Differential friction plate for double-twisting machine and machining method of differential friction plate

A processing method and technology of double twisting machine, applied in friction linings, chemical instruments and methods, metal processing equipment, etc., can solve problems such as difficulty in guaranteeing friction performance and service life, and achieve small friction fluctuation, stable operation and excellent performance. The effect of friction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

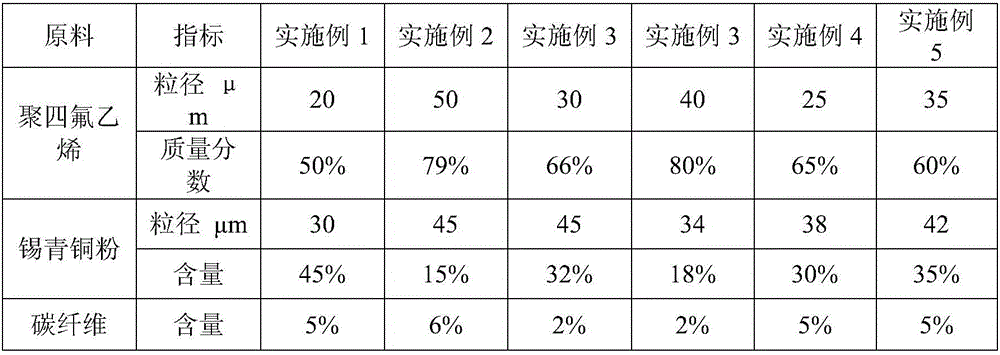

[0023] As shown in Table 1, the differential friction plate for double-twisting machine provided by the present invention is processed by the raw materials of the following mass fractions: polytetrafluoroethylene 50%, particle size 20 μm; tin bronze powder 45%, particle size 30 μm; carbon fiber 5%.

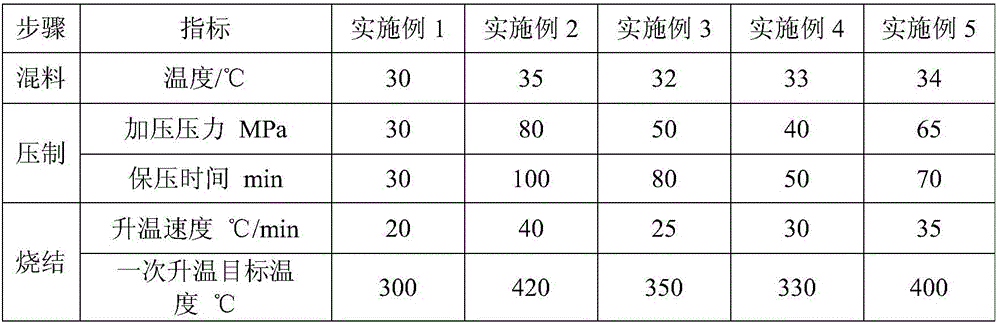

[0024] As shown in Table 2, the processing method of the differential gear friction plate for the above-mentioned double twisting machine comprises the following steps:

[0025] 1) Mixing: use a mixer to mix the raw materials evenly at 30°C;

[0026] 2) Compression: Put it into the mold and pressurize, the pressurization pressure is 30MPa, and the holding time is 30min;

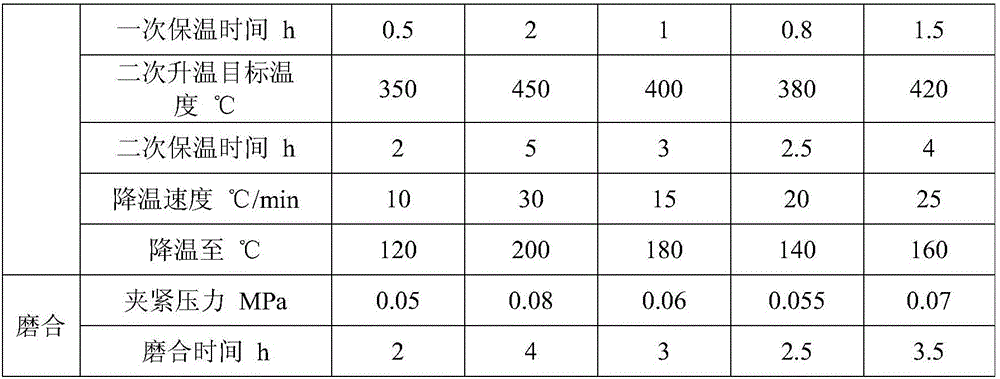

[0027] 3) Sintering: put the molded modified PTFE billet into a high-temperature sintering furnace, sinter under circulating hot air, the heating rate is 20°C / min, and the temperature is raised to 300°C in the first stage (corresponding to the one-time heating in Table 2) , heat preservation for 0.5 hours (corr...

Embodiment 2~5

[0032] The raw materials that each embodiment adopts are as shown in table 1;

[0033] The processing steps of each embodiment using the corresponding raw materials in Table 1 are basically the same as that of Embodiment 1, the difference is the parameter index of each embodiment, as shown in Table 2.

[0034] See Table 3 for the properties of the friction plates prepared in each embodiment.

[0035] Table 1 Raw material composition

[0036]

[0037] Table 2 Processing step parameters

[0038]

[0039]

[0040] Table 3 product performance

[0041] index

[0042] In Table 3, the tension fluctuation is the output tension fluctuation of the differential of the double-twisting machine using the corresponding friction plate, and the service life is the time taken for the wear amount to reach 0.5mm in actual use, which is quantitative data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com