Lubricant composition

A lubricating oil composition and the technology of the composition, which are applied in the directions of lubricating compositions, petroleum industry, etc., can solve problems such as adverse effects, and achieve the effects of excellent friction characteristics, excellent sludge inhibition, and excellent water separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

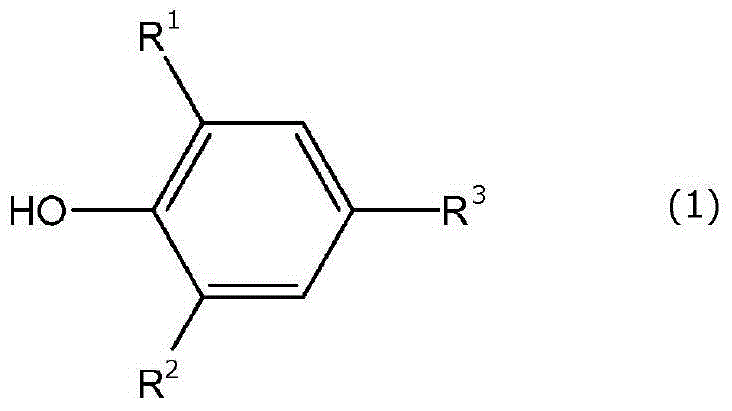

Method used

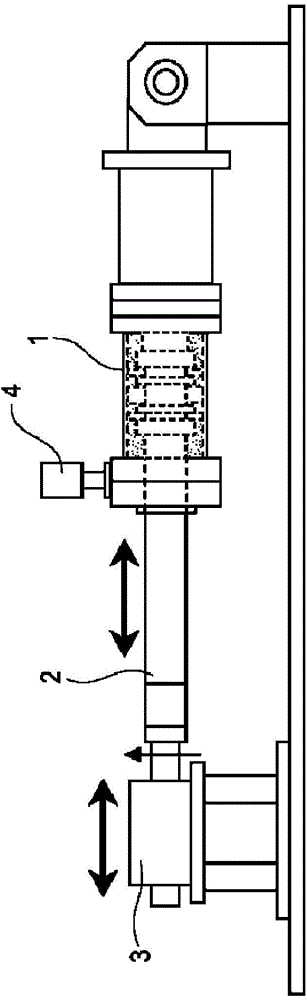

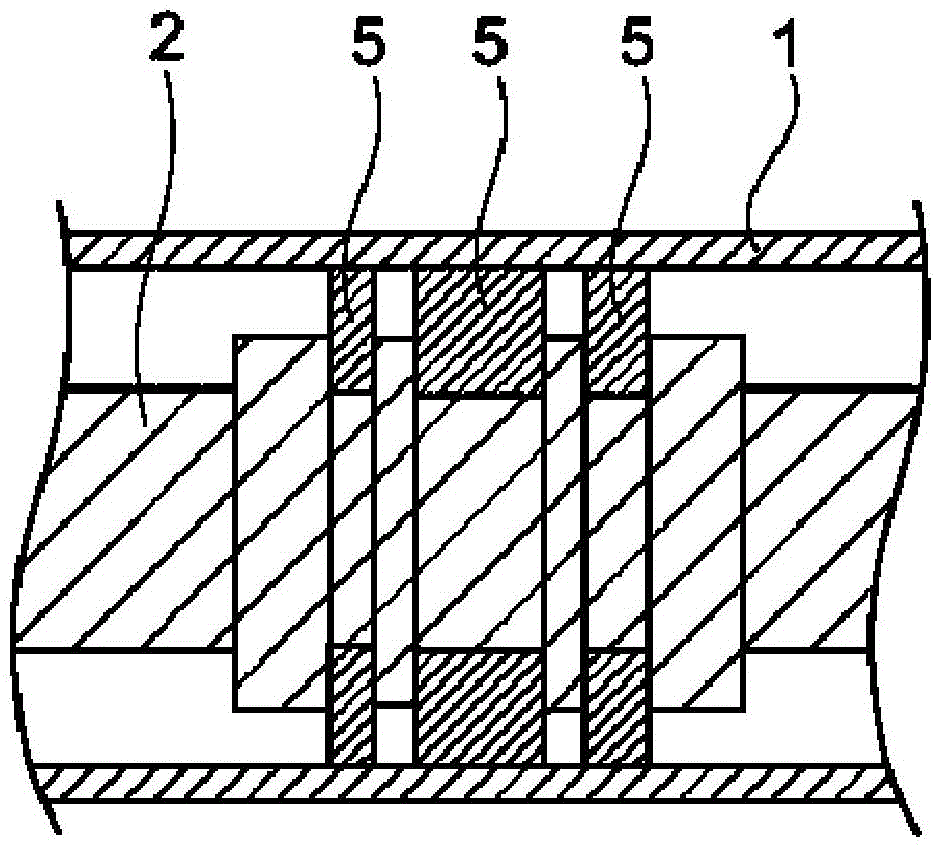

Image

Examples

Embodiment 1~10 and comparative example 1~2

[0318] Each lubricating oil composition of the present invention shown in the Examples of Table 1 was prepared. The contents of base oil and additives are based on the total amount of the composition. As the lubricating oil for comparison, a commercially available Zn-based hydraulic oil (manufactured by ExxonMobil Corporation; trade name: DTEOIL25) as Comparative Example 1 and a commercially available turbine oil (manufactured by JXNIPPONOIL & ENERGY CORPORATION; trade name: FBKTurbineOil46) as Comparative Example 2 were used. . The following evaluation tests were performed on these lubricating oil compositions, and the results are shown in Table 1 together.

[0319] [Thermal Stability Test]

[0320] According to the "lubricating oil thermal stability method" stipulated in JISK2540, take 50ml of sample oil into a 50ml capacity beaker, add a coil-shaped catalyst of iron and copper, and perform a certain period of time (10 days, 20 days) in an air constant temperature bath at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| carbon number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com