Manual transmission lubricating oil for automobiles

A gearbox and lubricating oil technology, applied in the field of lubricating oil, can solve problems such as poor operability, low transmission efficiency, and inability to operate the gearbox, and achieve good performance and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

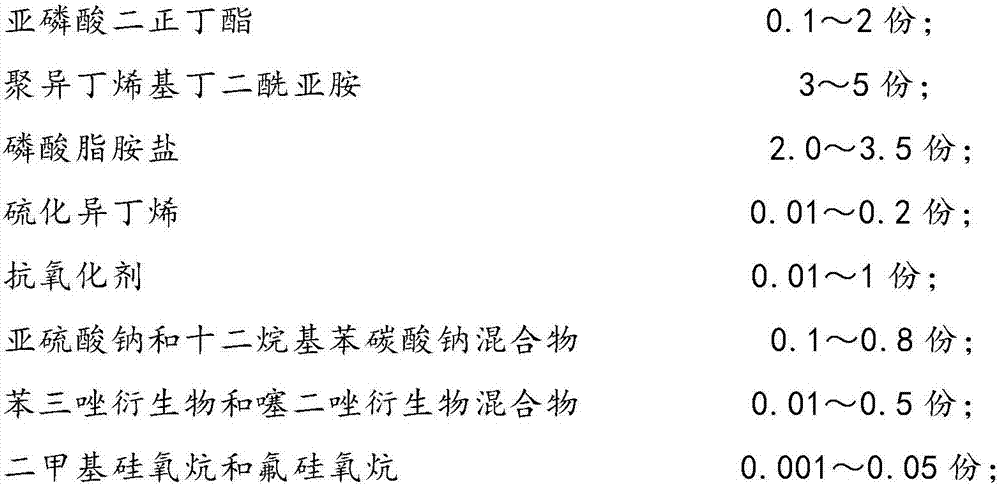

[0017] An embodiment of a manual gearbox lubricating oil for automobiles disclosed in the present invention includes the following components and parts by weight:

[0018]

[0019]

[0020] Heat the PAO4 and pentaerythritol esters of the above components to 40~55℃, stir and dehydrate for 50~80 minutes to prepare the composite base oil, dehydrate the remaining components, add them to the composite base oil, and heat to 50~60℃, The lubricating oil of this embodiment can be obtained by stirring for 60-100 minutes, cooling and filling the finished product container.

Embodiment 2

[0022] An embodiment of a manual gearbox lubricant for automobiles disclosed in the present invention includes the following components and parts by weight:

[0023]

[0024] Heat the PAO6 and pentaerythritol esters of the above components to 40~55℃, stir and dehydrate for 50~80 minutes to prepare the composite base oil, and then dehydrate the remaining components, add them to the composite base oil, and heat to 50~60℃, The lubricating oil of this embodiment can be obtained by stirring for 60-100 minutes, cooling and filling the finished product container.

Embodiment 3

[0026] An embodiment of a manual gearbox lubricant for automobiles disclosed in the present invention includes the following components and parts by weight:

[0027]

[0028] Heat the PAO6 and pentaerythritol esters of the above components to 40~55℃, stir and dehydrate for 50~80 minutes to prepare the composite base oil, and then dehydrate the remaining components, add them to the composite base oil, and heat to 50~60℃, The lubricating oil of this embodiment can be obtained by stirring for 60-100 minutes, cooling and filling the finished product container.

[0029] The invention adopts kinematic viscosity determination method (GB / T265), pour point determination method (GB / T3535), copper corrosion test (GB / T5096), extreme pressure lubricating oil friction and wear performance test method (ASTMD6425-05) in the laboratory. ), automobile transmission fluid-anti-shake performance test (JASO M349), four-ball wear scar diameter measurement method (1200RPM, 40Kg, 75℃, 60min) (SH / T0189), FZ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com