Method for manufacturing airplane carbon brake wheel with double element carbon base optimal combination

An optimized combination, carbon brake disc technology, applied in the direction of mechanical equipment, friction linings, etc., can solve the problems of friction coefficient attenuation, braking performance deterioration, etc., achieve high friction characteristics, increase service life, and reduce wear rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

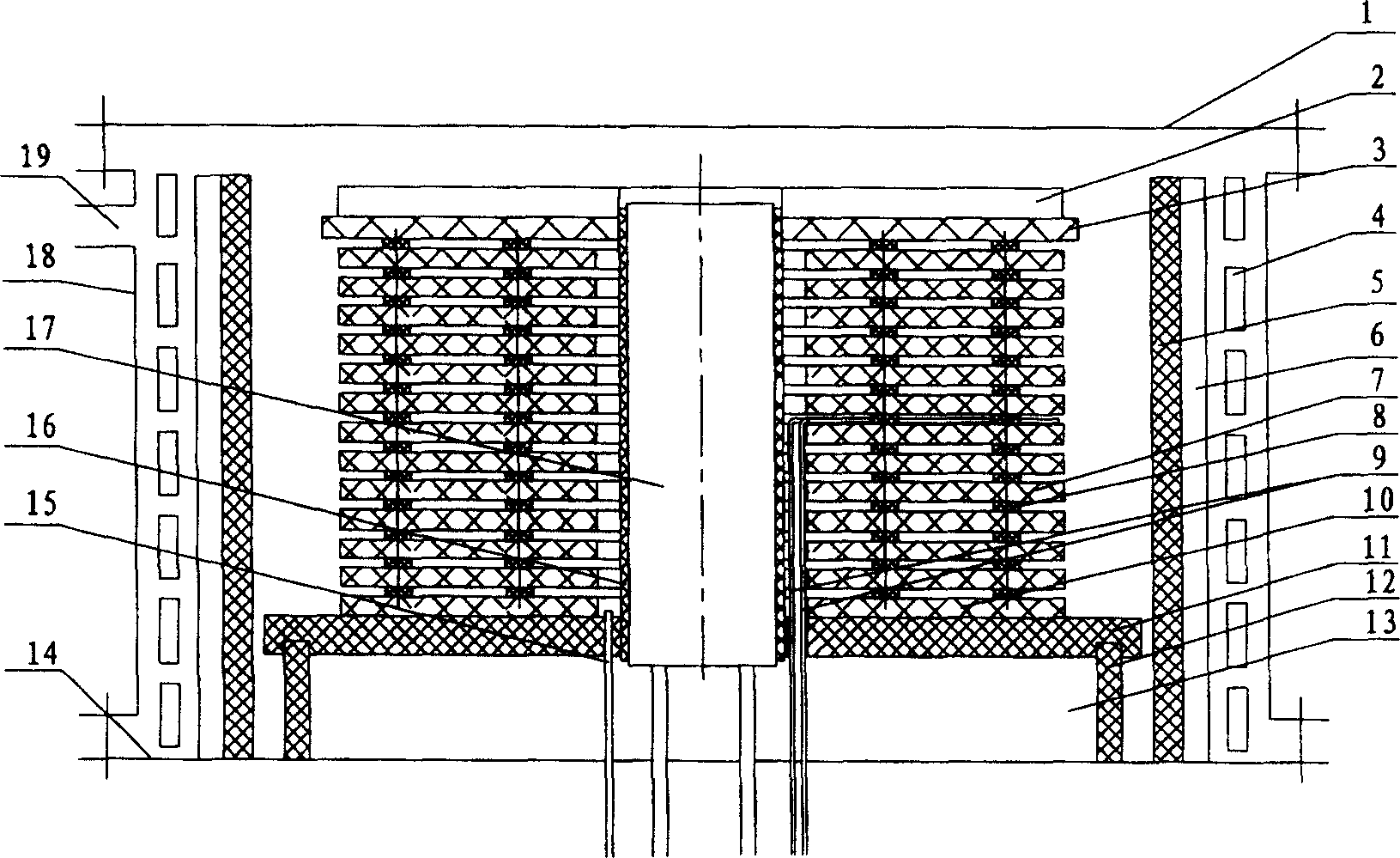

Image

Examples

Embodiment 1

[0019] (1) being that 30% by weight is used as the non-weft carbon cloth needle-punched integral prefabricated body of the carbon brake disc moving disc is packed in the thermal gradient vapor deposition furnace in the negative pressure directional flow, and 30% by weight is used as The non-weft carbon cloth needle-punched overall prefabricated body of the static disc and tail disc of the carbon brake disc is loaded into a negative pressure directional flow external thermal gradient vapor deposition furnace, and the temperature of the low-temperature side of the above-mentioned integral carbon disc prefabricated body is controlled to be 800 °C, and the high-temperature side The temperature gradient with the low-temperature surface is 30°C, and the carbon source gas C is adjusted according to the total mass of the preform 3 h 6 The flow rate can be 2.6m 3 / h, directional flow through the surface of the carbon plate prefabricated body, after 300 hours of carbon deposition proce...

Embodiment 2

[0023] (1) being that 30% by weight is used as the non-weft carbon cloth needle-punched integral prefabricated body of the carbon brake disc moving disc is packed in the thermal gradient vapor deposition furnace in the negative pressure directional flow, and 30% by weight is used as The non-weft carbon cloth needle-punched overall prefabricated body of the static disc and tail disc of the carbon brake disc is loaded into a negative pressure directional flow external thermal gradient vapor deposition furnace, and the temperature of the low-temperature side of the above-mentioned integral carbon disc prefabricated body is controlled to be 1000 °C, and the high-temperature side The temperature gradient with the low temperature surface is 380°C, and the carbon source gas C is adjusted according to the total mass of the preform 3 h 6 The flow rate can be 4.0m 3 / h, directional flow through the surface of the carbon plate prefabricated body, after 600 hours of carbon deposition pro...

Embodiment 3

[0027] (1) being that 30% by weight is used as the non-weft carbon cloth needle-punched integral prefabricated body of the carbon brake disc moving disc is packed in the thermal gradient vapor deposition furnace in the negative pressure directional flow, and 30% by weight is used as The non-weft carbon cloth needle-punched overall prefabricated body of the static disc and tail disc of the carbon brake disc is loaded into a negative pressure directional flow external thermal gradient vapor deposition furnace, and the temperature of the low temperature side of the whole carbon disc prefab is controlled to be 900 ° C, and the high temperature side is in contact with the The temperature gradient of the low temperature surface is 200°C, and the carbon source gas C is adjusted according to the total mass of the preform 3 h 6 The flow rate can be 3.0m 3 / h, directional flow through the surface of the carbon plate prefabricated body, after 450 hours of carbon deposition process, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com