or sleep apnea and alleviating associated conditions

InactiveUS20160095740A1Reduce incidenceReduce severityTeeth fillingRespiratory masksTeeth grindingDrug-induced apnea

Techniques and wearable appliances for monitoring bruxism, and / or for alleviating bruxism or sleep apnea related to bruxism are provided. In certain example embodiments, there is provided a custom teeth guard configured to be attached to at least some teeth in one of the upper or lower jaws, having at least two different non-zero amounts of padding arranged at positions located between teeth in the upper jaw and teeth in the lower jaw in accordance with predetermined strength of grinding of teeth at the positions. The custom teeth guard may be useful in helping to preempt apneic events and / or the like, e.g., by reducing the incidence and / or severity of teeth grinding.

Owner:MARDIROSSIAN ARIS +1

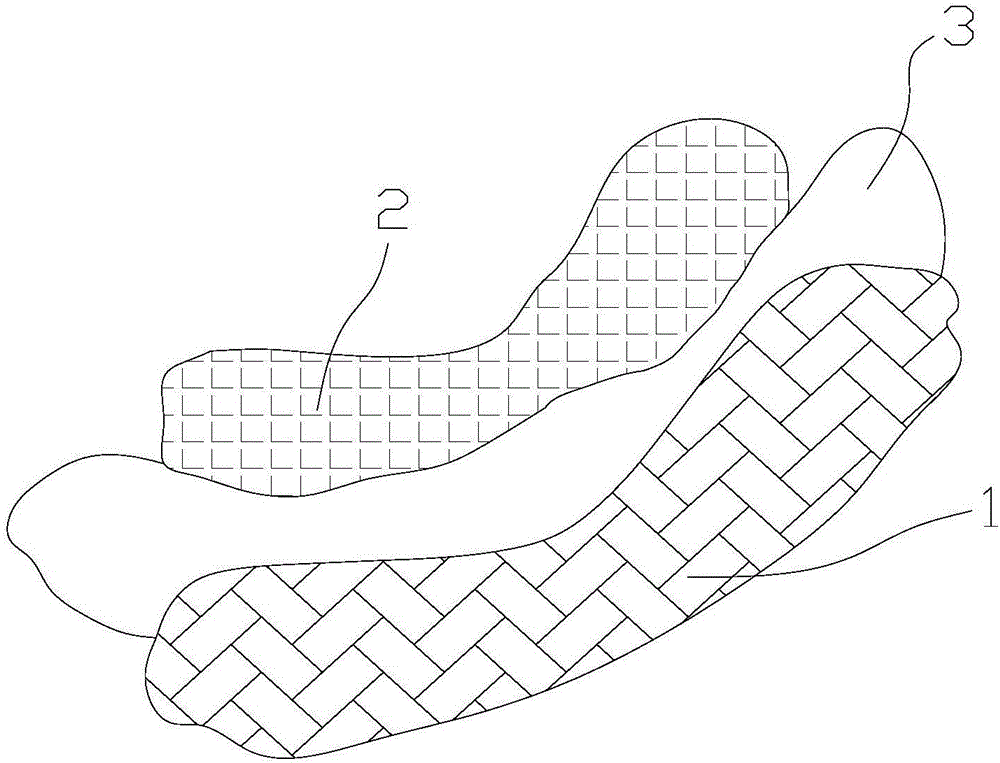

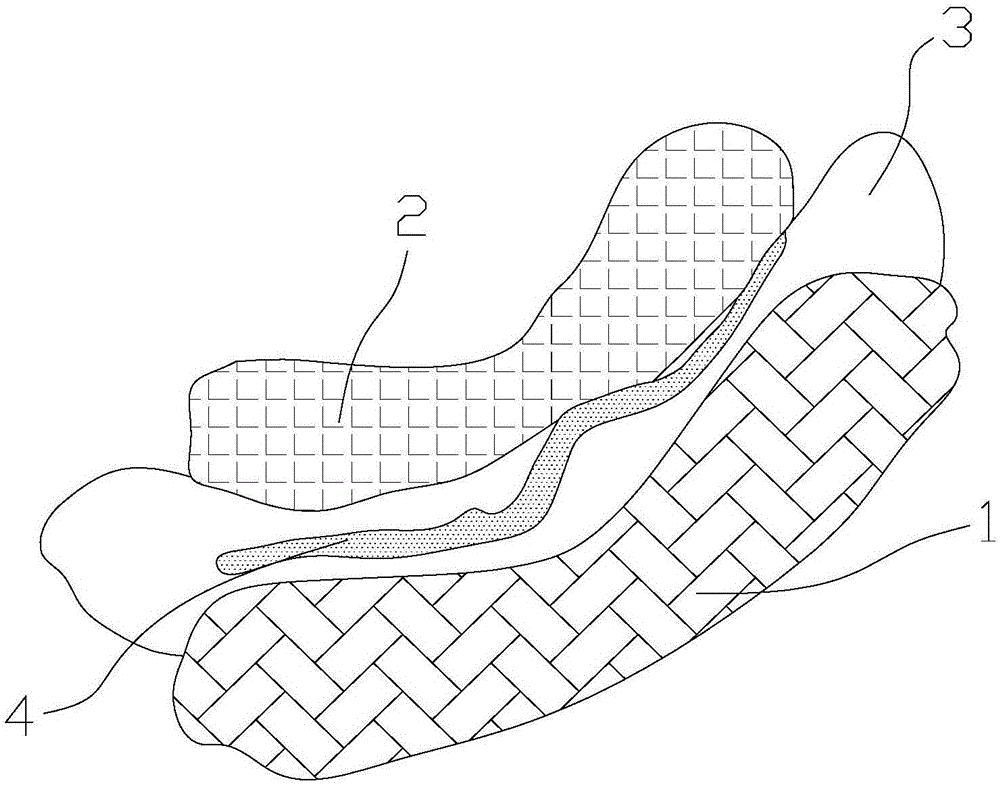

Tooth grinding hotdog for pets and preparation method of tooth grinding hotdog

ActiveCN106720946APrevent obesityReasonable collocationAnimal feeding stuffAccessory food factorsHydrolysateFish oil

The invention discloses a tooth grinding hotdog for pets. The tooth grinding hotdog is prepared from an inner-layer sausage, interlayer stuffing and an outer-layer pork skin, wherein the inner-layer sausage is prepared from a first meat material, a component A and a component B; the interlayer stuffing is prepared from a second meat material, a component C and a component D; the component A is prepared from rice flour, vegetable protein, white granulated sugar, yeast hydrolysate, sweet potato flour, table salt, citric acid, garlic powder and functional auxiliary materials; the component B is prepared from glycerol and smoking spice; the component C is prepared from starch and table salt; the component D is prepared from glycerol and fish oil. The tooth grinding hotdog for the pets, disclosed by the invention, has balanced nutrients, bright color and very good layering, has the effects of cleaning teeth and grinding the teeth, and can also be used for improving digestion and refreshing the breath. The invention further discloses a preparation method of the tooth grinding hotdog for the pets; the preparation method has the advantages of a few of steps, simple flow and safety in operation.

Owner:SHANDONG HAICHUANG IND & TRADE CO LTD

Method and Oral Appliance for Improving Air Intake and Reducing Bruxism

ActiveUS20180207022A1Numerous medical conditionImprove performanceChiropractic devicesSnoring preventionDiseaseThroat

Provided is a soft flexible oral appliance having protuberances that mimic naturally occurring dental Tori. An upper, palatial appliance and a lower, mandibular appliance may be used in conjunction or separately to alleviate a variety of disorders, improve facial tone, and increase physical performance. The appliances are lightweight, thin, and do not prohibit normal speech patterns when in use Small protuberances are strategically molded along key surfaces of each appliance to stimulate nerves in the tongue and affect forward protrusion. Forward positioning of the tongue dilates the airways of the throat improving breathing while the use is sleeping, playing sports, or talking. It also reduces bruxing or grinding of the teeth. A method is further provided, for adding protuberances to other types of oral appliances, thereby conferring some of the benefits listed above on appliances originally intended for other dental uses.

Owner:DENTAL CHOICE HLDG LLC

Split tooth prosthesis for fixing and repairing deficient toot and production method thereof

The invention provides a fission-typed dental prosthesis used for fixedly restoring lost tooth, comprising a whole bracket and a key way typed bridge tooth; the whole bracket is fixedly bonded to enamel used for abutment teeth at two sides of the lost tooth; the key way typed bridge tooth is fixedly bonded to the whole bracket in a zigzag way by a concave trough which is concave internally and arranged at the bottom of the key way typed bridge tooth, and forms a concave-surface contact with the adjacent surface of the abutment tooth. The preparation method of the fission-typed dental prosthesis of the invention is characterized in that non-functional area and inverted concave area of the abutment teeth at two sides of the lost tooth are analyzed on a model; wax-pattern is directly prepared on the copied original model; a suspension casting sprue is directly embedded so as to prepare the whole bracket by embedding, scorification and casting; subsequently, the key way typed bridge tooth is prepared. The fission-typed dental prosthesis needs no surgical operation, leads the manual denta prothesis to be firmly fixed on adjacent abutment teeth on the basis of no tooth-grinding or little tooth-grinding so as to bear the engaging force along all directions and uniformly disperse the force onto the abutment tooth, has good and natural appearance, good function, low cost, short treatment period, good fixing effect, and eliminates the black triangle area of adjacent teeth at the same time.

Owner:李奎范 +1

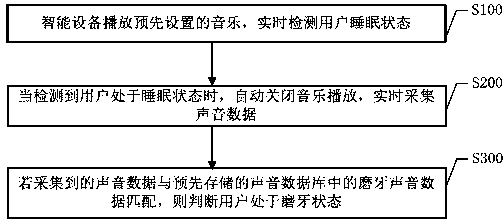

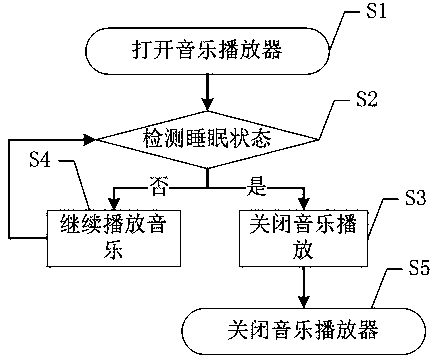

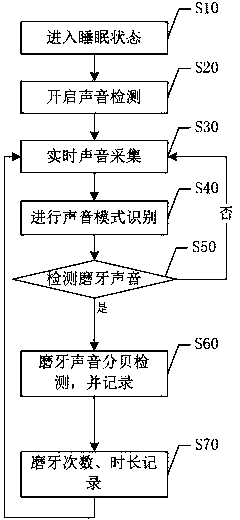

Teeth grinding detection method and detection system based on smart device

InactiveCN104866575AReal-time detection of sleep statusEffective intelligent identificationSpecial data processing applicationsData matchingSleep state

The present invention disclosed a teeth grinding detection method and detection system based on a smart device. The method comprises: playing predefined music and detecting a sleeping state of a user in real time by a smart device; when it is detected that the user is in a sleeping state, automatically stopping playing the music, and acquiring voice data in real time; and if the acquired voice data matches with teeth grinding voice data prestored in a voice database, determining that the user is in a teeth grinding state. According to the present invention, by means of the sleep detection, voice mode recognition and the like technologies, teeth grinding voice is effectively and smartly identified, thereby improving the accuracy in teeth grinding detection, facilitating the user to find his or her teeth grinding phenomenon, improving the sleeping quality, and bringing convenience to the user.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Automatic tooth grinding machine

ActiveCN105081467APrevent splashImprove grinding qualitySawing tools dressing arrangementsCircular sawEngineering

The invention discloses an automatic tooth grinding machine. The automatic tooth grinding machine comprises a machine frame. A grinding head motor is arranged on the machine frame and provided with a circular saw blade. The circular saw blade is connected with the grinding head motor through a rotating mechanism. The machine frame is provided with a front angle adjustment left-and-right movement mechanism. The grinding head motor is connected with the front angle adjustment left-and-right movement mechanism. The machine frame is further provided with a chamfer front-and-back movement mechanism. The chamfer front-and-back movement mechanism is connected with the front angle adjustment left-and-right movement mechanism. The machine frame is further provided with a tooth grinding up-and-down movement mechanism. The tooth grinding up-and-down movement mechanism is connected with the chamfer front-and-back movement mechanism. According to the automatic tooth grinding machine, high-speed automatic tooth grinding of the circular saw blade is achieved, and the saw blade tooth grinding quality and the saw blade tooth grinding efficiency are improved correspondingly; the circular saw blade and a grinding wheel can be controlled to move more flexibly, and the working efficiency is greatly improved.

Owner:浙江缙云韩立锯业有限公司

Pet chews with tooth-care effect and preparation method thereof

ActiveCN108243988AFlexibleMalleableAnimal feeding stuffAccessory food factorsAdhesivePathogenic bacteria

The invention discloses a pet chews with a tooth-care effect and a preparation method thereof and belongs to the field of pet tooth-care toys. The pet chews comprises a carrier, an adhesive, probiotics and prebiotics, wherein the probiotics are human intestinal prebiotics flora beneficial to human bodies. The pet chews has the advantages that the tooth-grinding-liking nature of pets is utilized, the probiotics and the prebiotics are added into the pet chews, and pet teeth can be cleaned when a pet chews the pet chews for a long time; in addition, the probiotics and the prebiotics are mixed through the adhesive, a lot of the probiotics and the prebiotics are adhered to the oral cavity of the pet, the prebiotics promote the planting of the probiotics to form the dominant prebiotics flora, the growth of oral cavity pathogenic bacteria and germs harmful to human bodies is inhibited, pet oral cavity health can be maintained, and pet oral cavity odor can be eliminated.

Owner:GONGLIN IND SHENZHEN

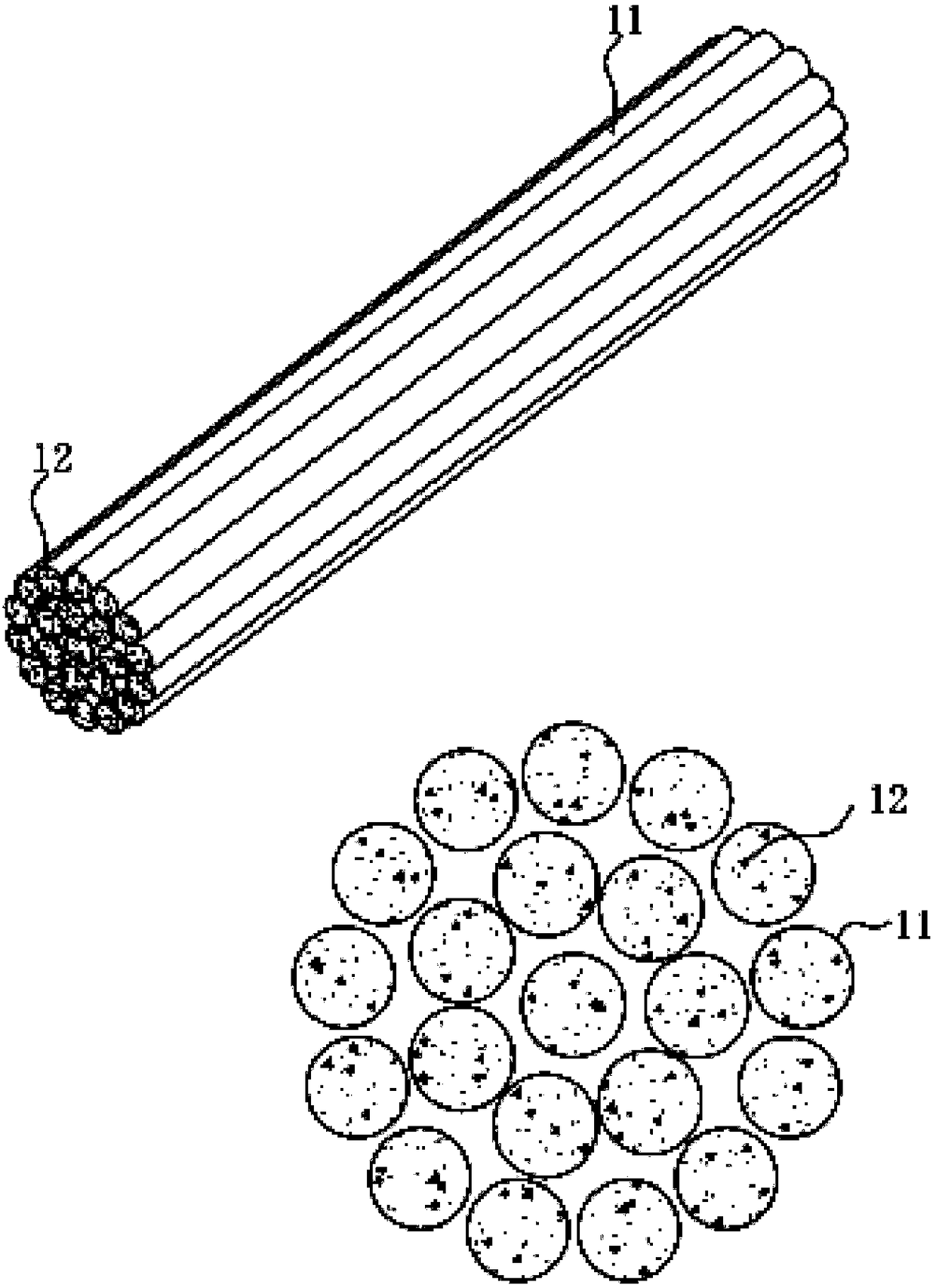

Design method of large axial modification amount gear and large axial modification amount gear

ActiveCN104565289AAvoid Hardness LossAvoid defects such as deep enoughPortable liftingGearing elementsHardnessEngineering

The invention provides a design method of a large axial modification amount gear and the large axial modification amount gear. The design method comprises the steps of determining the design parameters of the large axial modification amount gear according to conditions based on the parameters and the axial modification amount of a set basic gear model, determining the tooth surfaces of the first non-modified gear model and the second non-modified gear model of the large axial modification amount gear before modification, performing axial modification on the tooth surfaces of the first non-modified gear model and the second non-modified gear model, and then obtaining the large axial modification amount gear so that the axial modification amount of one side of the left and right tooth surfaces is 0, while the axial modification amount of the other side is the absolute value of d-c; as a result, a tooth grinding lug boss is avoided, the tooth surface hardness and the depth of a carburized layer are improved, and the reliability of the gear is improved.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

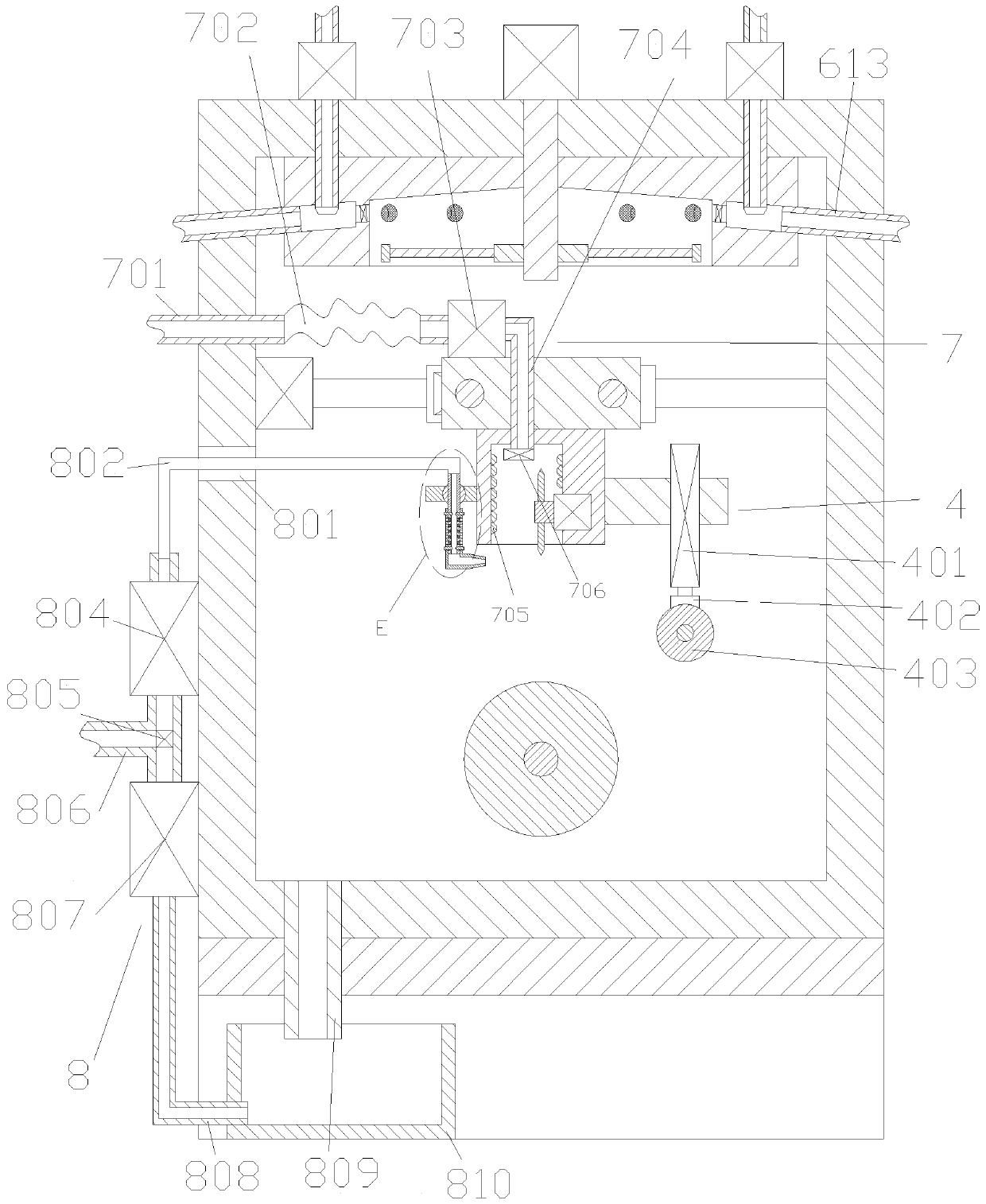

Numerical control tooth grinding machine with slotting function

InactiveCN110788400AUniform sizeFast absorptionSawing tools dressing arrangementsCnc grindingMachine

The invention discloses a numerical control tooth grinding machine with a slotting function. The numerical control tooth grinding machine comprises a box body, a concave base is fixedly installed at the bottom of the box body, a translation mechanism is installed inside the box body, and an abrasion wheel box of which the bottom is communicated with the outside is installed on the translation mechanism. The numerical control tooth grinding machine has the advantages of being simple in structure and easy to operate, saw webs can move up and down, thus errors generated in the traditional machining mode are reduced to guarantee the uniformity of the size of sawteeth, the tooth bottoms of the saw webs can be immediately slotted after tooth grinding on the saw webs is finished, extra detachmentis omitted, the working efficiency is improved, and the cost is reduced; the jetting angle and the jetting position of cooling liquid can be adjusted, and machining of the saw webs with different models can be better adapted to; and moreover, the cooling liquid can be recycled, extra cost is reduced, during machining, smoke can be quickly and timely absorbed and discharged after being diluted, subsequent treatment is facilitated, blockage on the device caused by the oil is also avoided, and the numerical control tooth grinding machine is simple, efficient, rapid and convenient.

Owner:缙云县先锋工具有限公司

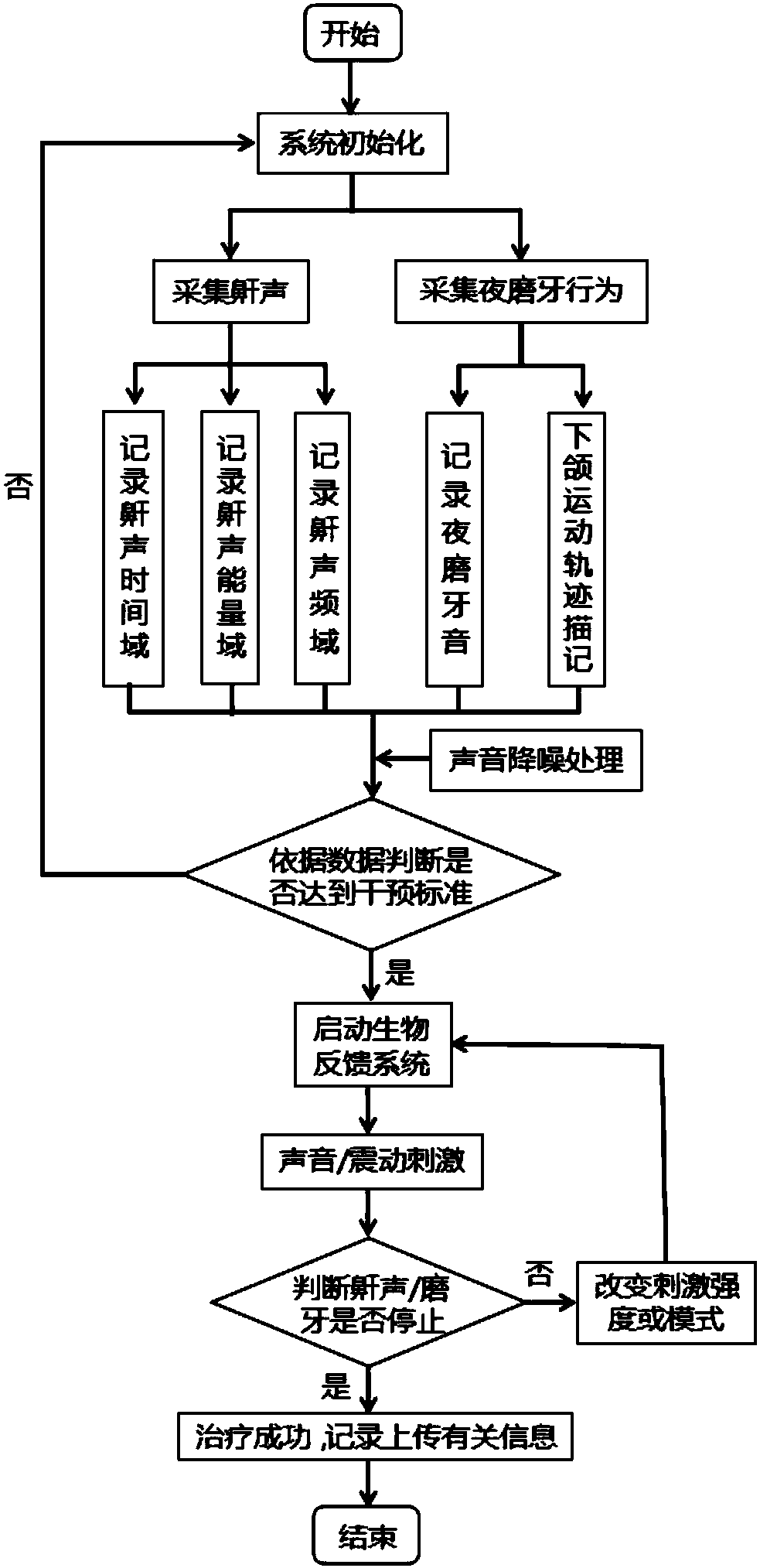

Biofeedback therapy mechanism and intelligent sleep diagnosis and treatment system based on biofeedback therapy mechanism

PendingCN108451503AChanging sleep stagesDoes not affect sleep qualitySnoring preventionNon-surgical orthopedic devicesInformation processingTreatment experience

The invention provides a biofeedback therapy mechanism and an intelligent sleep diagnosis and treatment system based on the biofeedback therapy mechanism. The biofeedback therapy mechanism analyzes collected characteristic data of human body snoring and teeth grinding actions and judges the strength grade of the human body actions, according to the strength grade of the human body actions, the corresponding grade of stimulation is determined, thereby improving the sleep quality of the human under the state of not awakening. The intelligent sleep diagnosis and treatment system comprises an earhook type diagnosis and treatment instrument, an intelligent equipment end information processing control end used cooperatively, a used database and a cloud computing service, the automatic feedbackof a user can be combined, the stimulation strength can be adjusted intelligently to ensure the sleep quality of the user, thereby achieving the personalized diagnosis and treatment experience.

Owner:卢纪元

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com