Electrical conductivity lubricating grease composition

A technology of grease composition and conductivity, which is applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of conductivity degradation, etc., and achieve the effect of good conductivity and good friction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

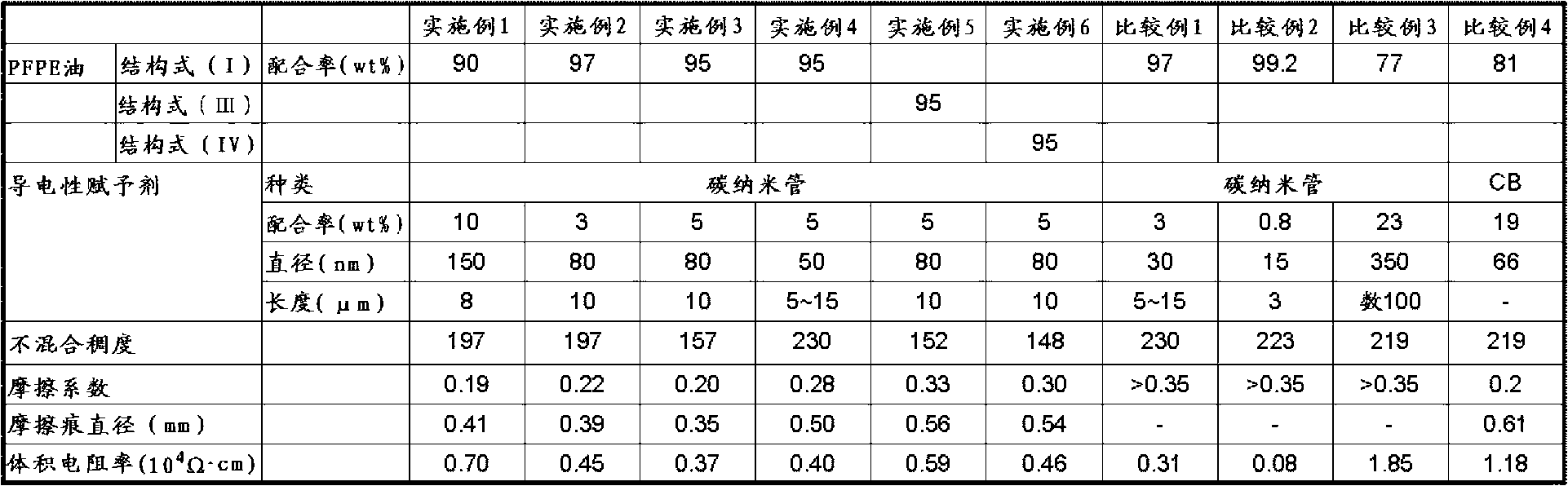

[0059] (Examples 1-4, Comparative Examples 1-4)

[0060] In PFPE (40°C dynamic viscosity 400mm 2 / s) by adding a conductivity-imparting agent and kneading twice with a three-roll mill. The oil pressure of the three-roll mill is 1 MPa, the inlet and outlet of the first pass (pass) are 20 μm, the inlet and outlet of the second pass are 100 μm, and the inlet and outlet of the third pass are 20 μm.

[0061] The above-mentioned PFPE and conductivity-imparting agent were prepared according to the compounding ratios in Table 1 to obtain respective grease compositions. As PFPE, structural formulas (I), (III), and (IV) are specifically used.

[0062] Structural formula (I) CF 3 CF 2 CF 2 O[CF(CF 3 ) CF 2 O] m CF 2 CF 3

[0063] Dynamic viscosity at 40°C: 400mm 2 / s

[0064] Structural formula (III) RfO (CF 2 CF 2 O) j (CF 2 O) k Rf

[0065] Dynamic viscosity at 40°C: 310mm 2 / s

[0066] Structural formula (IV) F (CF 2 CF 2 CF 2 O) n CF 2 CF 3

[0067] Dynami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com