Bearing cage segment, bearing cage and method for manufacturing the same

A bearing cage and cage technology, applied in the direction of bearings, bearing components, roller bearings, etc., can solve the problems such as the inability to guarantee the guiding function of the plastic cage, the strength limit, the high manufacturing cost, etc., and achieve good emergency operation characteristics, outstanding Friction characteristics, effect of low running noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

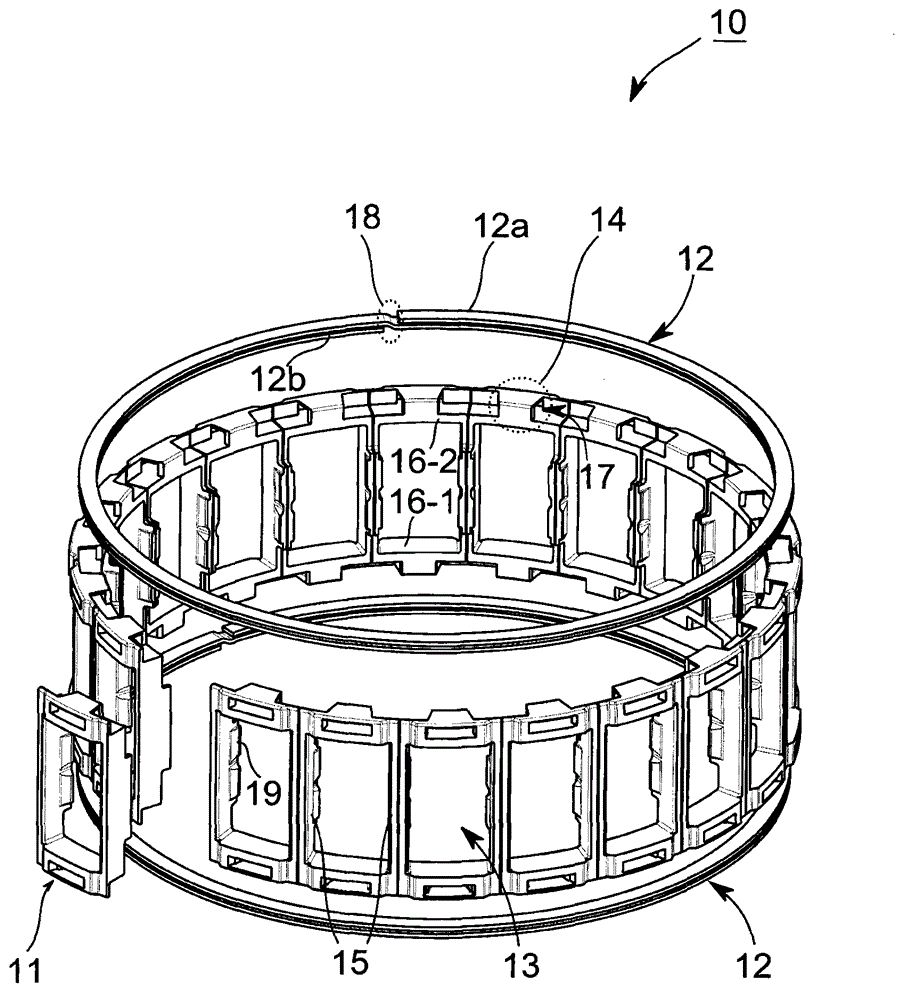

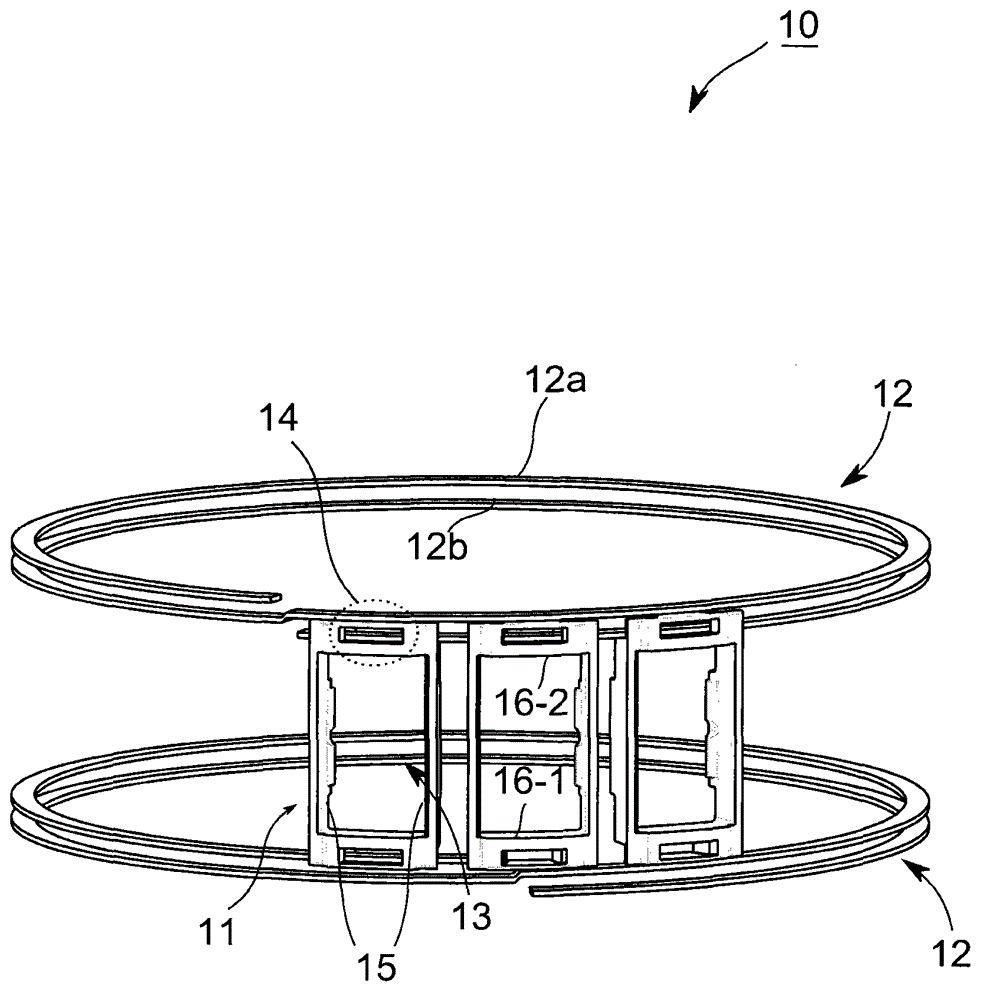

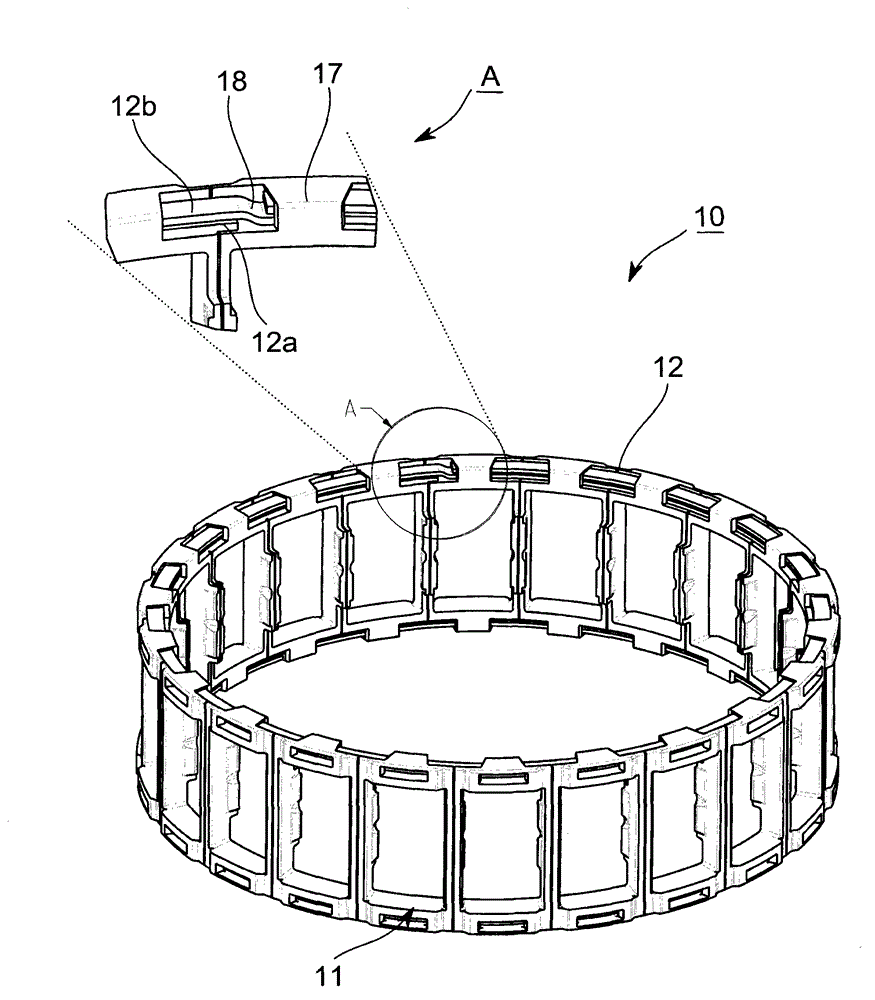

[0033] figure 1 Shown is a perspective view of a bearing cage 10 with a plurality of separate cage pieces 11 (which can be mounted on two axially spaced apart lamellar support rings 12 ), an uncompleted bearing cage 10 , and a diagram for example only.

[0034] A plurality of bearing cage segments 11 are used to support rolling bodies (not shown) in rolling body pockets 13 formed by the bearing cage segments 11 . For this purpose, the bearing cage section 11 comprises at least two circumferential connection sections 16 - 1 , 16 - 2 arranged in the circumferential direction and axially spaced at a certain distance. Furthermore, at least one connecting web 15 connecting the circumferential connecting sections 16 - 1 , 16 - 2 is arranged in a bearing cage section 11 , so that two The bearing cage section 11 forms at least one pocket 13 or window for bearing rolling elements. Although it is sufficient for this to arrange exactly one connecting web 15 per bearing cage section 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com