Patents

Literature

64results about How to "Improve friction characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

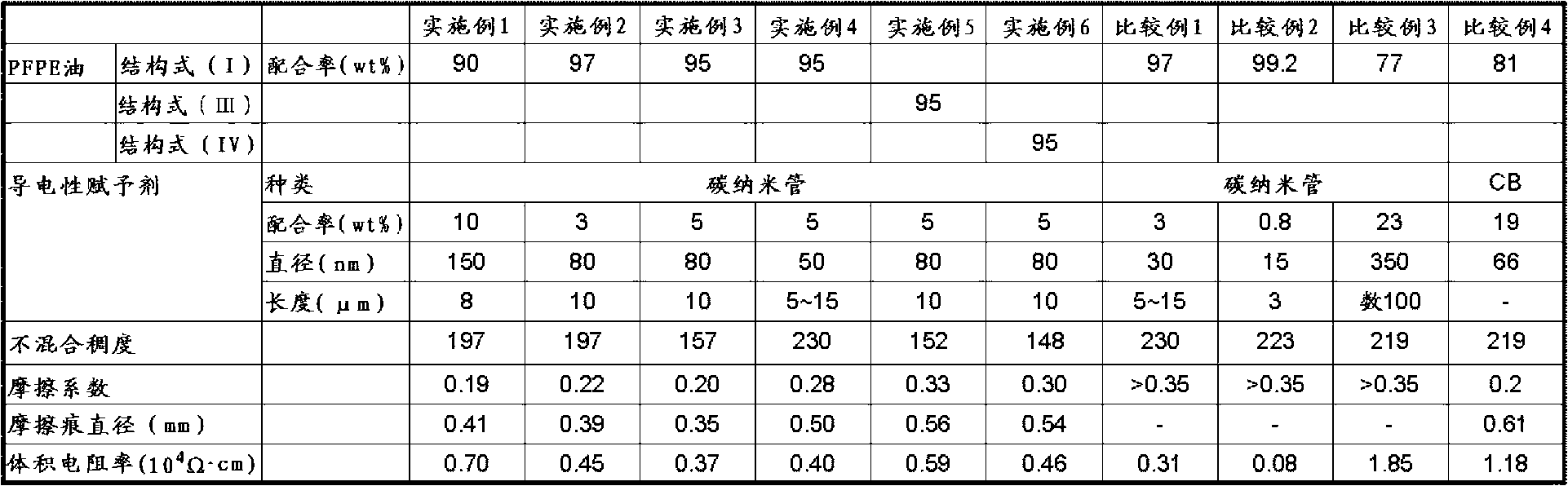

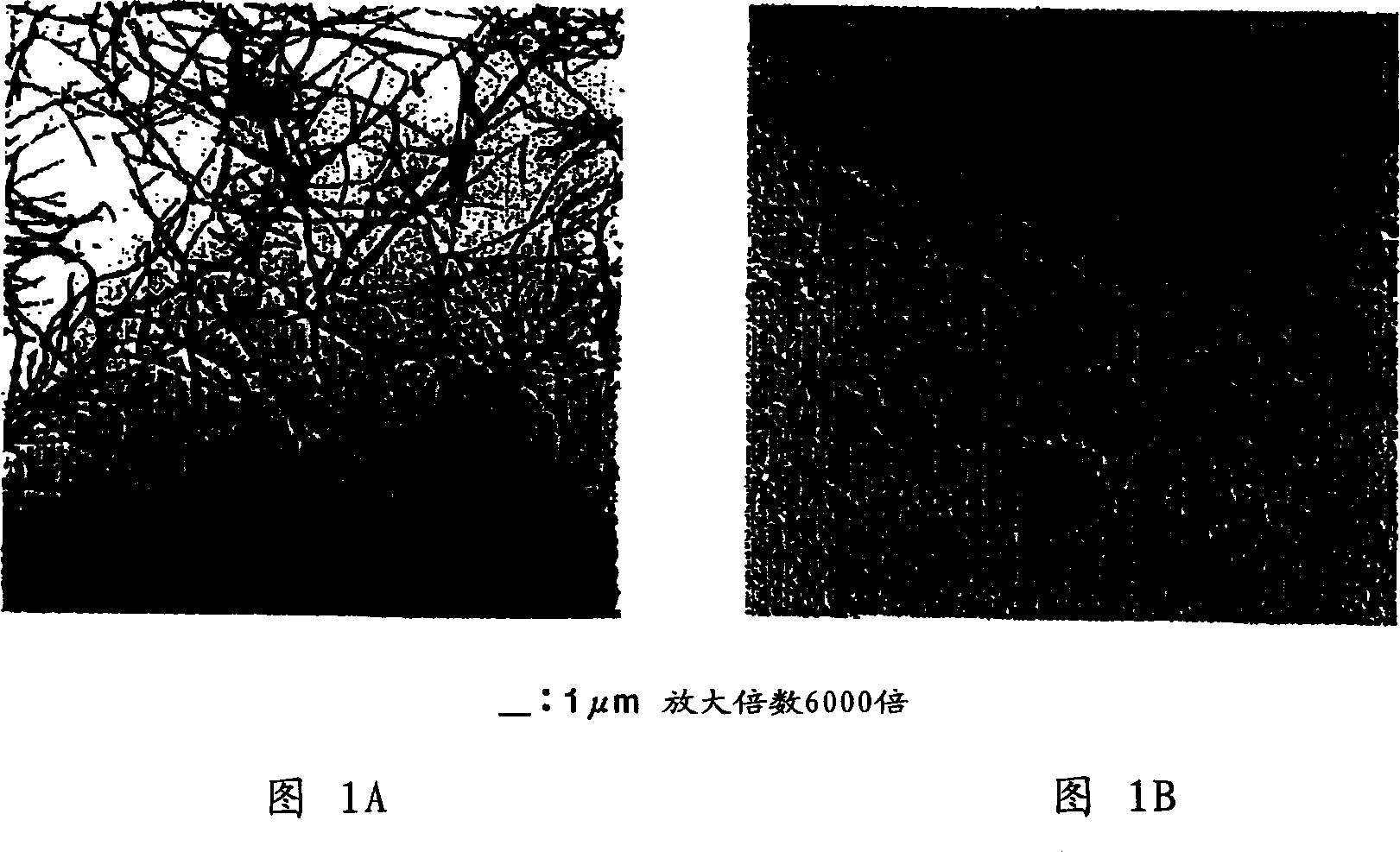

Electrical conductivity lubricating grease composition

InactiveCN102827673AImprove friction characteristicsLubricant compositionPerfluoropolyetherCarbon nanotube

The invention relates to an electrical conductivity lubricating grease composition which shows excellent electrical conductivity and has excellent frictional characteristics, and is characterized in that serving as a base oil, the composition contains perfluoropolyether, and serving as an electrical conductivity imparting agent, the composition contains carbon nano tubes, wherein the diameter of the carbon nano tubes is 40 to 200 nm, and the carbon nano tubes takes up 0.1 to 20 percent by weight in the whole lubricating grease.

Owner:NOK KLUEBER CO LTD

Lube base oil, lubricating oil composition for internal combustion engine, and lubricating oil composition for drive transmission device

InactiveCN101379171AExcellent viscosity-temperature characteristicsReduce energy lossBase-materialsMeth-Chemical composition

A lube base oil satisfying at least one of the following requirements (a) and (b). A lubricating oil composition for internal combustion engines is provided which comprises the lube base oil, an ash-free antioxidant containing no sulfur as a constituent element, and at least one member selected among ash-free antioxidants containing sulfur as a constituent element and organ omolybdenum compounds. Also provided is a lubricating oil composition for drive transmission devices which comprises the lube base oil, a poly(meth)acrylate-type viscosity index modifier, and a phosphorus compound. (a) The content of saturated matters is 90 mass% or higher and the proportion of cyclic saturated matters in those saturated matters is 10-40 mass%. (b) The lube base oil satisfies the relationship represented by the following expression (1). 1.440=n20-0.002OEv100=1.453 (1) [In the expression, n20 indicates the refractive index at 20 DEG C of the lube base oil and kv100 indicates the dynamic viscosity (mm2 / s) at 100 DEG C of the lube base oil].

Owner:NIPPON OIL CO LTD +1

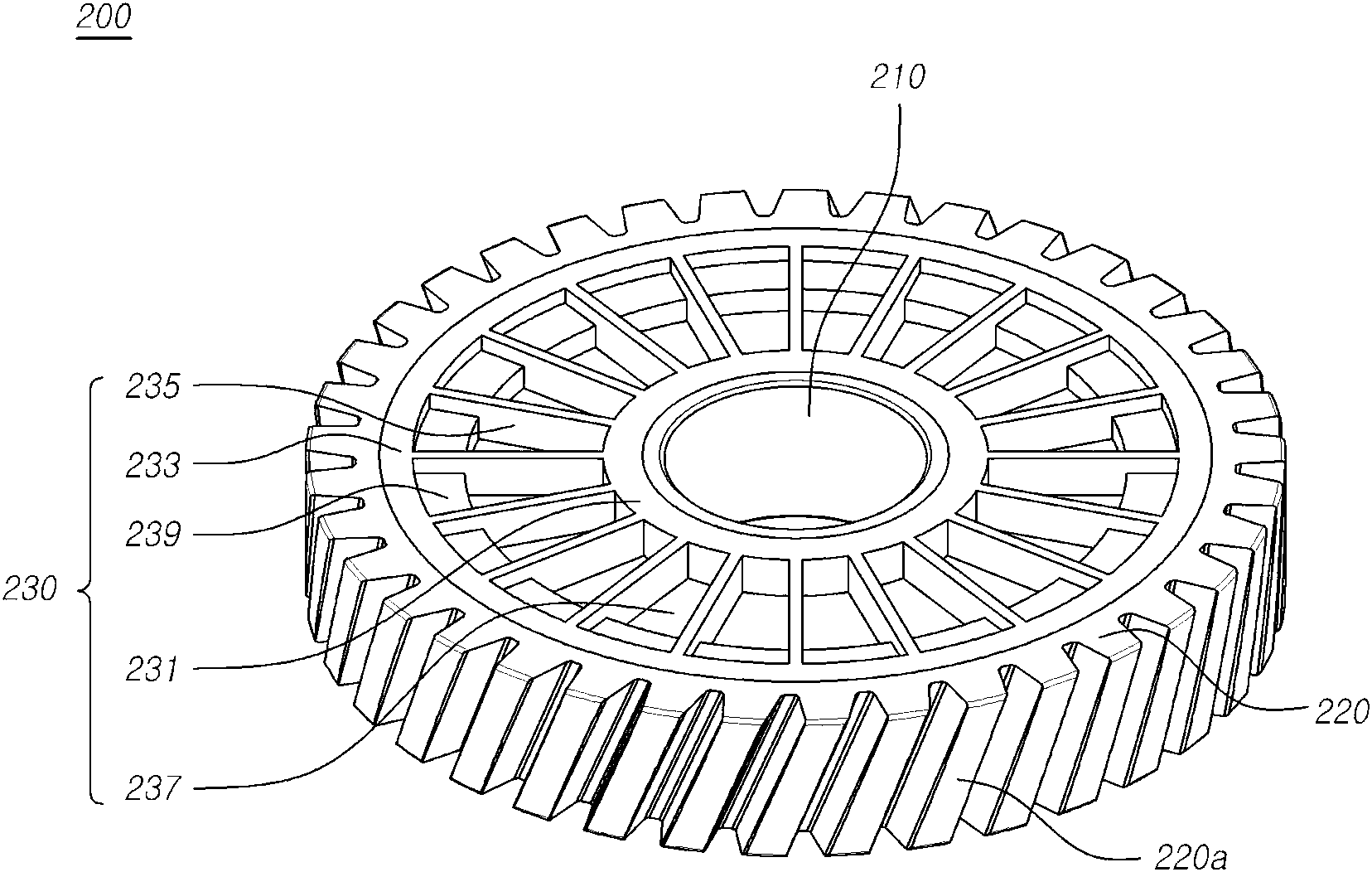

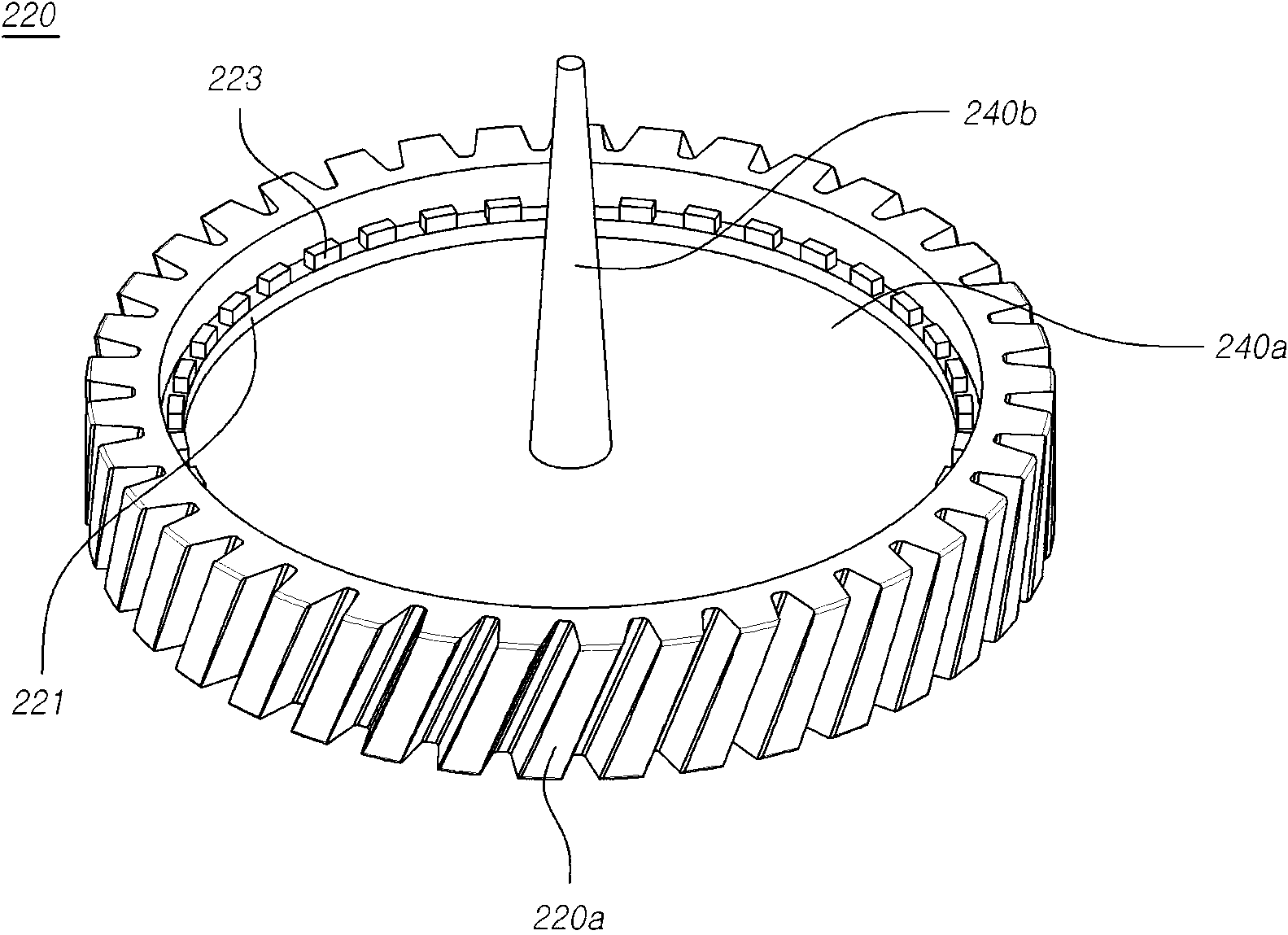

Worm wheel for electric power steering apparatus and method for manufacturing the same

InactiveCN103287481AStable for long-term useGood molding effectMechanical steering gearsGear wheelsElectric power steeringReduction drive

Disclosed is a worm wheel of a reducer of an electric power steering apparatus which is manufactured by integrally injection-molding a hub, a boss, and a gear forming part, thereby making it possible to increase a forming performance of the worm wheel and reduce an amount of material, and increasing a mechanical durability and frictional characteristics of the worm wheel to allow the reducer to be stably used for a long time, and a method for manufacturing the same.

Owner:HL MANDO CORP

Lubricant composition and rolling unit

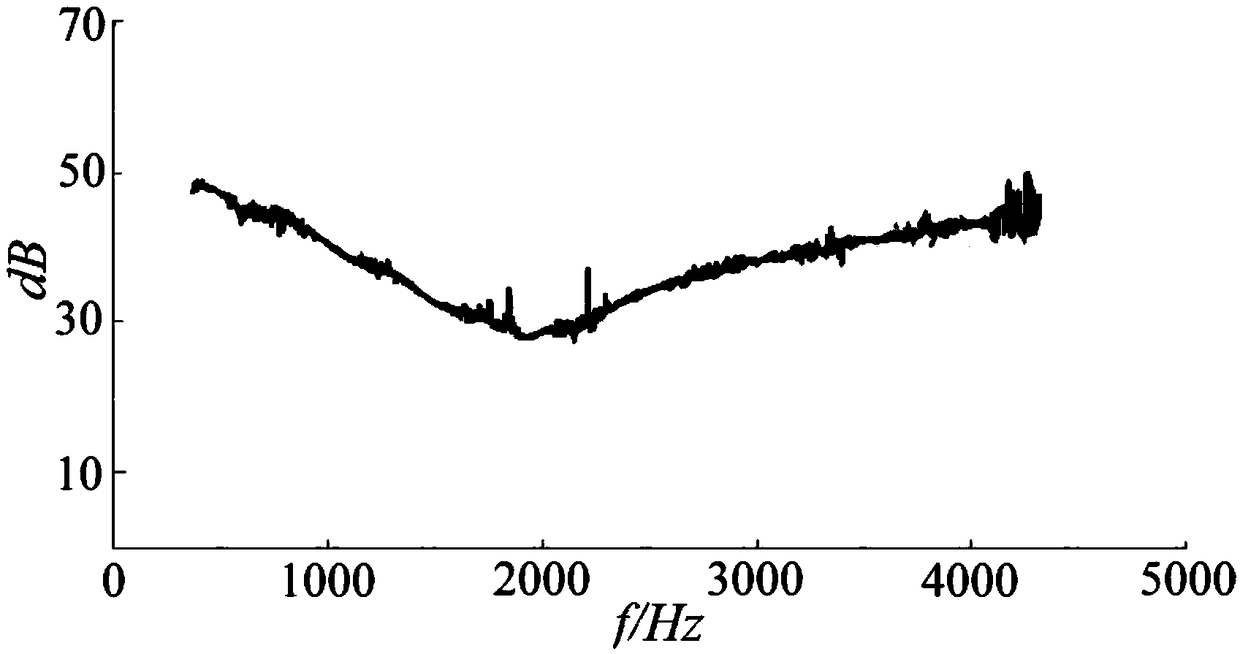

InactiveCN1356381ALower shear resistanceReduce rolling torqueBearing componentsThickenersFiberEngineering

A grease composition is disclosed, wherein a metallic soap-base thickener containing a long-fiber material having a major axis part length of at least 3 mum is blended with a base oil obtained by mixing a lubricating oil having a polar group within the molecule structure and a non-polar lubricating oil, which can improve the initial sound (cage sound) of bearing at the starting of operation in a low-temperature environment and is effective on the reduction of fretting damage (abrasion) or torque, and also a rolling bearing and a linear acting apparatus each obtained by packing the grease composition are disclosed, which exhibit excellent low-temperature acoustic property and are reduced in the fretting damage (abrasion) or torque.

Owner:NSK LTD

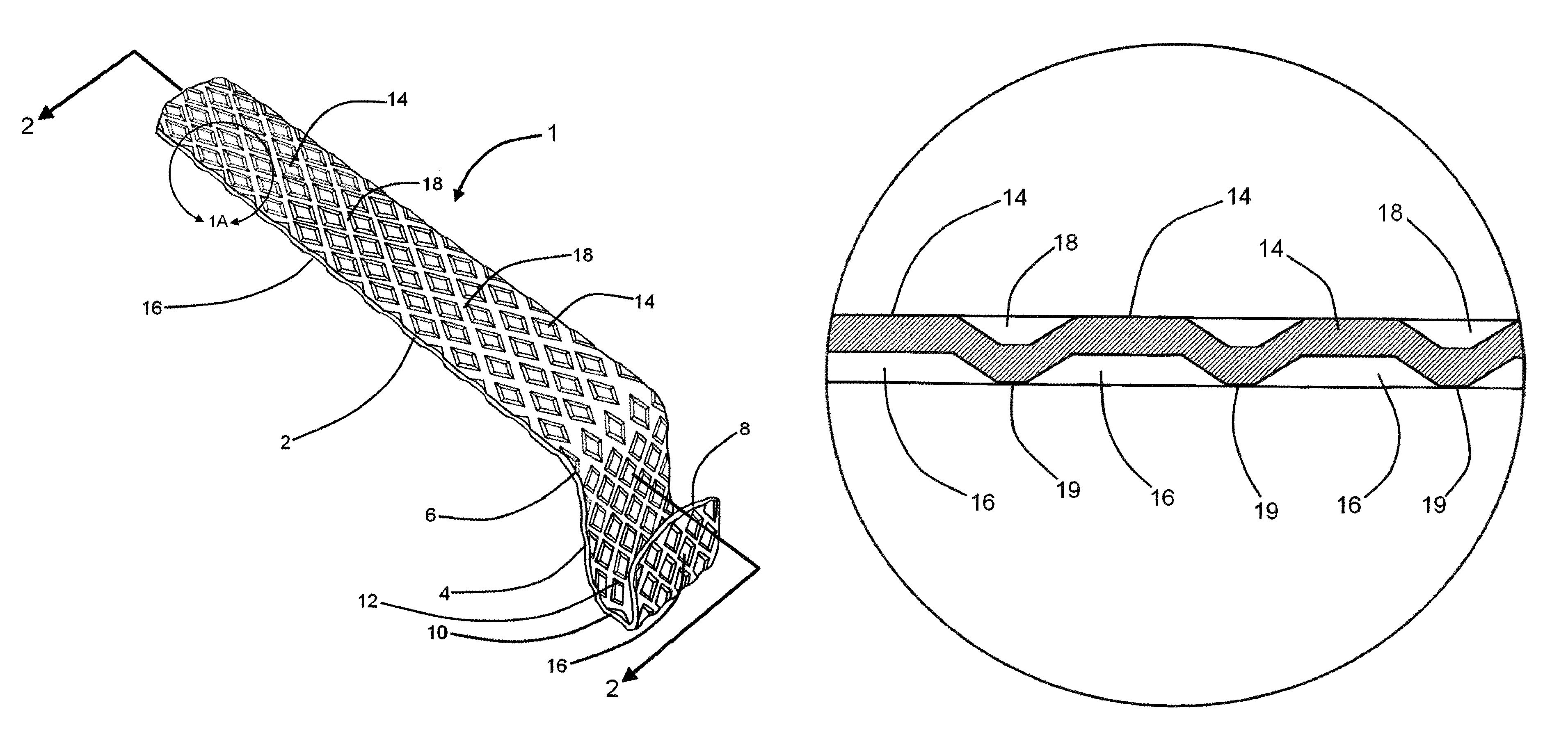

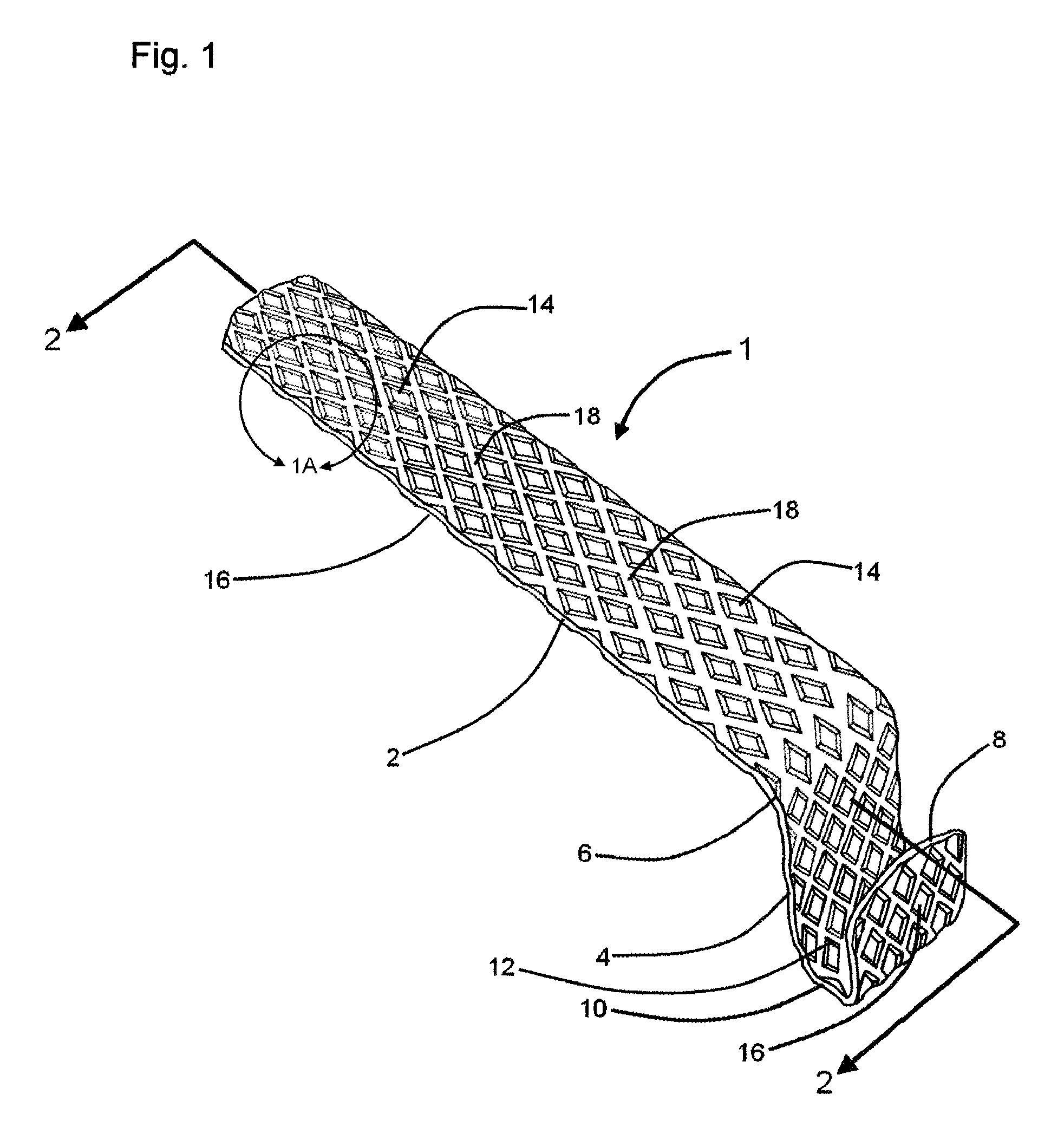

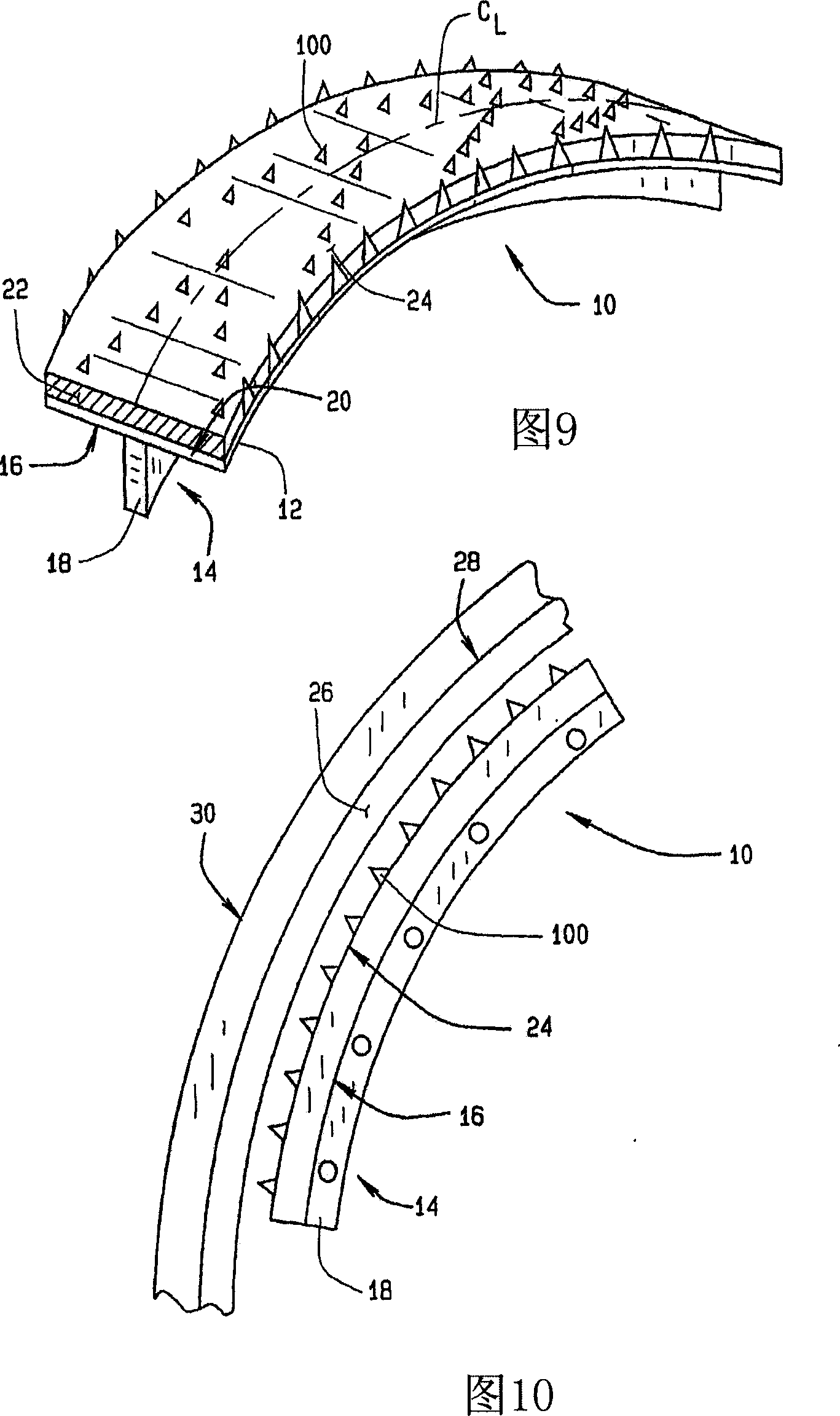

Roof line light holder

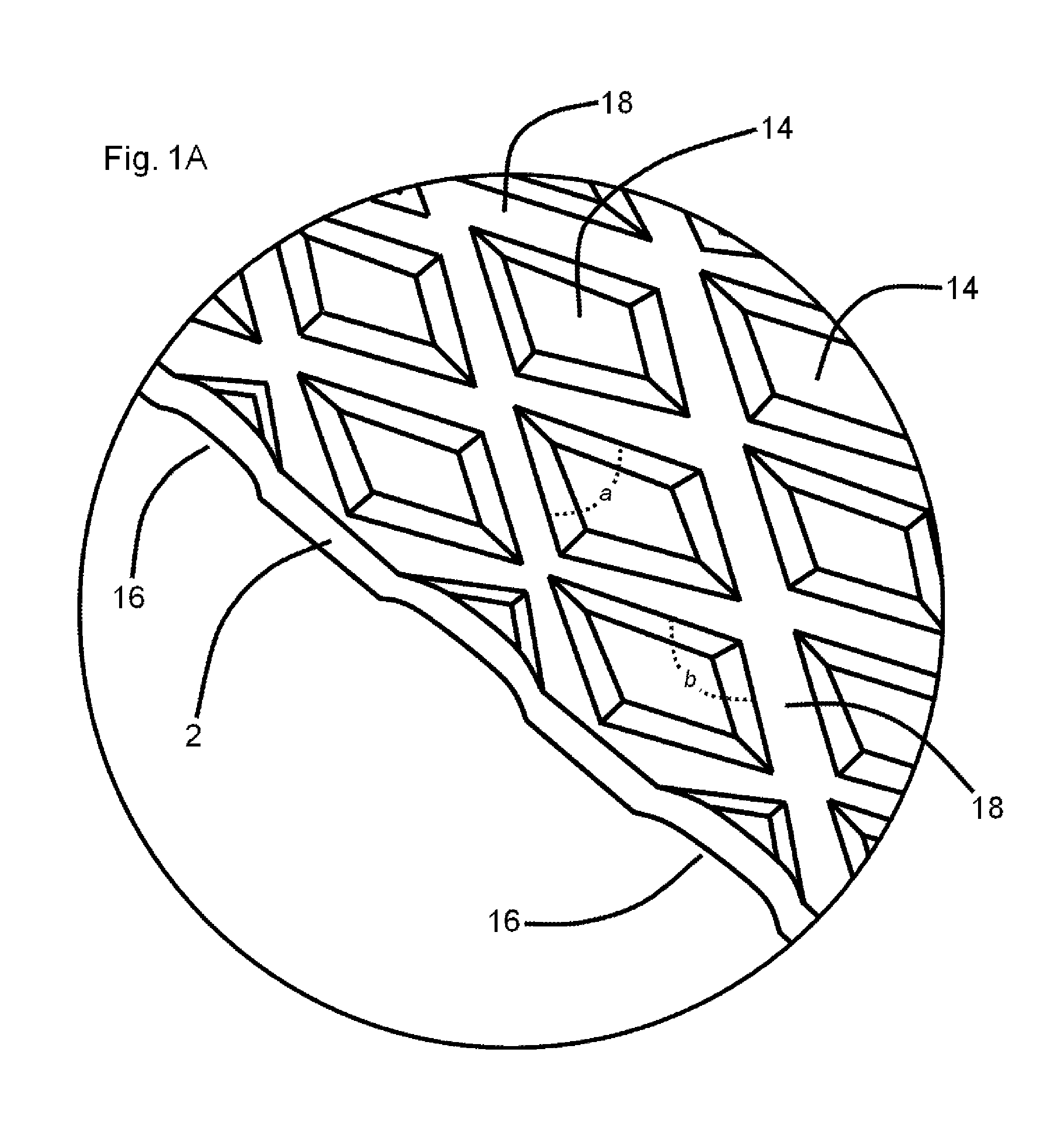

ActiveUS8313215B1Good friction propertiesSimple structureNon-electric lightingLighting support devicesEngineeringConcave side

A light holder including a suspension tie; a wire cradle attached to the suspension tie; a friction arm attached to the suspension tie; a matrix of knurls extending from the friction arm; and a matrix of concavities aligned with and underlying the matrix of knurls; each knurl among the matrix of knurls having a rhombus shaped periphery and each concavity among the matrix of concavities having a rhombus shaped periphery; each of the rhombus shaped peripheries of the matrices of knurls and concavities having a longitudinal vertex and an oppositely longitudinal vertex, each vertex being acutely angled; the matrices of knurls and concavities corrugating the friction arm and defining an overlying channel grid and an underlying ridge grid.

Owner:WAWAK UMSCHEID TRUDY K +1

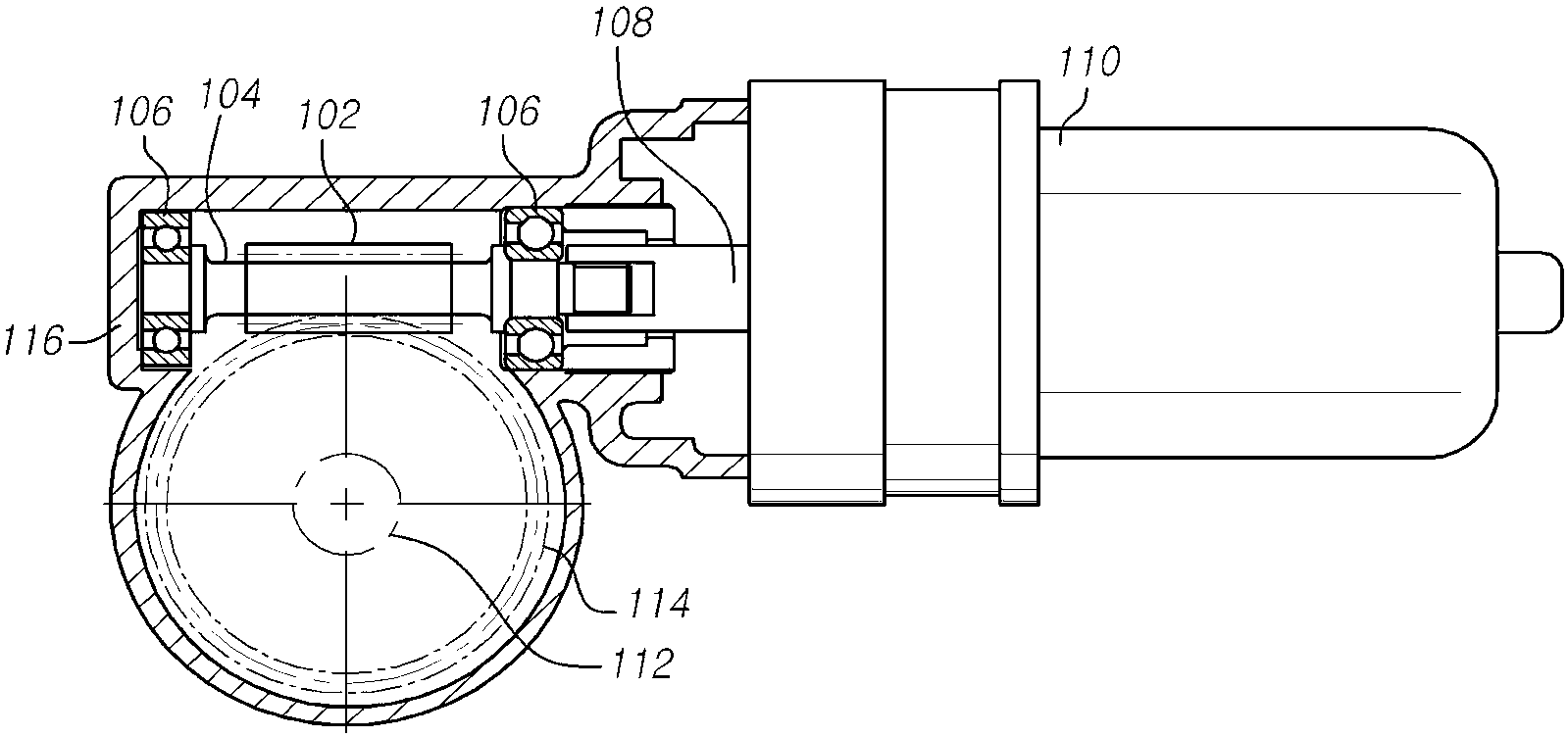

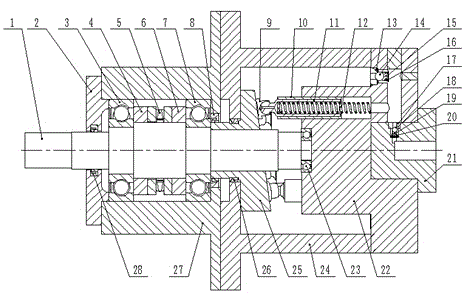

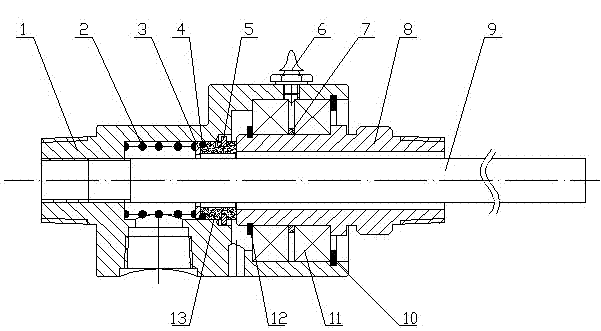

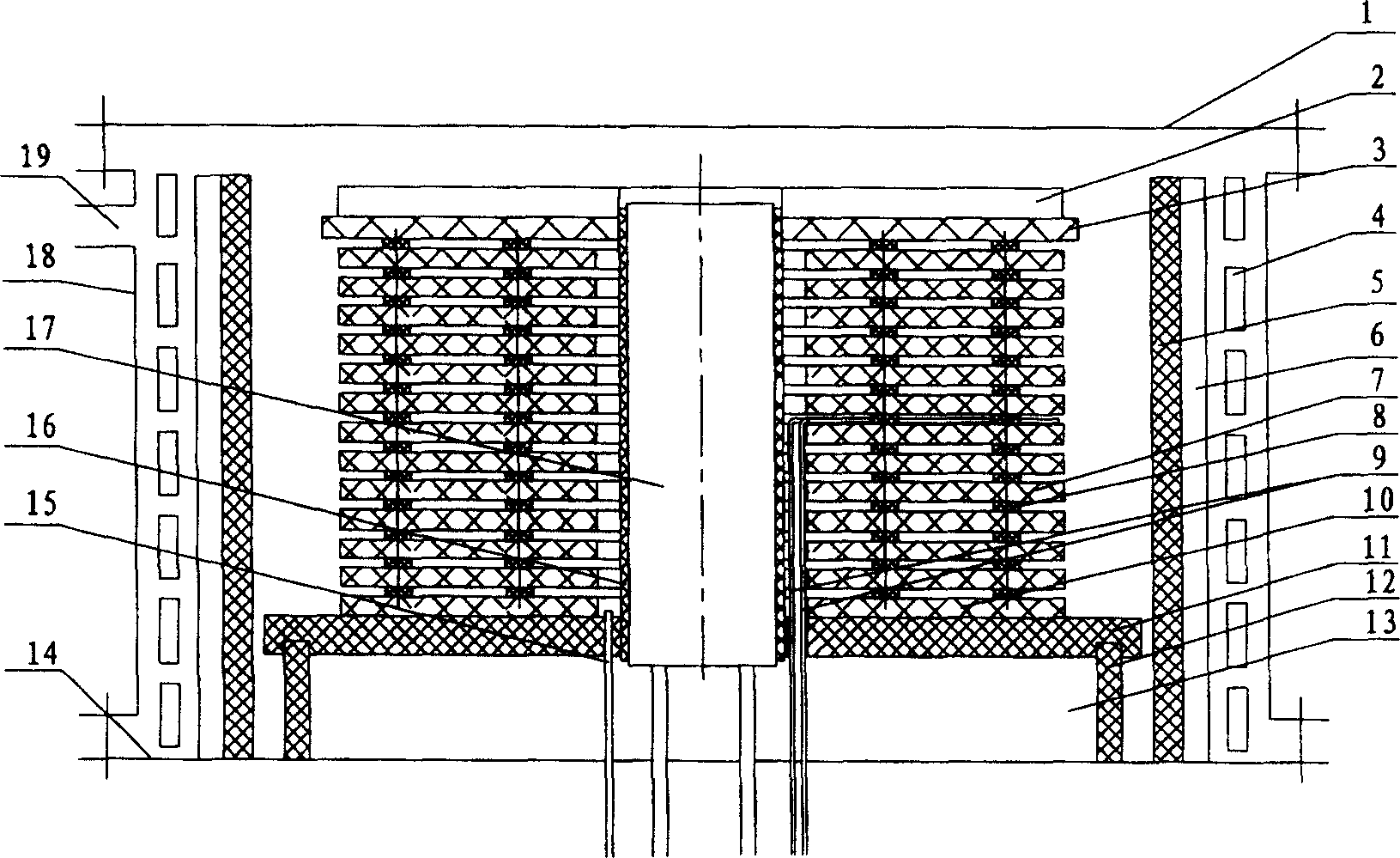

Inclined-disc-rotating internally-disposed valve flow distribution axial plunger pump

ActiveCN104454420AReasonable structureEasy to usePositive displacement pump componentsPositive-displacement liquid enginesBall bearingWorking pressure

The invention discloses an inclined-disc-rotating internally-disposed valve flow distribution axial plunger pump which comprises a front end cap, a front pump body, a pump shaft, a bearing component, a sealing component, a rear pump body, an inclined disc, a plunger sliding shoe component, a return spring, a cylinder body, a suction valve set, a rear end cap and an extrusion valve set. The pump shaft is arranged in the front pump body, the bearing component is mounted in the pump shaft, the inclined disc is mounted in the rear pump body, the suction valve set is mounted in the cylinder body, the extrusion valve set is mounted in the rear end cap, the pump shaft drives the inclined disc to rotate through a spline and jointly bears axial force and radial force of the inclined disc through a thrust bearing and a deep groove ball bearing, the cylinder body is fixed on the rear pump body and is relatively static, and the suction valve set and the extrusion valve set are mounted at the tail of the cylinder body and the rear end cap respectively. The inclined-disc-rotating internally-disposed valve flow distribution axial plunger pump is simple in structure, convenient to maintain, higher in specific power and performance-cost ratio, high in anti-fouling performance and especially suitable for high-pressure water pumps, leakage of the plunger pump is reduced effectively, and working pressure and volume efficiency are improved.

Owner:ZHEJIANG UNIV

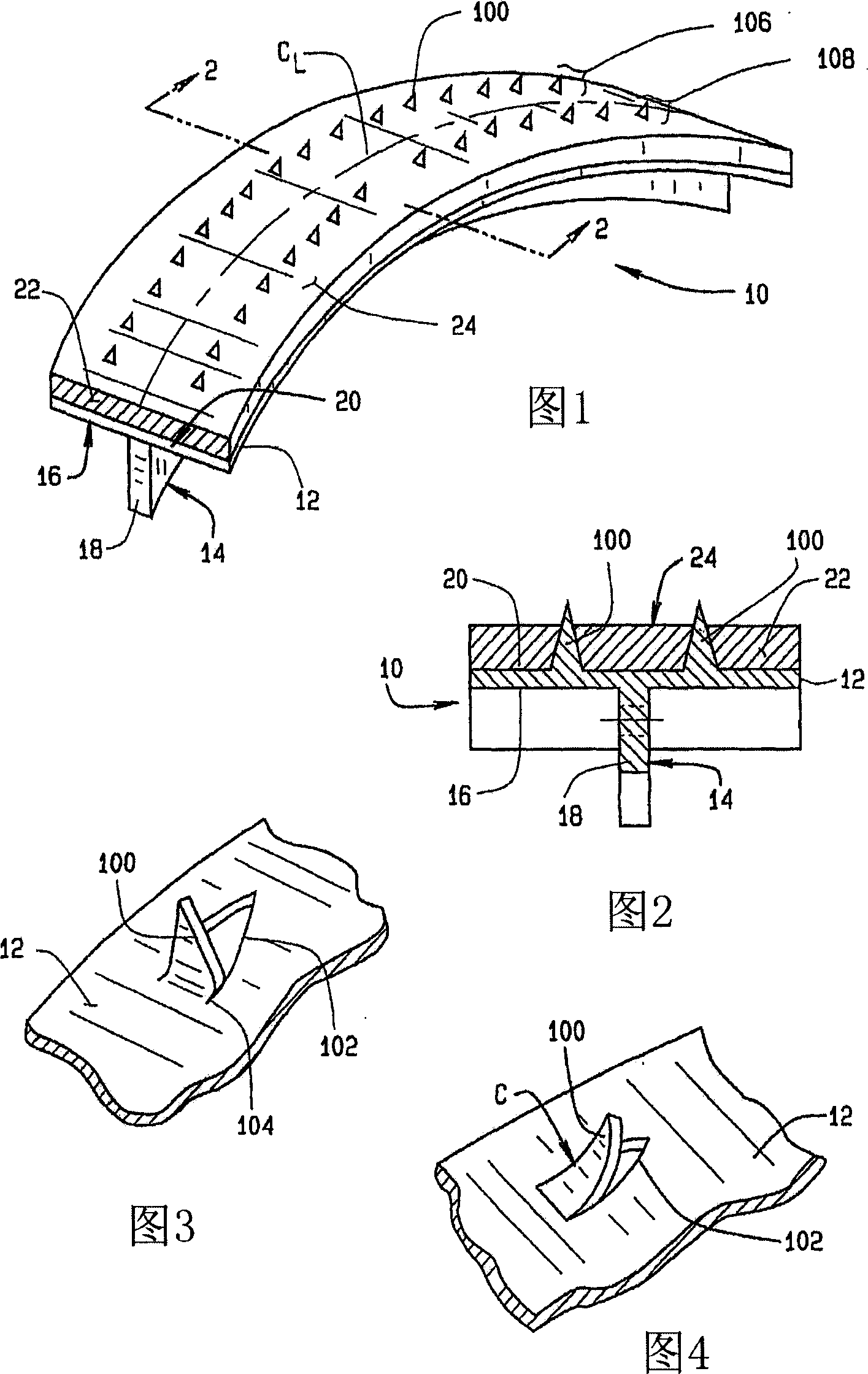

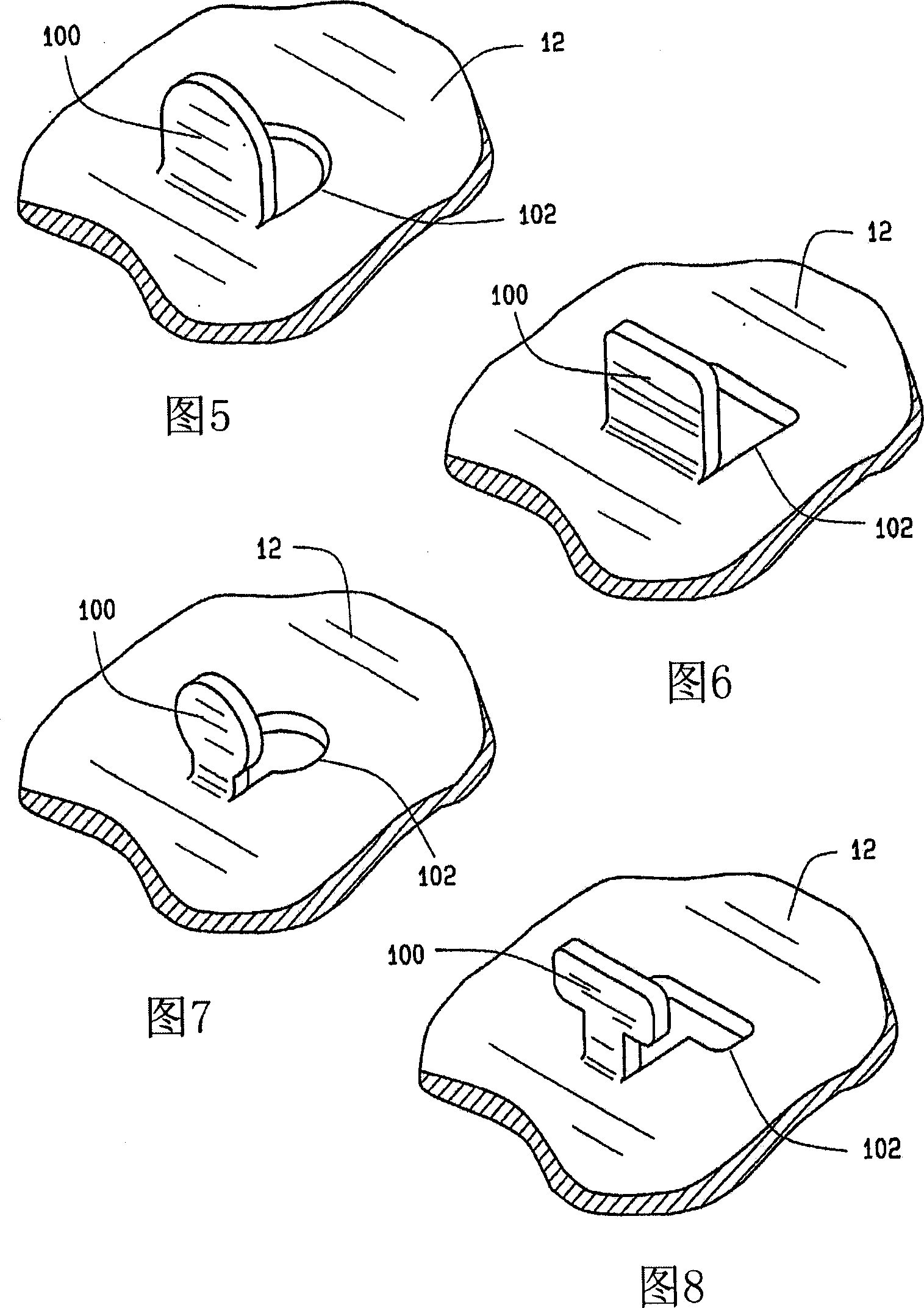

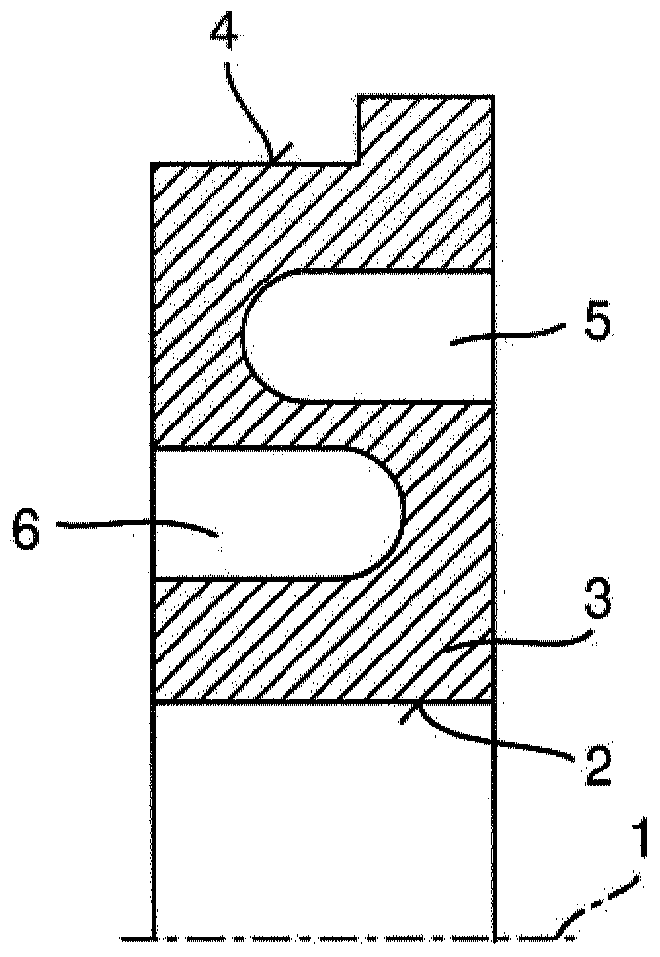

High friction brake shoe assembly

InactiveCN101133259AIncrease frictionImprove friction characteristicsBraking membersFriction liningBrake shoeBiomedical engineering

A vehicle brake shoe component (10) having a rigid back plate (12) incorporating a plurality of extensions (100) protruding through the brake friction material matrix (22) to the brake shoe component (10 ) of the external friction surface (24). Each extension (100) is configured to cooperate with the brake friction material matrix (22) to simultaneously engage an opposing friction element (28) with the friction material (22), enhancing the durability of the component (10) during initial use. Static and dynamic friction properties that exceed those obtained using one of the brake friction material (22) or the protruding portion (100).

Owner:FEDERAL MOGUL CORP

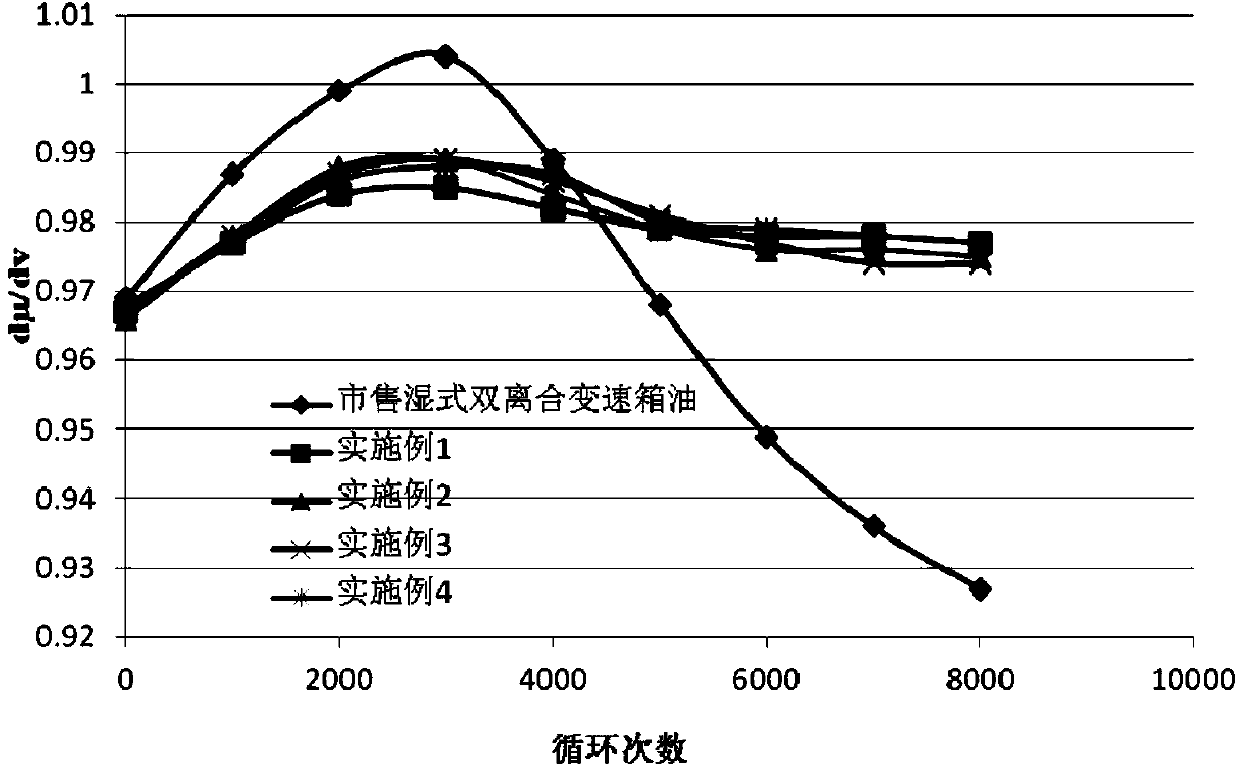

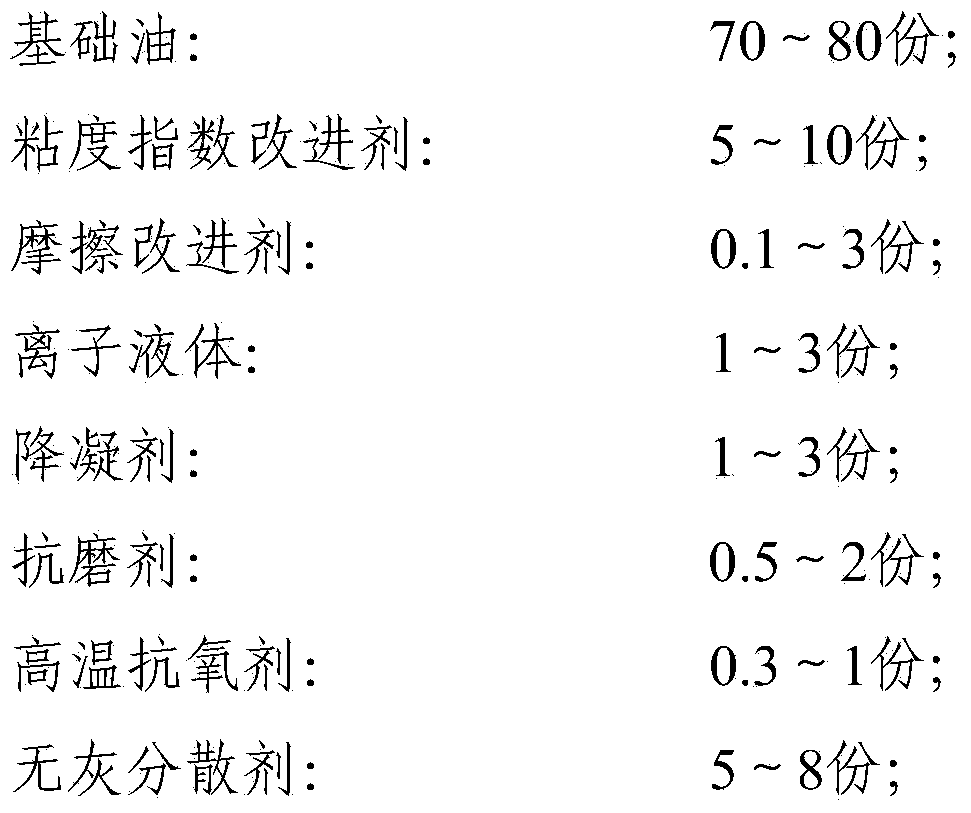

Composition for double clutch gearbox oil, use of composition and lubricating oil comprising composition

InactiveCN104194881AGood low temperatureImprove friction characteristicsAdditivesMarketed productsViscosity index

The invention relates to a composition for double clutch gearbox oil. The composition comprises the following components in parts by mass: 0.5-15 parts of viscosity index improver, 0.05-10 parts of friction improver and 0.1-10 parts of ionic liquid. The invention further relates to use of the composition and wet type double clutch gearbox lubricating oil comprising the composition. The composition provided by the invention can satisfy the lubricating requirements of clutches, a synchronizer, a gear and a bearing in a wet type double clutch gearbox, and thus can be used for the wet type double clutch gearbox lubricating oil. The lubricating oil has excellent low temperature performance, frictional characteristic, performance of the synchronizer and rust and corrosion resistance. Compared with similar marketed products, the lubricating oil added with the composition has a remarkable advantage in wearing endurance and is simple in ingredients and simple and convenient in manufacturing process.

Owner:CHINA PETROLEUM & CHEM CORP

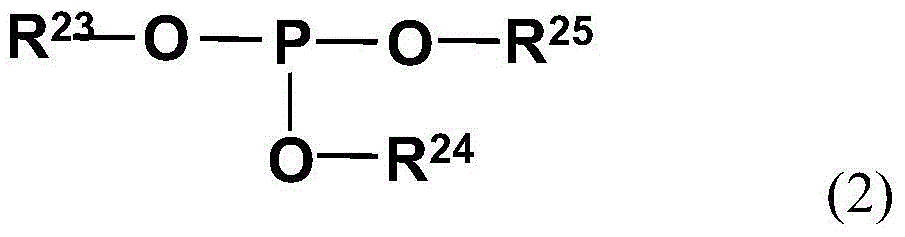

Lubricating oil composition for continuously variable transmission

ActiveCN104487557AReduce coefficient of frictionLow friction propertiesAdditivesChemical compositionEngineering

Provided is a lubricating oil composition for a continuously variable transmission, said composition exhibiting a low viscosity whilst maintaining the viscosity required of the lubricating oil composition throughout a period of use in a mechanism, and maintaining a high friction coefficient between metals so as to ensure a high power-transmitting force provide the wet clutch friction characteristics and the shudder prevention properties required in a transmission. The composition also achieves improved fuel economy due to a low traction coefficient. In the composition, (B) a phosphorus compound, (C) a calcium salicylate and / or a calcium sulfonate, (D) a boron-modified ashless dispersant, and (E) a friction regulating agent are included, each at a specified amount, in a base-oil that has been adjusted so that the product (ECxV40) of the mass percent (EC(mass%)) of a saturated cyclic component, as based on the total base-oil mass, and the kinematic viscosity (V40(mm2 / s)) at 40 DEG is equal to or less than 500, and the kinetic viscosity at 100 DEG is 3.6-4.1mm2 / s. The lubricating oil composition has a kinematic viscosity at 100 DEG of 5.2-5.6mm2 / s and a viscosity index of equal to or greater than 165.

Owner:JX NIPPON OIL & ENERGY CORP

Linear guide rail pair and machining technology thereof

The invention provides a linear guide rail pair and a machining technology thereof, and belongs to the technical field of linear guide rail pairs. The linear guide rail pair comprises a sliding block body. The linear guide rail pair is characterized in that the body is in a U shape; a guide rail groove is formed in the bottom of the body, an installing groove is formed in the upper end face of the body, and two arc load grooves for supporting balls are formed in the inner walls of the two sides of the guide rail groove respectively; the two corners of the bottom of the guide rail groove are circular chamfers; and steps are arranged at the opening ends of the guide rail groove. The machining technology of the linear guide rail pair comprises the following steps of raw material preparing, head cutting, head rolling, head grinding, polishing, parkerising, saponifying and drawing. According to the linear guide rail pair, a unique double-arc structure is adopted in the load grooves, and when the impact load and the heavy load are borne, the bearing contact area is enlarged, and the rigidity of the system is improved. According to the machining technology of the linear guide rail pair, one-time joint forming is achieved during drawing, a plurality of later machining procedures are omitted, and cost, labor and the production time are saved.

Owner:浙江建鑫型钢科技股份有限公司

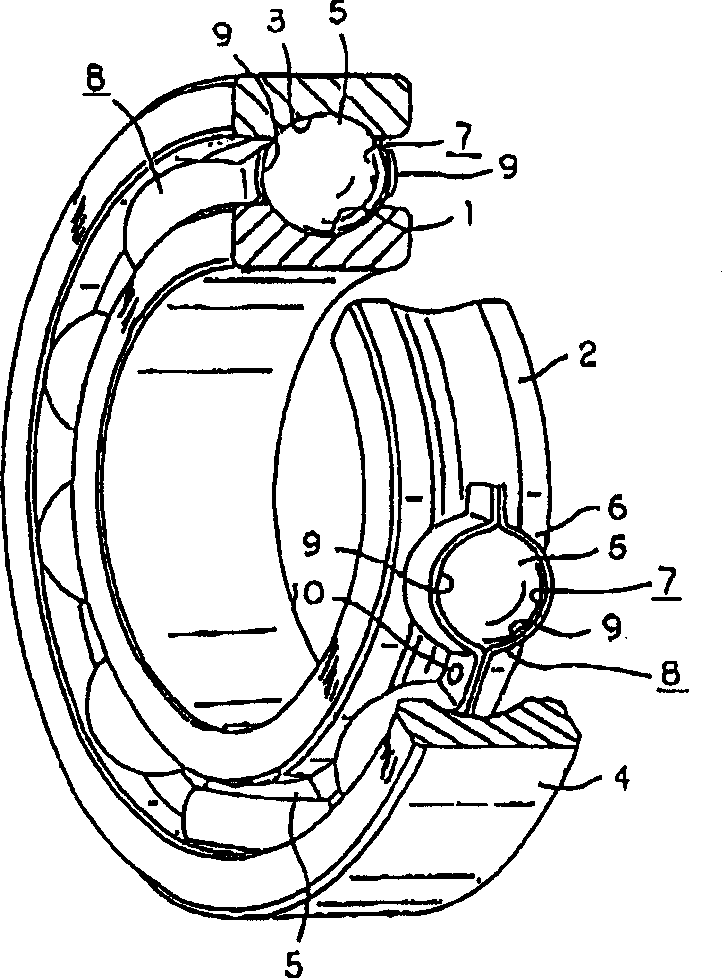

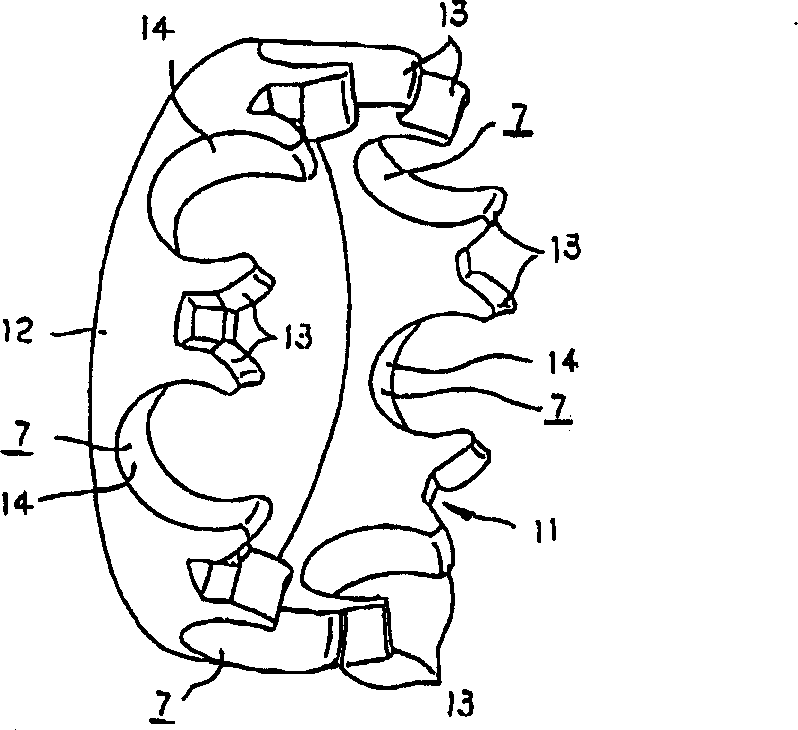

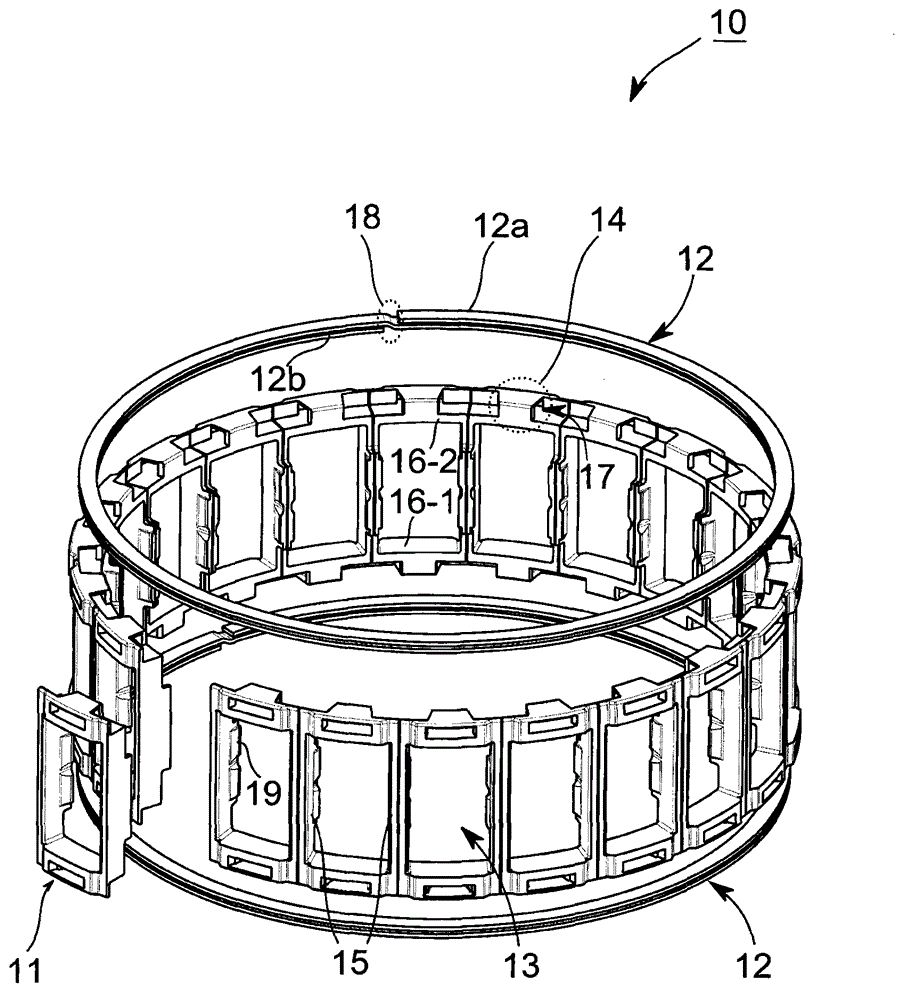

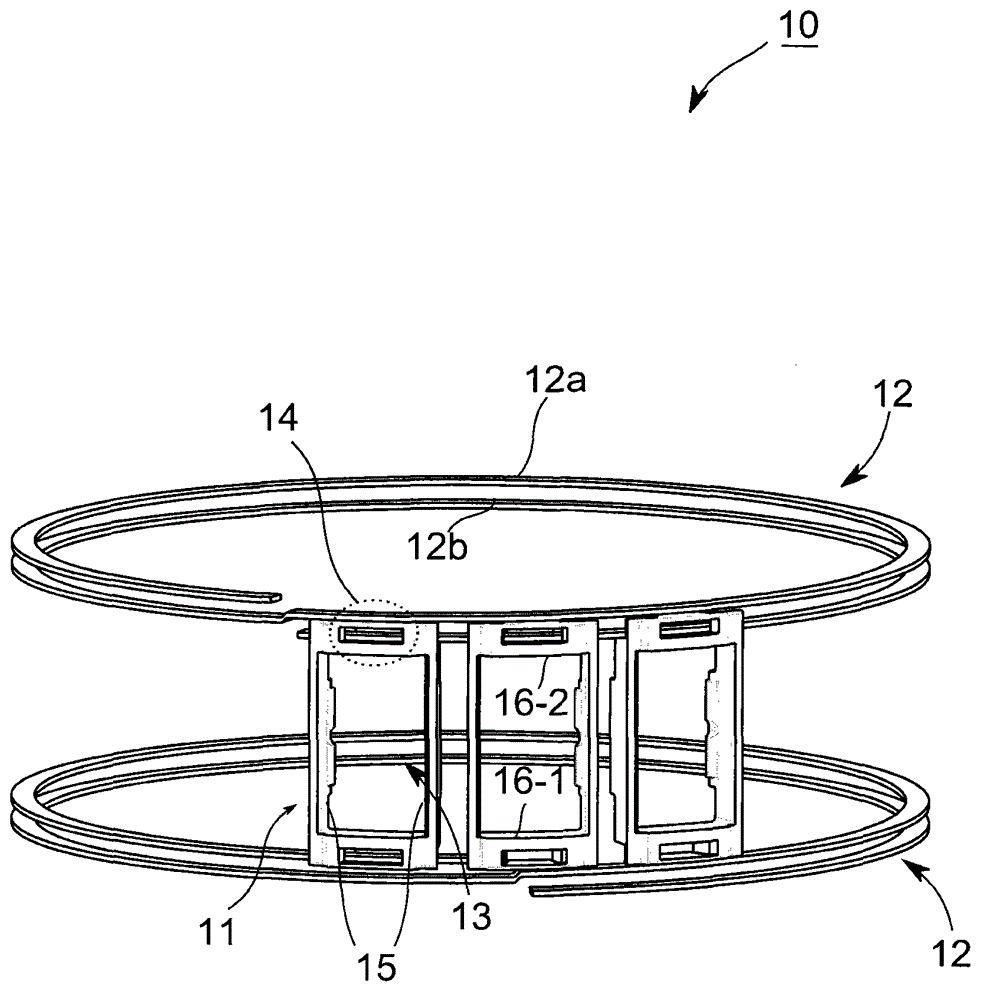

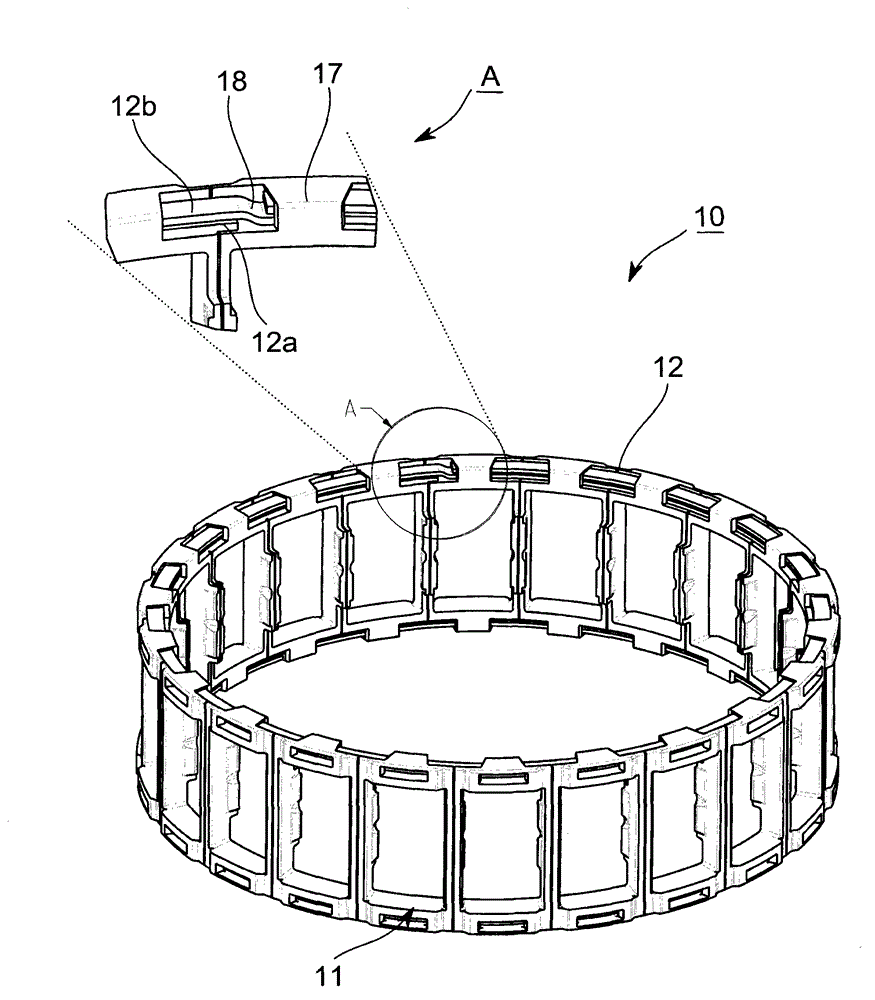

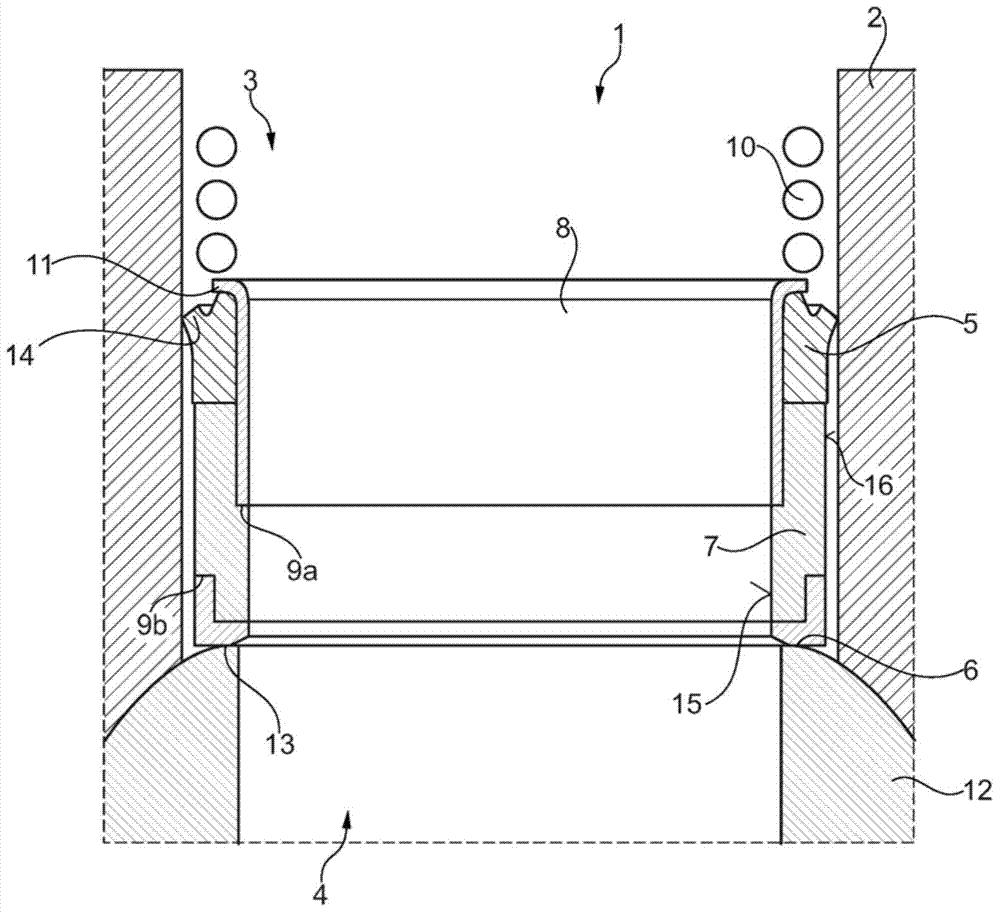

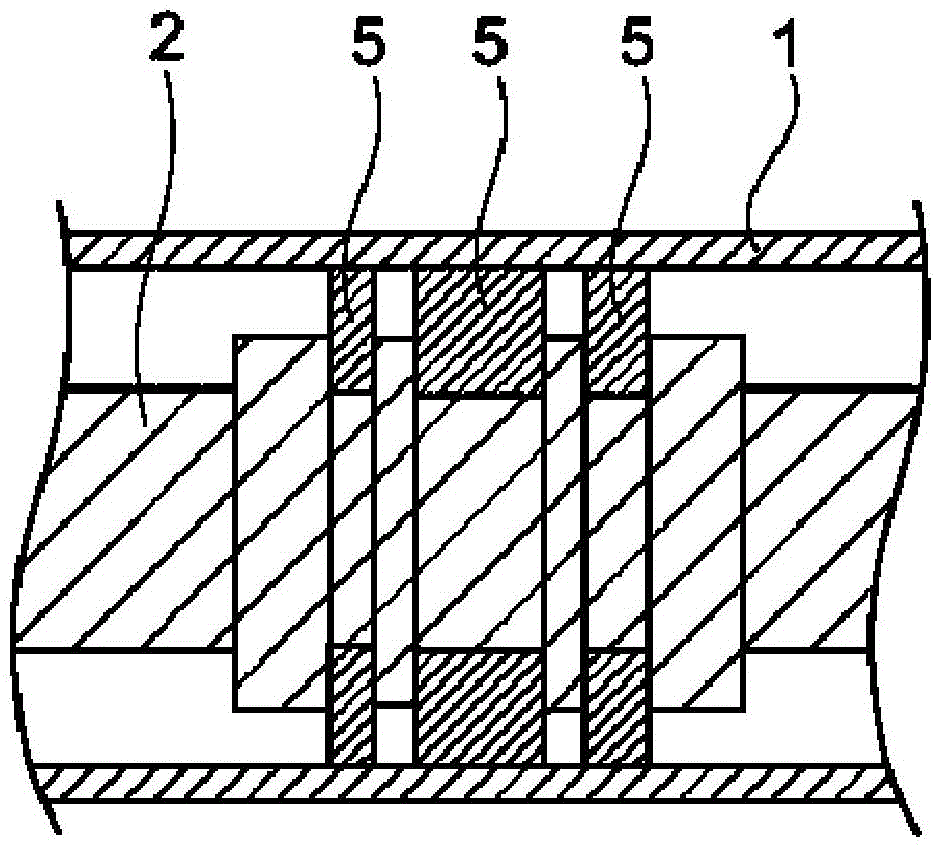

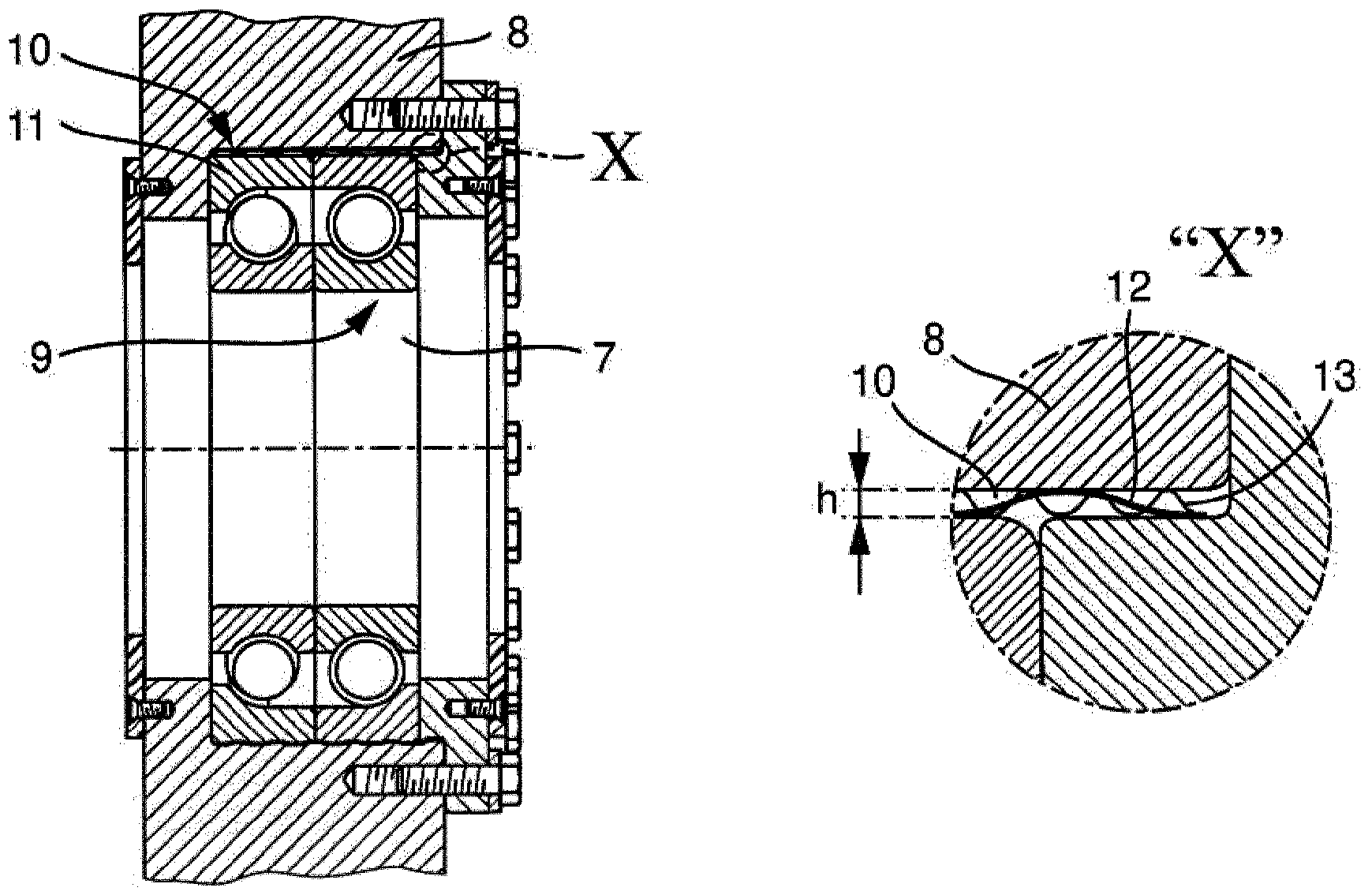

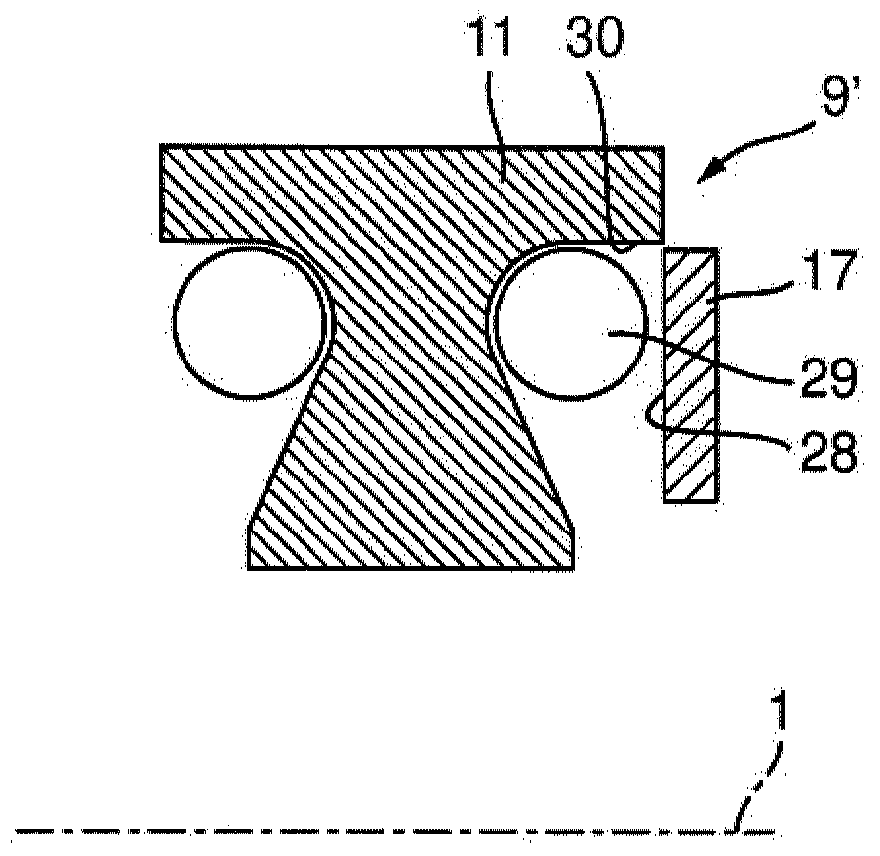

Bearing cage segment, bearing cage and method for manufacturing the same

ActiveCN102913556AReduce weightReduce running noiseRoller bearingsShaftsEngineeringRolling-element bearing

The embodiment of the invention relates to a bearing cage used for rolling bearings. The bearing cage (10) has a plurality of bearing cage segments (11) for accommodating rolling bodies in rolling body pockets (13) formed through the bearing cage segments (11). Each bearing cage segment comprises a coupling arrangement (14), which is formed to arrange the segments on a carrier ring (12) that is formed as a lamellar ring. The bearing cage (10) has at least one carrier ring (12) that is formed as a lamellar ring, the carrier ring (12) brings the segments on the carrier ring by the coupling arrangement (14), so that at least one rolling body pocket (13) is formed by two bearing cage segments (11) arranged in a circumferential direction adjacent to the carrier ring.

Owner:AB SKF

H-type rotary joint

The invention relates to an H-type rotary joint which comprises a joint body, a space ring, a hollow shaft, an inner water pipe, an internal circlip, a bearing, an external circlip, a spring compensating component and a sealing component, wherein the inner water pipe is arranged in the joint body, and the spring compensating component and the sealing component are connected mutually and are arranged in the rear of the hollow shaft. The H-type rotary joint is small in size, lightweight, more reliable in sealability, less in friction force and longer in service life, and working stability and the service lives of rollers of a continuous casting machine are further guaranteed.

Owner:YANGZHOU HONGCHENG METALLURGICAL EQUIP

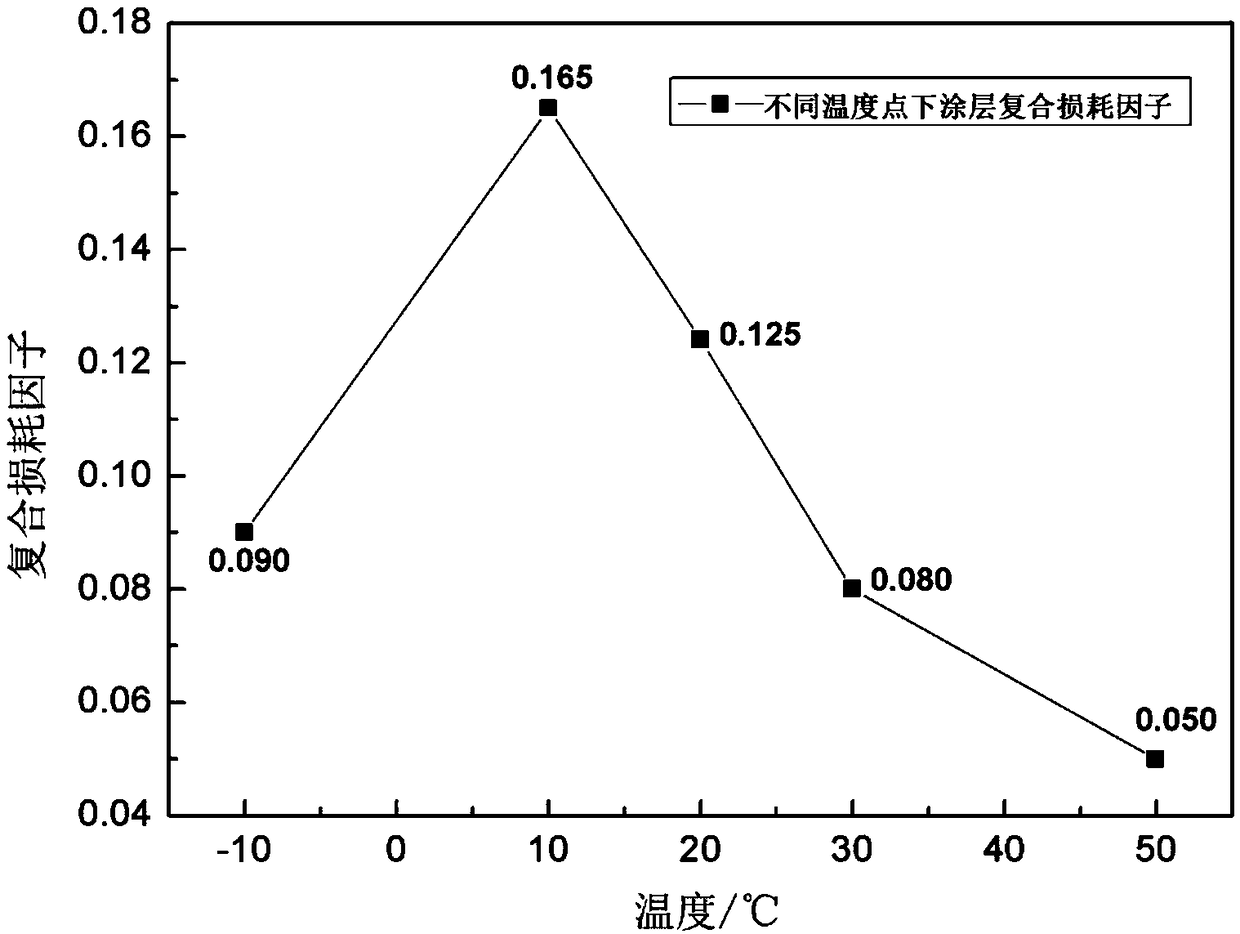

Solvent-free type corrosion inhibiting, vibration damping, and noise reducing coating material and preparation method thereof

ActiveCN108610925AIncrease dampingImprove sound insulationFireproof paintsAnti-corrosive paintsEpoxyAdhesion force

The invention relates to a solvent-free type corrosion inhibiting, vibration damping, and noise reducing coating material and a preparation method thereof, and belongs to the technical field of chemical materials. The coating material comprises two components: a component (A) and a component (B). The component (A) is composed of long-side-chain hydroxyl acrylic resin, epoxy resin, a thixotropic agent, a dispersing aid, an antifoaming agent, a damping filler, a heavy sound insulation filler, a fire retardant, and color paste. The component (B) is an isocyanate curing agent. Adopted long-side-chain hydroxyl acrylic resin and epoxy resin are compounded to form IPN type polymer, which can effectively enhance the properties of the coating material such as damping performance, fire retardant performance, adhesion force, and the like; the shortage that a conventional damping paint only has one single function is overcome; at the same time, the coating material contains the damping filler, thedamping performance is improved, at the same time, the compactness of the coating is further strengthened, the anticorrosion performance of the coating is enhanced; and moreover, the coating materialdoes not contain any organic solvent or water, barely pollutes the environment, can be rapidly cured at a room temperature, and is convenient for construction.

Owner:BEIJING UNIV OF CHEM TECH

Control valve for thermal management module

InactiveCN104847893ASave installation timeAvoid installation errorsPlug valvesEngine sealsExternal combustion engineCoolant flow

The invention relates to a control valve for regulating a coolant circuit of an internal combustion engine, preferably, controlling different cooling water flowing in a thermal management module. The control valve has a valve housing, on which a supply port for cooling water is arranged, which is connectable to an exhaust port, depending on the position of the valve body housed in the valve housing. Thus, the coolant flow paths are adequately sealed, the control valve comprises a sealing ring, which seals in the radial direction, and a sealing element which seals in an axial direction.

Owner:SCHAEFFLER TECH AG & CO KG

High-performance self-lubricating composite material and preparation method thereof

InactiveCN109334161AGuaranteed Long Life RequirementsMeet the use requirementsLaminationLamination apparatusFiberInorganic materials

The invention provides a high-performance self-lubricating composite material. The composite material does not need to be rolled, and overcomes the defect that the conventional material is prepared byrolling; and a bearing made of the material has good friction resistance and long service life, and meets higher use requirements of customers. The composite material comprises a metal flat plate anda polymer material pad compounded into a whole, wherein the polymer material pad is specifically a composite pad formed by weaving self-lubricating polymer material fibers or organic or inorganic material fibers.

Owner:WUJIANG MINGYANG NEW MATERIALS TECH

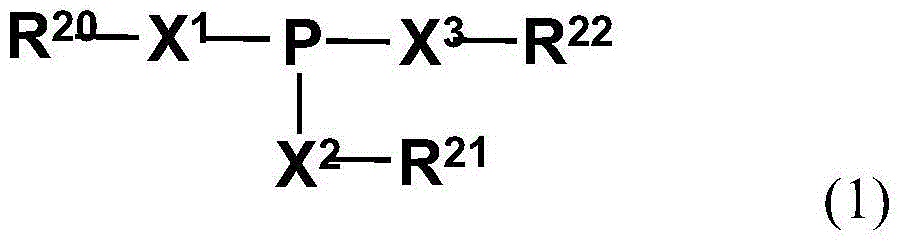

Lubricant composition

ActiveCN105087111AImprove friction characteristicsExcellent abrasion resistanceLubricant compositionOperating pointAntioxidant

The invention aims to provide a lubricant composition which has excellent attrition resistance and excellent sludge inhibition and is applicable to hydraulic operating oil and the like used at high temperature and high pressure. According to the solving means, the lubricant composition is characterized in that mineral oil and / or synthetic oil are used as base oil; the lubricant composition is prepared from 0.01-3 mass percent of antioxidant (A) and 0.01-10 mass percent of phosphorous compounds (B), based on the total amount of the composition; and the kinematic viscosity of the composition at 40 DEG C is 1.5-1000mm<2> / s, and the lubricant composition does not contain zinc dithiophosphate substantially.

Owner:JX NIPPON OIL & ENERGY CORP

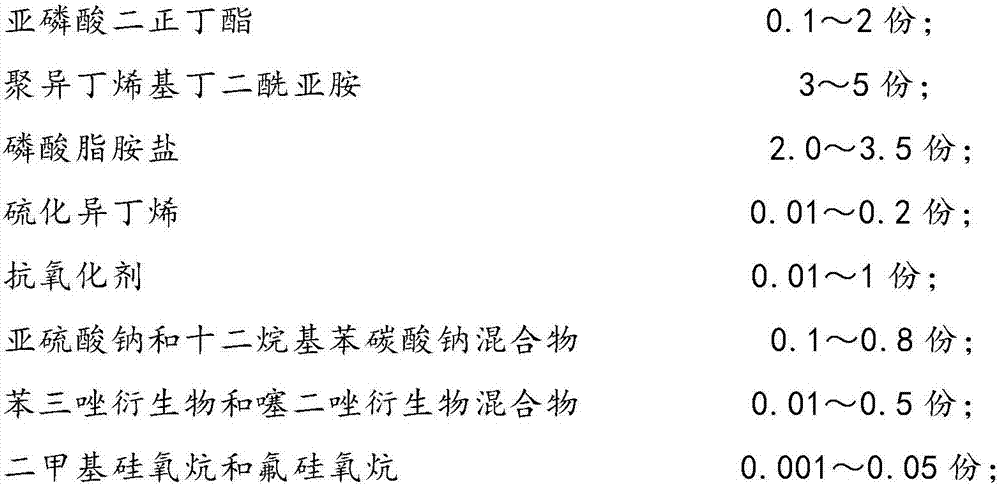

Manual transmission lubricating oil for automobiles

InactiveCN107384532AIncreased durabilityImprove friction characteristicsLubricant compositionManual transmissionChemistry

The invention discloses manual transmission lubricating oil for automobiles. The lubricating oil comprises the following components in parts by weight: 75-85 parts of composite base oil, 6-15 parts of polymethacrylate, 0.1-2 parts of di-n-butyl phosphite, 3-5 parts of polyisobutylene succinimide, 2-3.5 parts of a phosphate amine salt, 0.01-0.2 part of isobutenyl sulfide, 0.01-1 part of an antioxidant, 0.1-0.8 part of a mixture of sodium sulfite and sodium dodecyl benzene carbonate, 0.01-0.5 part of a mixture of benzotriazole derivatives and thiadiazole derivatives and 0.001-0.05 part of dimethyl siloxane and fluorosiloxane, wherein the composite base oil is formed by compounding poly alpha-olefin and ester synthesized base oil in a proportion of 10:(1-1.5). The manual transmission lubricating oil for automobiles provided by the invention has excellent durability, frictional characteristic, wear resistance, anti-rust and anti-corrosion properties, an anti-micropitting property, shearing stability and thermal oxidation stability.

Owner:SHANGHAI DELIAN CHEM

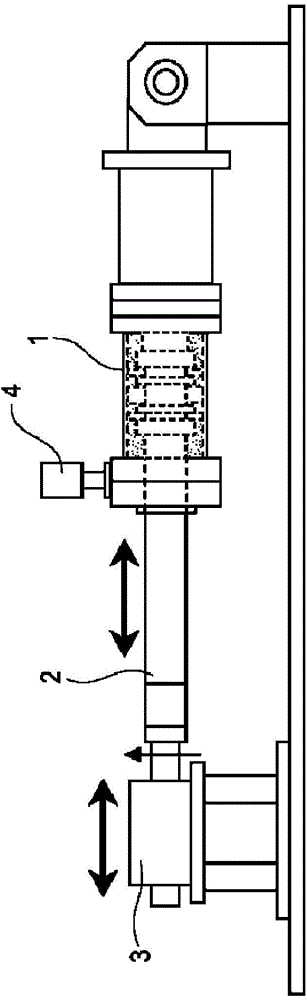

Bearing arrangement with a back-up bearing, in particular for mounting the rapidly rotating shaft of a compressor

InactiveCN103534499AIncrease the ripple amplitudeStrong absorption capacityRolling contact bearingsShaftsBall bearingRolling-element bearing

The invention relates to a bearing arrangement for the rotatable mounting of a shaft (7) in relation to a housing (8), comprising a back-up bearing (9) which is designed as a rolling contact bearing, wherein the rolling contact bearing can absorb forces in the axial and radial direction and is designed in particular as an angular roller bearing, especially as a two-row angular ball bearing, wherein the rolling contact bearing (9) is substantially left open in the radial direction. The problem addressed by the invention is that of providing a bearing arrangement with a back-up bearing for a shaft, which bearing arrangement can better absorb in particular the forces occurring in the mounting of rapidly rotating, solid shafts.

Owner:SCHAEFFLER TECH AG & CO KG

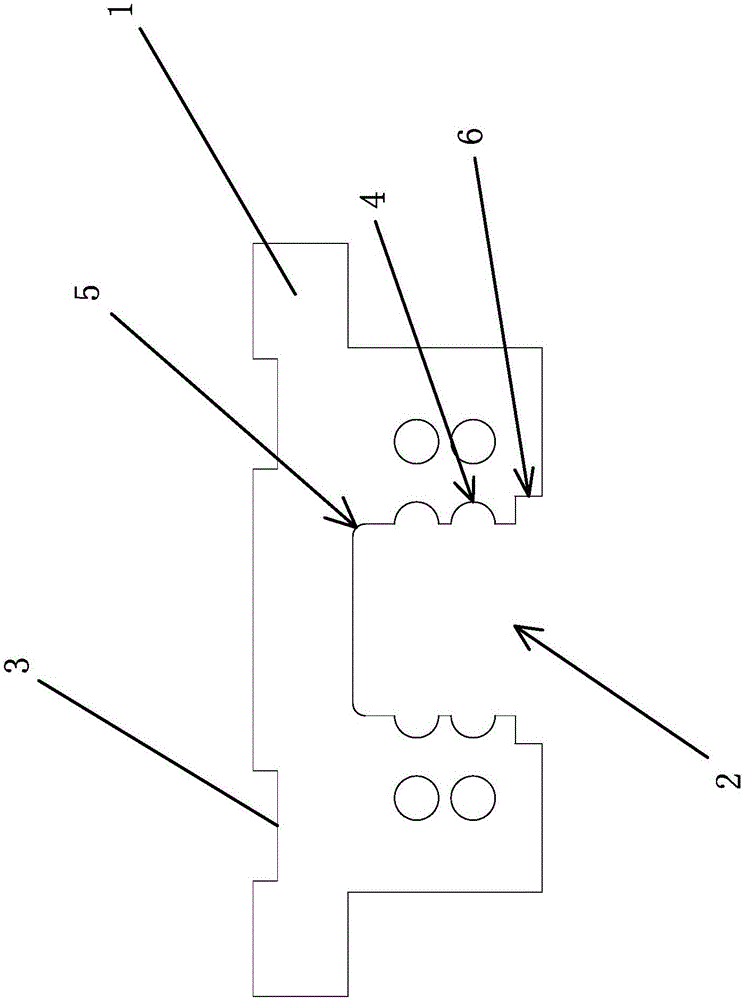

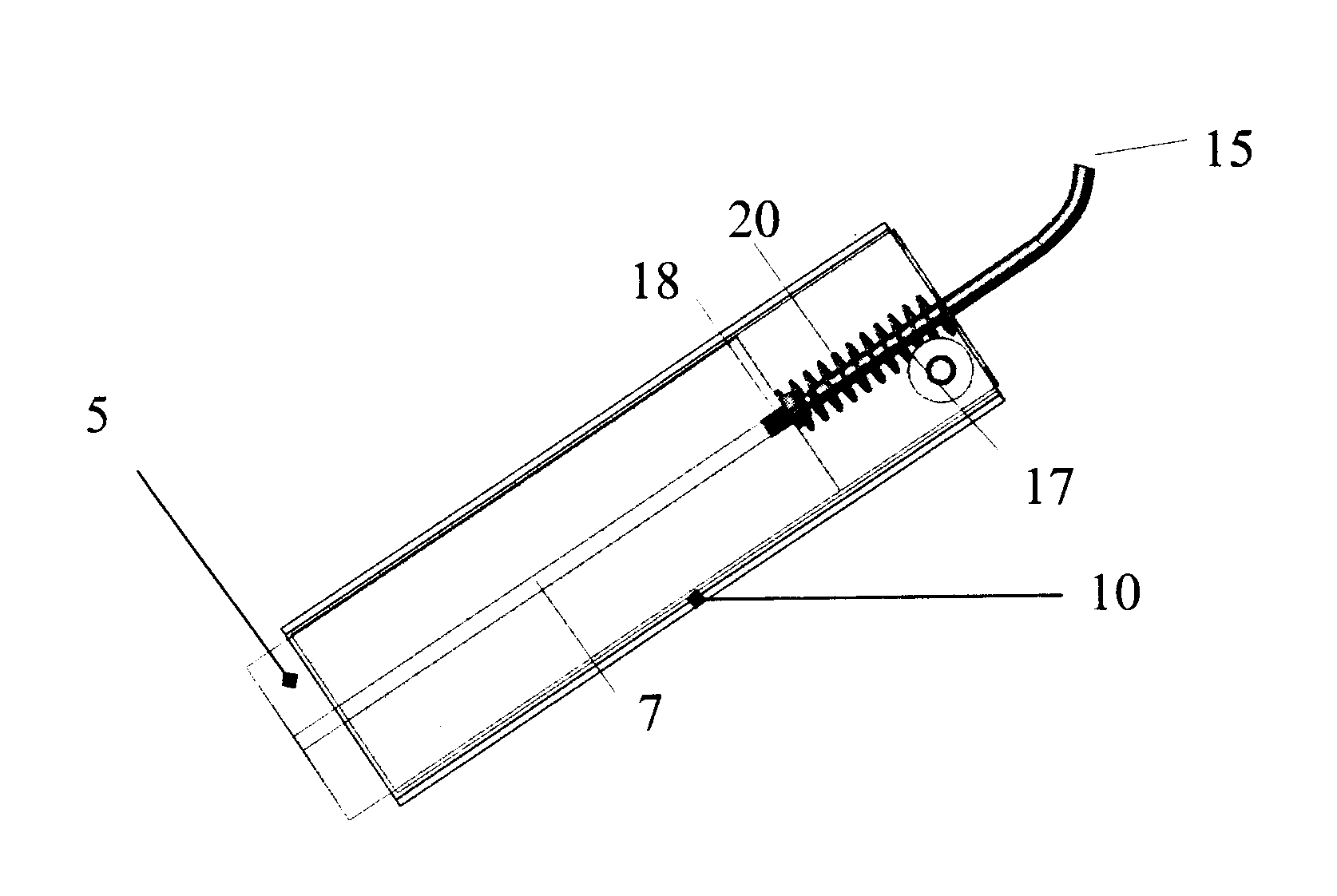

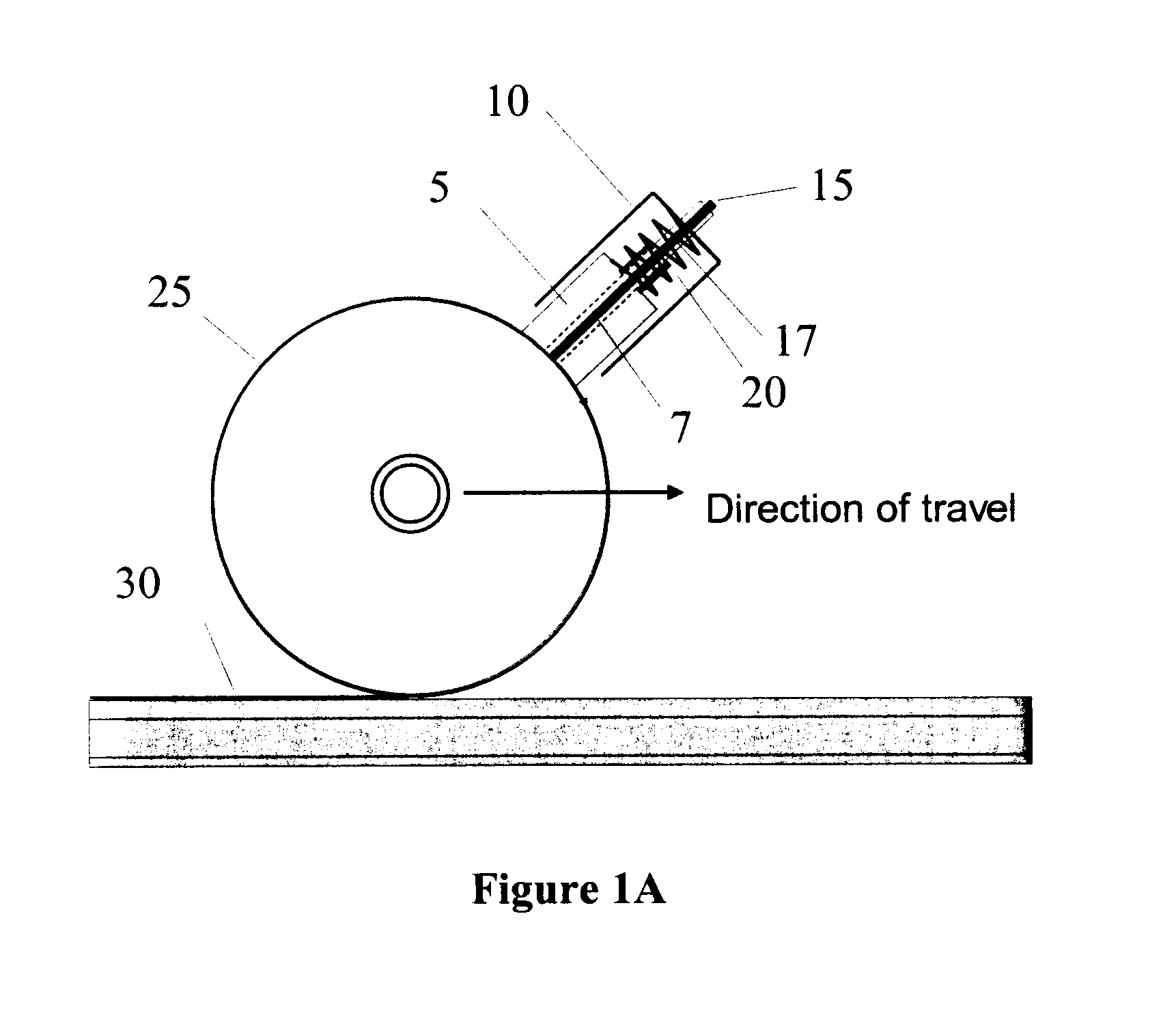

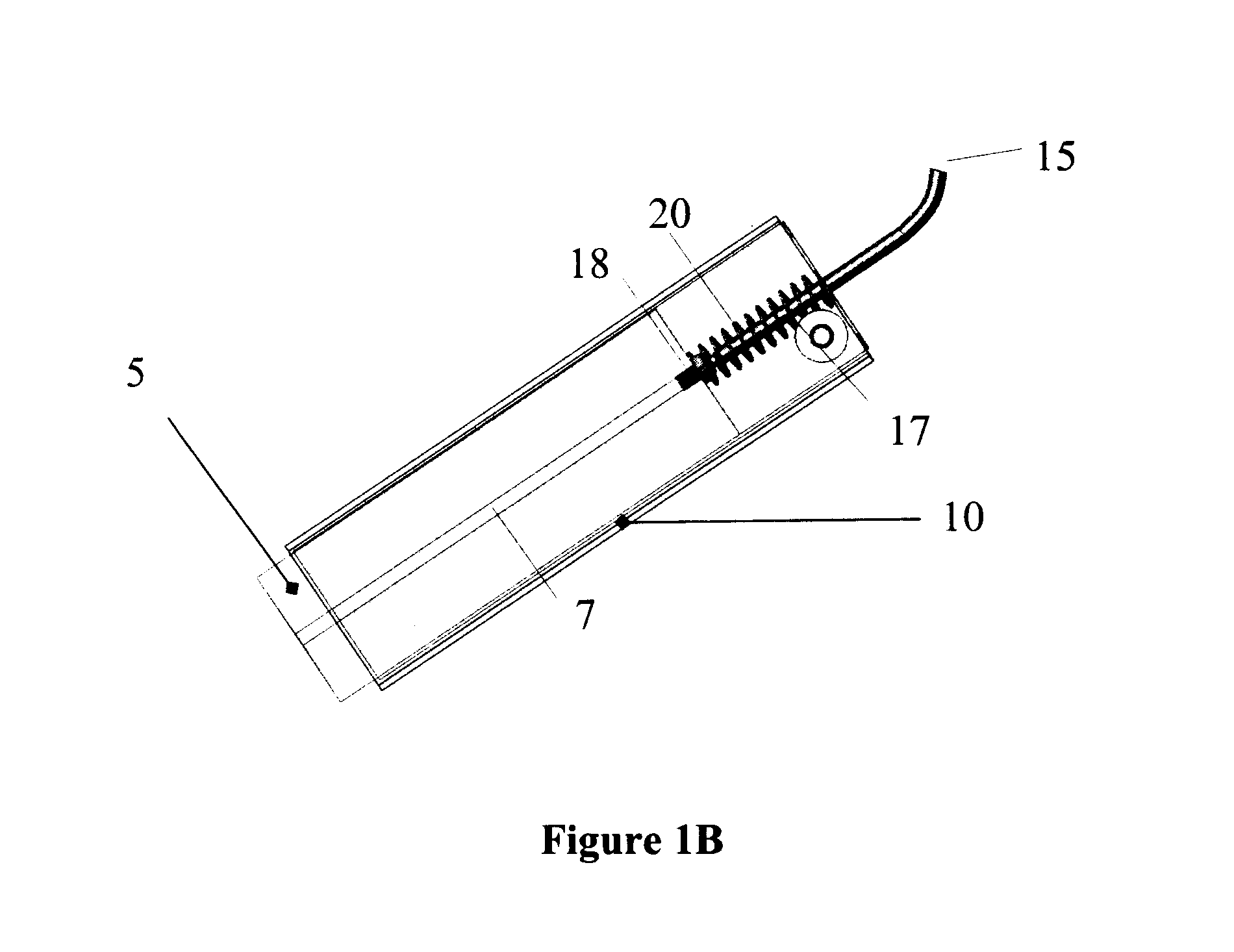

Consumable Applicator

InactiveUS20110290589A1Reduce maintenanceMinimize contaminationLiquid/solution decomposition chemical coatingRail lubricationHardnessBiomedical engineering

A consumable applicator comprising one or more conduits in a fluid communication with a liquid composition dispensing system wherein the liquid composition comprises friction control components. The consumable applicator comprises a solid body having hardness of less than or equal 150 HB, a housing and a biasing member within said housing for advancing the consumable applicator toward a dispensing end. The consumable applicator may be used for applying a friction control consumable to sliding metallic parts such as the railway rails or wheels.

Owner:KELSAN TECH

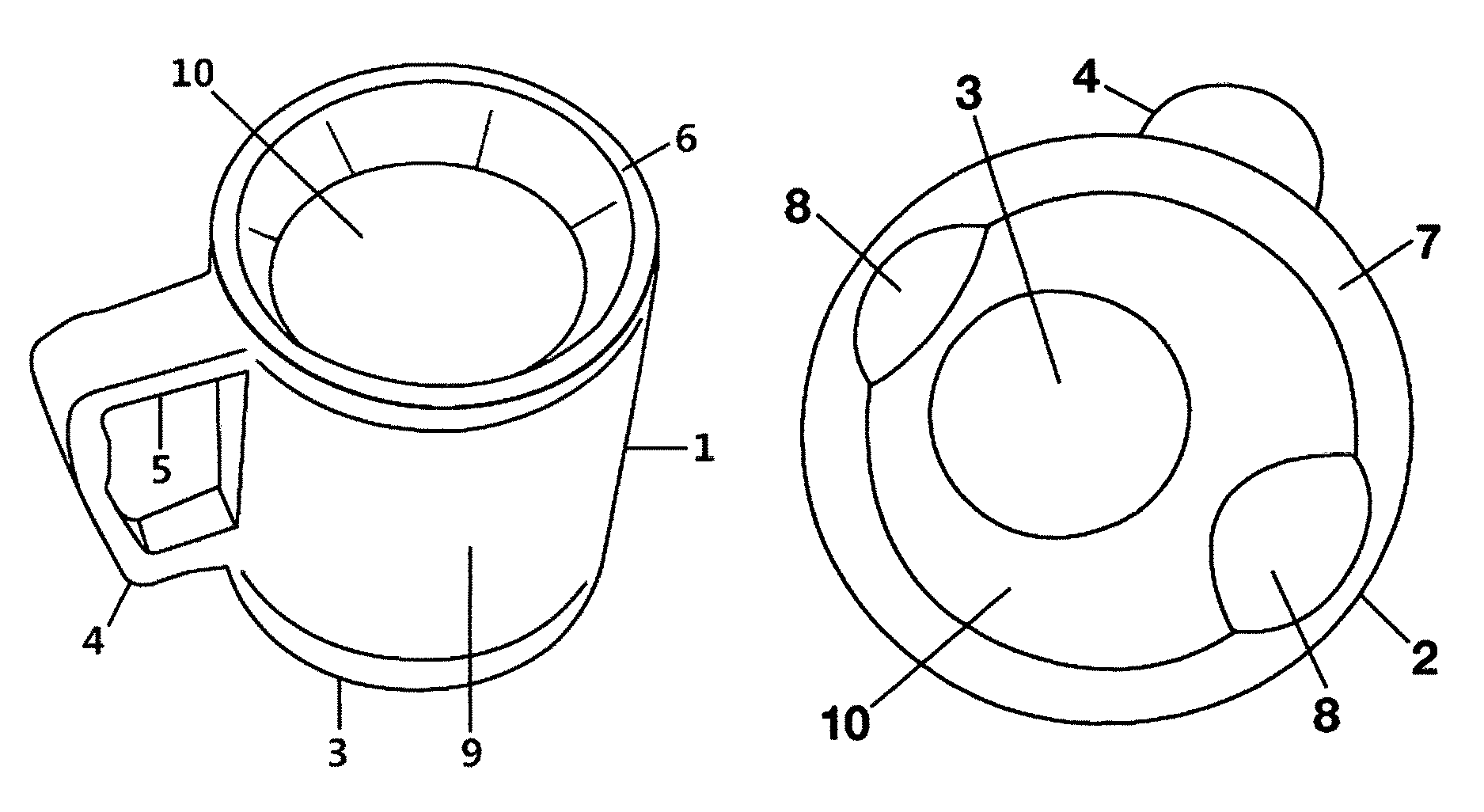

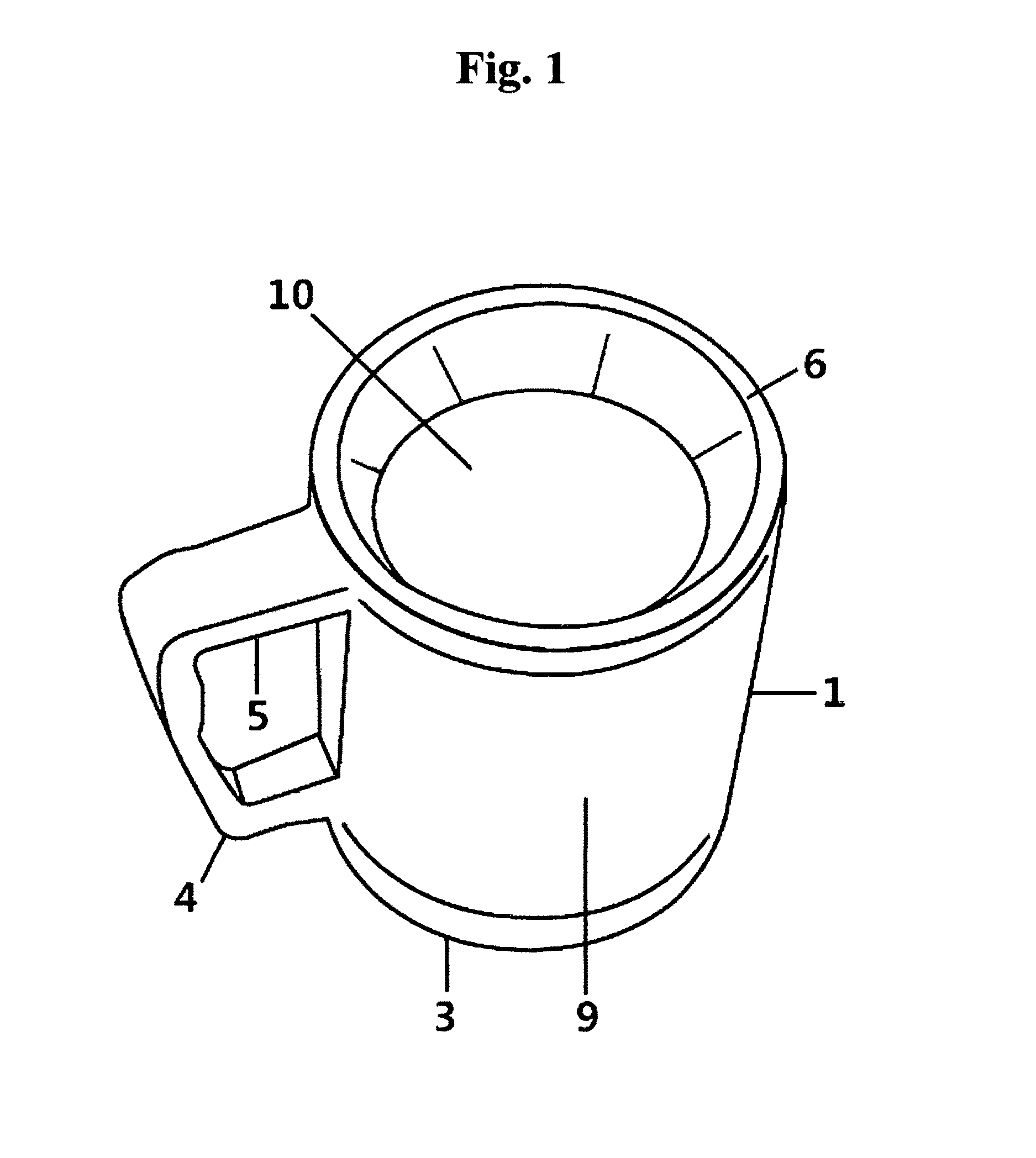

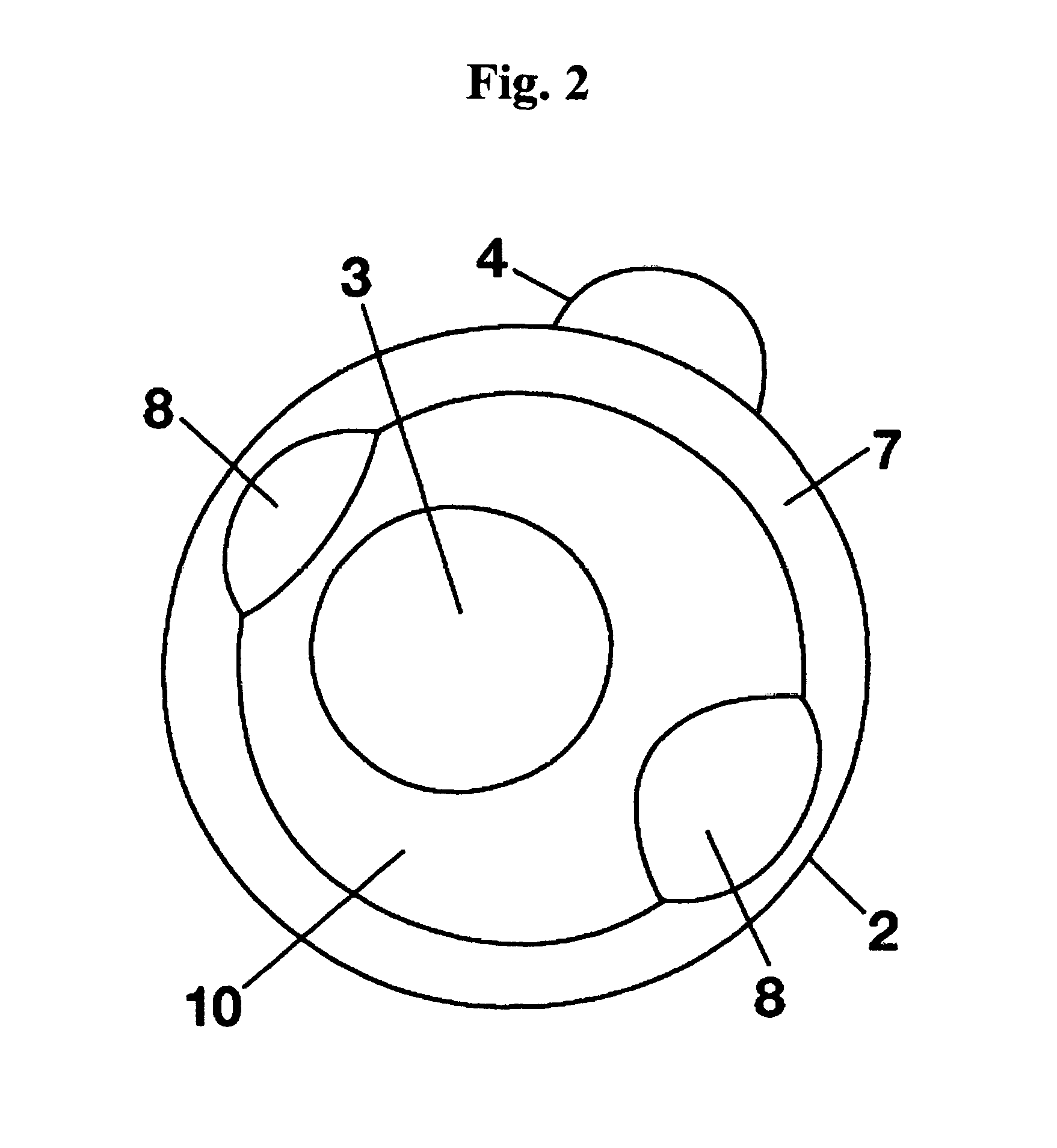

Weight training beverage mug

InactiveUS9585502B2Increase valueImprove security levelDumb-bellsLayered productsEngineeringMaterial line

A drinking mug that doubles as an exercise apparatus is formed of non-toxic porcelain ceramic, glass, or wire reinforced glass. The combination of dimensions of the mug adds up to a total mass of at least 1.360 kilograms and possesses the ratio of dimensions of substantially 1, 3.9, 3.9, 2.443, 5.777, and 4.0 between the thickness of a base, diameter of the base, outer diameter of a barrel, inner diameter of the barrel at the end where the barrel connects to the base, height of the barrel, and vertical length of the handle, respectively. A neoprene material lines the base, handle, and the outside barrel surface. A substantially circular brim serves as a surface transition between the inside and outside surfaces of the cylindrical barrel and can contain a plurality of substantially concave scoops, each centered approximately ninety radial degrees offset of the handle.

Owner:KANG ERIC

Machinery lubricating oil and preparation method thereof

InactiveCN108690691AEvenly dispersedImprove anti-wear performanceLubricant compositionMetal particleMaterials science

The invention discloses machinery lubricating oil including, by weight, 60-80 parts of basic oil, 10-15 parts of paraffin, 8-13 parts of glyceryl stearate, 7-12 parts of modified kaolin, 3-6 parts ofnano graphite, 1-4 parts of zinc stearate, 2-3 parts of nano metal particles, 2-4 parts of carbon nano-tubes, 1-3 parts of an antioxidant and 2-4 parts of an anti-rust agent. The machinery lubricatingoil has great friction characters, excellent mechanical stability, and great thermal stability and oxidation stability, can reduce friction loss better, and can prolong service life of machinery.

Owner:合肥展游软件开发有限公司

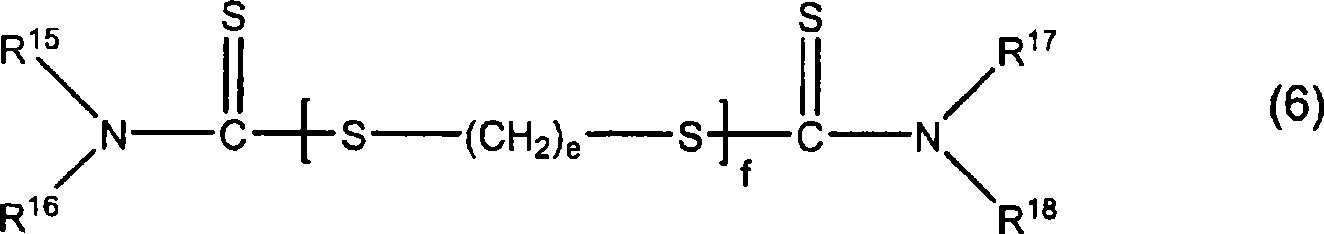

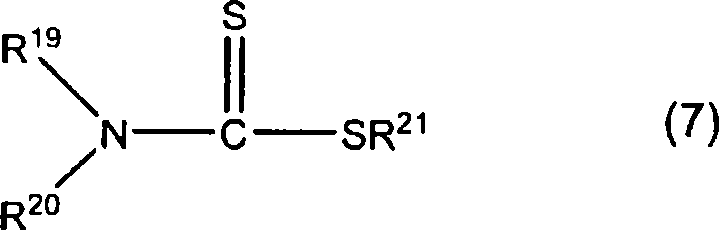

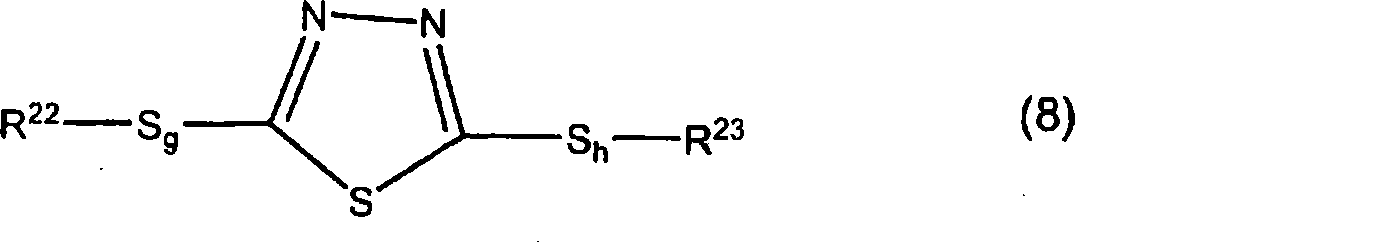

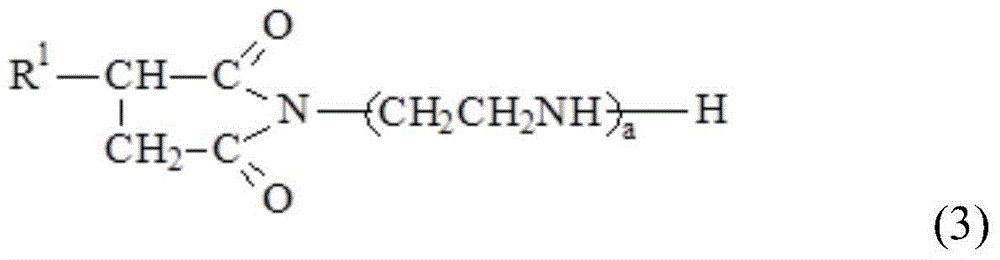

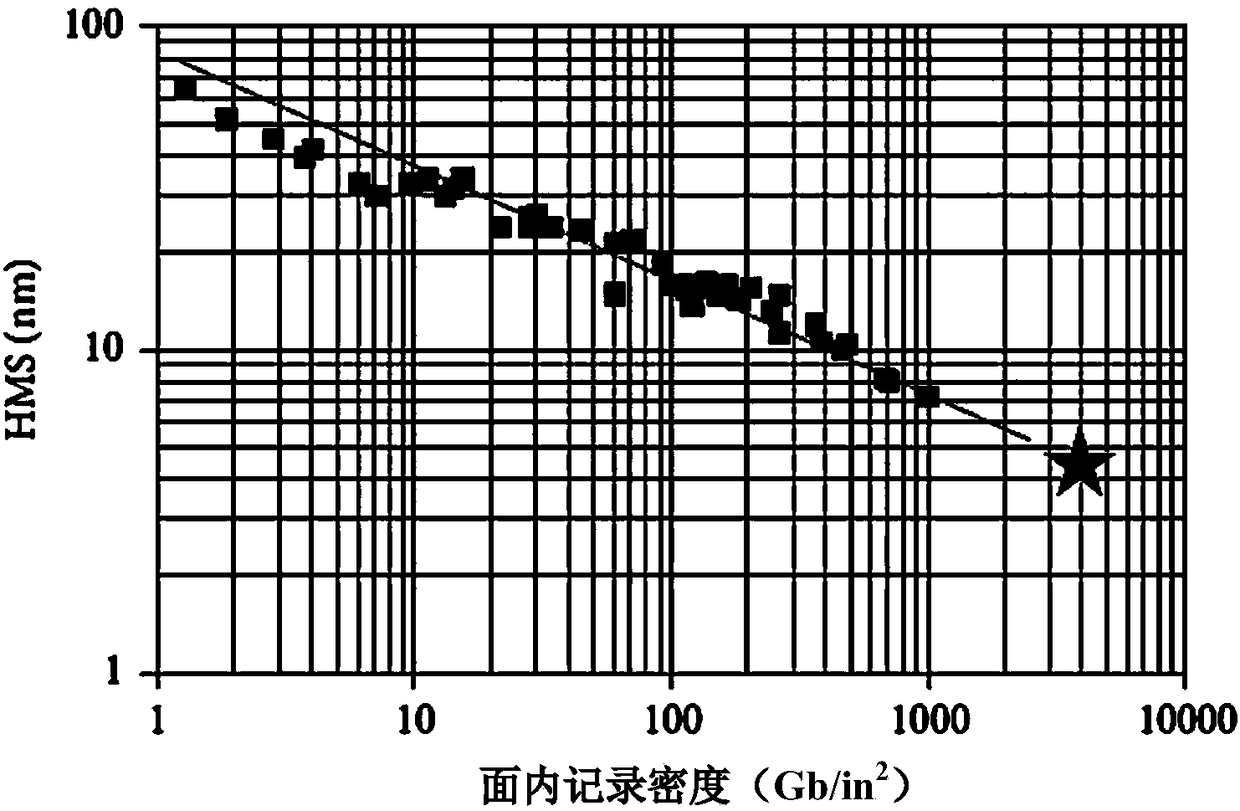

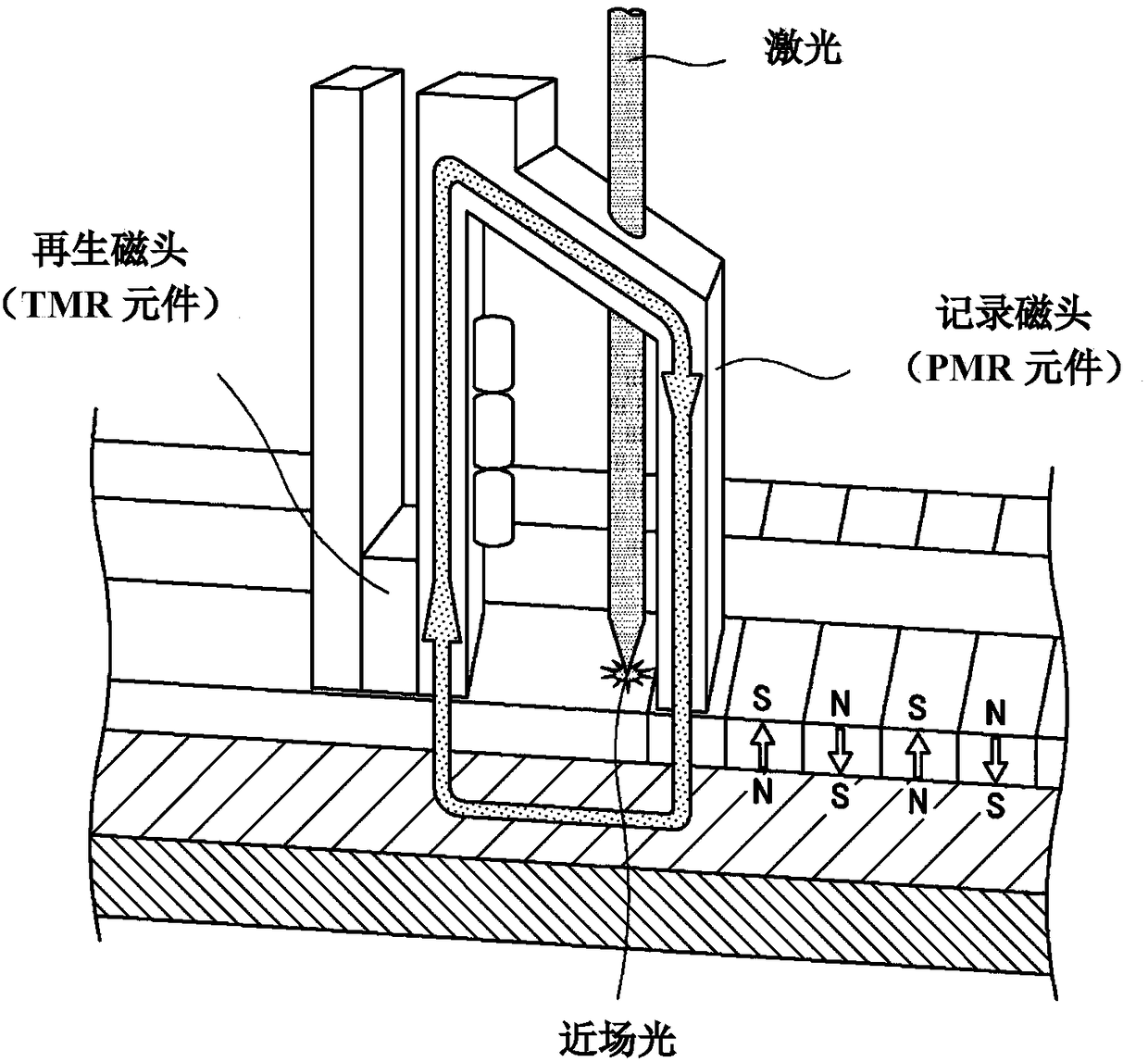

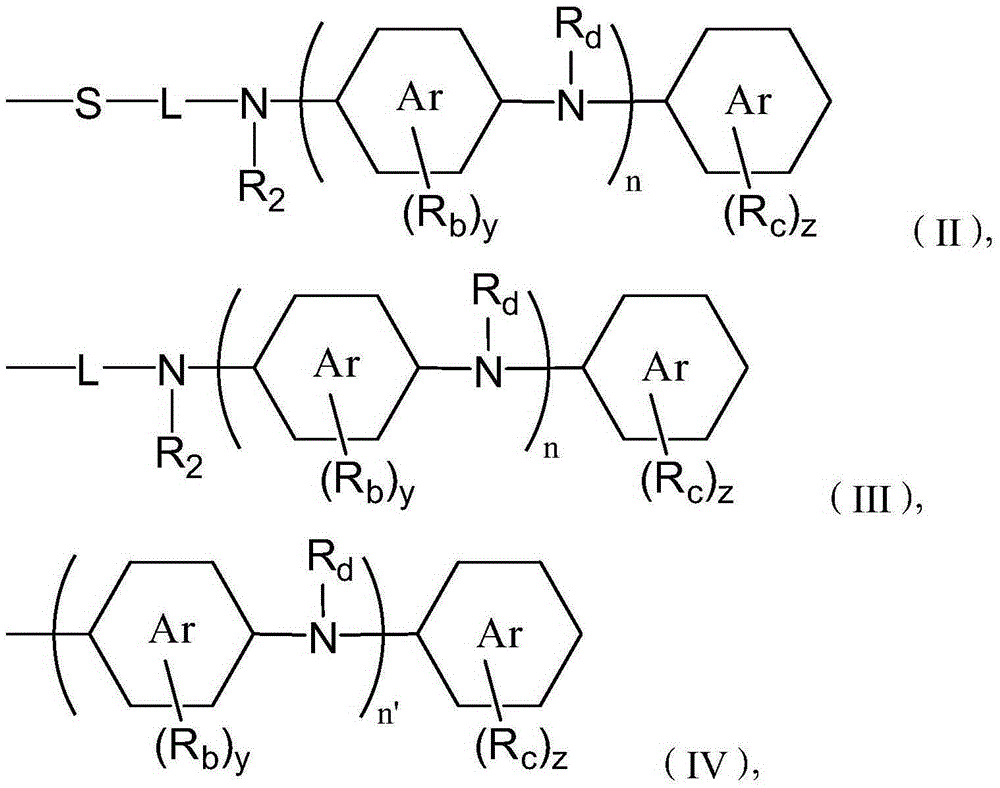

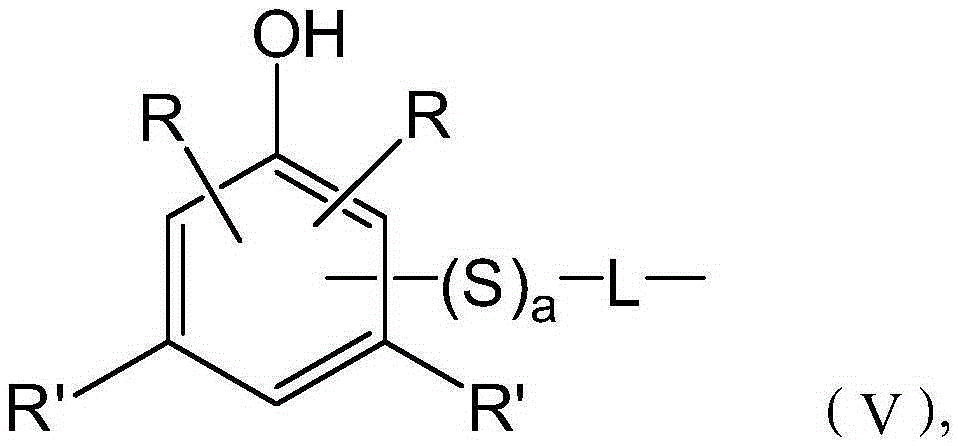

Ionic liquid, lubricant, and magnetic recording medium

InactiveCN108690676AImprove friction characteristicsExcellent practical featuresProtective coatings for layersRecord information storagePolymer scienceIonic liquid

The present invention provides a lubricant or the like. The lubricant uses an ionic liquid which is free from fluorine and has excellent friction characteristics. A lubricant contains an ionic liquidhaving cations and anions, wherein the cations are represented by the following formula (A) and do not have fluorine atoms, and the anions are represented by the following formula (X), and do not havefluorine atoms.

Owner:DEXERIALS CORP

Anti-static type penetrating agent for leather and preparation method of anti-static type penetrating agent

InactiveCN104313917AImprove friction characteristicsExcellent abrasion resistanceDyeing processAlkylphenolCis-Butenedioic Acid

The invention discloses an anti-static type penetrating agent for leather and a preparation method of the anti-static type penetrating agent. The anti-static type penetrating agent for leather is prepared from the following raw materials in parts by weight: 50-55 parts of alkylphenol polyoxyethylene ether, 8-10 parts of zinc cyanurate, 4-5 parts of urea, 2-4 parts of sodium lauryl sulfate, 6-7 parts of maleic anhydride, 5-7 parts of methyl isobutyl ketone, 3.5-4.0 parts of quaternary ammonium surfactant, 8-9 parts of pentaerythritol, 2-4 parts of triethanolamine, 3-4 parts of polyvinylpyrrolidone, 15-20 parts of modified moss and 30-55 parts of water. The anti-static type penetrating agent for leather has good friction characteristic and abrasion resistance and also has functions of the conventional leather; the anti-static effect of the leather can be obviously enhanced by utilizing properties of triethanolamine and quaternary ammonium surfactant, and the properties of a coating are stable; meanwhile, the overall performance of the anti-static type penetrating agent can be effectively improved by virtue of modified moss, the level dyeing property is excellent, and the penetration performance of leather dye can be obviously enhanced.

Owner:HEFEI ANSHAN COATING FABRICS

Method for manufacturing airplane carbon brake wheel with double element carbon base optimal combination

The invention is a method of making plane carbon brake disc by optimizing and combining binary carbon basal body, and its characteristic: placing a no-latitude carbon distribution needled precast body acting as dynamic disc of the carbon brake disc in negative pressure oriented inner thermal gradient gas-phase deposition furnace, and placing a precast acting as static disc of the carbon brake disc in negative pressure oriented outer thermal gradient gas-phase deposition furnace, controlling the temperature of the low-temperature surface of the above procast bodies at 800-1000 deg.C, temperature gradient at 30-380 deg.C, to make gas-phase carbon deposition for 300-600 hours, thus obtain a rough layer structural themolysis basal body at weight percent of 55%-65%, then making resin dipping-carbonized compaction to obtain optimized and combined binary carbon basal body with resin carbon at weight percent of 5%-15%, and finally making high-temperature graphitizing processing to obtain the brake disc material at hole rate less than 10%. At the time of plane braking to stop flying, it has the advantages of large friction coefficient, good braking performance and low cost.

Owner:XIAN CHAOMA SCI TECH

Wear-resistant noctilucent zipper and preparation method thereof

PendingCN111849120AImprove toughnessImprove creep resistanceSlide fastenersBoron nitrideMolybdenum disulfide

The invention discloses a wear-resistant noctilucent zipper. The wear-resistant noctilucent zipper is provided with a zipper belt, a puller, an upper stop piece and a lower stop piece. The zipper teeth on the zipper belt are prepared from the following raw materials in parts by mass: 80-100 parts of POM, 5-10 parts of PTFE, 10-15 parts of noctilucent powder, 3-6 parts of molybdenum disulfide powder, 3-6 parts of nano boron nitride particles, 1.5-3 parts of a heat stabilizer, 1-2 parts of a silane coupling agent and 1-2 parts of a compatilizer. By means of the mode, a layer of PTFE transfer film can be formed on the surface of POM, friction force and scratch resistance of the surface of the zipper are reduced, and the service life of the whole noctilucent zipper is prolonged.

Owner:江苏大棕科技有限公司

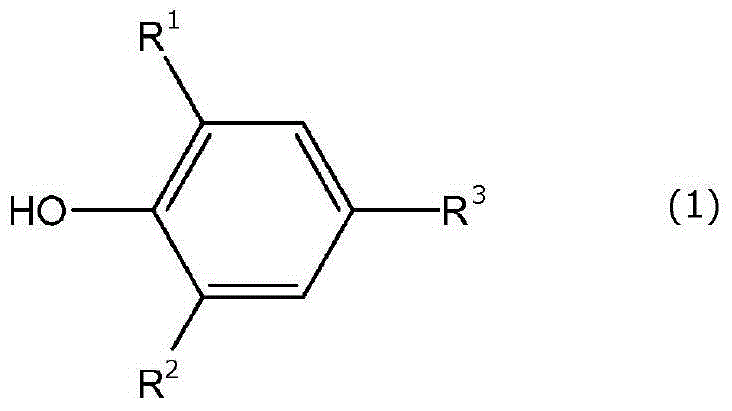

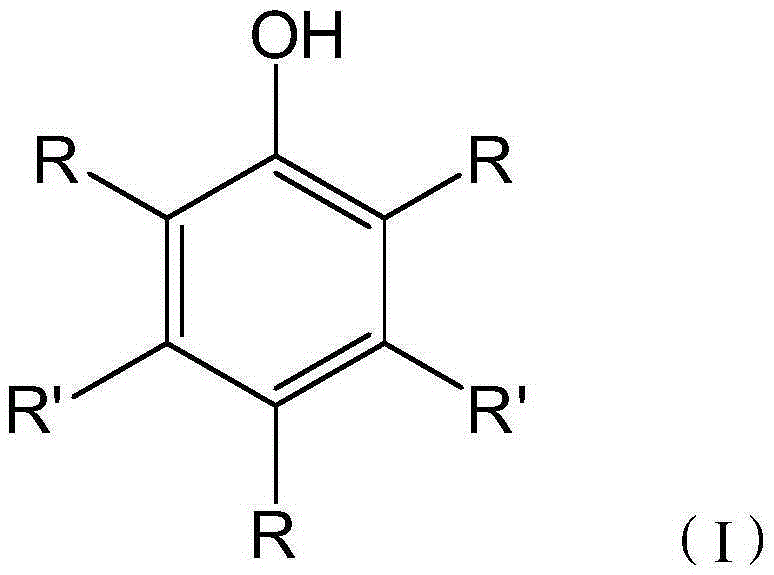

Automatic transmission fluid composition and manufacturing method thereof

The invention relates to an automatic transmission fluid composition including a shielding phenol compound, an anti-wear reagent at extreme pressure, a dispersing agent, a metal passivating agent, an anti rust agent, an ashless friction modifier and a major amount of lube base oil; the structure of the shielding phenol compound is as shown in formula (I), and all groups are defined in the specifications. The automatic transmission fluid composition can meet increasingly stringent oxidation resistance requirements of higher-specification products in modern times, and show excellent cleaning dispersing performance, friction properties, wear resistance, corrosion resistance and rust resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

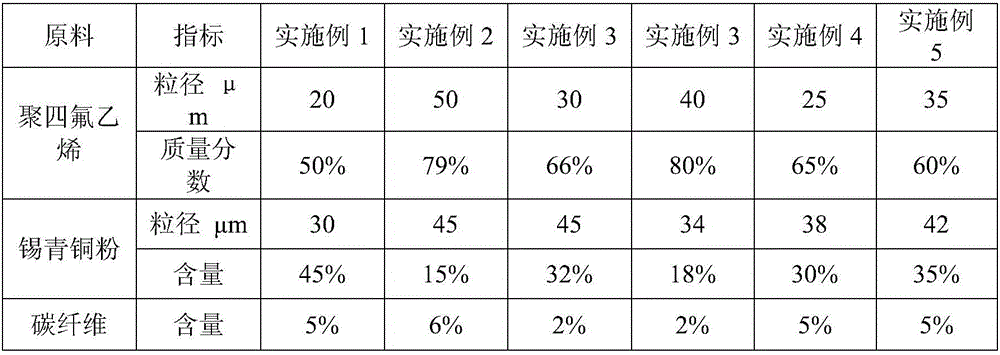

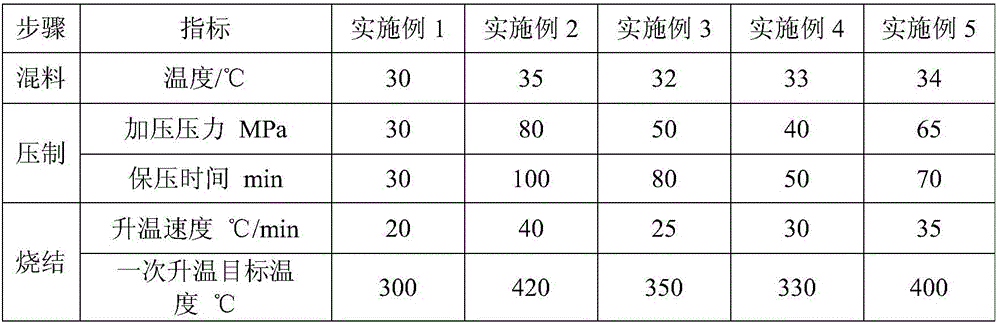

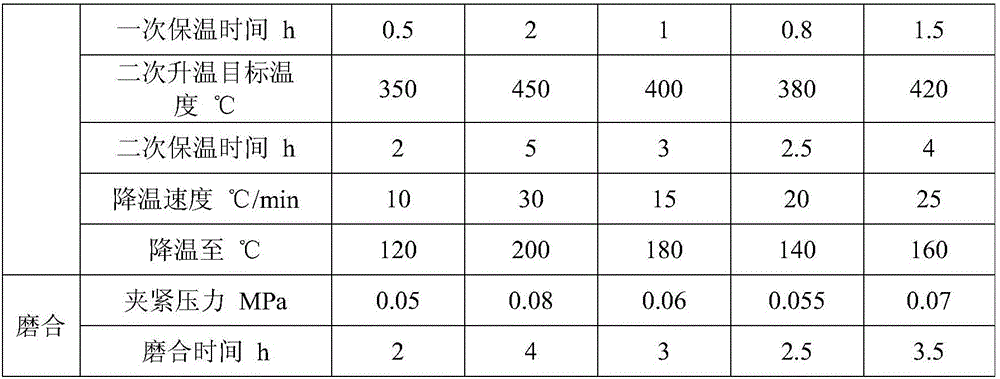

Differential friction plate for double-twisting machine and machining method of differential friction plate

InactiveCN105864329AImprove friction characteristicsStrong enoughOther chemical processesTransportation and packagingFiberCarbon fibers

The invention discloses a differential friction plate for a double-twisting machine and a machining method of the differential friction plate. The friction plate is mainly formed by machining and manufacturing the following raw materials including, by mass percent, 50%-80% of teflon, 15%-45% of tin bronze powder and 2%-6% of carbon fibers. The machining method includes the following steps that firstly, materials are mixed, wherein a material mixer is used for evenly mixing the raw materials; secondly, pressing is conducted, wherein the raw materials are put into a die to be pressurized, the pressurizing pressure ranges from 30 MPa to 80 MPa, and the pressure maintaining time ranges from 30 min to 100 min; thirdly, sintering is conducted, wherein a modified teflon blank formed in a die pressing manner is put into a high-temperature sintering furnace to be sintered; fourthly, machining is conducted, wherein machining is performed till the size and the shape which are required by the double-twisting machine are achieved; and fifthly, friction face running-in is conducted, wherein the friction plate is installed on a special tool, and mutual running-in is conducted on the friction plate and another running-in plate. The manufactured friction plate has an excellent friction characteristic and enough strength and can run stably in practical use, the friction force fluctuation is little, and the service life is long.

Owner:湖北三江航天江北机械工程有限公司

Gear oil and preparation method thereof

InactiveCN106893624APrevent oxidative deteriorationAvoid generatingAdditivesPolymethyl methacrylateCleansing Agents

The embodiment of the present invention discloses a gear oil, which comprises the following components by weight percentage: 1.5% polymethyl methacrylate, 0.3% V1156 pour point depressant, 0.3% di-tert-butyl-p-cresol, dialkyl dithio Zinc phosphate 2%, bis-succinimide 1%, friction system improver 0.5%; antifoaming agent 0.0001%, pigment 0.0001%, and the rest is base oil. A preparation method of the above-mentioned cleaning agent is also disclosed. The above raw materials are stirred and mixed evenly at room temperature; the gear oil and its preparation method of the embodiment of the present invention have excellent high temperature stability, prevent oil from oxidative deterioration and deposit formation, and keep the gearbox clean. Excellent anti-wear protection, effectively prolonging the service life of components. Excellent friction characteristics to ensure continuous, reliable and trouble-free operation of the transmission. Good friction stability and smoother gear shifting.

Owner:SHENZHEN PINGCHI IND

Lubricating oil composition for two wheeled vehicle, method for improving fuel economy of two wheeled vehicle using the lubricating oil composition, and method for producing the lubricating oil composition

The present invention provides a lubricating oil composition for two-wheeled vehicles, which is able to not only suppress a lowering of fatigue life of engine parts while making fuel saving properties (in particular, fuel saving properties at the time of low speed) favorable but also make clutch friction characteristics of two-wheeled vehicles favorable. The present invention is concerned with a lubricating oil composition for two-wheeled vehicles, including a base oil (A) having a viscosity index of 120 or more, an ethylene-propylene copolymer (B), and a metal-based detergent (C), wherein the content of the ethylene-propylene copolymer (B) is 0.30% by mass or more on the basis of the whole amount of the lubricating oil composition; the metal-based detergent (C) contains a calcium phenate (C1) and a calcium sulfonate (C2), and a mass ratio of the content (Ca1) of the calcium phenate (C1) as expressed in terms of a calcium atom to the content (Ca2) of the calcium sulfonate (C2) as expressed in terms of a calcium atom is satisfied with a relation of (1.0≤Ca1 / Ca2); and the lubricating oil composition has a kinematic viscosity at 100° C. is less than 9.3 mm2 / s and an HTHS viscosity at 150° C. is 2.9 mPa·s or more.

Owner:IDEMITSU KOSAN CO LTD

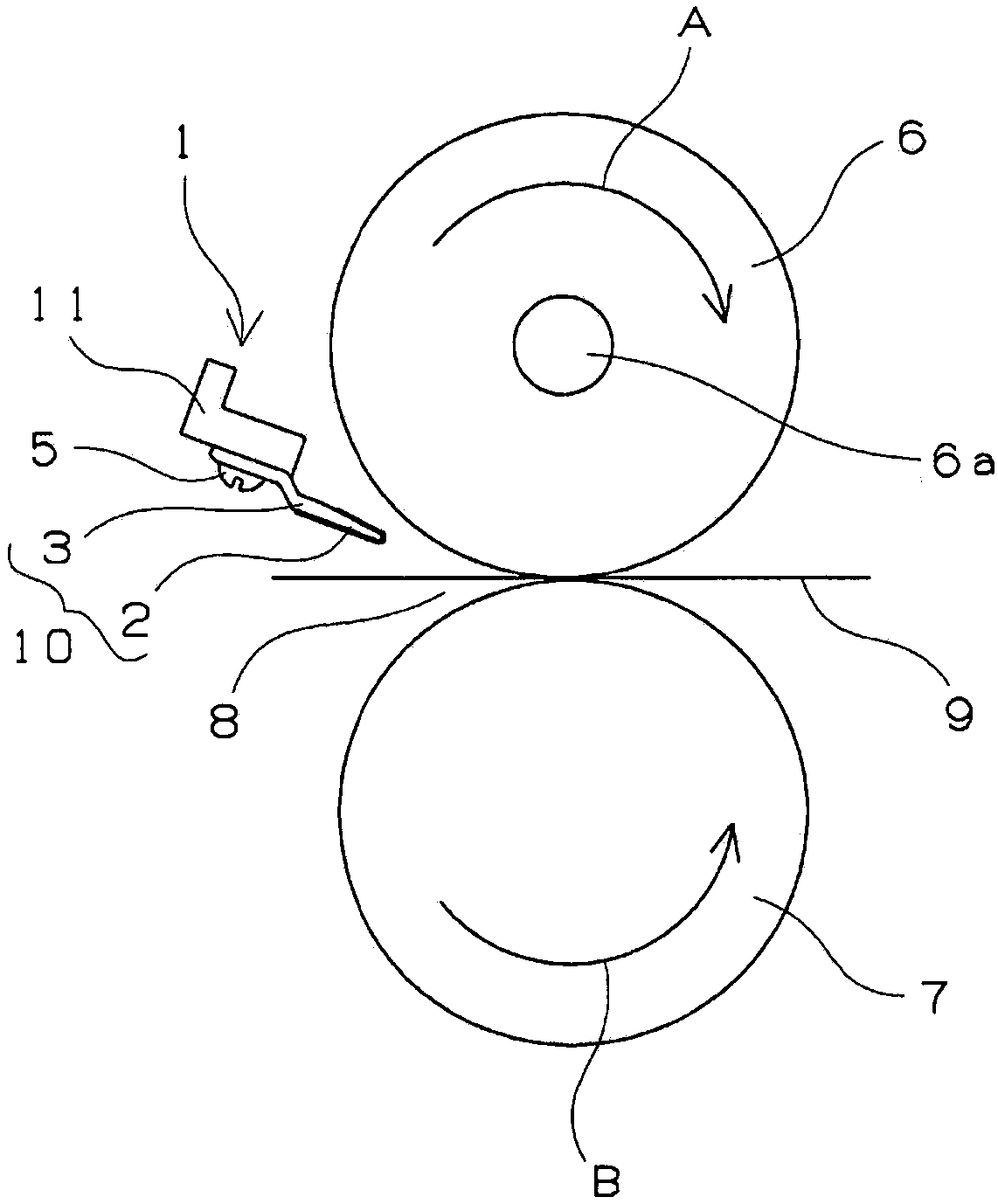

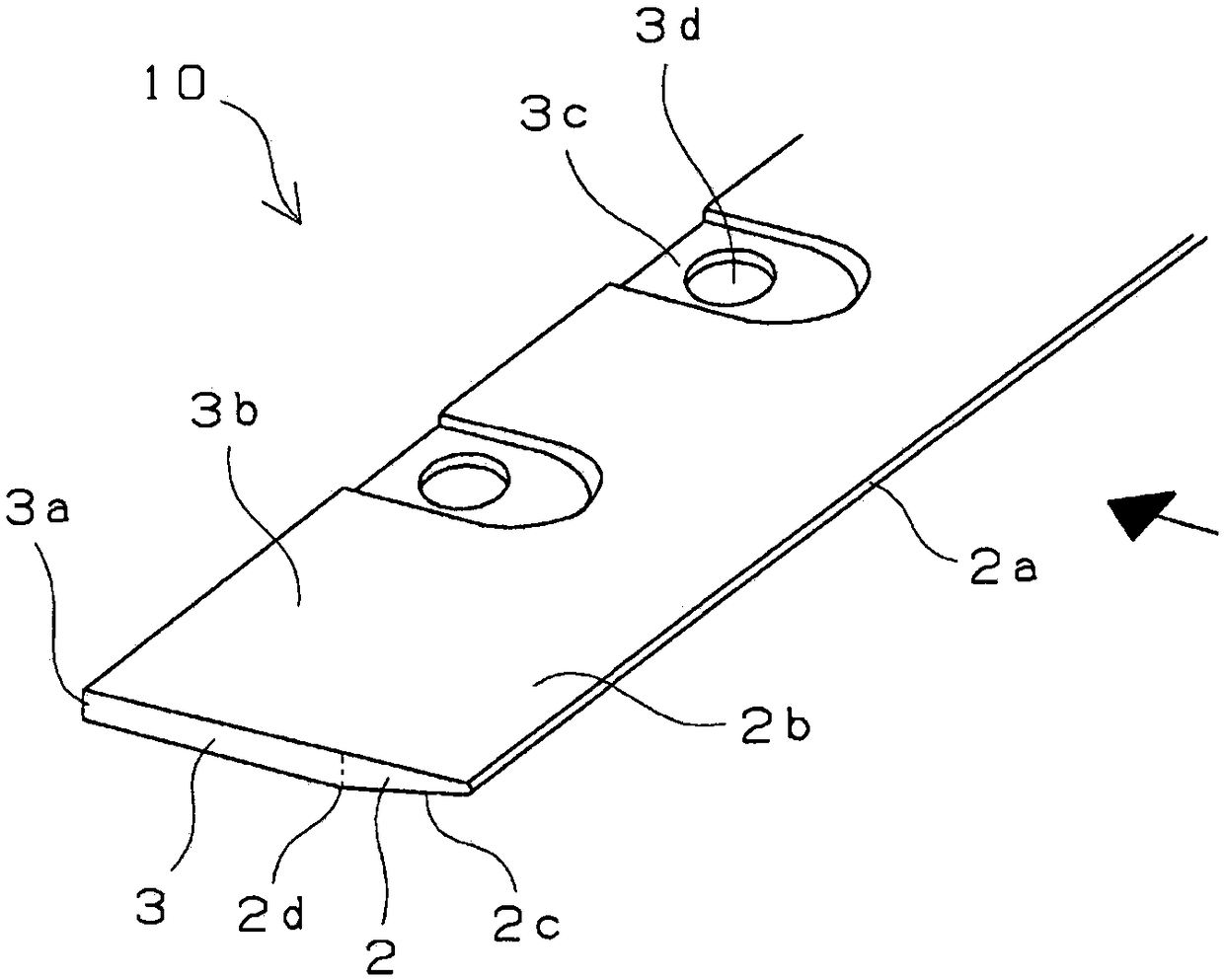

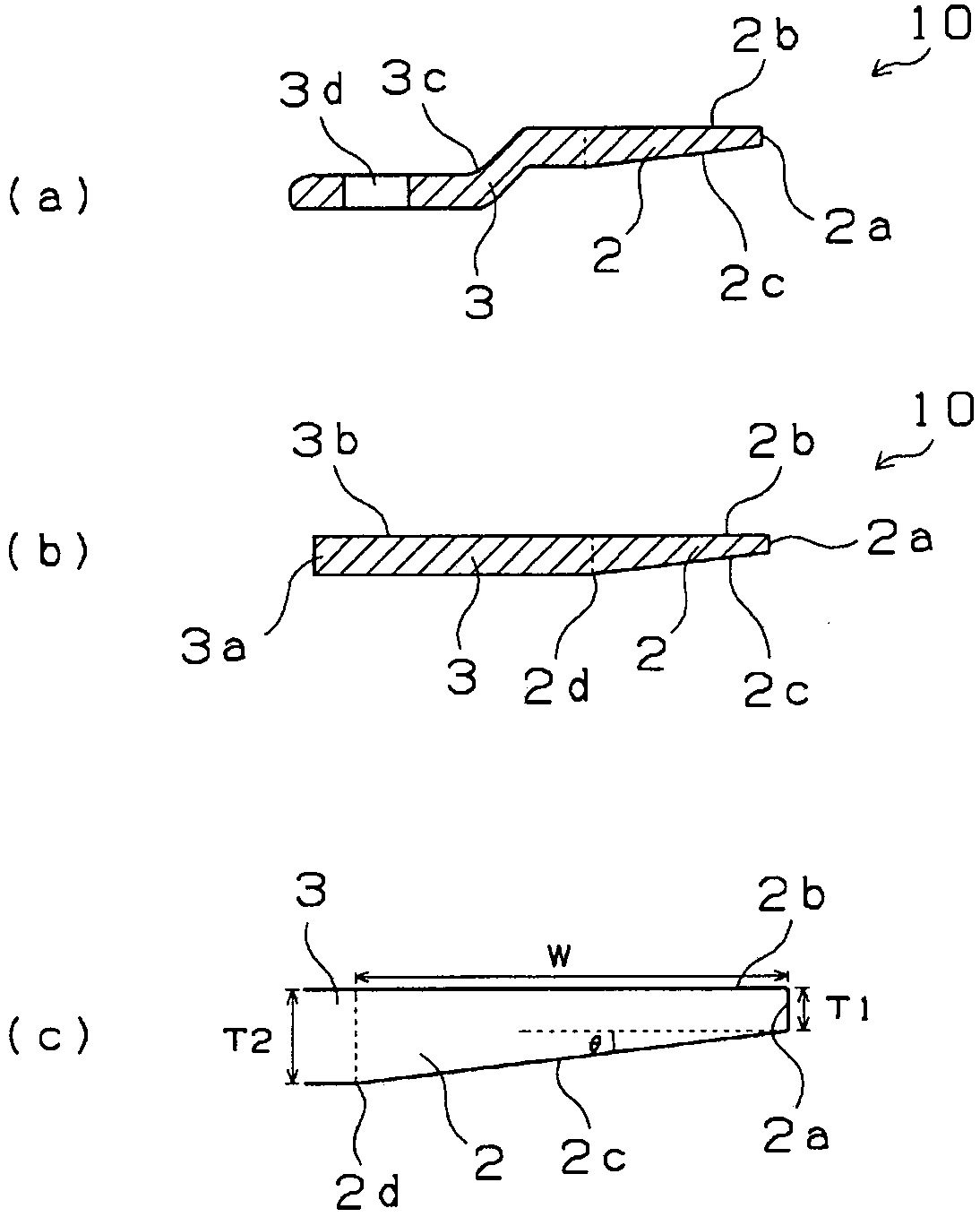

Peeling member and peeling device

InactiveCN108369397AAvoid deformationEasy to insertElectrographic process apparatusEngineeringMechanical engineering

Provided are a peeling member that can suppress the phenomenon of peeling sheet creasing, can have sufficient linear contact with a roller, can prevent deformation by jamming of paper, and can exhibitsuperior paper peeling performance, and a peeling device provided with this peeling member. The peeling member, which has a peeling sheet (10) for peeling paper from an electrophotographic device fuser roller (6), is formed from one metal plate and has a peeling part (2) constituting a tip part and a support part (3) that is thicker than the peeling part (2). The peeling part (2) is provided on one long side of the metal plate, a paper passing surface (2b) thereof is a flat surface continuous with the surface of the support part (3), and the side opposite from the paper passing surface is aninclined surface (2c) inclined with respect to the paper passing surface (2b) such that the thickness of the peeling part (2) increases from the very tip (2a) of the peeling part (2) toward a boundarypart (2d) with the support part (3). The inclined surface (2c) is the surface disposed on the fuser roller (6) side, and distance (D1) between the very tip (2a) and the roller and distance (D2 from the boundary part (2d) and the roller satisfy D1<=D2<=5*D1.

Owner:NTN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com