Design method of large axial modification amount gear and large axial modification amount gear

A design method and technology of modification amount, applied in the direction of components with teeth, belt/chain/gear, mechanical equipment, etc., can solve the problem of reducing the strength and life of the gear, increasing the grinding amount of the tooth surface, reducing the hardness of the tooth surface, etc. To avoid the reduction of tooth surface hardness and reduce the amount of tooth grinding modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

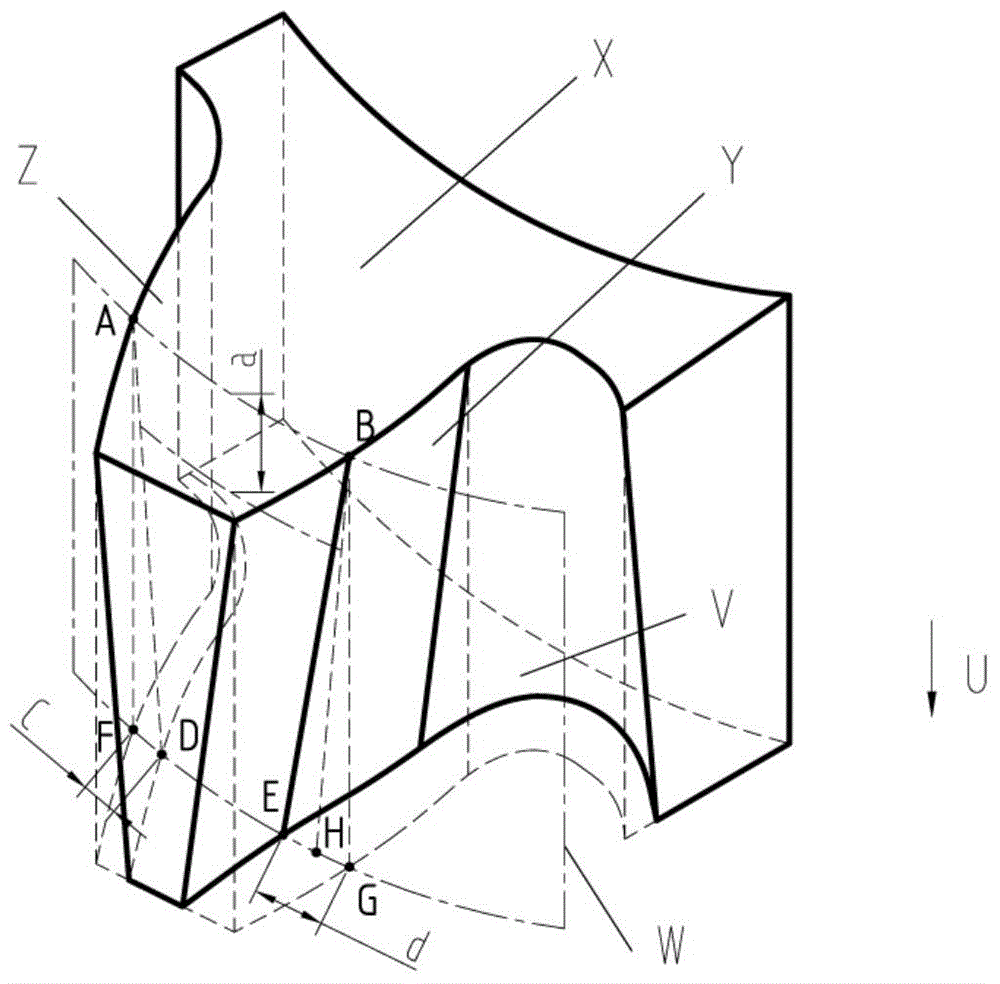

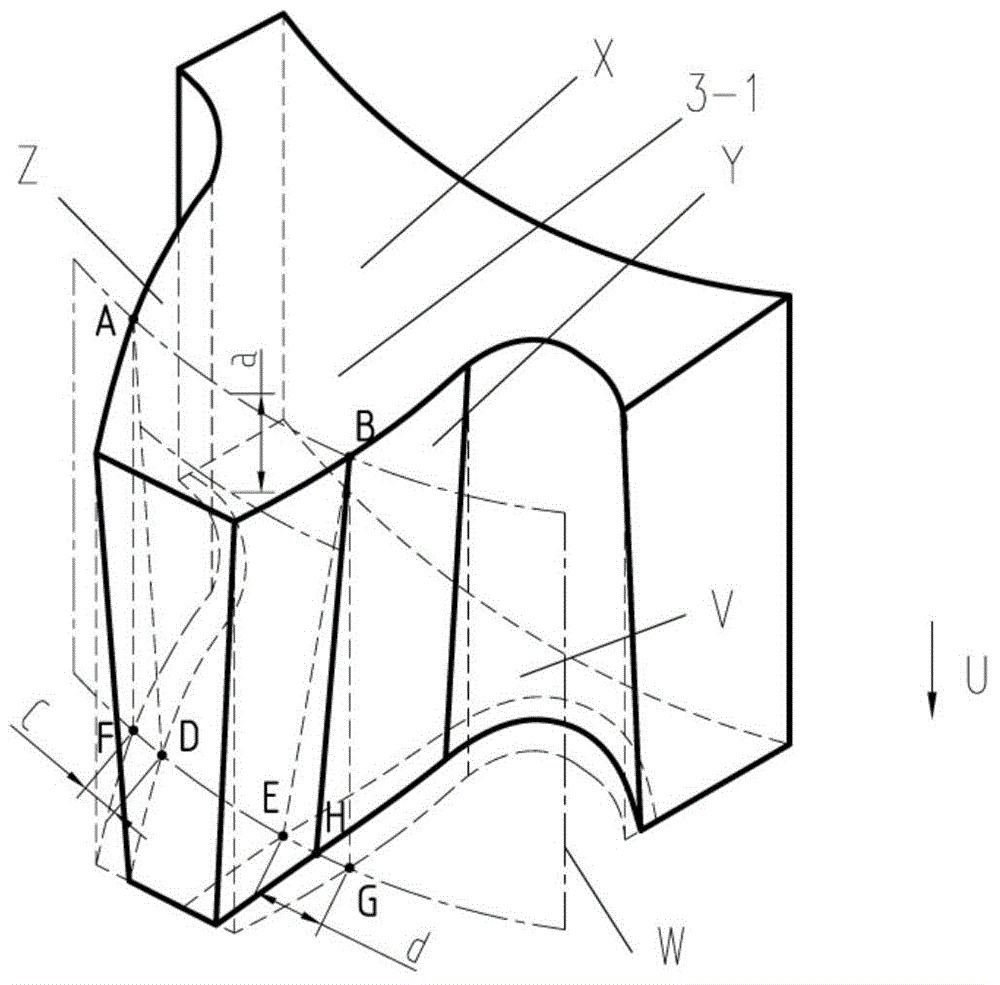

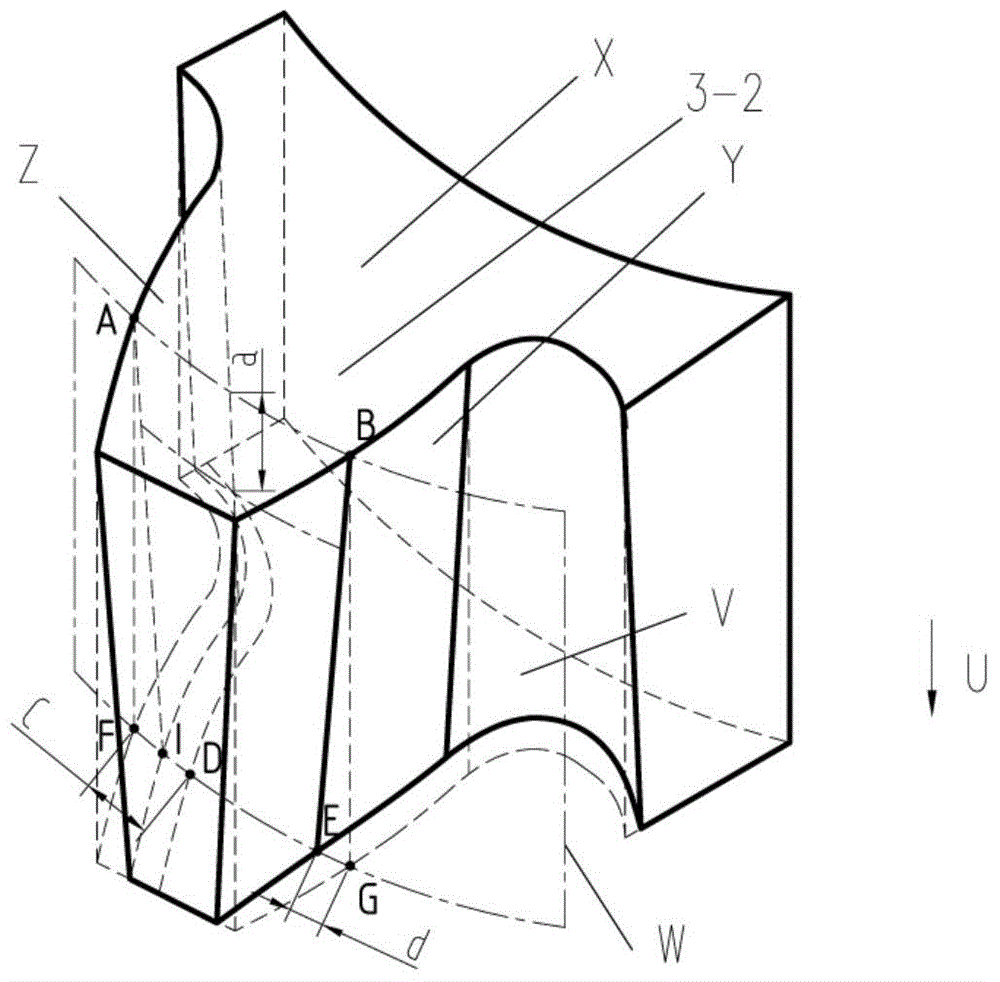

[0037] Such as figure 1 , 2 , 3, 4, 5, and 6, the design method of a large tooth direction modification amount gear of the present invention includes:

[0038] (a) Set the design parameters of the basic gear model 1: the number of teeth z 1 , modulus m 1 , tooth width b 1 , pressure angle α 1 , Variation coefficient x 1 ; The method also includes:

[0039] (b) Determine the tooth surface of the basic gear model 1 based on the set design parameters of the basic gear model 1. The intersection line of the indexing circular cylindrical surface and the right tooth surface of gear model 1 is marked as profile line BG, and the common normal of the basic gear model 1 is W 1 ;W 1 Calculate according to the following formulas I and II:

[0040] W 1 = m 1 cosα 1 ·[π(k 1 -0.5)+z 1 ·invα 1 ]+2x 1 m 1 sinα 1 (I),

[0041]

[0042] In formula II, k 1 Values are rounded to integers;

[0043] (c) setting the tooth direction modification amount of the left and right t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com