Control valve for thermal management module

A technology for controlling valves and valve housings, applied in coolant flow control, sliding valves, valve devices, etc., can solve the problem of Teflon losing shape stability, shorten installation time, reduce costs, and compensate for losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

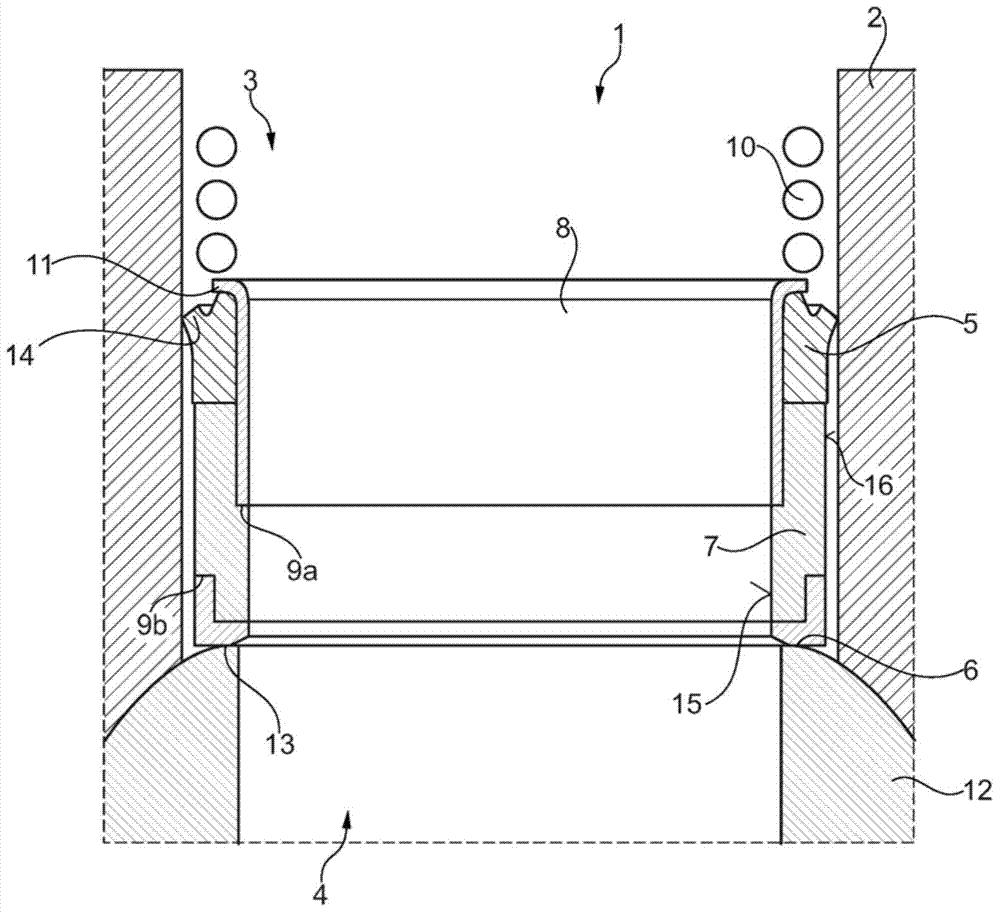

[0012] figure 1 The control valve 1 is shown in cross section. The control valve 1 has a valve housing 2 on which is provided an inlet connection 3 for cooling water which, depending on the position of a valve element 12 installed in the valve housing 2 , can be connected to an outlet connection 4 . In order to adequately seal the coolant flow path, the control valve 1 has a sealing ring 5 which seals in the radial direction and a sealing element 6 which seals in the axial direction.

[0013] The sealing element 6 bears against the outer circumferential surface of the valve element 12 by means of its end face formed as a sealing surface 13 which is adapted to the outer contour of the valve element 12 . In this way a minimum sealing gap is obtained. This sealing gap is further reduced by the fact that the pressure of the spring 10 acts indirectly on the sealing element 6 in the axial direction. The spring 10 ensures the pressing pressure required to ensure a sufficient seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com